3D Printing Medical Parts & Product Service In China

The application of 3D printing technology in China’s medical industry began in the late 1980s. It was initially mainly used for the rapid manufacture of 3D medical models. At that time, 3D printing technology was mainly used to help doctors communicate with patients, accurately judge the condition and carry out surgical planning. It can be said that China’s exploration of the application of 3D printing technology in the medical industry has a long history, and it has gone deeper with the development of 3D printing technology.

In recent years, with the development of 3D printing technology and the growth of precise and personalized medical needs, the application of 3D printing technology in the medical industry has developed significantly in both breadth and depth. In terms of the breadth of applications, from the initial rapid manufacturing of medical models, it has gradually developed to 3D printing to directly manufacture hearing aid shells, implants, complex surgical instruments and 3D printed medicines. In terms of depth, the direction of 3D printing inanimate medical devices is developing towards printing biologically active artificial tissues and organs.

China Manufacturer of 3d printing for medical products,devices and parts industries. Rapid prototyping services are available.Prototype manufacturer offering additive manufacturing services. Capabilities include fused deposition modeling (FDM), polyjet 3D printing, direct metal laser sintering (DMLS) ,stereolithography (SLA) and more. Works with polyethylene, PVC, polycarbonate, nylon, polypropylene, polyester, polyacetal, polystyrene, acrylic, silicone and fluorocarbon.

Professional doctors process the data provided by the medical institution, and convert the image data obtained by the X-ray CT machine and MR1 nuclear magnetic resonance scan into the data required for input into the 3D printer. At present, we can apply 3D printing services in the medical industry mainly include:

Our Advantage Of 3D Printing Medical Product

- ISO 9001:2015 certified and ITAF 16949 certified

- Fully compliant with the exacting requirements of our customers,High customer satisfaction and loyalty

- Average 7 days turnaround time and 99.85% on time delivery

- Multiple options of machining materials to meet specific properties.

- Skilled in KanBan and other customer driven quality and inventory management systems

- Efficient 3d printing china factory for mass production rapid prototyping service

- Fast free quotation within 24 hours after inquiry

- Rich design and manufacturing experience

Outstanding 3D Printing Medical Product Equipment

- P200 Industrial DLP 3D Printer

- ProJet MJP 5500X

- TPM ELITE P5000 SLS 3D Printer

- P480DL SLS 3D Printer

- ASM1500H SLA 3D Printer

- ASM-1200 SLS Molding Machine

- M400-4—SLM Metal 3D Printer

- DQ1200 FDM 3D printer

- Check Out BE-CU Equipment List

-

Black Nylon Medical Threaded Screw By MJF 3D Printing

-

MJF 3D Printing Black Nylon Red Dot Sighting For Medical

-

FFF Fused Wire Extrusion 3D Printed Pure Copper Parts

-

MJF 3D Printing Black Nylon Medical Arm Guards

-

3D Printing Ti-6Al-4V Sacroiliac Screws

-

3D Printing Titanium Alloy Dental Teeth

-

3D Printing Titanium Grade 5 Medical Implants

-

Rapid Silica Gel Vacuum Reverse Mould For Medical Products

-

DMLS 3D Printing Medical Device Metal Accessories

3D Printing In Medical Devices And Other Industry

Three-dimensional modeling is performed based on the patient’s CT or MRI data before surgery, and then the model is printed by a 3D printer to obtain a medical model. The main function of 3D printed medical models is to allow doctors to visually see the three-dimensional structure of the surgical site before surgery, which is helpful for doctors to plan surgical plans. Especially for complex surgery, it helps to reduce the risk of surgery and improve the success rate of surgery. Surgical guides are an important tool for doctors to assist in surgery, and 3D printing devices technology is especially suitable for manufacturing special-shaped or personalized guides.

