Investment Casting

- Sizes: 0.1 in to more than 3 feet

- Weights: a few grams to one metric ton

- Surface: very smooth finish

- Tight tolerances;Reliable process controls and repeatability;

- Design and casting versatility

- ISO 9001:2015, ITAF 16949

>>>All uploaded drawings are strictly confidential, check the confidentiality agreement

Investment Casting Services & Parts Supplier

If you focus on the shape complexity and surface finish of the parts, investment castings are where you can go. Be-cu provides high-quality custom ferrous and non-ferrous investment casting parts and components for a wide range of industries.

China Lost Wax Castings Manufacturer

Investment casting is a very versatile process which is ideal for simple or complex, low or high volume production. Be-cu investment casting services can reduce the processing time and cost of CNC machining parts, as we can manufacture a large number of prototypes in batch quickly and modify the appearance with CNC techniques to deliver the final desired parts. Whether you want to look for an investment casting manufacturer casting stainless steel, duplex stainless steel, titanium, carbon steel, tool steel, and aluminum alloys, professional technicians will perform investing casting process with a wide variety of metals, and be able to offer complex detail, smooth surface finish, and high definition in an economic way for clients. Weight range from a few grams to almost one metric ton. We also provide a broad range of secondary service including machining, surface finishing etc.Our investment casting parts are used across broad fields, such as energy, automotive, gas, and oil, food, etc. ISO 9001 certification and multiple-stage quality inspection implementation will ensure the quality and performance of the lost wax casting products to be delivered.

Why Choose Be-cu Investment Casting?

- Be-cu company annual output of stainless steel, carbon steel, alloy steel, aluminum alloy and other castings and precision machining parts to 3800 tons

- The company adheres to the management concept of “people-oriented, excellence, sustainable operation, and steady development”, and strictly controls all links in accordance with the requirements of ISO9001 quality management system. At the same time, it introduces casting simulation software CAE, ERP management software, automatic wax injection machine, and automatic shell making machinery. Arm, OKUMA precision machining equipment and other advanced software and hardware, and constantly improve the technological level and production efficiency.

- Production and testing are carried out in strict accordance with ASTM, DIN, BS, JIS and other international material standards and tolerance standards, with complete testing and laboratories, equipped with imported precision spectrometers, optical measuring instruments, hardness measuring instruments, surface roughness measuring instruments and other advanced Testing equipment can provide customers with various component analysis, size and product performance testing reports to ensure that every product delivered to customers meets the requirements and can be traced.

