Laser Cut For Medical Parts

Medical laser cutting has revolutionized the field of medical device manufacturing, offering precision, efficiency, and customization that were once unimaginable. From intricate catheters to life-saving stents, laser cutting technology has become an indispensable tool in crafting medical instruments with unparalleled accuracy and quality.

Laser cutting involves the use of high-powered lasers to precisely cut through materials, such as metals, polymers, ceramics, and various alloys, with incredible precision. In the medical field, this technology plays a crucial role in fabricating devices that are used in surgical procedures, diagnostics, and patient care.

The Advantage Of Medical Laser Cutting

One of the primary advantages of medical laser cutting is its ability to create intricate designs and shapes that are otherwise challenging to achieve through traditional manufacturing methods. This precision is vital in the production of medical instruments, where even the slightest deviation from specifications can have significant consequences. Whether it’s crafting intricate patterns on surgical tools or creating precise shapes for implants, laser cutting ensures accuracy down to micrometer levels, meeting the stringent demands of the medical industry.

Furthermore, laser cutting in the medical field offers exceptional consistency in mass production. With automated processes and advanced software control, manufacturers can reproduce intricate designs with uniform quality, meeting high-volume demands while ensuring each device meets exact specifications. This consistency is paramount in maintaining the safety and reliability of medical devices used in various procedures.

The use of lasers also minimizes material waste during manufacturing. The precise nature of laser cutting allows for efficient use of materials, reducing scrap and optimizing resources—a significant advantage in an industry that values sustainability and cost-effectiveness.

However, despite its numerous advantages, medical laser cutting also presents challenges. Ensuring the safety of patients and medical professionals during the manufacturing process requires strict adherence to regulatory standards and quality control measures. Additionally, the initial investment in acquiring and maintaining laser cutting equipment can be substantial, limiting access to this technology for some manufacturers.

As technology advances, the future of medical laser cutting holds even more promise. Innovations in laser technology, coupled with developments in robotics and artificial intelligence, are expected to further enhance precision, speed, and capabilities in manufacturing medical devices. These advancements may open doors to new applications and enable the creation of even more complex and sophisticated medical instruments.

In conclusion, medical laser cutting has transformed the landscape of medical device manufacturing, offering unmatched precision, customization, and efficiency. Its ability to create intricate designs, customize devices, ensure consistency in production, and minimize material waste makes it an invaluable asset in the quest for better healthcare outcomes. As technology continues to evolve, the potential for medical laser cutting to further revolutionize the medical field remains vast, promising a future of increasingly advanced and tailored medical devices.

Medical Laser Cutting Company – Precision Laser Cut For Medical Parts

The versatility of laser cutting technology enables the customization of medical devices according to patient-specific needs. For instance, implants tailored to fit a patient’s unique anatomy can be created with remarkable precision, enhancing the efficacy of treatments and reducing the risk of complications. This level of customization is particularly crucial in fields like orthopedics and cardiology, where implants need to integrate seamlessly with the patient’s body.

Medical devices parts and components have high tolerance and performance requirements. Its cutting involves comprehensive designing, meticulous selection of materials, and high accuracy. Hence, the need to partner with the best manufacturer for the best results.Be-Cu prototype is your best bet for efficient and effective medical laser cutting services for easy approval of your medical product for sale in a market filled with different products.

