China Top Metal Casting Service & Supplier

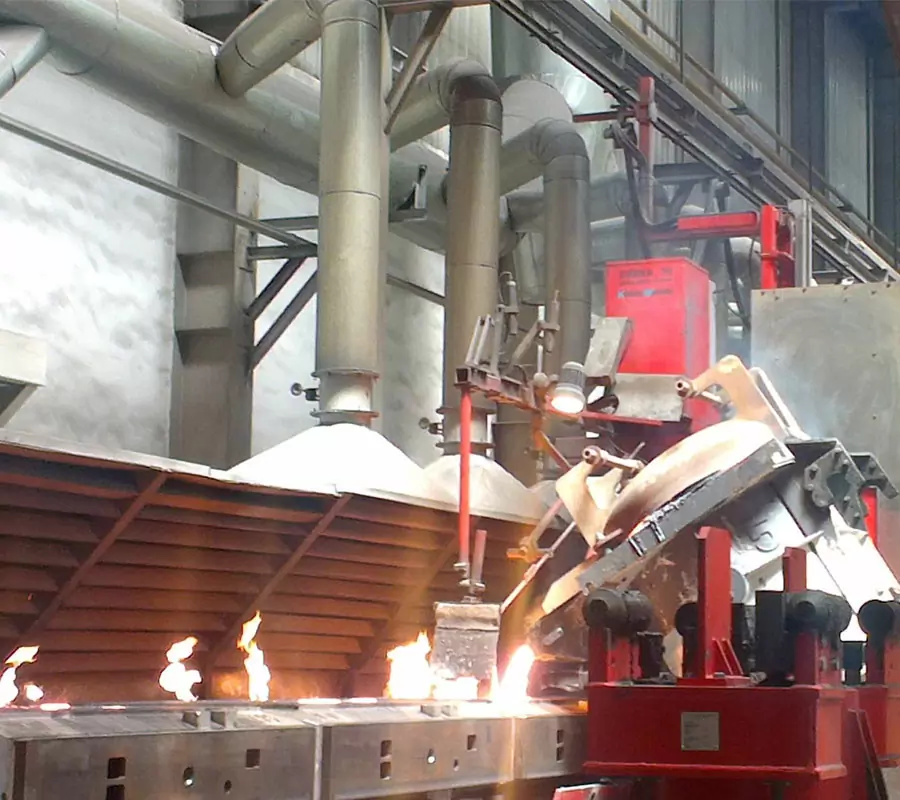

Be-cu is a trusted online metal casting services supplier that is able to provide custom metal casting parts for your project with top quality and fast shipping. With decades of experience and expert capabilities, our metal casting services can use an extensive range of materials using die casting, investment casting, sand casting and other technologies.According to your requirements and applications, we’ll offer suggestions for the product design, suitable materials, and the most cost-effective methods for metal casting and manufacturing. Minimal cost, time and best quality are our purposes. Equipped with state-of-the-art facilities and measuring equipment in our factory, metal casting and fabrication line now supply volume production parts for a number of business sectors and private individuals, catering both long and short production runs.

- Highly trained machinists and skilled engineers can help you create and improve the design.

- A broad range of techniques can be performed at our casting shop with efficiency and speed.

- With up-to-date manufacturing facilities, our technologies work with a number of materials.

- Prompt reply and communication, we’ll get you updated on the whole progress of the production.

- Free online quotes and design feedback to provide effective solutions and suggestions.

How To Make A Casting Mold For Metal

The casting mold means that in order to obtain the structural shape of the part, the structural shape of the part is made in advance with other easily formed materials, and then the mold is placed in the sand mold, so that a cavity with the same structural size as the part is formed in the sand mold. Then pour a fluid liquid into the cavity. After the liquid is cooled and solidified, a part with exactly the same shape and structure as the mold can be formed. Casting molds are an important part of the casting process.

- Process analysis

- Pouring position

- Castable parting surface selection

- Casting system design

- Riser design

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and other customer driven quality and inventory management systems

- ITAF 16949 certified

Top Metal Casting Services Capabilities

die casting is a metal casting process, which is characterized by applying high pressure to the molten metal using the cavity of the mold. Molds are usually made of higher-strength alloys, and this process is somewhat similar to injection molding. Most die castings are iron-free, such as zinc, copper, aluminum, magnesium, lead, tin, and lead-tin alloys and their alloys. BE-CU has been China's top die casting service since 1995.

The biggest advantage of investment casting is that because investment castings have high dimensional accuracy and surface finish, they can reduce machining work, but leave a little machining allowance on the parts with higher requirements. It can be seen that the use of investment casting method can save a lot of machine tool equipment and processing man-hours, and greatly save metal raw materials.

Sand Casting is a traditional casting process that uses sand as the main modeling material to make molds. Gravity casting is generally used for sand molds, and low-pressure casting, centrifugal casting and other processes can also be used when there are special requirements. Sand casting has a wide range of adaptability, small pieces, large pieces, simple pieces, complex pieces, single pieces, and large quantities can be used.

Low Pressure Casting means that the mold is generally placed above a sealed crucible, and compressed air is introduced into the crucible to cause a low pressure (0.06~0.15MPa) on the surface of the molten metal, so that the molten metal rises from the riser pipe to fill the mold and control Solidified casting method. This casting method has good feeding and dense structure, easy to cast large thin-walled complex castings, no risers, and a metal recovery rate of 95%. No pollution, easy to realize automation.

