Precision Stamping For Automotive Industry

The automobile is known as the “machine that changed the world”. Because of its strong industrial links, the automotive industry is considered an important indicator of a country’s level of economic development. There are four major processes in the automotive industry, and the stamping process is one of the most important and the first of the four major processes.

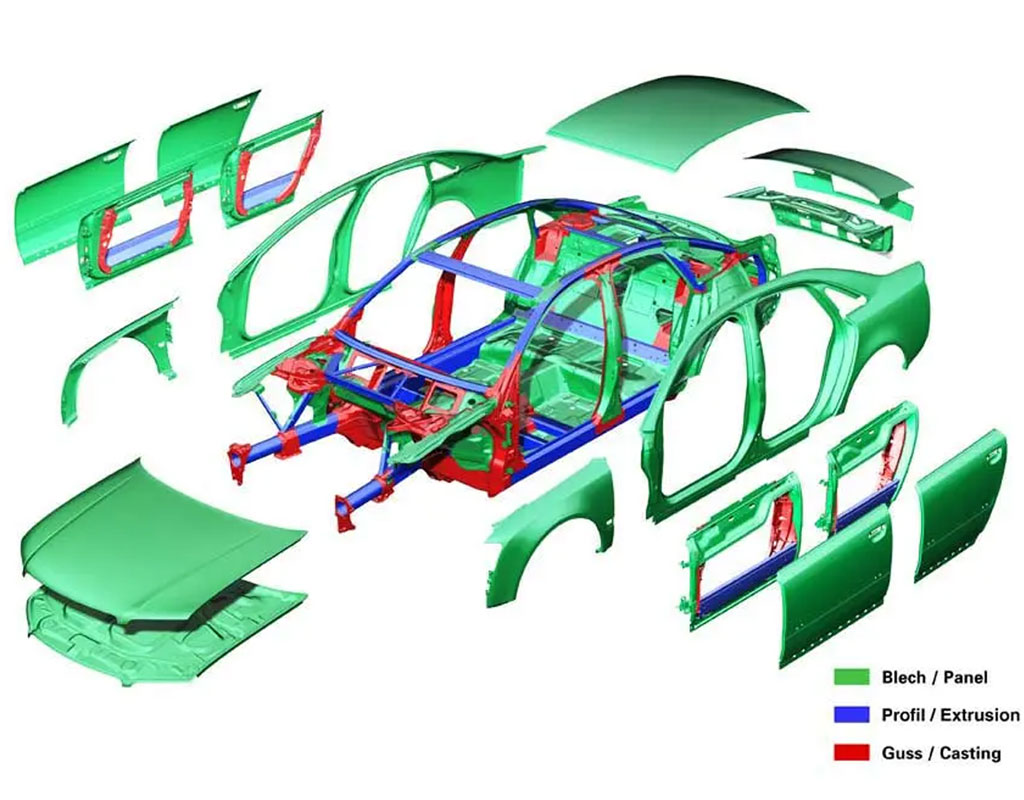

Metal Stamping is a shape fabrication process in which metal sheets of various sizes are pressed (through presses and dies) to deform or separate them plastically, thus obtaining workpieces of various shapes and sizes required (stampings); according to the stamping fabricate temperature, they are divided into hot and cold stamping, with car body stamping belonging to cold stamping, which is carried out at room temperature; the blanks for stamping are mainly hot-rolled and cold-rolled steel sheets and strips. Of the world’s steel, 60 to 70% is sheet steel, most of which is stamped into finished products.

Automotive stamping is at the heart of China manufacturing. Be-cu.com fabricates parts for several automotive companies across the China We take a lot of pride in working closely with automotive product developers and buyers to get parts made fast and right the first time. Our team of dedicated automotive stamping mechanics, mold operators and programmers get it, we understand that speed and price won’t make a difference if the mold and parts aren’t right. We are entrusted with the custom automotive sheet metal parts of top global companies. Experience why they keep coming back to Be-Cu stamping company for their automotive parts, request a quote today.

