World Class One-Stop CNC & Laser Micro Manufacturing Shop

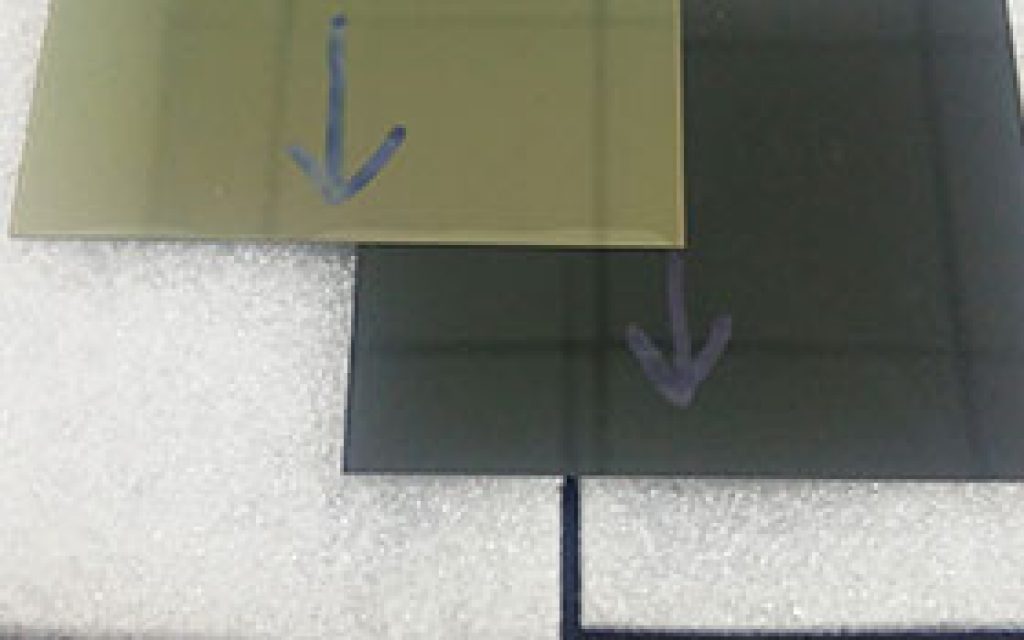

Micro Manufacturing Process

Unlike traditional production methods, micro manufacturing emphasizes customization, precision, and agility.These micro manufacturing process include:

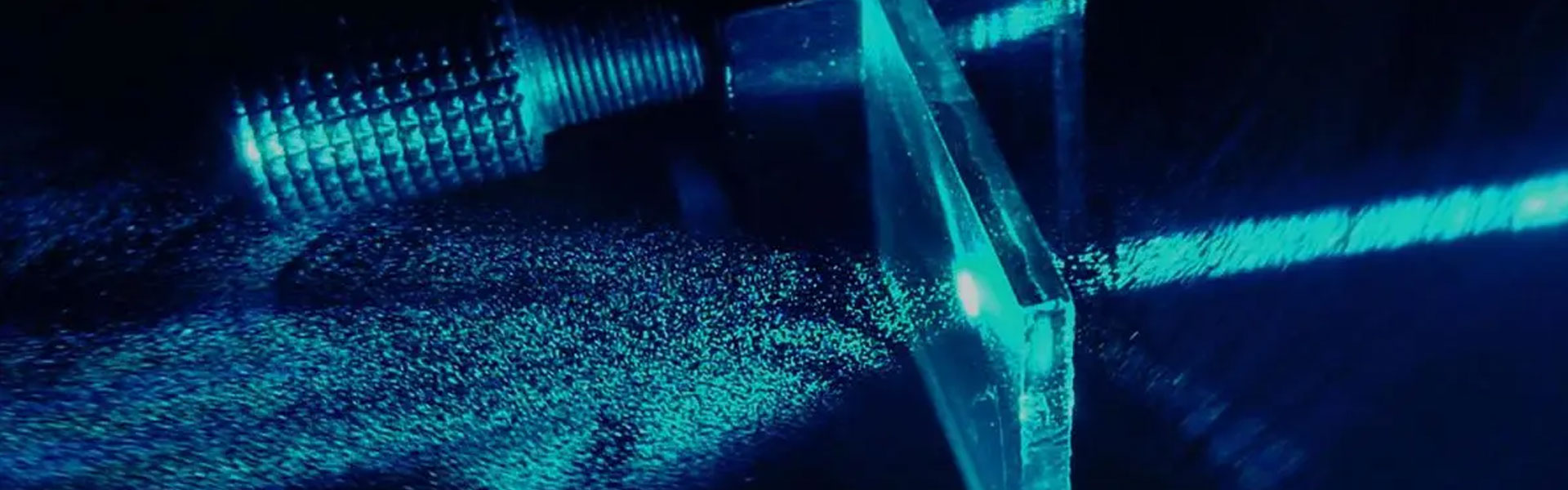

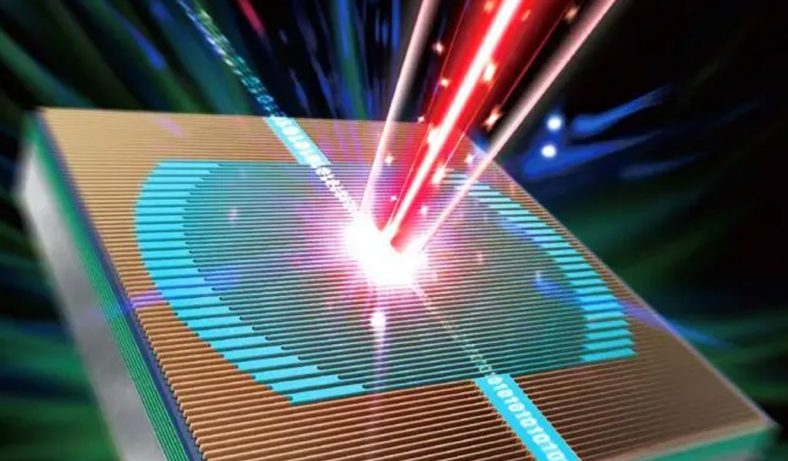

- Femtosecond Laser Cutting

- Laser Ablation

- Grinding

- Micro Laser Cutting

- Laser Drilling

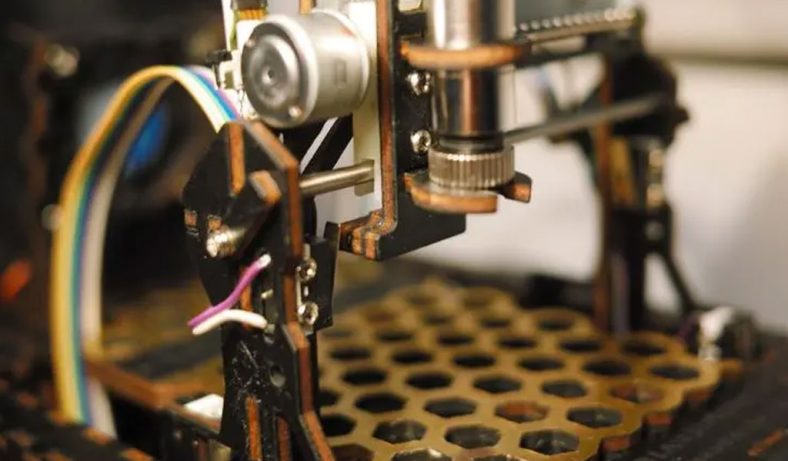

- Micro CNC Machining

- Nano Fabrication

- Wire Cutting And More

Be-Cu is china leader in micro manufacturing for the medical device and semiconductor industries, developing a wide variety of processing capabilities to manufacture components, sub-assemblies, and devices.You are also welcome to contact us for an informal chat about the solutions for your micro manufacturing.

Micro Manufacturing allows precision parts production at extremely small sizes and within micron tolerances.

Crafting Our Precision Parts, Micro by Micro, Across the World.

