Material List

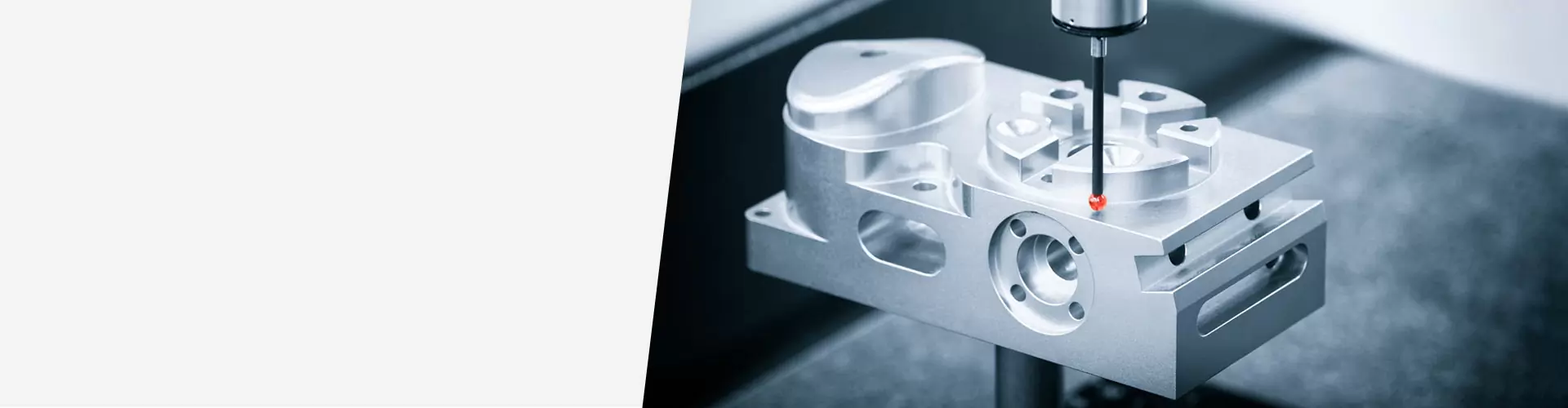

- Rapid Manufacturing on Demand

- 1 to 100000+ Metal and Plastic Parts

- Global delivery as fast as 10 days

- Equipped and experienced to offer more machining & material options

>>>All uploaded drawings are strictly confidential, check the confidentiality agreement

Precision Manufacturing Services for Various Material

Be-cu customers have the freedom to specify components in hundreds of different metals and alloys, while enjoying a single high standard of confidence in Be-cu’s ability to deliver as promised.

Upholding this standard requires an exceptional commitment to manufacturing resources. The wide variety of machining technology options in the Be-cu machine library is supported by an in-house tooling capability that adapts tools to the unique characteristics of each material. Behind it all is a staff of engineers and machining experts with a 30+ year track record of adapting to both new alloys and tried-and-true materials.We offer custom prototyping and manufacturing services for a wide range of performance-critical material. Material we serve include:

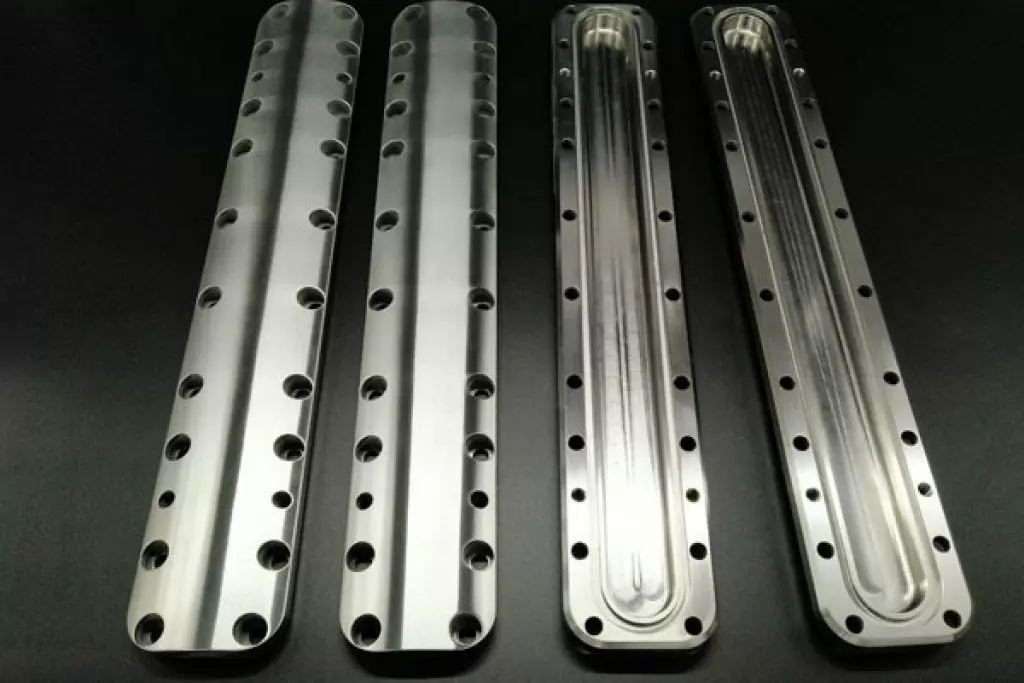

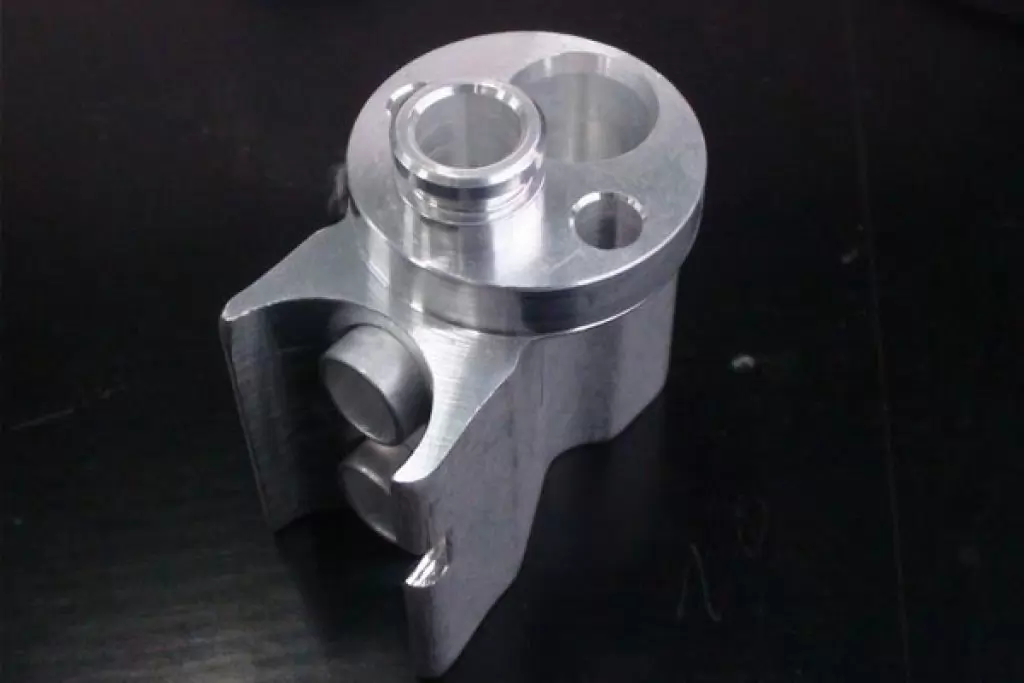

Aluminum is an essential industrial material and commonly CNC machined material, as it exhibits interesting thermal properties and excellent machinability, and is thus the preferred material in the most manufacturing sector in a wide range of industries.

Brass is an alloy made from copper and zinc, with strong wear resistance, ow coefficient of friction, low melting point, good malleability, and high corrosion resistance, it’s incredibly useful for hot machinery and products.So the brass is an ideal material for manufacturing parts.

Precision CNC machined stainless steel parts are becoming a choice for many industries due to its desirable physical properties! Stainless Steel is one of the most popular industrial alloys for many cnc machining projects, due to its excellent physical properties.