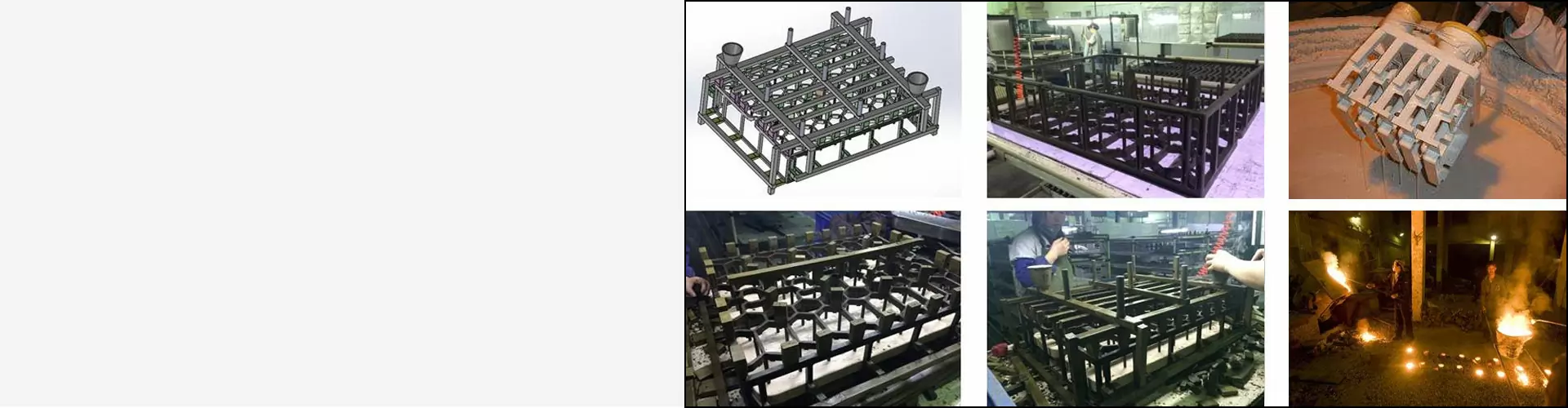

How Does Investment Casting Work? – Investment Casting Process

Investment casting involves creating an original wax model, building the image with plaster and successive layers until a strong shell surrounds the model. The surface of the wax mold is covered with a layer of refractory ceramic material. Once the ceramic material hardens, the desired casting geometry is formed inside. Then the paraffin is melted and exported, and the cavity is filled with molten metal. After the metal solidifies in the ceramic mold , and then take out the metal casting, this manufacturing technique is also known as the lost wax process.Investment casting provides economical undercutting, high resolution, sophisticated detail and smooth surface finish compared to machining separations. In most cases, investment casting is the only way the part can be made economically.

- Inject wax into a permanent die form wax pattern with the same details of the cast part.

- Assembly multiple wax components to form the gate and runner system.

- Immerse the entire wax assembly in refractory material like ceramic slurry, make it fully covered with the stucco, and forms a ceramic shell, which is built around a tree assembly by repeatedly dipping a pattern into a slurry.

- Heat the entire assembly to melt away the wax.

- When the residual wax pattern and gate material have been removed, the ceramic mold remains with a cavity in the shape of the part.

- Preheat the metal and pour the molten metal into the mold.

- Once the castings cooled, remove the part from the mold.

- Post-processing and machining to achieve required specifications.

- Normal linear tolerances of investment casting are as follows as a general rule: Up to 1” +/- .010”, for each additional inch up to ten inches +/- .003” per inch. For dimensions greater than ten inches allow +/- .005” per inch. Secondary operations such as straightening and sizing will produce closer dimensional tolerance.

- Dimensional and quality inspections and other testings before shipment.

The Metal Material Selection Of Investment Casting

With years of experience in different projects, Be-cu understands and complies with international standard material specifications, including but not limited to ASTM, AISI, ANSI, AS, BS, DIN, EN, JIS, KS, ISO, etc.

| Classification | China | America | Japan | Germany | WORKSTOFF NR.. |

|---|---|---|---|---|---|

| Classification | GB | ASTM | JIS | DIN | DIN |

| Carbon Structural Steel | 15 | 1015 | s15C | c15,CK15/H11 | 1.0401,1.1141 |

| Carbon Structural Steel | 20 | 1020 | s2oc | C22,CK22 | 1.1151 |

| Carbon Structural Steel | 25 | 1025 | s25c | C25,CK25 | 1.1158 |

| Carbon Structural Steel | 30 | 1030 | s3oc | c30,CK30 | 1.1178 |

| Carbon Structural Steel | 35 | 1035 | s35c | c35,CK35 | 1.1181 |

| Carbon Structural Steel | 40 | 1040 | s4oc | c40,CK40 | 1.1186 |

| Carbon Structural Steel | Q235 | A284GRB | USt37-3 | 1.0332 | |

| Alloy Structural Steel | 35Cr | 5132 | SCr430(H) | 34Cr4,37Cr4 | 1.7033,1.7034 |

| Alloy Structural Steel | 40Cr | 5140 | SCr440 | 41Cr4 | 1.7035 |

| Alloy Structural Steel | 45Cr | 5145,5147 | SCr445 | ||

| Alloy Structural Steel | 12CrMo | 13CrMo44 | 1.7335 | ||

| Alloy Structural Steel | 15CrMo | A-387Cr B | SCM415 | 16CrMo44 | 1.7337 |

| Alloy Structural Steel | 20CrMo | 4119,4118 | SCM420 | ||

| Alloy Structural Steel | 25CrMo | 4125 | 25CrMo4 | 1.7218 | |

| Alloy Structural Steel | 30CrMo | 4130 | SCM430 | ||

| Alloy Structural Steel | 42CrMo | 4140 | SCM440 | 42CrMo4 | 1.7225 |

| Alloy Structural Steel | 35CrMo | 4135 | SCM435 | 34CrMo4 | 1.7720 |

| Alloy Structural Steel | 15CrMn | 5115 G51150 | 16MnCr5 | 1.7131 | |

| Stainless Steel | 1Cr18Ni9 | 302/S30200 | sUS302 | x12CrNi188 | |

| Stainless Steel | 1Cr18Ni9Ti | sUs321 | x1OCrNiS189 | 1.4305 | |

| Stainless Steel | 0Cr18Ni9Ti | ||||

| Stainless Steel | Y1Cr18Ni9 | 303/S30300 | sUS303 | x12CrNiS188 | |

| Stainless Steel | 0Cr19Ni9 | 304/S30400 | suS304 | X5CrNi189 | 1.4301 |

| Stainless Steel | 00Cr19Ni9 | 304L/S30403 | suS304L | x2CrNi189 | |

| Stainless Steel | OCr18Ni11Ti | 321/S32100 | sUS321 | x10CrNiTi189/x6CrNiTi1810 | 1.4541 |

| Stainless Steel | OCr13Al | 405/S40500 | sUS405 | X7CrAl13 | |

| Stainless Steel | oOCr17Ni13Mo2 | sUS316L | x2CrNi810 | 1.4404 | |

| Stainless Steel | 1Cr1l7 | 430/S43000 | sUS430 | x8Cr17 | |

| Stainless Steel | 1Cr13 | 410/S41000 | sUS410 | x1OCr13 | 1.4006 |

| Stainless Steel | 2Crl3 | 420/S42000 | sUS420J1 | x2OCr13 | 1.4021 |

| Stainless Steel | 3Cr13 | sUS420J2 | x30Cr13 | 1.4028 | |

| Heat Resistant Steel | 2Cr25Ni20 (1Cr25Ni20Si2) | AlSI 310 | SUH310 | x15CrNiSi25 20 SEW470 | 1.4841 |

| Heat Resistant Steel | zG30Cr26Ni5 | HD | SCH11 | G-x4OCrNiSi27-4 | 1.4841 |

| Heat Resistant Steel | 2Cr23Ni13 | 309 | SUH309 | 1.4823 1.4776 | |

| Heat Resistant Steel | oCr18Ni11Nb | 347/S34700 | suS347 | x1OCrNiNb189 | |

| Heat Resistant Steel | 1Cr13Mo | suS410J1 | |||

| Heat Resistant Steel | 1Cr17Ni2 | 431/S43100 | suS431 | x22CrNi17 | |

| Aluminum Alloy | ZAISi7Mg(ZL101) | 356.2 | AC4C | G-AISi7Mg(3.2371.61) | |

| Aluminum Alloy | ZAISi7MgA(ZL101A) | ||||

| Aluminum Alloy | ZAISi12(ZL102) | 413.2 | AC3A | G-AIS112(3.2581.01) | |

| Aluminum Alloy | zAISi5Cul1Mg(ZL105) | 355.2 | G-AISi5Cu | ||

| Aluminum Alloy | ZAISi2Cu2Mg1(ZL108) | 413.0 | AC8A | G-Al12(Cu) | |

| Aluminum Alloy | ZAISi7Mg1A(ZL114A) | ||||

| Bronze | QSn4-0.3 (Tin Bronze GB5233-85) | C51100 | C5111 | cuSn4 | 2.1016 |

| Bronze | QSn6.5-0.1; | C51000 | C5102 | CuSn5 | 2.1018 |

| Bronze | QSn6.5-0.4 ( Tin Bronze GB5233-85) | c51900 | C5191 | CuSn6 | 2.1020 |

| Bronze | QSn8-0.3 ( Tin Bronze GB5233-85) | C52100 | c5210 | cuSn8 | 2.1030 |

| Bronze | Qcr0.5/QCr0.4-0.6 | ||||

| Bronze | QAI7 ( Aluminum Bronze ) | ||||

| Bronze | QAI10-4-4 Aluminum Bronze | c63300 HR50 | C6191 BD-F | CuAl10NiSFe4 F74 | 2.0966-98 |

| Bronze | zcuSn10Pb1/10-1 Tin Bronze | GC-cuSn 12 | 2.1054 | ||

| Brass | HPb59-1( Tin Brass ) | c37700/C37000 | c3771/C3710 | cuzn39Pb3/CuZn40Pb2 | 2.0380 |

| Brass | H68 | C26800/C26000 | C2680/C2600 | cuzn33/CuZn30 | 2.0280/2.0265 |

| Brass | H85 | C23000 | c2300 | CuZn15 | 2.0240 |

| Brass | zCuZn38 | C27200HO1 | c2720R-1/2H | CuZn37F37 |

Stainless Steel

We are very experienced in stainless steel casting. The sizes of the stainless steel casting parts range from 0.1 inch up to 24 inches. The weights of the stainless steel casting parts are from an ounce to 50 pounds. Typical tolerances are ± .005” per inch.