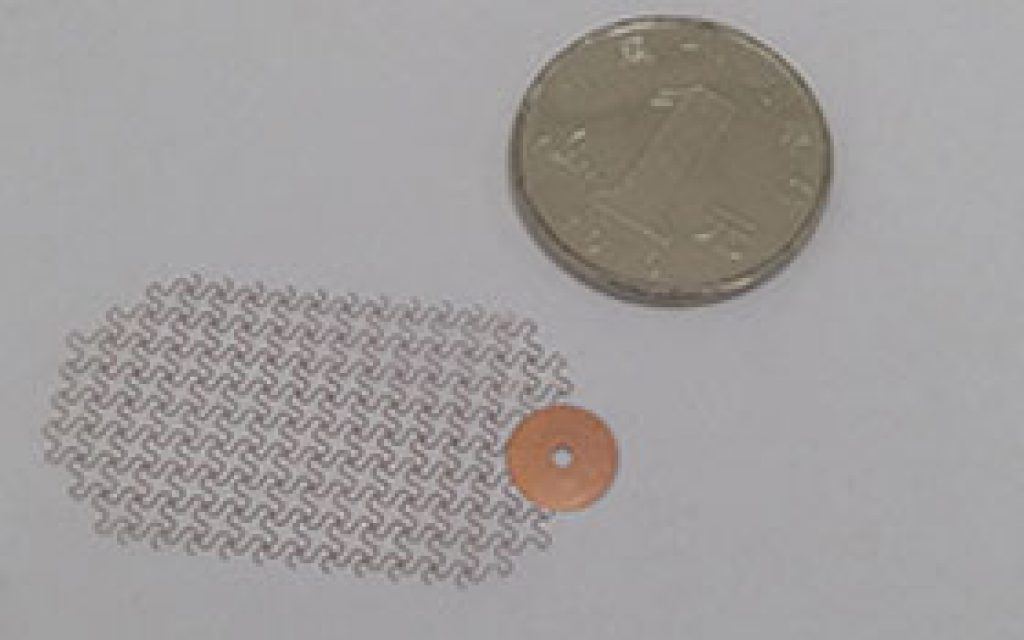

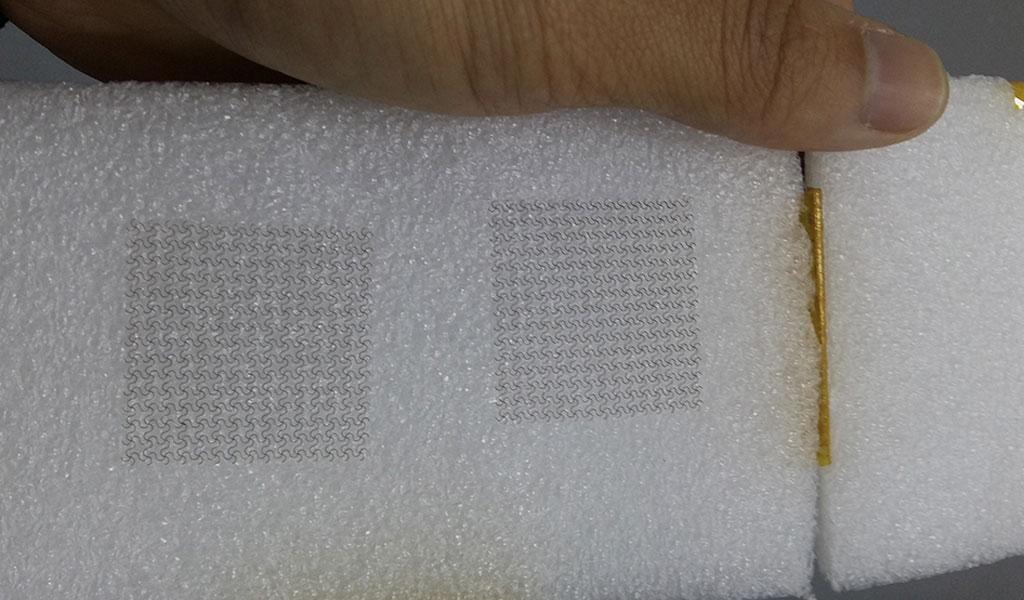

We offer precision micro-manufacturing capabilities that allow our customers to meet unique demands like aspect ratios of 38:1, features sizes as small as 10um, use of wire diameters of 20um.Combining state-of-the-art equipment with experienced engineers, we manufacture the most intricate parts with flawless accuracy. Our Micro Manufacturing process can create parts with:

Feature sizes as small as 10μm

Surface finishes to 4Ra micro inch

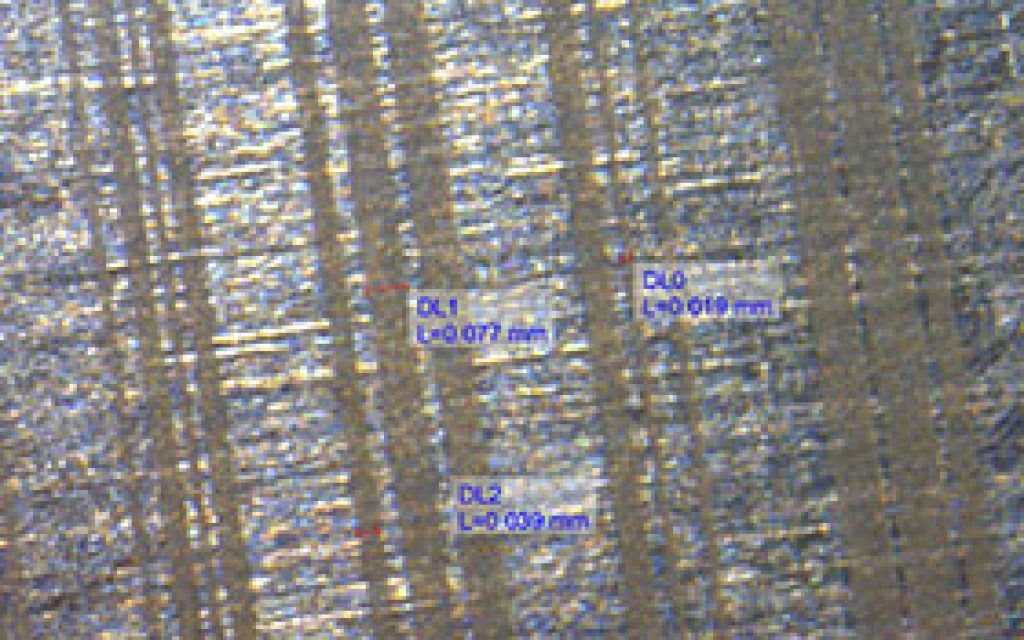

Tolerances as low as 1 micron

Top Micro Manufacturing Service – China Micro Laser Machining Parts Suppliers

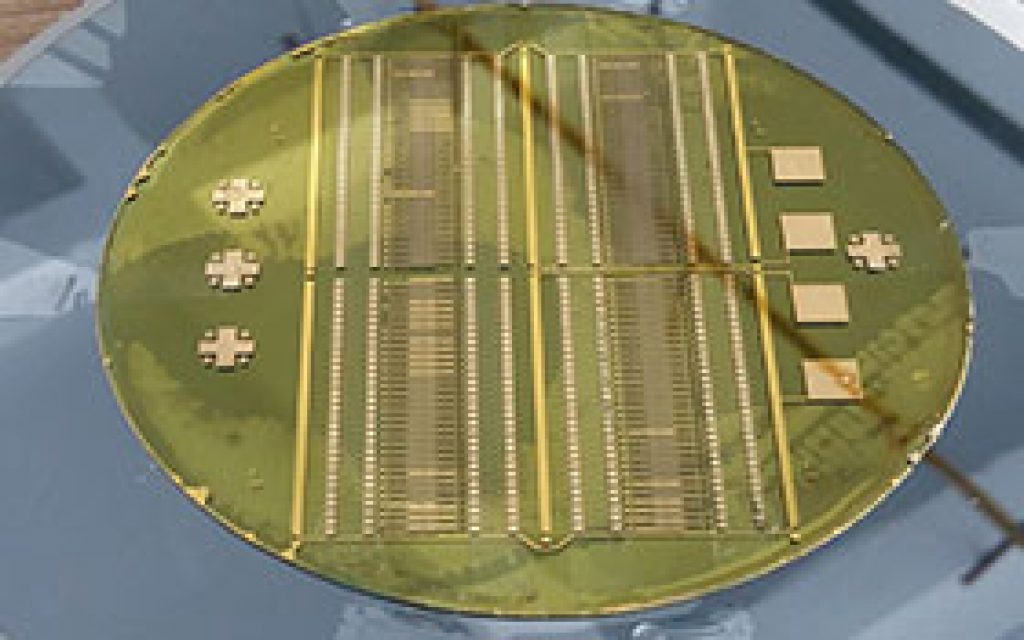

Be-Cu Prototype develops and provides µM laser machining line for vast medical and electronic of industry. New high-tech products & applications can be created with this new micro-scale production technology. Traditionally manufactured (MEMS, lithography) microparts can be functionalized and modified in ways which are impossible with conventional solutions. The parameters of the company’s laser cutting machines are as follows:

- Processed product thickness: ≤1.5mm

- Galvanometer scanning speed: ≤3000mm/s

- Platform moving speed: 500mm/s

- Workbench positioning accuracy: ±2μm

- Workbench repeatability: ±1μm

- Processable file formats: standard Gerber files, DXF files, PLT files, etc.