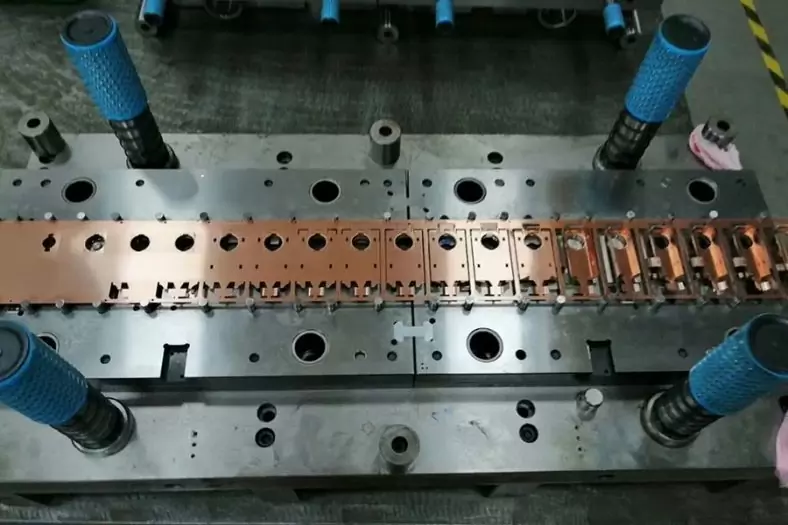

Tooling And Mold Making For Automotive

In modern industrial production, moulds are important process equipment for the production of various industrial products, which shape the raw materials in a certain way with their specific shape. In the automotive industry, in various types of cars, an average of one model needs about 2000 sets of stamping moulds, among which nearly 300 sets of large and medium-sized covering parts moulds. Moulds have become an important means of contemporary industrial production and one of the directions of process development.

The development of varieties of modern industrial products and the improvement of production efficiency depend to a large extent on the development and technical level of moulds. At present, moulds have become one of the important symbols to measure the manufacturing level of a country.

The sketch of the mould structure is used as a strong basis for drawing the general assembly drawing. In the assembly drawing, the relationship between the parts should be clear and unambiguous, relevant sections and projections should be presented, workpiece drawings drawn, relevant requirements stated and parts details filled in.

The working parts of the mould have certain standards in the production process and should follow them in terms of calculation, positioning, pressing and fastening. If the wall thickness punch is small and long and the concave die is thin, the calibration should be reinforced to determine the size and structure of the concave die and to carry out the design, in accordance with the choice of the perimeter die holder, to ensure that the closing height, size and pressure of the die are adapted to the relevant equipment and to draw the relevant sketches of the die structure.