From orthopedic surgery to heart surgery to liver surgery… More and more surgeries are starting to use 3D printed medical models. For example, in 2015, the team of Professor Peng Zhihai, director of the General Surgery Center of Shanghai First People’s Hospital, used 3D printing technology to perform living donor liver transplantation for a patient from Guizhou with congenital autoimmune cirrhosis and portal hypertension. In order to accurately formulate a surgical plan before surgery, experts thought of 3D printing technology. 3D printing presents the patient’s hepatobiliary and pancreatic organs and the corresponding lesions to the doctor in a 1:1 “physical” form. By accurately evaluating the three-dimensional relationship between the lesion range and adjacent organs and tissues, the expert team determined that the patient was resected 307 grams of liver. During liver resection, experts bring the model into the operating room for real-time comparison during the operation. By adjusting the 3D printed model and placing it in the best anatomical position, it provides intuitive real-time navigation for key steps of the operation, and quickly identifies and analyzes key parts. Positioning: By accurately locating lesions and blood vessels, and guiding the joining of important blood vessels in real time, the accuracy of surgery is improved and the risk of surgery is effectively reduced.

The precise design of the 3D printed surgical guide is an important guarantee for the success of the surgery. Shanghai Yidong Medical Technology Co., Ltd. uses the world’s leading SSM_Knee® technology in the field of orthopedic surgical guides to perform 3D Statistical Shape Modeling (SSM) and 3D force measurement of the knee joint from multiple weight-bearing X-ray data. Analyzed, simulated the osteotomy plane on the computer, the whole process of artificial total knee replacement surgery, and virtualized the design of the guide guide for osteotomy and 3D printing with medical materials. During the operation, the doctor only needs to attach the guide plate to the joint surface and then perform the positioning osteotomy. The accuracy is higher than the traditional method, avoiding human factors, and the operation is simple and does not damage the medullary cavity.

3D Printed Medical Models And Surgical Guides

Three-dimensional modeling is performed based on the patient’s CT or MRI data before surgery, and then the model is printed by a 3D printer to obtain a medical model. The main function of 3D printed medical models is to allow doctors to visually see the three-dimensional structure of the surgical site before surgery, which is helpful for doctors to plan surgical plans. Especially for complex surgery, it helps to reduce the risk of surgery and improve the success rate of surgery. Surgical guides are an important tool for doctors to assist in surgery, and 3D printing technology is especially suitable for manufacturing special-shaped or personalized guides.

From orthopedic surgery to heart surgery to liver surgery… More and more surgeries are starting to use 3D printed medical models. For example, in 2015, the team of Professor Peng Zhihai, director of the General Surgery Center of Shanghai First People’s Hospital, used 3D printing technology to perform living donor liver transplantation for a patient from Guizhou with congenital autoimmune cirrhosis and portal hypertension. In order to accurately formulate a surgical plan before surgery, experts thought of 3D printing technology.

3D printing presents the patient’s hepatobiliary and pancreatic organs and the corresponding lesions to the doctor in a 1:1 “physical” form. By accurately evaluating the three-dimensional relationship between the lesion range and adjacent organs and tissues, the expert team determined that the patient was resected 307 grams of liver. During liver resection, experts bring the model into the operating room for real-time comparison during the operation. By adjusting the 3D printed model and placing it in the best anatomical position, it provides intuitive real-time navigation for key steps of the operation, and quickly identifies and analyzes key parts. Positioning: By accurately locating lesions and blood vessels, and guiding the joining of important blood vessels in real time, the accuracy of surgery is improved and the risk of surgery is effectively reduced.

The precise design of the 3D printed surgical guide is an important guarantee for the success of the surgery. BE-CU.COM uses the world’s leading SSM_Knee® technology in the field of orthopedic surgical guides to perform 3D Statistical Shape Modeling (SSM) and 3D force measurement of the knee joint from multiple weight-bearing X-ray data. Analyzed, simulated the osteotomy plane on the computer, the whole process of artificial total knee replacement surgery, and virtualized the design of the guide guide for osteotomy and 3D printing with medical materials. During the operation, the doctor only needs to attach the guide plate to the joint surface and then perform the positioning osteotomy. The accuracy is higher than the traditional method, avoiding human factors, and the operation is simple and does not damage the medullary cavity.