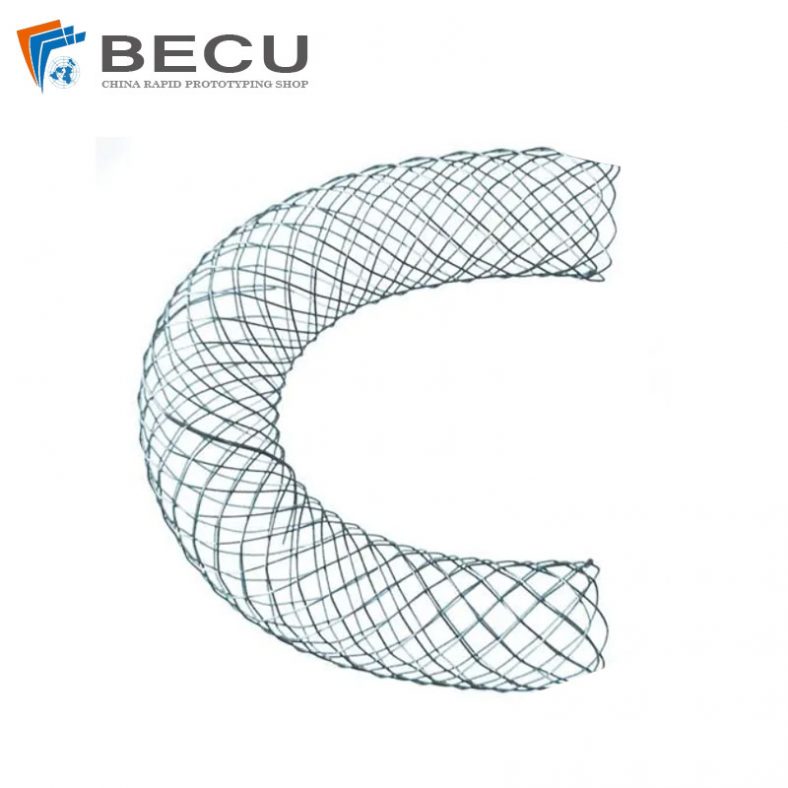

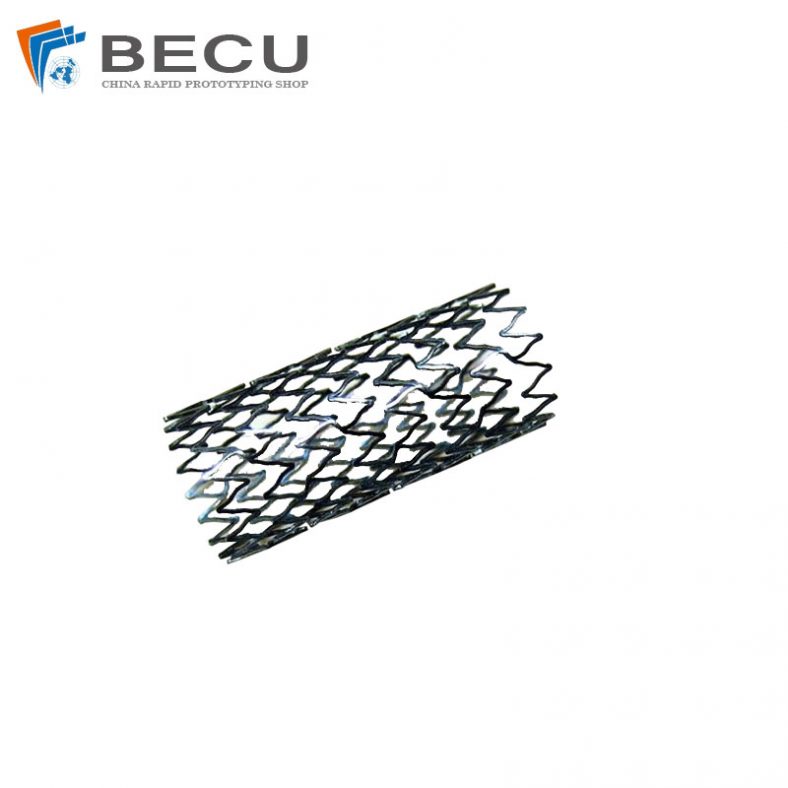

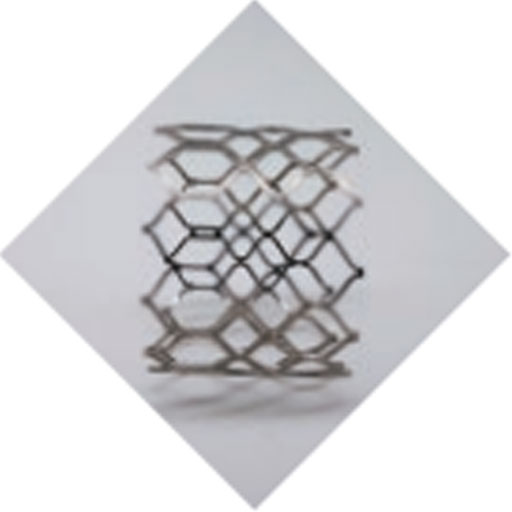

Display Of Samples Of Interventional Medical Instruments

Ni-Ti-∅7mm-WT0.4mm-Valve-Stent-Microstructure

Ni-Ti-L605-∅23mm-WT0.5mm-Valve-Stent

316L-L605-Bare-Metal-Coronary-Stent

∅3.2mm-Degradable-Polymer-Stent

0Ni-Ti Bracket Laser Cutting Forming

Ni-Ti-∅5.5mm-WT0.3mm Mitral Valve Stent

∅1.9mm-Ni-Ti Bolt Removal Bracket

∅2.0mm-Ni-Ti Bolt Removal Bracket

∅0.45mm-Ni-Ti Reticular Medical Basket

∅1.0mm-Ni-Ti Neurointerventional Stent

Endoscopic Display Of Snake Bone Samples

∅2.8mm Fully Automated Pressing Of Urological Cobra Bone

∅4.5mm Disposable Biliary Cobra Bone

SUS304 Snake Bone Joint For Medical

SUS304∅2.8mm L700mm Disposable Urological Cobra Bone

SUS304∅16mm L1200mm Anorectal Cobra Bone

∅2.5mm Stainless Steel Medical Tube Forming

Ni-Ti∅2.6mm L80mm Urological Cobra Bone

Snake Bone Wire Head Fixed Welding Parts

SUS 304∅9.7mm L90mm Gastrointestinal Cobra Bone

SUS304 Snake Bone Thread Earrings

Sample Display Of Surgical Instruments

∅0.65mm Hypotube Spiral And Its Tongue Structure

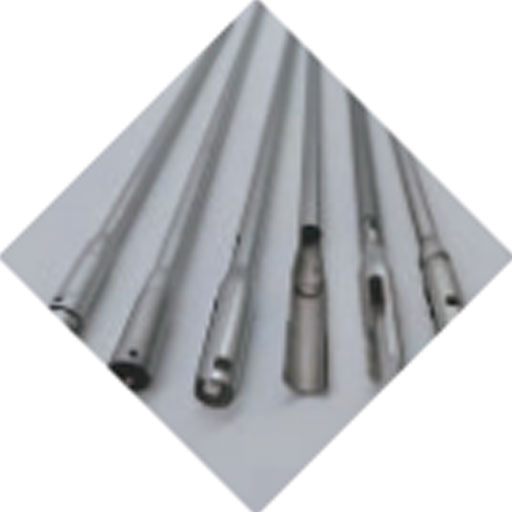

∅3.0mm Stainless Steel Medical Tube Forming

Hypotube Marking Ring For Medical

Medical Endoscopic Nail Box Sleeve

Medical Used Hypotube Luer Markings

Orthopedic Puncture Needle Slotting

Orthopedic Soft Drills And Planers Knife