Titanium Alloy has some beneficial properties and characteristics like good ductility, high melting point, and low thermal conductivity, it’s resistant to corrosion from sea water, chlorine and more medias, extremely strong but lightweight, and non-magnetic.

Zinc has low melting point, good fluidity, easy fusion welding, brazing, corrosion resistance in the atmosphere, but low creep strength, prone to dimensional changes caused by natural aging.We produce zinc die casting parts from a few grams to more than 100 pounds with superior quality ready for assembly.

Magnesium is the lightest structural material, about 1.8 grams per cubic centimetre. magnesium is the 8th most abundant element in the earth’s crust. It occurs naturally in Dolomite, Magnesite, Carnallite and Chloride (sea water). Magnesium is produced from sea water, brines .

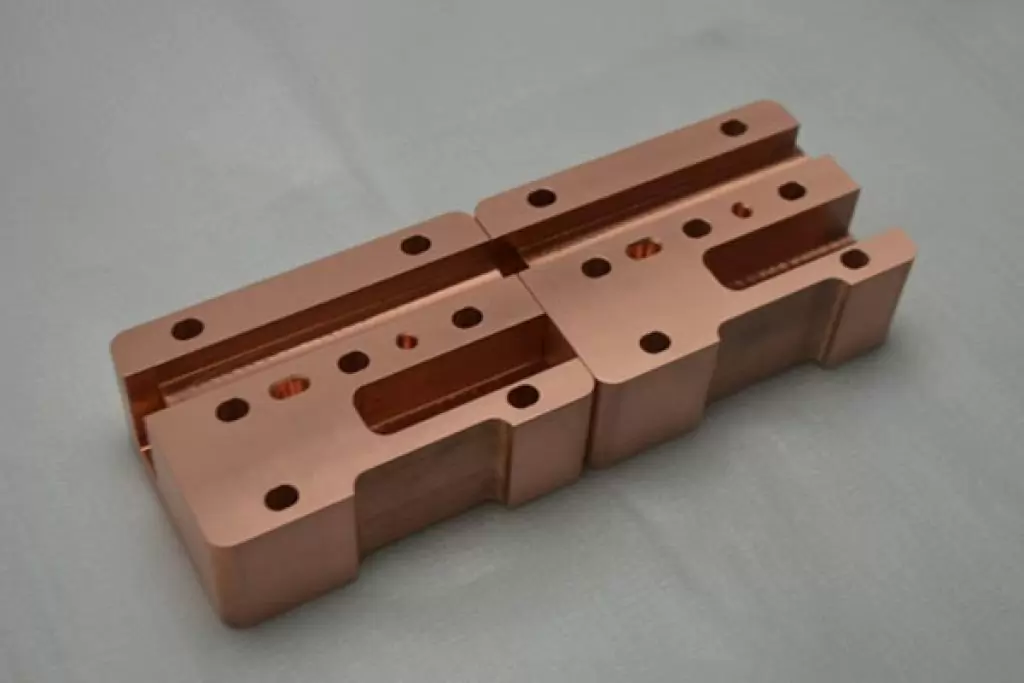

In CNC metal machining, pure copper is hard to machine because of its high plasticity and extremely ductile, but most copper alloys that contain other elements such as aluminum and zinc have improved and even excellent machinability, which makes them popular materials for custom copper parts

Supperalloy Parts

Be-cu has a reputation for successfully machining the metals other producers prefer not to handle. Customers can confidently design with new materials, secure in the knowledge that Be-cu can machine even the most exotic, high-temperature alloys for a quality, cost effective result.

Steel Parts

Steel is an alloy of iron and carbon usually contains many other elements such as manganese, silicon, phosphorus, and oxygen. The carbon content in steel improves its strength and fracture resistance. Most steels have good machinability and weldability, and can be well heat treated.

Iron Parts

Iron is a shiny silver-white metal, hard and ductile, with a melting point of 1535°C and a boiling point of 3000°C, strong ferromagnetism, good plasticity and thermal conductivity. The specific heat capacity is about 0.461000J/KG℃,The crystal structures are face-centered cubic and body-centered cubic.