3D Printed Rehabilitation Equipment

The real value brought by 3D printing to rehabilitation equipment such as orthopedic insoles, bionic hands, hearing aids is not only the realization of precise customization, but also the replacement of manual production methods with accurate and efficient digital manufacturing technology and shortening the production cycle. Let’s take the hearing aid shell industry, which has achieved mass customized production of 3D printing as an example. In the traditional way, the technician needs to make an injection mold from the patient’s ear canal model. The plastic product is then obtained by UV light. The final shape of the hearing aid is obtained by drilling sound holes and manual processing of the plastic product. If something goes wrong in this process, the model needs to be remade. The process of using a 3D printer to make a hearing aid begins with the design of a silicone mold or impression of the patient’s ear canal, which is done with a 3D scanner. The scanned data is then converted into a design file readable by a 3D printer using CAD software. Designers can use software to modify 3D images and create the final product shape. The EnvisionTec printer can print 65 hearing aid housings or 47 hearing aid models in approximately 60 to 90 minutes.

3D Printing Medical Implants

Bone defects, maxillofacial injuries, skull repairs, etc. caused by bone tumors, car accidents, etc. cannot be treated with general repair products, but 3D printing products provide an effective solution, especially these printed prostheses are based on patients. It is made by tailoring its own characteristics.

However, the words “tailor-made” are only one of the meanings of 3D printing technology in the field of implant manufacturing.

Another significance of 3D printing technology in this field is that it can print a biomimetic bone trabecular microporous structure integrated with the implant, which is conducive to the growth of human bones.The same holds true for 3D printed standardized implants. In the past, the trabecular bone structure was achieved by coating the surface of the implant, which could not guarantee the long-term survival rate of the prosthesis. In 2015, the 3D printed artificial hip joint jointly developed by the team of Professor Zhang Ke of Peking University Third Hospital and Aikang Yicheng Company was approved by the State Food and Drug Administration and became the first 3D printed implant approved for industrialization in my country.

However, the lack of versatility of common 3D printing materials for implants limits their application in the treatment and repair of defects caused by orthopedic diseases (eg, bone tumors). The Biomaterials Research Center of the Shanghai Institute of Ceramics, Chinese Academy of Sciences has made progress in this field. The research center is mainly engaged in the research of 3D printing multifunctional bioactive ceramics for bone repair and treatment. Using 3D printing technology, the research team designed a variety of experimental schemes, including the use of nutrient elements, biomimetic structures and functional interfaces, and thermal treatment to develop new multifunctional materials that combine treatment and repair.

3D Printed Medicines

The impact of 3D printing technology on pharmaceuticals is mainly reflected in four aspects: one is to realize the personalized customization of active ingredients of drugs; the other is to customize the dose to provide patients with personalized treatment plans. This layer-by-layer printing method binds the different coatings tightly to each other, so that the maximum dose of a substance can be placed in a single tablet. In this way, the patient can swallow a small amount or smaller tablets; the third is to realize the personalized customization of the shape. This may be a good idea for children who don’t like taking medicine. 3D printing technology is used to print various interesting shapes to coax the baby to take the medicine; the fourth is to use the 3D printing technology to make the medicine have a special microstructure and improve the release behavior of the medicine, thereby improving the curative effect and reducing the side effects. For example, in 2015 the U.S. Food and Drug Administration (FDA) approved the world’s first tablet made entirely of 3D printing. The drug, called Spritam, was developed by American Aprecia Pharmaceuticals for the treatment of epilepsy patients. The most important significance of the Zipdose 3D printing technology used by Aprecia is to enable the drug to rapidly disintegrate a high dose of the drug in a small amount of water, which brings great convenience to patients at the time of the disease.