Brass

We have over 30 years of brass investment casting experience. All of our brass casting components are subject to our rigorous inspection regime with designated inspectors, in-process inspection and a full final inspection completed on every part.

Aluminum

Aluminum is a great choice for oem parts with the highly valued combination. Our Invest Casting center for aluminum components exclusively consists of state-of-the-art investment casting machines and skillful engineers to satisfy our customers’ requirements.

Titanium

We are well capable of titanium investment castings such as aerospace parts, titanium turbochargers parts , musical instruments,titanium motorcycle parts, bicycle parts, titanium parts for the oil and gas industries and etc.

Carbon Steel

Be-cu Company Carbon steel casting parts and alloy steel casting parts could be produced either by Water Glass Investment Casting or Silica Sol Investment Casting.Water Glass Investment Casting: carbon steel castings with tolerance CT7-CT8.

The Tolerance Of Investment Castings

The dimensional accuracy of Investment castings is one of the important quality indicators of castings. The dimensional tolerance standards of investment castings are the objective basis for measuring the dimensional accuracy of castings. Be-cu strictly follows the national standard GB/T6414-2017.For investment castings, select the following corresponding tolerance classes according to their maximum nominal size:

- When the maximum nominal size is less than or equal to 100, choose DCTG4~DCTG6 grade;

- 100<maximum nominal size≤400, choose DCTG4~DCTG8 grade;

- When the maximum nominal size is greater than 400, select DCTG4~DCTG9 grade.

The Dimensional Tolerance Of Investment Casting(DCTG)

Nominal Size

| > | To |

|---|---|

| 10 | |

| 10 | 16 |

| 16 | 25 |

| 25 | 40 |

| 40 | 63 |

| 63 | 100 |

| 100 | 160 |

| 160 | 250 |

| 250 | 400 |

| 400 | 630 |

| 630 | 1000 |

Casting Dimensional Tolerance Grade (DCTG) And Corresponding Linear Dimensional Tolerance Value

| DCTG1 | DCTG2 | DCTG3 | DCTG4 | DCTG5 | DCTG6 | DCTG7 | DCTG8 | DCTG9 |

|---|---|---|---|---|---|---|---|---|

| 0.09 | 0.13 | 0.18 | 0.26 | 0.36 | 0.52 | 0.74 | 1.5 | |

| 0.1 | 0.14 | 0.2 | 0.28 | 0.38 | 0.54 | 0.78 | 1.1 | 1.6 |

| 0.11 | 0.15 | 0.22 | 0.3 | 0.42 | 0.58 | 0.82 | 1.2 | 1.7 |

| 0.12 | 0.17 | 0.24 | 0.32 | 0.46 | 0.64 | 0.9 | 1.3 | 1.8 |

| 0.13 | 0.18 | 0.26 | 0.36 | 0.5 | 0.7 | 1 | 1.4 | 2 |

| 0.14 | 0.2 | 0.28 | 0.4 | 0.56 | 0.78 | 1.1 | 1.6 | 2.2 |

| 0.15 | 0.22 | 0.3 | 0.44 | 0.62 | 0.88 | 1.2 | 1.8 | 2.5 |

| 0.24 | 0.34 | 0.5 | 0.7 | 1 | 1.4 | 2.8 | ||

| 0.4 | 0.56 | 0.78 | 1.1 | 1.6 | 2.2 | 3.2 | ||

| 0.64 | 0.9 | 1.2 | 1.8 | 2.6 | 3.6 | |||

| 0.72 | 1.4 | 2 | 2.8 | 4 |

The Straightness Tolerance Of Investment Casting

| > | To |

|---|---|

| 10 | |

| 10 | 30 |

| 30 | 100 |

| 100 | 300 |

| 300 | 1000 |

| 1000 | 3000 |

| 3000 | 6000 |

| 6000 | 10000 |

| DCTG2 | DCTG3 | DCTG4 | DCTG5 | DCTG6 | DCTG7 | DCTG8 |

|---|---|---|---|---|---|---|

| 0.08 | 0.12 | 0.18 | 0.27 | 0.4 | 0.6 | 0.9 |

| 0.12 | 0.18 | 0.27 | 0.4 | 0.6 | 0.9 | 1.4 |

| 0.18 | 0.27 | 0.4 | 0.6 | 0.9 | 1.4 | 2 |

| 0.27 | 0.4 | 0.6 | 0.9 | 1.4 | 2 | 3 |

| 0.4 | 0.6 | 0.9 | 1.4 | 2 | 3 | 4.5 |

| 3 | 2 | 6 | g | |||

| 6 | 12 | 18 | ||||

| 12 | 16 | 24 | 36 |

The Flatness Tolerance Of Investment Casting

| > | To |

|---|---|

| 10 | |

| 10 | 30 |

| 30 | 100 |

| 100 | 300 |

| 300 | 1000 |

| 1000 | 3000 |

| 3000 | 6000 |

| 6000 | 10000 |

| DCTG2 | DCTG3 | DCTG4 | DCTG5 | DCTG6 | DCTG7 | DCTG8 |

|---|---|---|---|---|---|---|

| 0.12 | 0.18 | 0.27 | 0.4 | 0.6 | 0.9 | 1.4 |

| 0.18 | 0.27 | 0.4 | 0.6 | 0.9 | 1.4 | 2 |

| 0.27 | 0.4 | 0.6 | 0.9 | 1.4 | 2 | 3 |

| 0.4 | 0.6 | 0.9 | 1.4 | 2 | 3 | 4.5 |

| 0.6 | 0.9 | 1.4 | 2 | 3 | 4.5 | 7 |

| 4 | 6 | 14 | ||||

| 8 | 12 | 18 | 28 | |||

| 16 | 24 | 36 | 56 |

Roundness, Parallelism, Squareness and Symmetry Tolerances

| > | To |

|---|---|

| 10 | |

| 10 | 30 |

| 30 | 100 |

| 100 | 300 |

| 300 | 1000 |

| 1000 | 3000 |

| 3000 | 6000 |

| 6000 | 10000 |

| DCTG2 | DCTG3 | DCTG4 | DCTG5 | DCTG6 | DCTG7 | DCTG8 |

|---|---|---|---|---|---|---|

| 0.18 | 0.27 | 0.4 | 0.6 | 0.9 | 1.4 | 2 |

| 0.27 | 0.4 | 0.6 | 0.9 | 1.4 | 2 | 3 |

| 0.4 | 0.6 | 0.9 | 1.4 | 2 | 3 | 4.5 |

| 0.6 | 0.9 | 1.4 | 2 | 3 | 4.5 | 7 |

| 0.9 | 1.4 | 2 | 3 | 4.5 | 7 | 10 |

| 6 | 9 | 14 | 20 | |||

| 12 | 18 | 28 | 40 | |||

| 24 | 36 | 56 | 80 |

The Concentricity Tolerance Of Investment Casting

| > | To |

|---|---|

| 10 | |

| 10 | 30 |

| 30 | 100 |

| 100 | 300 |

| 300 | 1000 |

| 1000 | 3000 |

| 3000 | 6000 |

| 6000 | 10000 |

| DCTG2 | DCTG3 | DCTG4 | DCTG5 | DCTG6 | DCTG7 | DCTG8 |

|---|---|---|---|---|---|---|

| 0.27 | 0.4 | 0.6 | 0.9 | 1.4 | 2 | 3 |

| 0.4 | 0.6 | 0.9 | 1.4 | 2 | 3 | 4.5 |

| 0.6 | 0.9 | 1.4 | 2 | 3 | 4.5 | 7 |

| 0.9 | 1.4 | 2 | 3 | 4.5 | 7 | 10 |

| 1.4 | 2 | 3 | 4.5 | 7 | 10 | 20 |

| 9 | 14 | 20 | 40 | |||

| 18 | 28 | 40 | 60 | |||

| 36 | 56 | 80 | 120 |

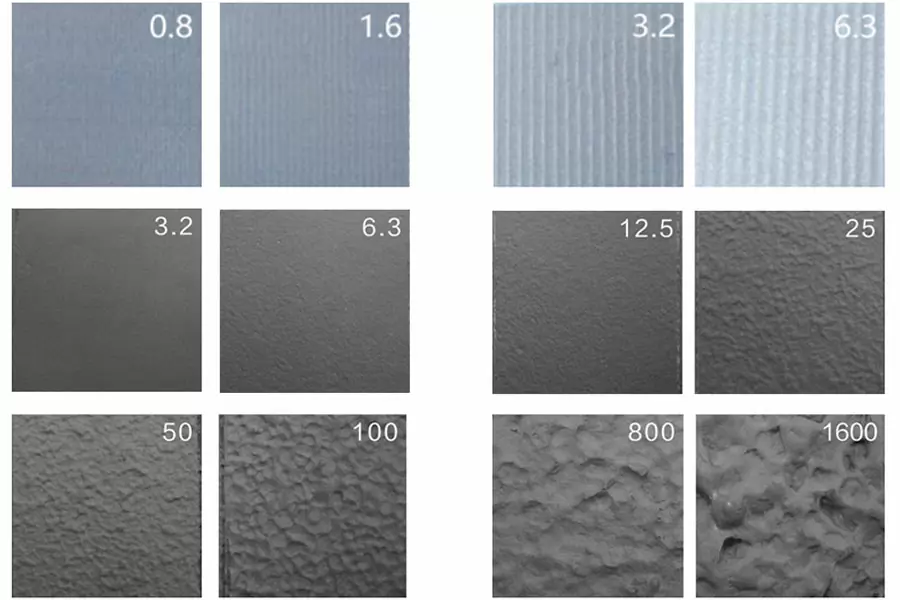

The Roughness Comparison Of Investment Casting

This standard is based on the casting surface roughness comparison sample block specified in (GB/T 15056-2017) for the inspection of casting surface roughness plating, as a reference for casting process and casting surface roughness selection.

- The surface roughness (Ra) of stainless steel sand casting is 25-50

- The surface roughness (Ra) of stainless steel water glass investment casting is 6.3-12.5

- The surface roughness (Ra) of stainless steel silica sol investment casting is 3.2-6.3

- The surface roughness (Ra) of aluminum alloy sand casting is 25-50

- The surface roughness (Ra) of aluminum alloy silica sol investment casting is 3.2-6.3

- The surface roughness (Ra) of aluminum alloy die casting is 2.5-3.2

- The surface roughness (Ra) of copper alloy sand casting is 25-50

- The surface roughness (Ra) of copper alloy silica sol investment casting is 3.2-6.3

- The surface roughness (Ra) of steel/aluminum/copper CNC Machining is 0.8-3.2

Investment Casting Applications – What is Investment Casting Used for

Because the investment casting allows a very high precision without altering the structure of the material with a good rate of manufacture, investment casting is becoming increasingly common as its machine range, control systems and cutting tools are just growing. Our investment casting service is used to produce a variety of custom-designed investment casting parts and products in all areas of the industry:

The Case Studies Of Investment Casting Parts

You have a complex part design, Our investment casting service can help you turn it into a reality. With the right equipment, strong technical knowledge, and a focus on quality.. From tool design to finishing and then on to shipment, Be-cu prototpe ensure that every project is completed to a high standard and that your orders are delivered on time, every time.

-

Investment Casting Stainless Steel Motorcycle Crankshaft

-

Precision Machinery Parts By Brass Investment Casting

-

Stainless Steel Investment High Pressure Precision Casting

-

Stainless Steel Investment Casting Medical Handle Parts

-

316 Stainless Steel Investment Casting Scissor Handle

-

Stainless Steel Investment Casting Bicycle Parts

-

Custom Stainless Steel Investment Casting Exhaust Pipe

-

Auto Parts Carbon Steel Investment Precision Casting Manufacturer

-

Carbon Steel Investment Casting Railway Parts

-

Precision Carbon Steel Investment Casting Railway Products

-

Carbon Steel Investment Casting Construction Machinery Parts

-

316 Stainless Steel Precision Casting Owl Ring

-

Stainless Steel Investment Casting Craft Ornament Decoration Gift

-

Lost Wax Casting Stainless Steel 431 Golf Head

-

Investment Casting For TC4 Golf Putter Head

-

Investment Cast 925 Silver Moon Earrings

-

Casting Silver Rings

-

Tin Bronze Cast Valve Body And Bonnet

-

Precision CNC Machining Inconel 718 Cast Impeller

-

Large CNC Turning Inconel 625 Automobile Engine Camshafts