Casting Alloy

The metallic materials used to produce castings are called casting alloys. Commonly used smelting methods for casting alloys are: cupola smelting, reverberatory furnace smelting, electric arc furnace smelting, intermediate frequency and power frequency induction furnace smelting, crucible furnace smelting, etc.

We’ll select high-quality plastic materials, whether you want ABS, PS, PC, Nylon, PEEK, PA, POM, or other types to make the products.Be-cu is a ISO 9001 certificated 3d printing & cnc machining manufacturer, and able to offer plastic parts with tight tolerances and premium properties required.

Strong Collaborative Manufacturing Network

Be-cu has 8 self-operated factories, serving 10,000+ customers in more than 30 countries and regions around the world.

In the future, Be-cu will continue to empower traditional manufacturing and create a full industrial chain for manufacturing OEM parts

Fast proofing and mass production of parts, 24-hour quotation system, minimum order of 1 piece, delivery in the fastest 2 days, 100% full inspection.

Under the control of ISO9001 and TS 16949,All processes are carried out through hundreds of advanced die casting machines, 5-axis machining, and other facilities, ranging from blasters to Ultra Sonic washing machines

Strict follow-up and control of the entire process from quotation to delivery.Other Serviced Include Sheet metal rapid proofing, stamping die manufacturing and high-speed stamping, forging die manufacturing, etc.,

-

Precision Grinding Tungsten Steel Mold Parts

-

5 Axis CNC Machining Medical Olecranon Plate

-

Special-Shaped Non-Standard Medical Device Needles

-

High-Speed Steel (HSS) Die Punching Needles

-

Precision Tungsten Copper Alloy Eccentric Insert

-

5 Axis CNC Machining Spiral Bevel Gear Mold

-

Small Precision Injection Molding Inserts

-

5 Axis Machining Aluminum-Magnesium Alloy Water Aerator Impeller

-

Large CNC Turning Inconel 625 Automobile Engine Camshafts

-

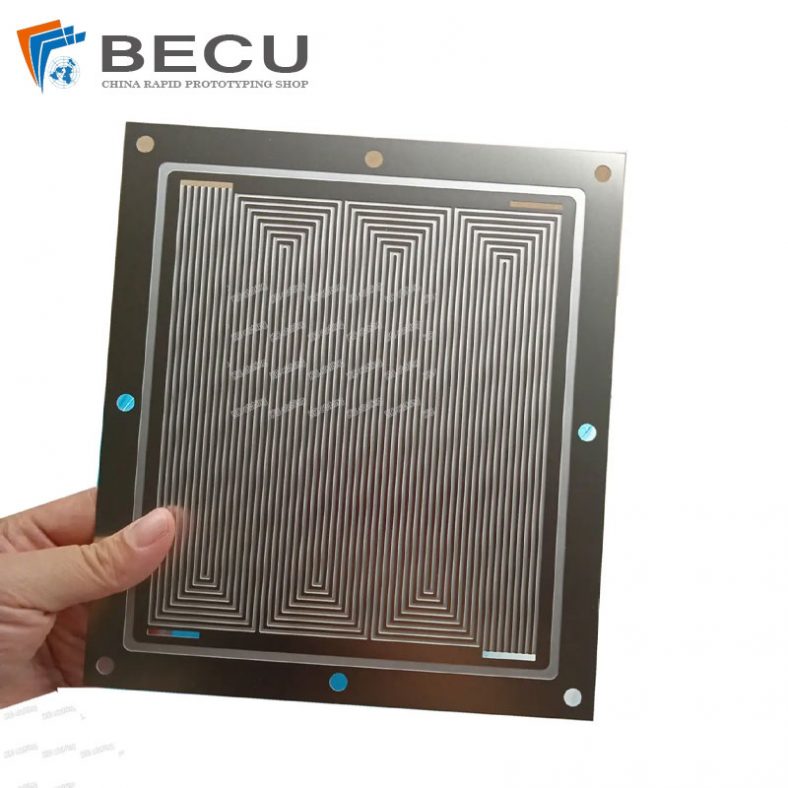

Metal Etched Hydrogen Fuel Cell Metal Bipolar Plates

-

Prototype CNC Spinning Stainless Steel 316L Outdoor Camping Pot

-

Precise Etching Stainless Steel 316 High-Speed Hair Dryer Networks