Special Shaped Microtubule Opening

Stainless Steel 304 Medical Pipe Grooving

SUS-316L Medical Stapler Tube Forming

Ultrasonic Scalpel Inner And Outer Cannula

WT0.8mm Titanium Alloy Cranial Fixation Film

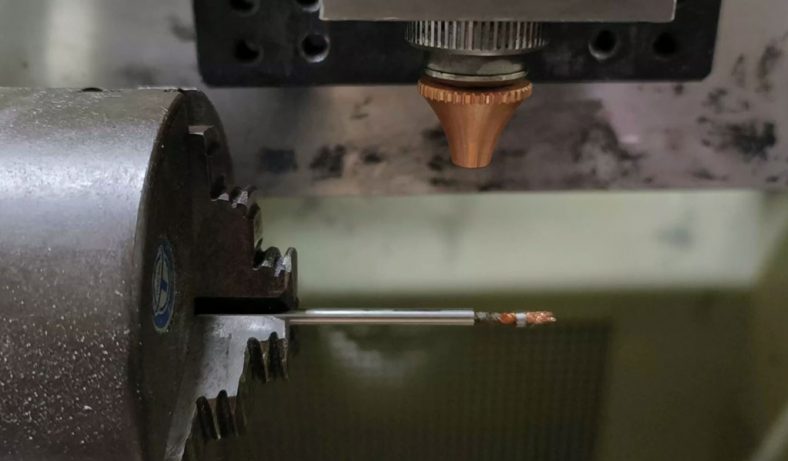

Super Precise Capillary Laser Cut:Tolerance to 0.0003mm

At BE-CU, we offer Super Precise Capillary Laser Cut service to create a working prototype for you. Precision capillary laser cutting is a specialized technique used in various industries, including medical device manufacturing, electronics, aerospace, and automotive sectors.

This method involves using high-powered lasers to precisely cut extremely small and delicate components, often with diameters as small as a fraction of a millimeter. Capillary tubes, micro-tubing, fine wires, and intricate patterns in thin materials are typical examples of items created through precision capillary laser cutting.

Be-Cu prototype is fully compliant with many ISO certifications, We have the authorization to manufacture medical prototypes and components in compliance with ISO 9001:2015 requirements,including ISO 13485.Our efficient quality management systems enable us to produce medical devices and components that meet specific requirements. We take pride in our team of experienced experts and quality inspectors with vast knowledge of the medical laser cutting requirements. Contact us today, and let’s discuss your next project!