- Focusing lens: 4040mm/1515mm (can be customized)

- Wavelength: 1064/532/355nm femtosecond and picosecond optional

- Focused spot: 5μm (depending on material)

- Minimum tangent width: <10μm (depending on material)

- Processable materials: silver paste, ITO, Cu, glass, sapphire, ceramics, ultra-thin metal sheets, polymer composite materials, silicon wafers

- Effective processing range of equipment: 500*400mm (can be customized)

- More

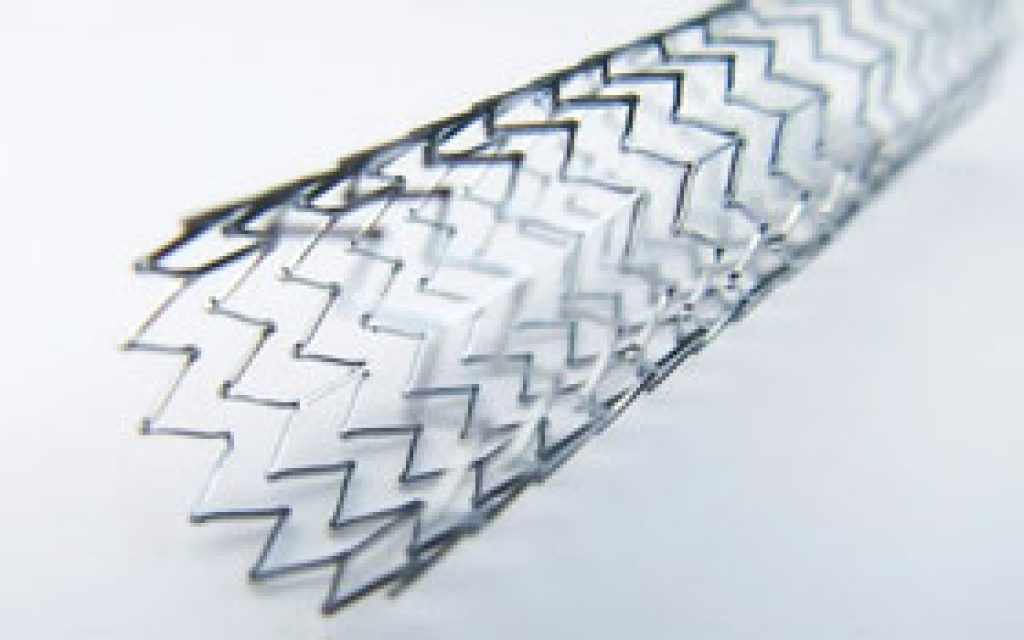

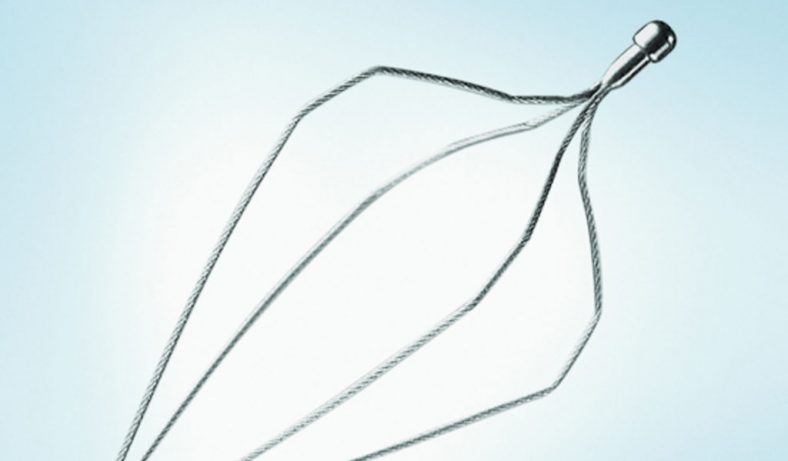

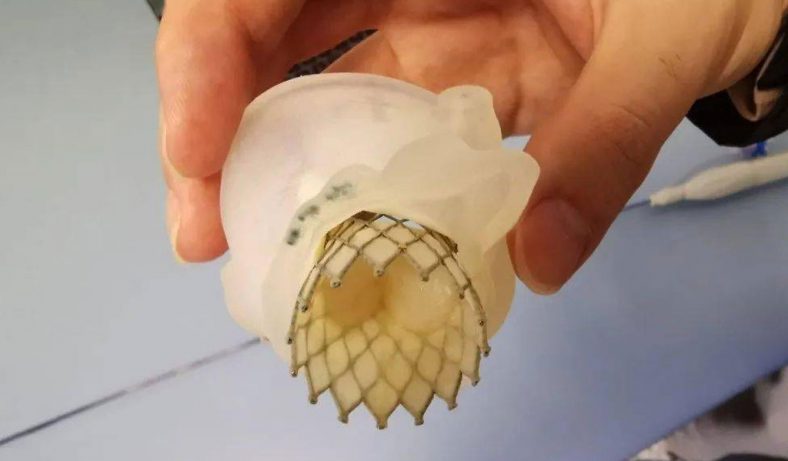

Single metal components (including stainless steel,nitinol,titanium,cobalt chrome and polymer and Glass)can be manufactured at a micro scale and cut with high precision. Be-Cu prototype company is ideal micro manufacturing shop for proof of concept, prototyping and industrial production evaluation.

