Micromachining

- Global delivery as fast as 30 days,Machined prototypes in as fast as 9 days.

- 100+metals and plastics

- Tolerances down to +-0.001mm

- ISO 9001:2015, ITAF 16949

- 3-, 4-, & 5-AXIS Milling.True 5-axis milling, 3+2,Mazak Turn+Mill Machine

>>>All uploaded drawings are strictly confidential, check the confidentiality agreement

One-Stop Non-Standard Precision CNC Micromachining Solutions

As products become more sophisticated and require frequent modifications, especially mechanical parts required in electronics ,aerospace,medical,shipbuilding, military and other fields require high precision, complex shapes and small batches.Micromachining or OEM super small parts refers to the cnc machining super small parts, usually used in the field of medical devices and electronics. Parts produced by micromachining processes often require microscope viewing. Be-cu adopts the latest technology and precision CNC equipment, Miniature Machined high-precision components for specific needs, CNC Micromachining has the advantages of strong adaptability, high machining accuracy, stable machining quality and high production efficiency, and can meet the customization needs of non-standard parts.

Online CNC Micromachining Service

Be-cu uses the most advanced Internet technology to realize online customized CNC Micromachining service. We integrate a considerable number of milling machines and lathes into a high-quality service network to provide:

- Sufficient production capacity, small batch production of precision parts;

- Competitive prices;

- Refined processing, processing complex precision parts;

- Surface treatment, dealing with the surface of various metals and plastics.

Miniature Machined Parts

- Micro Gears

- Micro Shafts

- Micro Fittings

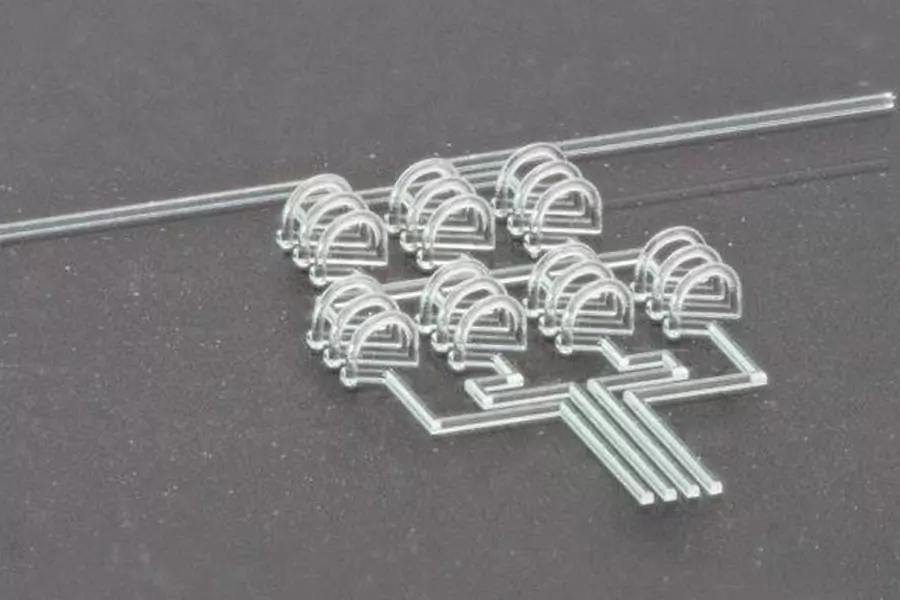

Plastic Micromachining

CNC plastic Micromachining is a way of making prototypes, mainly processing ABS, PC, PA, PMMA, POM and other plastic materials into tiny physical samples we need. The samples processed by CNC have the advantages of small molding size, high precision and good toughness, etc., and have gradually become the first choice for some industries (such as medical and electronic).

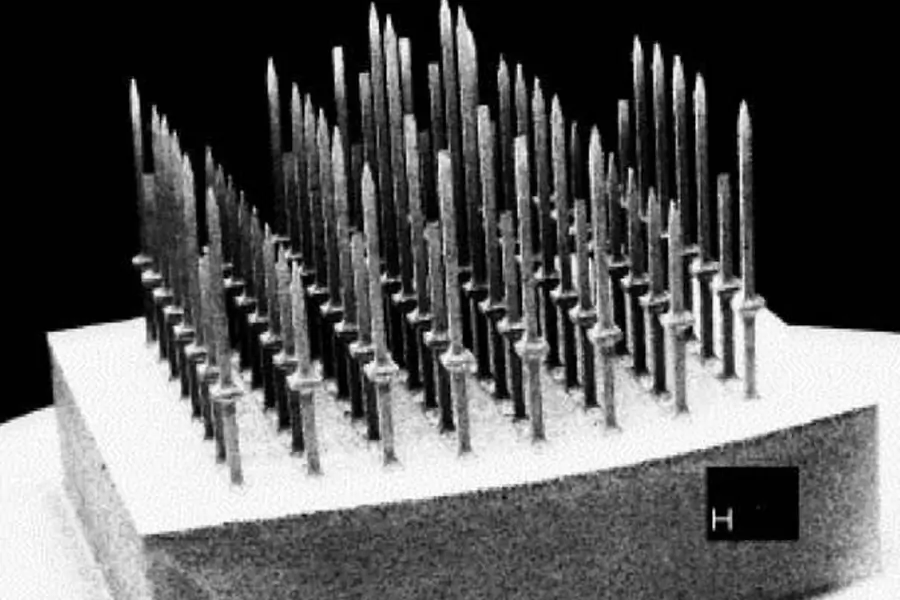

Metal Micromachining

In the manufacturing industry, Micromachining is mainly used to process and manufacture metal parts, such as: blood collection needles, bionic parts, electronic connectors, nozzles, etc. Miniature Machining has the advantages of high precision of processed products, high degree of automation, high production efficiency and low production cost. specialty.

The Standard Tolerances For Micro CNC Machining

| Nominal Size Limit | Plastic (ISO 2768-m) | Metal (ISO 2768-f) |

|---|---|---|

| 0.5mm – 3mm | ±0.1mm | ±0.05mm |

| 3mm – 3mm | ±0.1mm | ±0.05mm |

| 6mm – 30mm | ±0.2mm | ±0.1mm |

| 30mm – 120mm | ±0.3mm | ±0.15mm |

| 120mm – 400mm | ±0.5mm | ±0.2mm |

| 400mm – 1000mm | ±0.8mm | ±0.3mm |

| 1000mm – 2000mm | ±1.2mm | ±0.5mm |

| 2000mm – 4000mm | ±2mm |

There are many definitions of micromachining. In Be-cu, lathe micromachining refers to machining parts with an outer diameter of 0.0039 inch, an inner diameter of 0.0078 inch, and an overall feed of 0.0197 inch or smaller. In addition, this type of machining requires shallow depths of cut (less than 0.0039 inch), extremely low feed rates (less than 0.00019 ipm), lower cutting forces, and high surface quality requirements