The General Case Studies Of Medical Laser Cutting

You have a complex 3d medical design, Our Medical laser cutting service can help you turn it into a reality. With the right equipment, strong technical knowledge, and a focus on quality.. From tool design to finishing and then on to shipment, Be-cu prototpe ensure that every project is completed to a high standard and that your orders are delivered on time, every time.

Materials For Laser Cut Medical Devices

Medical laser cutting utilizes various materials to produce a wide array of precision medical devices and components. These materials are selected for their compatibility with laser cutting processes, biocompatibility, sterilization capabilities, and suitability for medical applications. Some common materials used in medical laser cutting include:

Stainless Steel Laser Cut For Medical

Titanium Laser Cut For Medical

Nitinol Laser Cut For Medical

Plastics and Polymers Laser Cut For Medical

Ceramics Laser Cut For Medical

Biodegradable Polymers Laser Cut For Medical

Laser Cutting Parts and Components for the Medical Industry

In the medical field, precision capillary laser cutting plays a vital role in the fabrication of intricate medical devices and components, especially those requiring high precision and miniaturization. Some of the key applications include:

Catheters

Stents and Implants

Microfluidic Devices

Surgical Tools

Implants

Dental Components

Electronics for Medical Devices

More

As technology advances, precision laser cutting continues to evolve, enabling the creation of even more intricate and personalized medical solutions that contribute to better patient care and treatment outcomes.The process of precision capillary laser cutting involves directing a highly focused laser beam onto the material, which melts, vaporizes, or burns away the targeted areas. Advanced control systems ensure accuracy down to micrometer levels, allowing for intricate designs and precise cuts without causing damage or deformation to the surrounding material.Key advantages of precision capillary laser cutting in the medical industry include:

- High Precision: Enables the creation of intricate and precise features with minimal material deformation.

- Versatility: Capable of working with a wide range of materials, including metals, polymers, ceramics, and alloys.

- Customization: Allows for the production of personalized medical devices tailored to individual patient needs.

- Minimization of Post-Processing: Produces high-quality finished products, often reducing the need for additional machining or finishing processes.

As technology continues to advance, precision capillary laser cutting is expected to become even more sophisticated, enabling the fabrication of increasingly intricate and customized medical devices that contribute to improved patient care and outcomes.

3D Laser Cutting Medical Devices Or Parts

3D laser cutting in the medical field has emerged as a revolutionary method for producing intricate, three-dimensional components and devices with precision.

This advanced manufacturing technique utilizes high-powered lasers to cut, shape, and engrave materials in three dimensions, offering several advantages in creating complex medical devices or parts.

3D Laser Cutting Is Transforming The Medical Industry

3D laser cutting allows for the fabrication of personalized implants and prosthetics tailored to match a patient’s unique anatomy. Whether it’s cranial implants, bone replacements, or limb prosthetics, this technology enables precise shaping and customization, enhancing the fit and function of the devices.

Surgical instruments requiring intricate designs or specific geometries benefit from 3D laser cutting.

Be-Cu.com

The technology enables the creation of complex patterns, microstructures, and fine features on instruments like forceps, retractors, and scalpels, enhancing their functionality and precision during surgical procedures.

The precise cutting capabilities of 3D laser cutting facilitate the production of microfluidic devices used in diagnostics, drug delivery, and lab-on-a-chip systems. These devices incorporate intricate channels, valves, and structures on a small scale, allowing precise manipulation of fluids for medical testing and research.

With the ability to create intricate patterns and precise microstructures, 3D laser cutting assists in producing drug delivery systems like microneedles or intricate patches. These systems offer controlled and targeted drug administration, enhancing therapeutic effectiveness.

Medical imaging data can be used to create patient-specific anatomical models through 3D laser cutting. These models aid surgeons in preoperative planning, education, and practicing complex procedures, contributing to improved surgical outcomes.

Benefits of 3D Laser Cutting Medical

The benefits of 3D laser cutting in the medical domain include:

- High Precision and Accuracy: Offers micron-level precision, ensuring intricate designs and fine details.

- Customization and Personalization: Allows for the creation of patient-specific medical devices and components.

- Enhanced Efficiency: Streamlines the manufacturing process, reducing production time for complex structures.

- Material Versatility: Works with various materials such as metals, polymers, ceramics, and composites, offering flexibility in design and functionality.

Online Cooperate With Medical Laser Cutting Manufacturer

Be-cu works with customers all over the world to bring customers ideas to life with the highest quality precision engineered medical components on the planet. We have both precision laser cutting and molds making capabilities that include both conventional and modernized production line. If you are looking for a partnership to help you apply new tools and technologies, or help you fully realize your design vision, let us help you move your business forward, contact our team ([email protected])or quote online today to get the conversation started.