Benefit Of Micro Manufacturing Service

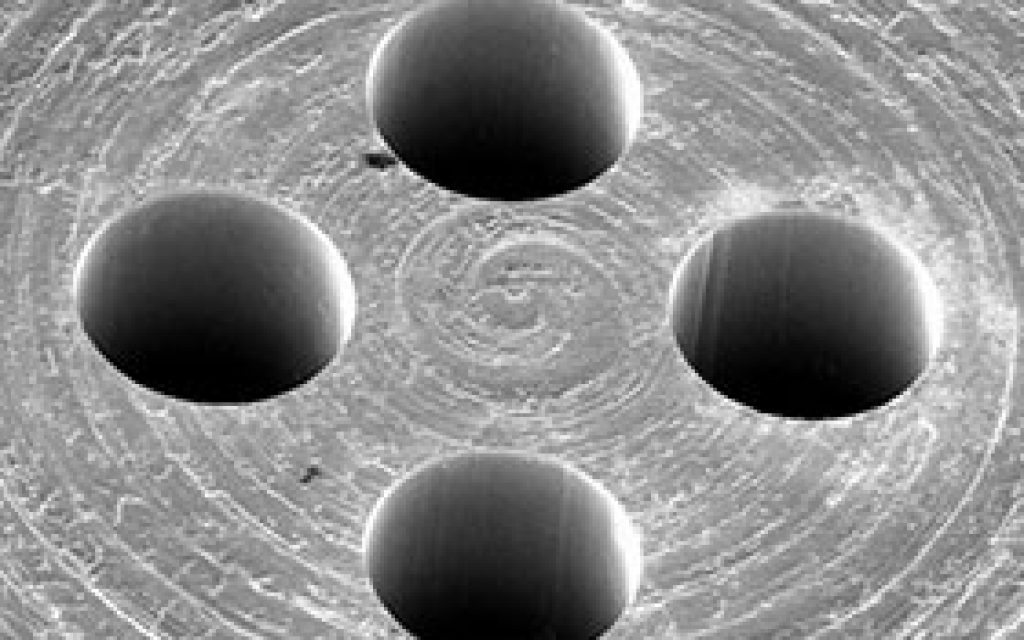

- Using picosecond or femtosecond lasers, ultra-short pulse processing has almost no heat conduction. It is suitable for high-speed cutting and drilling of any organic & inorganic materials, with a minimum chipping and heat-affected zone of 3 μm.

- CCD visual pre-scan & automatic target grasping and positioning, maximum processing range of 500×400mm, XY platform splicing accuracy ≤±3μm.

- Excellent beam quality, good long-term working stability, and negligible thermal impact.

- Higher single pulse energy and higher processing accuracy can achieve fine processing of almost any solid material.