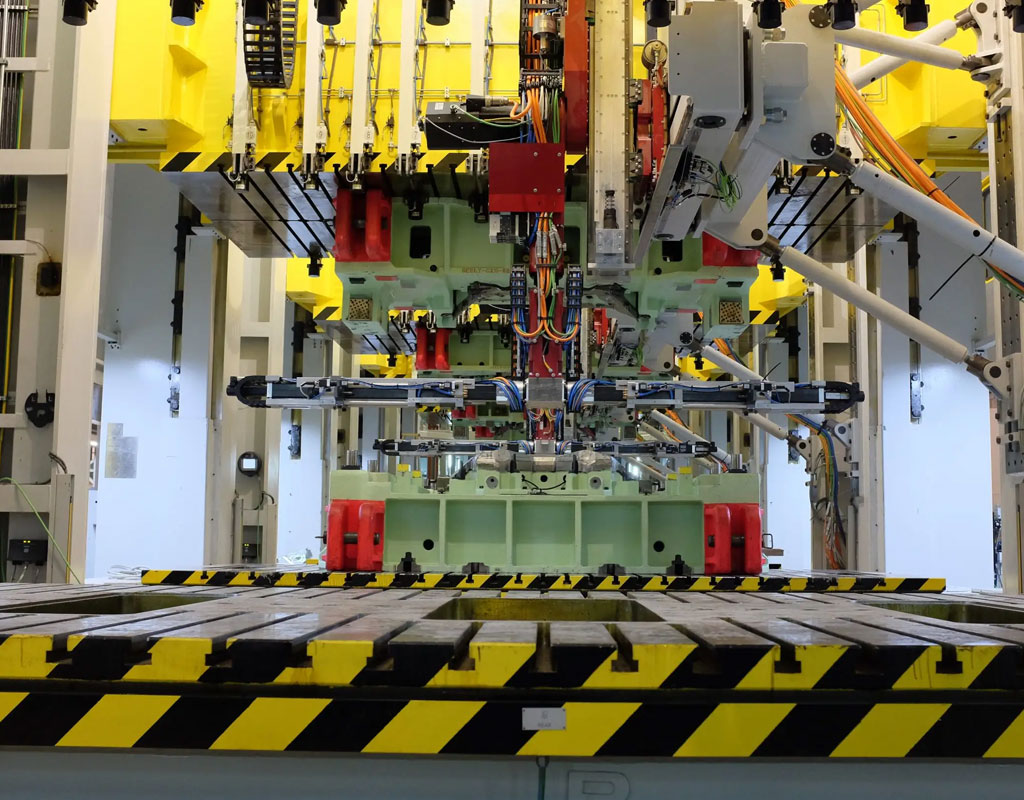

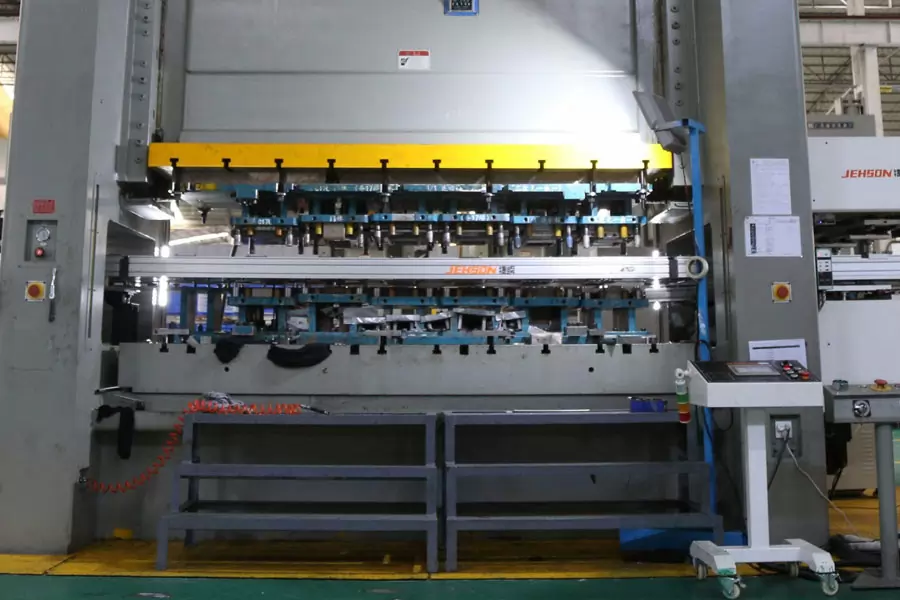

The large stamping lines currently produced in China for the manufacture of large cover parts for cars have reached contemporary international advanced levels. In order to meet the needs of automated stamping lines, well-known domestic press manufacturers have carried out the development and production of high-performance single presses with continuous lines. They have developed presses with large tonnage, large stroke and large table surface, as well as large tonnage air cushions, robotic automatic loading and unloading systems, fully automatic die change systems and touch screen monitoring systems with perfect functions, producing presses with high speed and high precision. These single machine linkage equipments have been successively equipped with a number of large automatic stamping lines of large domestic automobile manufacturers and are being expanded to more automobile plants and foreign companies, fully meeting the fast, high precision and efficient production requirements of automobiles.

Taking into account the requirements for punching pressure, the height and structure of the die closure, the characteristics of the part and the characteristics of the stamping process, the selection of equipment is based on the consideration of the existing equipment, the relationship between the selection of equipment and the design work of the die is established, the required quantity of equipment is determined and the type of equipment is selected. If the equipment is not large, the calculation of the punching force is small, but the die size is large, then a larger equipment can be selected, so that the size and structure of the die is adapted to the closing height of the equipment and the size of the leakage hole. The design of the die requires attention to several aspects.

- Firstly, in order to make the die balanced, it is necessary to make the die shank axis work and to bring the centre of pressure of the die into line with the centre of the press slide to prevent unconventional wear.

- Secondly, for deep-drawing dies, it is necessary to calculate the drawing power and to check the motor power.

- Thirdly, in the bending as well as in the drawing process, the works are on the large side. In order to make it easier to take out the workpiece as well as to prevent the blank, the press stroke needs to be calibrated to ensure that the stroke is in a specific range.

In the production of automotive moulds, the moulds and presses are used to stamp and shape the steel sheet.

Understanding automotive stamping mold design will make your precision stamping project easier. It will also help you save some time and money. However, you need the service of experts to get the right tool for the best results. Be-cu.com offers the best precision stamping services for custom metal automotive parts, providing quality tools, experts, and easy processes.

We have a wide range of materials, manufacturing processes, and surface finishing options for your automotive stamping parts. Also, our experts offer you manufacturing suggestions to ensure you get the most effective solution. After placing the order for precision stamping parts, Be-cu.com manufacturing partners would produce perfect precision stamping tooling to make the best automotive stamping parts. Upload your design file today and get an instant quote.

Why Choose BE-CU Stamping Mold Making Services

- High production capability and competitive prices for stamping service are offered.

- We have rich metal stamping manufacturing experiences for over 20 years and earned a good reputation.

- Multiple of stamping mold designs & types – 3D printed stamping mold & deep drawing mold (work in with CNC machining service) are available to meet custom needs.

- Do precision metal stamping parts manufacturing according to your drawings or samples.

- 700T Mechanical Press | Press bolster size: 35001500mm | Shut Height: 900mm | Coil feeder size: W600mmT4mm.

