Custom Superalloy Parts

- Global delivery as fast as 30 days

- Machined prototypes in as fast as 9 days.

- Perfect Service And High Quality

- Tolerances down to +-0.005mm

- ISO 9001:2015, ITAF 16949

>>>All uploaded drawings are strictly confidential, check the confidentiality agreement

Custom Superalloy Parts – China Top High-Temperature Alloys Parts Manufacturer

Superalloys are complex, high-performance alloys, which have a high tolerance of oxidising environments and high temperatures.Due to its complex and harsh working environment, the surface integrity of superalloys plays a very important role in the performance of superalloys. However, superalloys are typical difficult-to-machine materials. Their micro-strengthened items have high hardness and severe work hardening, and they have high shear stress resistance and low thermal conductivity.

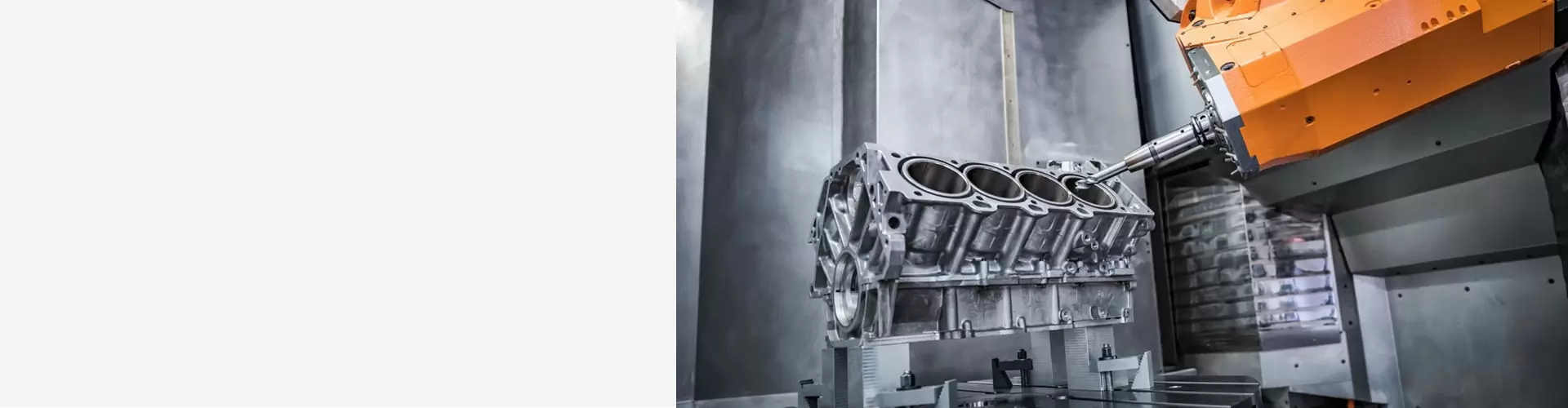

The cutting force and cutting temperature in the cutting area are high. The quality of the machined surface is low, and the tool damage is very serious. Under normal cutting conditions, the surface layer of superalloy will have problems such as excessive hardening layer, residual stress, white layer, black layer, and grain deformation layer.Services including:

Looking for reliable, quick-turn superalloys fabrication services suppliers and superalloys product manufacturers? Working with a specialized and seasoned manufacturer can help you save time and money, Be-cu is one of these options. Based on decades of experience in superalloys fabrication services, our engineers, designers, and technicians are capable to optimize the product design, prototypes building, cnc machining metal material selection, and superalloy parts production.

We also have a well-equipped machine shop and advanced manufacturing facilities to deliver custom superalloy parts with simple or complex geometries, applying various technologies including cnc milling, turning, drilling, wire EDM, grinding, or other machining processes, as well as finishing services and more fabrication methods. Whether you want to reach high precision, repeatability, or tight tolerances, our superalloy manufacturing parts will match your needs. For the best superalloy fabrication company, look no further than Be-cu, welcome to send your inquiry to us.

What Is Superalloy Parts – Superalloy Parts Define

Superalloy parts, refers to the name of the article after the structural change is finally fabrication by changing the high-temperature alloys with a suitable manufacturing process.

The properties of high temperature resistance and corrosion resistance of superalloy mainly depend on its chemical composition and structure. Taking the GH4169 nickel-based deformed superalloy as an example, it can be seen that the niobium content in the GH4169 alloy is high, and the degree of niobium segregation in the alloy is directly related to the metallurgical process. The high temperature of about 1 000 ℃ is similar to the US grade Inconel718. The alloy is composed of γ matrix phase, δ phase, carbide and strengthening phase γ’ and γ” phases. The chemical elements and matrix structure of GH4169 alloy show its strong mechanical properties. The yield strength and tensile strength are several times better than those of 45 steel, and the plasticity is better than that of 45 steel. The stable lattice structure and a large number of strengthening factors constitute its excellent mechanical properties.

Superalloy refers to a kind of metal material based on iron, nickel and cobalt, which can work for a long time under the action of high temperature above 600℃ and certain stress; and has high high temperature strength, good oxidation resistance and corrosion resistance, Good fatigue properties, fracture toughness and other comprehensive properties. The superalloy is a single austenite structure, which has good structure stability and service reliability at various temperatures.

Based on the above performance characteristics, and the high degree of alloying of superalloys, also known as “super alloys”, is an important material widely used in aviation, aerospace, petroleum, chemical, and ships. According to the matrix elements, superalloys are divided into iron-based, nickel-based, cobalt-based and other superalloys. The operating temperature of iron-based superalloys can generally only reach 750~780 °C. For heat-resistant parts used at higher temperatures, nickel-based and refractory metal-based alloys are used. Nickel-based superalloys occupy a special and important position in the entire field of superalloys, and are widely used to manufacture the hottest parts of aviation jet engines and various industrial gas turbines.

Custom Superalloy Parts Applications – What is Custom Superalloy Parts Used for

Because the fabrication allows a very high precision without altering the structure of the material with a good rate of manufacture, fabrication is becoming increasingly common as its machine range, control systems and cutting tools are just growing. Our fabrication service is used to produce a variety of custom-designed fabrication parts (as inconel cnc machining,kovar cnc machining,tungsten cnc machining,molybdenum etching and more)and products in all areas of the industry:

The Case Studies Of Custom Superalloy Parts

You have a complex superalloy parts design, Our fabrication service can help you turn it into a reality. With the right equipment, strong technical knowledge, and a focus on quality.. From tool design to finishing and then on to shipment, Be-cu prototpe ensure that every project is completed to a high standard and that your orders are delivered on time, every time.