What is Copper Alloy & What is it Used for

Ordinary pure copper is oxygen-containing copper with a copper mass fraction of not less than 99.7% and a very small amount of impurities, and its appearance is purple-red, so it is also called red copper. The main grades are T1, T2, T3.

Copper has poor high temperature oxidation resistance, and it is slowly oxidized at room temperature in the atmosphere. The corrosion rate in the atmosphere is 0.002~0.5mm/a, and the corrosion rate in seawater is 0.02~0.04mm/a. Copper has a high positive potential and maintains good corrosion resistance in non-oxidizing inorganic acid and organic acid media, but the corrosion rate is faster in ammonia, cyanide, mercury and oxidizing acid aqueous solutions.

Copper Alloy has excellent cold and hot working properties, and can be machined by various traditional pressure working processes, such as CNC machining, drawing, calendering, deep drawing, bending, precision pressing and copper spinning. During hot working, the atmosphere of the heating medium should be controlled to make it slightly oxidizing. The hot working temperature is 800~950℃.

Cnc Machining Copper Services – Custom Copper Machined Parts China

Looking for reliable, quick-turn Copper cnc machining services suppliers and CNC Machined product manufacturers?

No one knows the demands and challenges of machining copper better than the specialized expertise of Be-cu.com.We believes that to make others better is to make ourselves better. We are committed to providing rapid copper machining services including cnc milling,cnc turning,swiss machining,5 axis cnc machining copper parts and more. Relying on our international engineering team, complete supply chain and advanced in-housing equipment, we hope to fundamentally reduce the cost and time required to purchase precision parts. In the past few decades, we have continuously expanded our product range and global market. With strong production capacities and a well-trusted supply chain in China, which enable us to offer our customers top-class service and the highest quality copper cnc machining products at an affordable price!

Make Machined Beryllium Copper With Be-cu

Why choose a copper option unaided, when a BE-CU specialist is waiting to help? For a no-obligation consultation on your next copper machining project, contact us for a penny-pinching option with gold standard quality.

Why Choose Our Copper Cnc Machining Service?

- Save time and money for your copper project but quality guaranteed.

- High productivity, outstanding efficiency and high accuracy

- A wide range of copper grades and alloy materials can be machined

- Custom complex copper machined parts and components at specific tolerances

- High speed machining for prototyping and low to high volume production runs

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

Top Copper Cnc Machining Case Studies

Cnc Machining processes such as cnc milling, turning and swiss machining are today considered the most economic way to make copper prototypes. Sometimes, however, certain non-machiningable materials are needed, and sometimes 3d printing is the only option. Our company has rich experience making copper concept models and precise functional components. Understanding the properties of different copper alloy, with lots of testing and experimentation with pre-heating, tool paths and other factors, we are able to minimize deformation on copper alloy. Be-cu prototyping company provides a range of solutions for the machining of copper parts.

-

CNC Turning-Milling Machining Copper Facial Massage Roller

-

Precision Wire Cutting Plastic Injection Mould Core

-

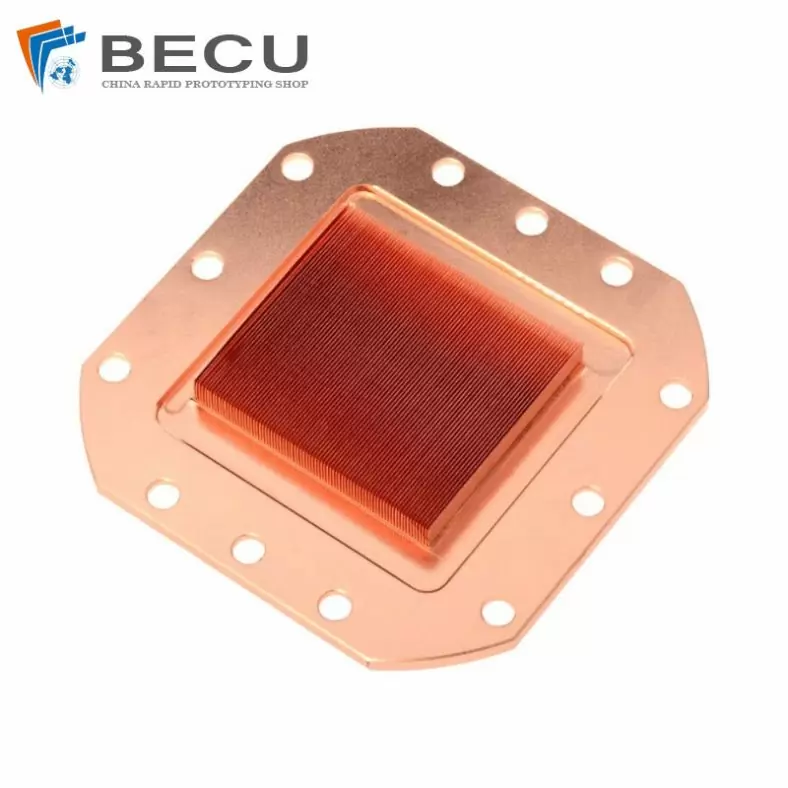

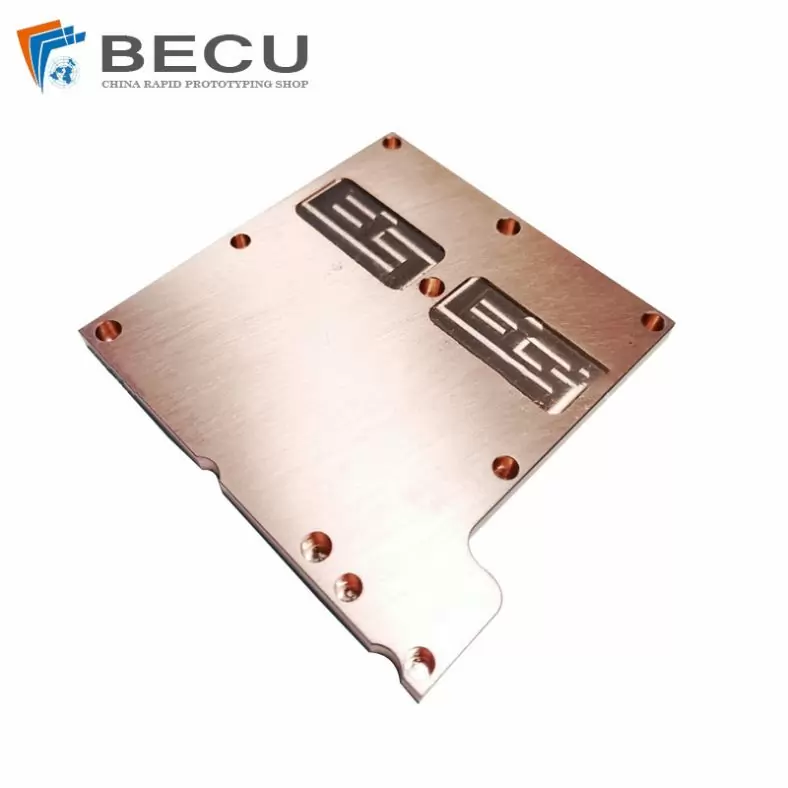

Custom Machining Copper Water Cooling Heat Sink

-

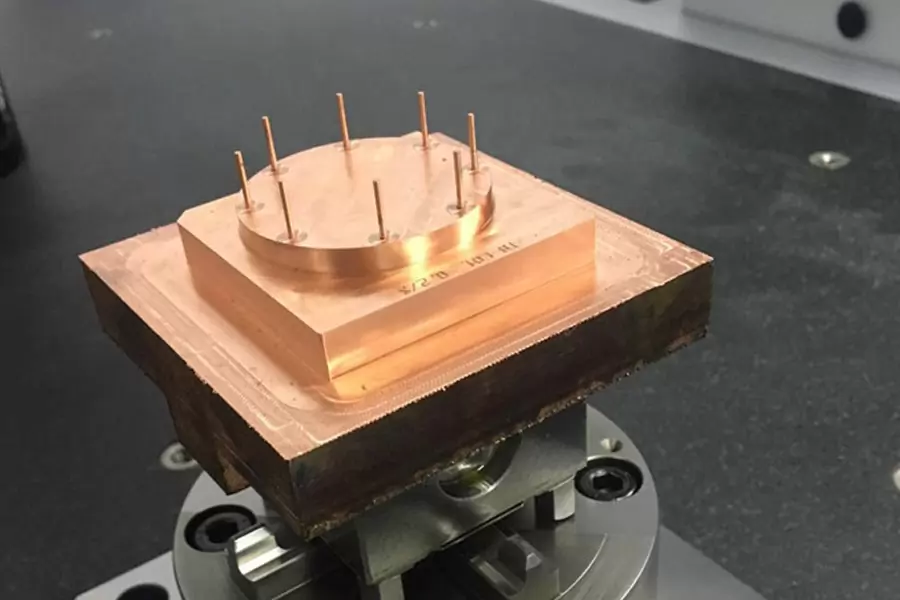

Cnc Carved Machining And Wire Cutting Copper Electrode

-

CNC Milling Automotive Audio Amplifier Base

-

Precision Machining Heatsink Spacer Substrate

-

Precision Turning T3 Copper Machinery Parts By Polishing

-

Precision Milling Machining Chrome-Plated Copper Spare Parts

-

Precision CNC Turning N9 Copper Parts

-

Swiss Turning Gold-Plated T2 Copper Parts

-

Precision Machined Copper Die Casting Parts

-

CNC Turning New Energy Vehicle Copper Connector

The Material Type Of CNC Machining Copper Alloy

Red copper is therefore also classified as copper alloys. Copper China cnc machining materials can be divided into: ordinary copper (T1, T2, T3, T4), oxygen-free copper (TU1, TU2 and high-purity, vacuum oxygen-free copper), deoxidized copper (TUP, TUMn), adding a small amount of alloy Elements of special copper (arsenic copper, tellurium copper, silver copper) four categories. The electrical conductivity and thermal conductivity of red copper are second only to that of silver, and it is widely used in the production of electrical and thermal conductivity equipment. Red copper has good corrosion resistance in the atmosphere, seawater and some non-oxidizing acids (hydrochloric acid, dilute sulfuric acid), alkalis, salt solutions and various organic acids (acetic acid, citric acid).

- Specific gravity of red copper: 8.89g/(mm)

- Cu ≥99.95%

- Oxides <0.003%

- Conductivity ≥57ms/m

- Hardness ≥85.2HV

- Density 8.89g/(mm)

- Other -0.02%