- Finish the parts with service of mold making in time to provide the strongest support for your R&D projects.

- Our automated quoting, design analysis, and manufacturing process allows us to ship stamping orders in as fast as 1 day.

- CMM machine | Brand: CAISI | Table Size: 1000800600mm | Software:PC-DMIS | Hardnessss machine | Spec.: 20-70HRC

- Accurate CAE analysis helps to improve parts quality and optimize tooling process. Concurrent engineering, product design review, and early involvement can help shorten the project lead-time.

- We have the most experienced engineers and tooling partners that will really make a difference in your lead times, costs and final quality.

- Be-cu has 8 designers with engineering capability for simulation, strip layout and die design. Our engineers and tools experts help prior to the development with technical advice in order to minimize problems during the subsequent production process.Can make up for your one-stop needs for plastic proofing and mass production

Automotive Stamping Supplier – Precision Stamping For Automotive

Be-Cu Prototype is an IATF16949 certificated manufacturer providing precision stamping tooling and stamping parts manufacturing solutions for automotive industry since 2015. From prototyping to mass production, all our procedure are strictly accordingly to IATF16949, to ensure product’s safety and stability in the actual application. The products are widely used in automotive applications such as automotive body, automotive engine shock absorption, automotive body shock absorption, automotive car seats, automotive hinges and automotive brake systems.

At present, we have established business relationship with many well-known enterprises such as the Ford and Volkswagen. With rich experience on stamping tool design and quality control, we believe our stamping technology strength can help to improve our customer’s marketing competitiveness.Welcome to send your inquiry or custom designs of metal stamping parts to be made, we’ll send you a free quote within 24 hours in working days and work out a schedule for recording the progress.

Automotive Stamping Operations

- Blanking

- Bending

- Punching

- Coining

- Drawing

- Embossing

- Piercing

- Curling

Our team of assemblers specialize in mechanical and electrical assembly of components. We are experienced with a large variety of assembly from simple one or two part additions to complete complex cabinets and assemblies.

Automotive Stamping Material

- Steel

- Stainless Steel

- Aluminum

- Copper

- Brass

- Nickel

- Galvanized

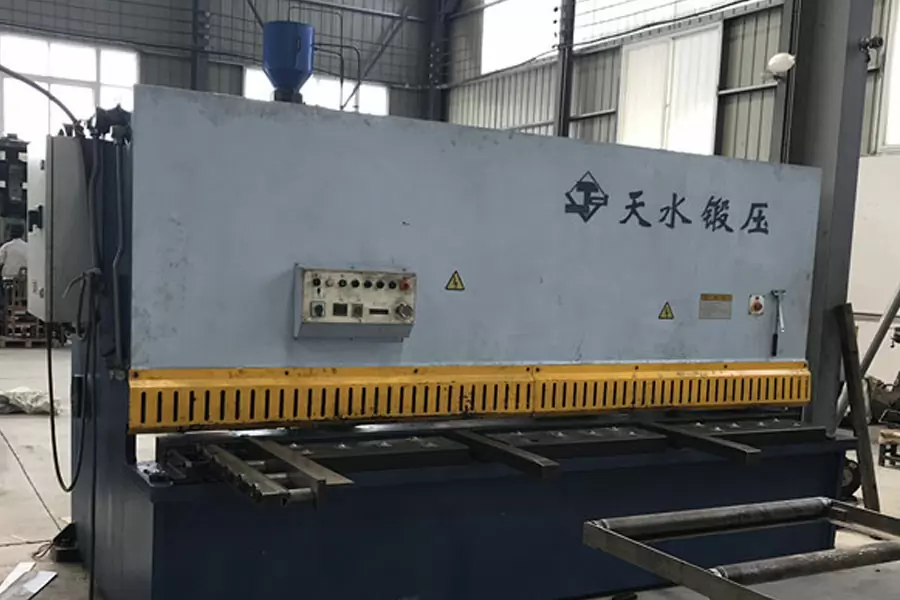

Our Outstanding Automotive Stamping Equipment

- Connecting Rod Metal Stamping Machine

- Automotive Cold Stamping Machine

- 3D Automatic Stamping Equipment

- 40-700T Metal Stamping Machine

- EDM Wire Cuuter

- Explorer CMM, Stroke 1200*1000*800

- Caisi CMM, Stroke 1000*800*600

- Cnc Machining Center

- Check Out BE-CU Equipment List

Top Automotive Stamping Parts And Case Studies

You have a complex automotive part design, Be-cu.com can help you turn it into a reality. With the right equipment, strong technical knowledge, and a focus on quality.. From tool design to finishing and then on to shipment, Be-cu ensure that every project is completed to a high standard and that your orders are delivered on time, every time.