- Excellent processing flexibility, capable of fine cutting in any shape

- Self-developed software control system can customize and upgrade various functions according to customer requirements

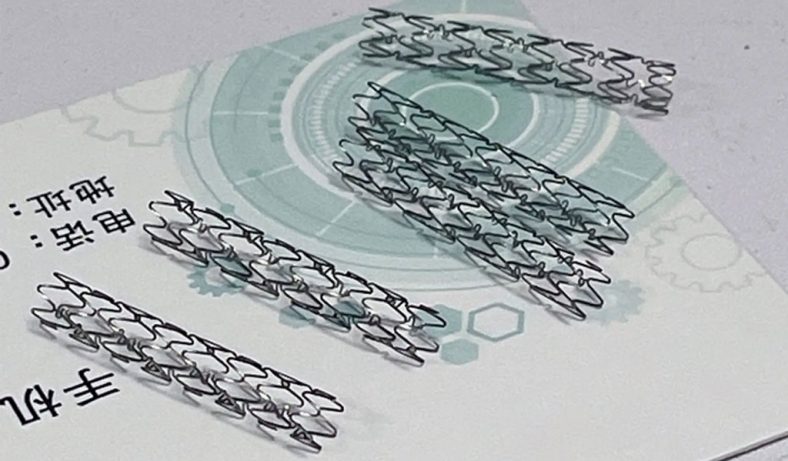

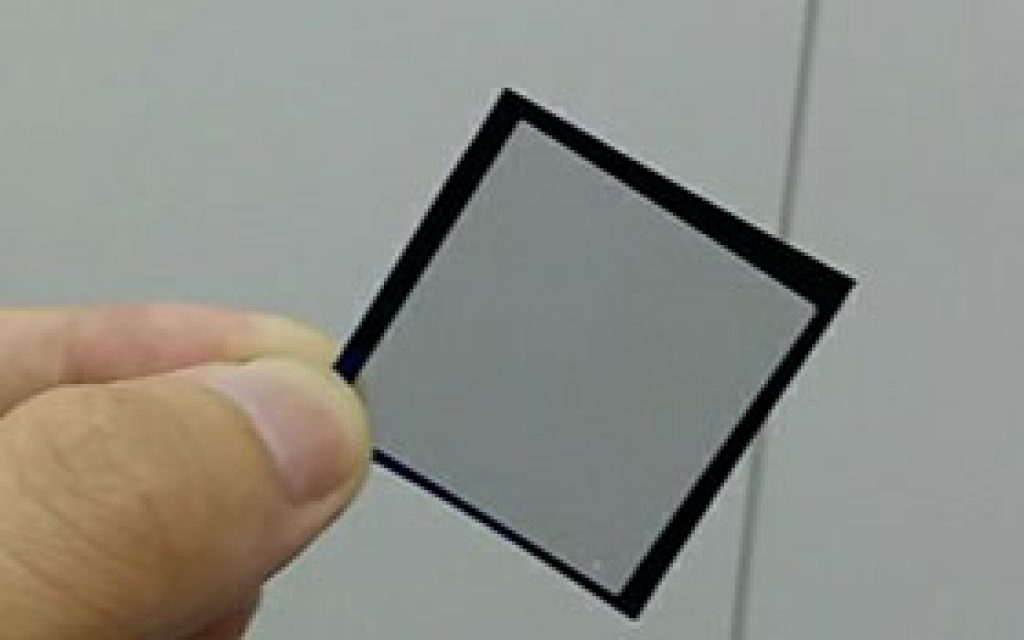

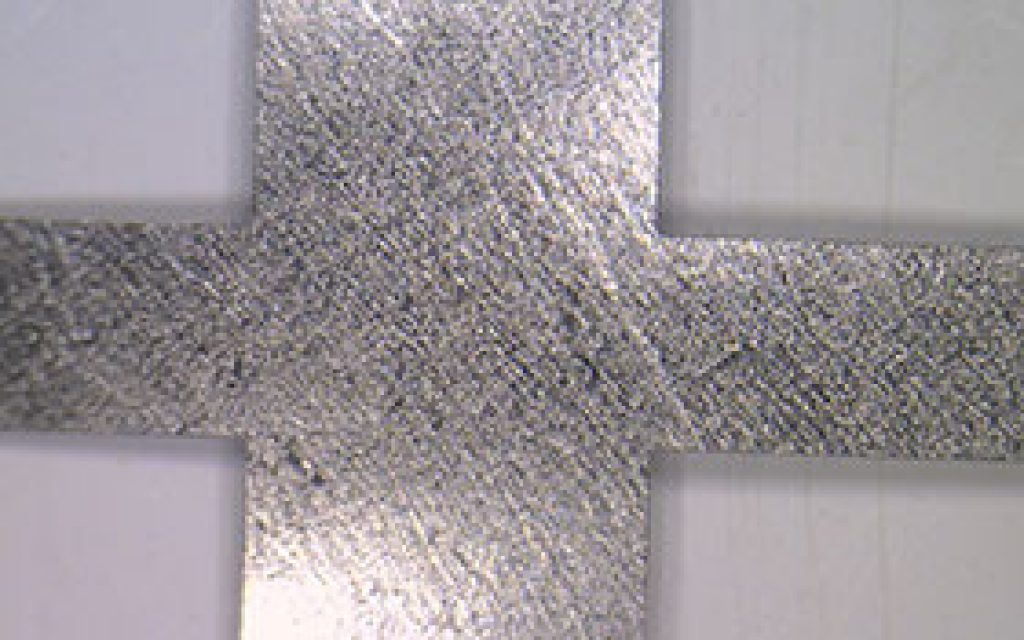

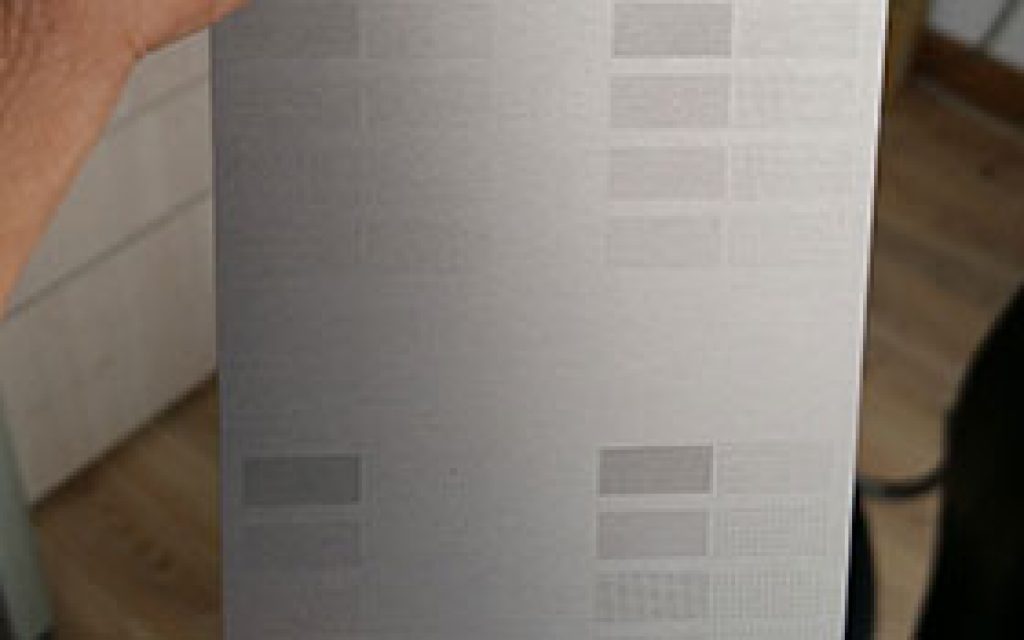

Gallery of Micro Manufacturing Parts

View the custom Micro Manufacturing prototypes and end-use parts we’ve produced for our customers.

Latest Micro Manufacturing Blog,Encyclopedia And Guide

View the custom Micro Manufacturing prototypes and end-use parts we’ve produced for our customers.

-

Exploring Ultra-Fine Nitinol Material: Define,History,Type And Applications

-

What Is Femtosecond

-

A Comprehensive Comparison Of Micro Laser Cut and Micro CNC Machining

-

Exploring the Marvels of Hypotube Spiral

-

Why Choose Laser Cutting For Surgical Instruments

-

What Is Reticular Medical Basket

-

Why Use Ni-Ti Laser Cutting For Bolt Removal Bracket

-

Valve Stent: Basics, Applications, and Advancements