Why Choose CNC Machining To Custom Bicycle Parts

CNC (Computer Numerical Control) machining is a manufacturing process that uses computer-controlled machines to produce precise and complex parts from a wide range of materials. CNC machines are capable of producing parts with extremely high precision, often down to within a few thousandths of an inch. This level of precision is particularly important for bicycle parts, where even small variations in dimensions can affect performance and safety.

CNC machines are able to produce parts with a high degree of consistency, ensuring that each part is virtually identical to the next. This consistency is particularly important for parts that need to fit together precisely, such as wheel hubs, bottom brackets, and headset components.

CNC machines are able to produce complex shapes and features that would be difficult or impossible to achieve using other manufacturing methods. This allows for the creation of custom-designed bicycle parts that can be optimized for performance, weight, and aesthetics.CNC machines can work with a wide range of materials, including aluminum, titanium, carbon fiber, and steel. This means that CNC machining can be used to produce lightweight and strong bicycle parts from a variety of materials to meet the specific needs of different riders.

CNC machines are able to produce parts quickly and efficiently, making it possible to manufacture large numbers of parts with short lead times. This is particularly important for companies that need to produce large quantities of high-quality bicycle parts to meet demand.So, CNC machining is ideal, in many ways, for manufacturing bicycle parts.

Application of CNC Technology in Manufacturing Custom Bicycle Parts

CNC milling and turning are the most common CNC machining techniques for manufacturing custom motorcycle parts. Let’s briefly delve into these standard machining processes.

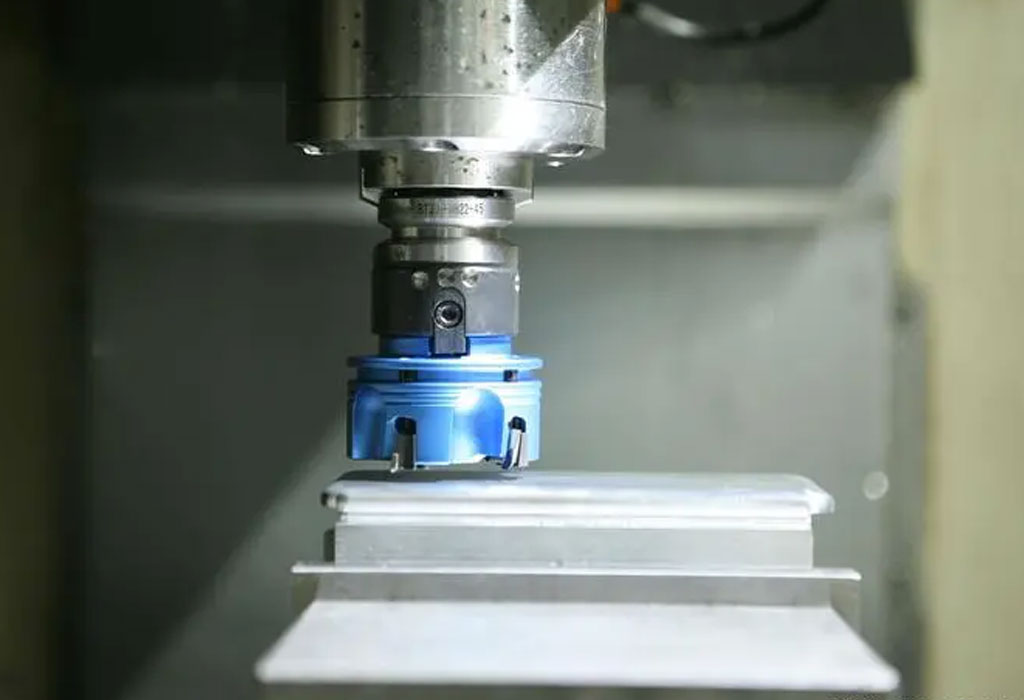

1. CNC Milling Bicycle Parts

CNC milling is a manufacturing process that uses a computer-controlled machine to remove material from a workpiece to create a custom-designed part. When used for producing bicycle parts, the CNC milling process can create high-quality, precise, and complex parts that meet the functional and aesthetic needs of the rider.

In Precision CNC Milling, the cutting tool rotates across the surface of the workpiece and continues to subtract excess material until the shape and size of desired parts get formed. The process is highly automated and precise, allowing for the creation of parts with tight tolerances and complex shapes that would be difficult or impossible to produce by hand.

To produce a bicycle part using CNC milling, a CAD (computer-aided design) model of the part is first created on a computer. This model is then translated into machine code using CAM (computer-aided manufacturing) software. The machine code contains the instructions for the CNC milling machine to follow, including the tool path, cutting parameters, and any other relevant information.

The CNC milling machine then uses this machine code to control the movement of the cutting tool and remove material from the workpiece. The part is machined to the precise dimensions and tolerances specified in the CAD model, resulting in a high-quality, custom-designed bicycle part.

CNC milling is commonly used to produce bicycle parts such as frames, forks, stems, handlebars, seat posts, and brake components. By using CNC milling, bicycle manufacturers and custom bike builders can create parts with high precision, accuracy, and repeatability, ensuring the functionality, safety, and performance of the final product.

