Manufacturing Strength

- 30000m² Self-Operated Factory

- 500+ Precision Equipment

- 30+ Carefully Selected High-quality Collaborative Factories

- 12 Million+ Cumulative Manufactured parts

- 97% on-time delivery rate, delivery within the fastest day

>>>All uploaded drawings are strictly confidential, check the confidentiality agreement

Be-cu,One-Stop OEM Parts DreamWorks

Build a distributed collaborative manufacturing network with self-operated factories + collaborative factories to achieve efficient and intelligent matching of orders and production capacity

Strong Collaborative Manufacturing Network

Be-cu has 8 self-operated factories, serving 10,000+ customers in more than 30 countries and regions around the world.

In the future, Be-cu will continue to empower traditional manufacturing and create a full industrial chain for manufacturing OEM parts

Fast proofing and mass production of parts, 24-hour quotation system, minimum order of 1 piece, delivery in the fastest 2 days, 100% full inspection.

Under the control of ISO9001 and TS 16949,All processes are carried out through hundreds of advanced die casting machines, 5-axis machining, and other facilities, ranging from blasters to Ultra Sonic washing machines

Strict follow-up and control of the entire process from quotation to delivery.Other Serviced Include Sheet metal rapid proofing, stamping die manufacturing and high-speed stamping, forging die manufacturing, etc.,

OUR INDUSTRIES

Many Technologies, One Standard: On-Time Quality

Our custom parts services are bolstered by our extensive be-cu machine library and general breadth of fabricate technology. Few can match be-cu in adherence to exacting specifications, or in the re-creation of complex geometries for high volume fabrication of all types of specialized material parts.See examples of our case studies on our Products Page

At BE-CU, we have implemented a Strict Quality Inspection Standard for our fabrication services to inspect parts and ensure the consistency of cosmetic appearance. We are proud to be fully certified. This demonstrates our commitment to continuous quality improvement, respect for our workers and for the environment.

-

CNC Machining Bakelite Circuit Board Test Fixture

-

Precision Grinding Tungsten Steel Mold Parts

-

5 Axis CNC Machining Medical Olecranon Plate

-

Special-Shaped Non-Standard Medical Device Needles

-

High-Speed Steel (HSS) Die Punching Needles

-

Precision Tungsten Copper Alloy Eccentric Insert

-

5 Axis CNC Machining Spiral Bevel Gear Mold

-

Small Precision Injection Molding Inserts

-

5 Axis Machining Aluminum-Magnesium Alloy Water Aerator Impeller

-

Large CNC Turning Inconel 625 Automobile Engine Camshafts

-

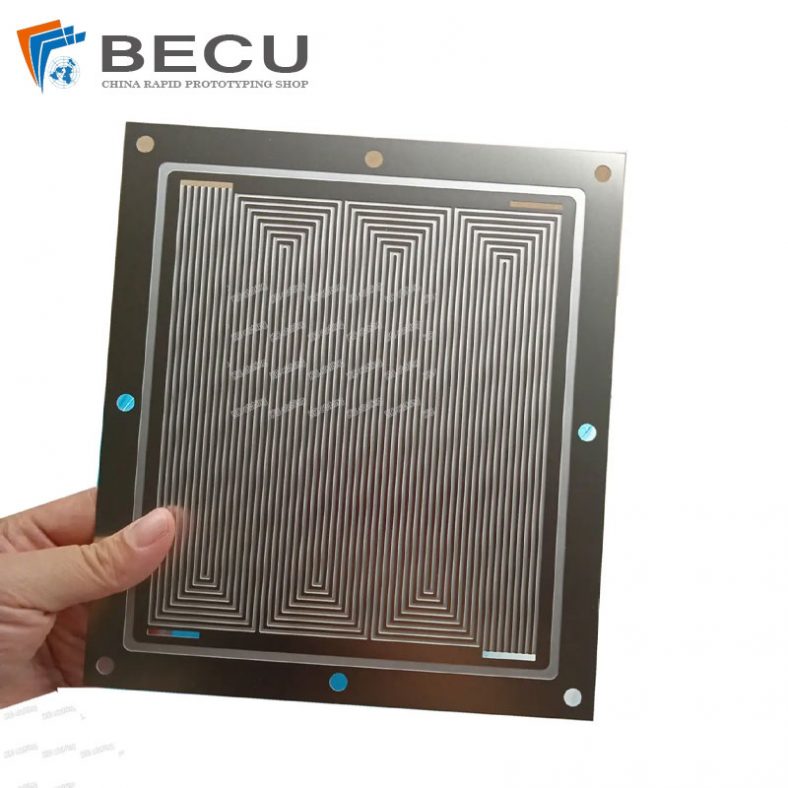

Metal Etched Hydrogen Fuel Cell Metal Bipolar Plates

-

Prototype CNC Spinning Stainless Steel 316L Outdoor Camping Pot