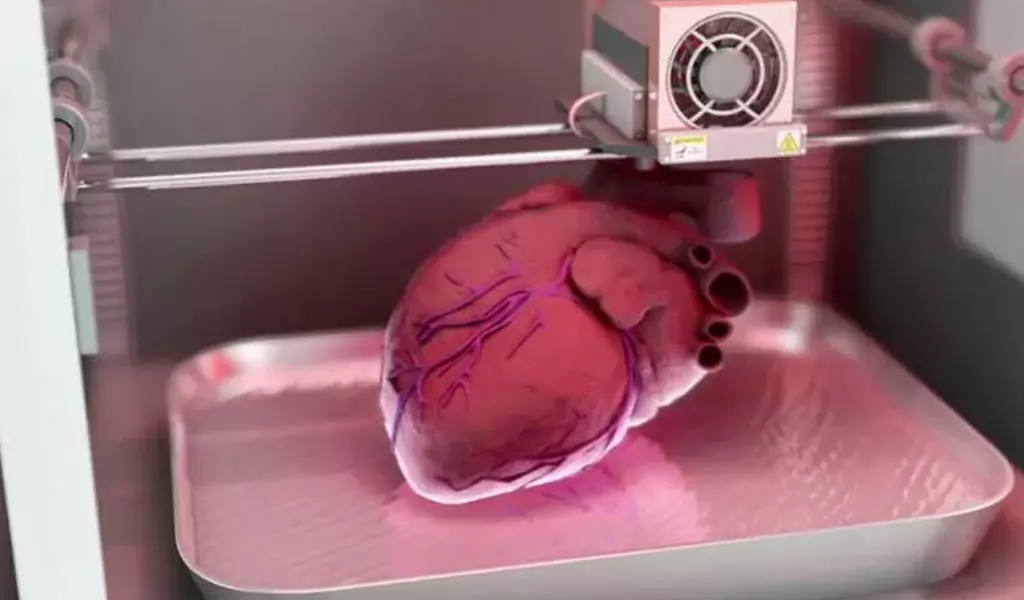

3DP Bioprinting Of Tissues And Organs

The application development time point of 3D printing in the medical field can be presented with a chart. Among them, bio-3D printing has the largest proportion on the chart: from 2013 to 2018, biomedical implant technology gradually matured; from 2013 to 2022, in situ biomanufacturing technology began to appear and gradually matured; from 2013 to 2032, 3D printing complete human organs Getting better.Although the 3D bioprinted organs currently appearing are not fully functional and structurally complete organs, they have already begun to play a role in the field of drug screening tests and disease research

The clinical conversion rate of common drug screening technology is low, and the best drug test object is actually the human body. However, this approach is unrealistic, because firstly, people cannot undertake the preliminary screening of drugs, and secondly, patients have large individual differences and complex body structures. It is an effective way to replace the human body for drug screening after the human cells are constructed in vitro. For example, the mass-produced 3D-printed liver unit of Hangzhou Genofei has been used by Merck for drug toxicity testing. The liver is an important organ responsible for drug toxicity, and the demand for artificial livers is also great. The adult liver consists of 500,000 to 1,000,000 units called hepatic lobules. The hepatic lobule is the basic unit of liver structure and function. The preparation of liver units by imitating the hepatic lobule structure is a key step in the manufacture of artificial livers. 3D-printed tissues and pathological models with human-derived cells can accurately reflect the pharmacological activities of chemical and biological drugs in the human body, thereby improving the success rate of drug screening.

3D Printing Dentistry Devices

The cost of dental restoration and treatment is an important factor that dental clinics and laboratories need to consider. Many prescient dental clinics and laboratories have introduced digital oral technology to improve efficiency and reduce costs. In recent years, dental restorations based on software design have become popular, and many dental clinics, laboratories or professional denture manufacturers have introduced 3D printing technology. The digital oral technology combined with 3D printing brings high precision, low cost, high efficiency, and oral data in line with the standardized production chain to the dental industry. 3D Science Valley believes that the more important significance of digital dental technology, including 3D printing, is to reduce the time doctors spend making models, dentures and other dental products by hand, and return their energy to the diagnosis of oral diseases and the implementation of oral surgery itself. For dental technicians, although far away from the doctor’s office, as long as the patient’s oral data is obtained, precise dental products can be customized according to the doctor’s requirements. The process and main application of 3D dental products can be illustrated by the following picture: