What Is 3 Axis CNC Machining

Conventional CNC machining consists of three-dimensional machining controlled by lateral, back and forth and up and down movements to remove material from the original block of plastic or metal material. It is suitable for most geometries.

In a 3-axis machining machine the tool moves in all three planes simultaneously to cut the raw metal or plastic with perfect angular accuracy, the spindle drops to provide absolute depth penetration, contouring and finishing the part with repeatable accuracy.

In a three-axis machine, the three axes are X, Y and Z. The X-axis moves from left to right, the Y-axis from front to back and the Z-axis up and down. A three-axis machine can work on each axis simultaneously.

As a more common technique for creating a variety of parts, it is important to understand how it works and how to use it in the production process. The cutting tool moves along three independent axes to mill the part being machined: from back to front, side-by-side up and down the cutting tool is fixed horizontally or vertically and rotates, while the workpiece being machined remains in place.

The Benefits Of 3 Axis CNC Machining

Use 3 Axis CNC machining equipment to mill slots, flatten surfaces, drill and tap holes and cut sharp edges. Some benefits of 3-axis machining are following:

- Three axes move together to create complex components more freely and efficiently.

- Most complete machined components can be produced using a 3-axis machining machine. These can include jigs, fixtures, stocks, chuck jaws and machine fixtures.

- 3-axis machining machines can be equipped with automatic tool changers, allowing multiple targets to be accomplished on a single machine.

- Upgrade to a 3-axis CNC milling machine by additional coding. Only one data entry is required for multiple uses. The 3-axis CNC machine definition enables the machine to move three different axes at the same time.

The 3-axis machining machine works by scraping and cutting away unwanted parts of the raw material. Multi Axis Machining aligns the tool with the material, which is then machined to the desired size and shape.The base configuration of some machines moves the machine while keeping the part stationary. The tool moves along three axes: X, Y and Z, or width, length and depth. These axial movements through the three dimensions involve two linear channels and a cutting head with a spindle.

The Difference Between 3 Axis And 5 Axis Machining

While known for being a more basic option, traditional 3-axis machining machines have come a long way in becoming more modern to keep up with digitally controlled 5-axis alternatives. The three-axis option is more widely used for manufacturing mechanical parts in fabrication, industrial work and construction.

The process uses three spindles (X, Y and Z) to cut the material into the desired shape. This process is not suitable for deep or narrow parts as it is limited in effectively reaching deep or narrow cavities in the material and can become more labour intensive. As the industry needs new updates to meet demand, the 3+1 and 3+2 options bridge the gap with the 5-axis alternative.

Unlike the X, Y and Z limits of a 3-axis machine, the 5-axis moves on the three previously mentioned linear axes and the A and B axes, which means that machined parts can be manipulated from all directions in one operation of the machine. Ideal for deeper parts, parts made from harder materials and more accurate due to its shorter tools. In addition, the 5-axis option is faster than the 3-axis option if machining times are insufficient. Alternatively, a 3-axis machining machine handles less complexity and requires less preparation time than a 5-axis machine. However, digital control makes 5-axis machining machines more user-friendly.

3 Axis Cnc Machining – Volume 3 Axis Cnc Machining Services

Product Accuracy Is Our Attitude,We offer Volume 3 Axis Cnc Machining services for precision parts. Meet your requirement on price and quality.Where We Build Your precision visions

At Be-cu.com, We offer quality 3 axis machining products, trained personnel and a commitment to “on time” completion schedules. Our goal is to provide the right 3 axis cnc machining parts, on time, and at a competitive price to our customers.Our care of service combined with extensive experience in manufacturing processes. This combination of experience and service ensures efficiency throughout the entire project, from design concept, through prototype, to the finished product. We provide concept, design, engineering, fabrication, painting, finish, assembly, packaging and shipping services.

The Advantage Of 3 Axis Cnc Machining

- By reducing the time required to create customised parts, three-axis CNC machining can significantly reduce project costs compared to using multiple workstations to manufacture individual parts.

- Three-axis machines work faster and more accurately. The entire design of the part can be put into the computer and made to work without additional input. As a result, an operator can generate multiple exact copies of the same part with just one computer interaction. Some more complex parts may require material changes to be cut along other axes, which increases the usefulness of a 3-axis CNC machine

- One advantage of three-axis CNC machines over machines with more axes is their compactness. As they take up less space in the workshop, 3-axis CNC machines are more space efficient. In addition, these systems replace a wide range of other tools, thus further reducing the space taken up in the work area. With the machines taking up less space, operators have more room to move around, allowing for increased productivity and comfort in the work environment.

Our Case Studies Gallery Of 3 Axis Cnc Machining Services Parts

We are in the business of creating products that save you time and money. In addition to our 3 Axis Cnc Machining services, we provide laser cutting, sheet metal manufacturing, die casting, and 3d printing. All customers’ orders are inspected by our team to ensure they ship complete with hardware, finish, silk-screening, electronic component assembly, and testing.

Don’t see what you are looking for? Reach out to us and learn how we can work together to create what you need.

-

Swiss Machining And Bending 304 Hand Sewing Needle For Textile Machinery

-

Automatic Swiss Turning Stainless Steel 316L U-bolt

-

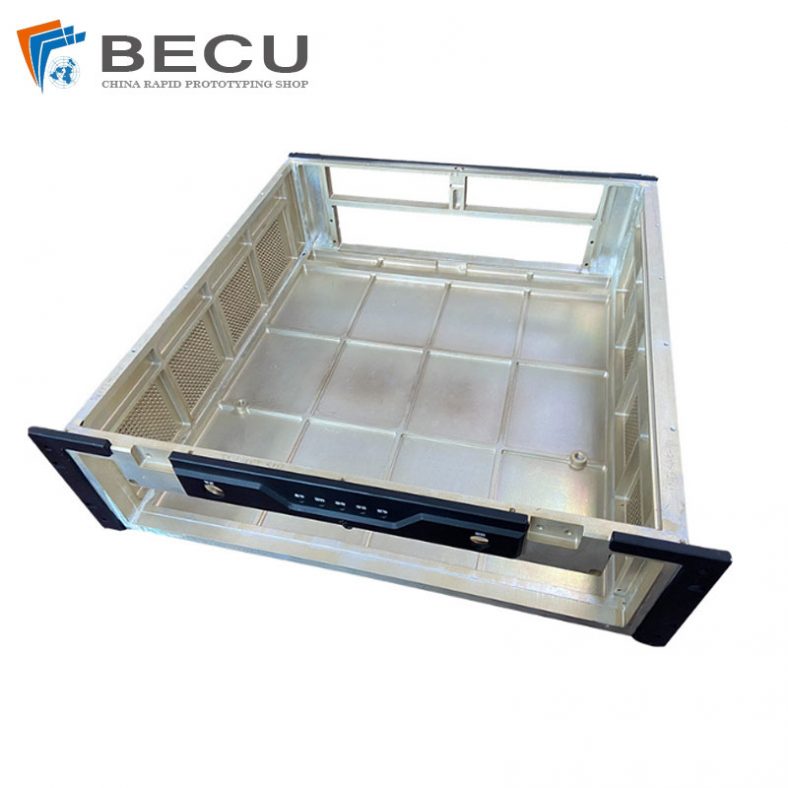

Precision Machining 6063 Aluminum Military Computer Server Chassis

-

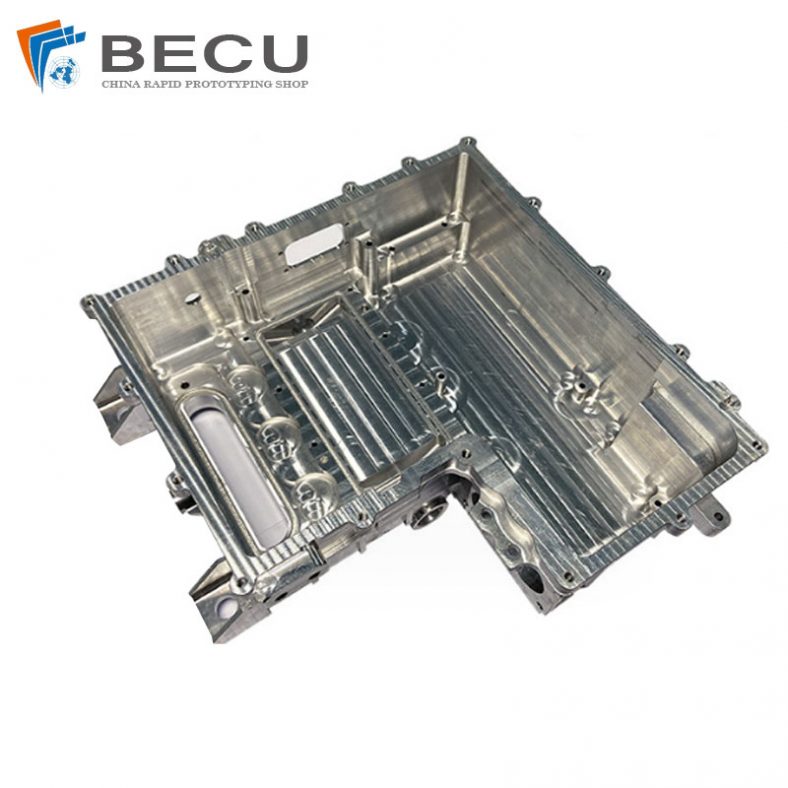

CNC 6063 Aluminum Automotive Motor End Cover

-

4 Axis CNC Machining Titanium Grade 5 Mobile Phone Buttons

-

CNC Machining Anti-static Translucent PC Optical Parts

-

Precision Turning 20° Acrylic Downlight Reflector

-

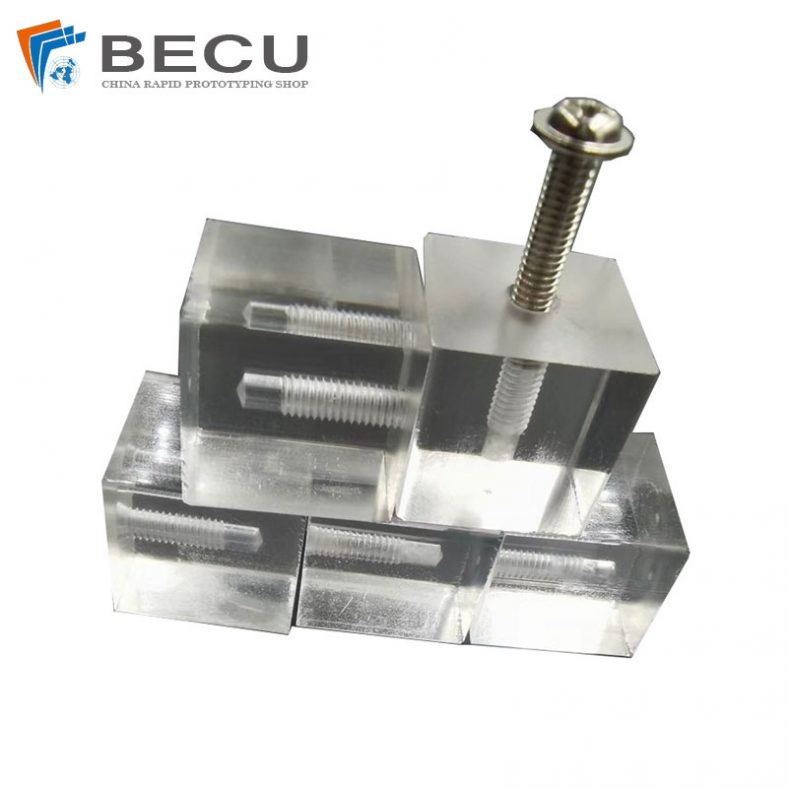

Transparent Acrylic Faceted Cube Threaded Clamp

-

CNC Turning Transparent PMMA Wear-Resistant Mechanical Parts

-

4 Axis Machining Highly Transparent Acrylic LED Tunnel Light Lens

-

CNC Turn-Mill Machining Hastelloy c276 Parts

-

Precision CNC Machining Inconel 718 Cast Impeller