Permanent Mold Casting have a long life and high production efficiency, not only have good dimensional accuracy and smooth surface, but also have higher strength than sand castings and are less likely to be damaged when the same molten metal is poured. Therefore, in the mass production of medium and small non-ferrous metal castings, as long as the melting point of the casting material is not too high, metal casting is generally preferred.

lost foam casting is to combine paraffin wax or foam models similar to the casting size and shape into model clusters. After brushing and drying refractory coatings, they are buried in dry quartz sand for vibration modeling, and poured under negative pressure to gasify the model. , The liquid metal occupies the position of the model and forms a new casting method after solidification and cooling.

Centrifugal Casting is a technique and method of injecting liquid metal into a high-speed rotating mold, so that the liquid metal is centrifugal motion to fill the mold and form a casting. Due to the centrifugal movement, the liquid metal can fill the mold well in the radial direction and form the free surface of the casting; it affects the crystallization process of the metal, thereby improving the mechanical and physical properties of the casting.

Vacuum Molding is a casting process in which metal is smelted, poured and crystallized in a vacuum chamber. Vacuum Molding can minimize the gas content in the metal and prevent metal oxidation. This method can produce very demanding special alloy steel castings and extremely easily oxidized titanium alloy castings. Be-cu Casting has a vacuum molding sub-factory, which is enough to solve all the problems related to vacuum casting

Top Metal Casting Case Studies

BE-CU Casting fabrication services are available for both design to reality and low to high volume production runs of your die casting parts,sand casting parts,investment casting parts,metal casting parts, lost foam casting parts and more.

-

Casting Silver Rings

-

Investment Cast 925 Silver Moon Earrings

-

CNC Machining Gas Stove Bottom Joint

-

Zinc Die Casting PA10 Transformer Connector Terminal

-

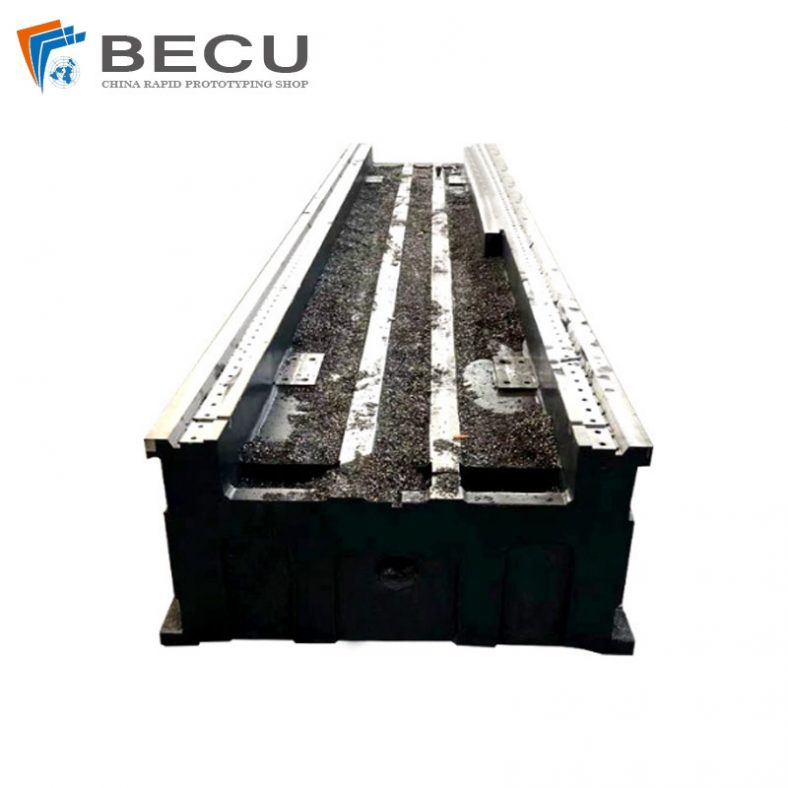

Ductile Cast Iron Large Gantry Machine Tool Bed Castings

-

Malleable Cast Iron Agricultural Machinery Support Seat

-

CNC Machining Cast Iron Explosion Proof Junction Base

-

CNC Machining Large V-belt Pulleys

-

Investment Casting For TC4 Golf Putter Head

-

Lost Wax Casting Stainless Steel 431 Golf Head

-

Stainless Steel Investment Casting Craft Ornament Decoration Gift

-

316 Stainless Steel Precision Casting Owl Ring

Latest Metal Casting Blog,Encyclopedia And Guide

View the custom metal casting and end-use parts we’ve produced for our customers.

-

How to Calculate Investment Casting Cost & Lost Wax Casting Prices

-

Casting Geometric Tolerances (GD&T) Charts

-

Investigating the Multifaceted Causes of Pitting Defects in Investment Casting

-

Transitioning from Die Casting to CNC Machining

-

Lost Foam Casting vs Lost Wax Casting

-

Difference Of Aluminum Die Casting and Aluminum Gravity Casting

-

The Ultimate Guide Of Choose the Right Material for Investment Casting