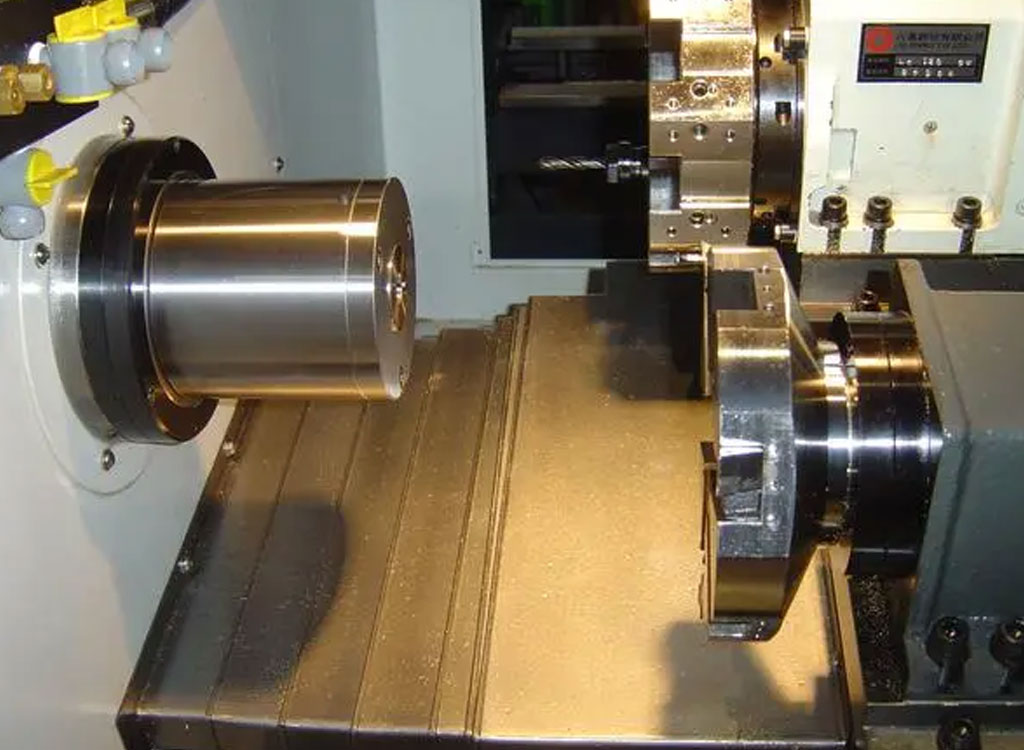

2. CNC Turning Bicycle Parts

CNC turning is a manufacturing process that involves rotating a workpiece on a lathe while a cutting tool removes material to create the desired shape and features. When used for producing bicycle parts, the CNC turning process can create high-quality, precise, and complex parts that meet the functional and aesthetic needs of the rider.

In CNC turning, the workpiece is rotated on a lathe while a cutting tool removes material from the workpiece to create the desired shape and features. The cutting tool moves along multiple axes (usually 2 to 4) to achieve the desired geometry of the part. The process is highly automated and precise, allowing for the creation of parts with tight tolerances and complex shapes that would be difficult or impossible to produce by hand.

To produce a bicycle part using Precision CNC Turning, a CAD (computer-aided design) model of the part is first created on a computer. This model is then translated into machine code using CAM (computer-aided manufacturing) software. The machine code contains the instructions for the CNC turning machine to follow, including the tool path, cutting parameters, and any other relevant information.

The CNC turning machine then uses this machine code to control the movement of the cutting tool and remove material from the workpiece. The part is machined to the precise dimensions and tolerances specified in the CAD model, resulting in a high-quality, custom-designed bicycle part.

CNC turning is commonly used to produce bicycle parts such as hubs, axles, bottom brackets, cranksets, and headset components. By using CNC turning, bicycle manufacturers and custom bike builders can create parts with high precision, accuracy, and repeatability, ensuring the functionality, safety, and performance of the final product.

The Process Of CNC Machining Bicycle Parts

CNC machining is a popular manufacturing process for producing bicycle parts due to its ability to produce precise and complex parts quickly and efficiently. Here’s a general overview of the CNC machining process for producing bike parts:

- Design: The first step in CNC machining is to create a digital design of the bike part using computer-aided design (CAD) software. The design specifies the dimensions, geometry, and other features of the part.

- Programming: Once the design is complete, a computer program is created that specifies the tool paths and cutting instructions for the CNC machine. This program is loaded into the machine’s computer, which controls the movement of the cutting tools.

- Material Selection And Preparation: The material for the bike part is selected based on the desired properties, such as strength, weight, and stiffness. The material is then prepared by cutting it to the appropriate size and shape for the CNC machine.

- Machining: The CNC machine is set up with the appropriate cutting tools, such as drills, mills, and lathes, and the machining process begins. The cutting tools are guided by the computer program to cut away material from the workpiece, creating the desired shape and features of the bike part.

- Finishing: Once the machining process is complete, the bike part may require additional finishing steps, such as polishing, sanding, or coating, to improve its appearance and performance.

- Inspection: The finished bike part is inspected to ensure that it meets the specified tolerances and quality standards. If necessary, adjustments may be made to the CNC program or machining process to improve the quality of future parts.

CNC Machining is a versatile and efficient manufacturing process for producing high-quality bicycle parts. Its ability to produce precise, complex, and customized parts makes it an ideal choice for the bike industry.

Cnc Machining Bike Parts – Bicycle Machining Specialist

Be-cu Prototype has been developing and manufacturing experience in the Bicycle Machined Parts industry for over 20 years. We have constantly changed our engineering, quality, and production capabilities to meet the bike industry’s development speed, We can produce a series of parts from frame, wheel, handlebars and stems, Brakes to components of the bike aftermarket, based on different materials from stainless steel, aluminum, copper, etc. We well know that the bike industry is very high quality to our daily life during driving, so we have to ensure the quality requirement for each of the parts before shipment.

In order to meet our customers ‘ requested to make good product appearance,Be-Cu provides parts finishing services such as powder coating, polishing, heat treating or color anodizing, etc after machining process, these are completed under our strictly standard, make your project better.

In order to meet our customers ‘ requested,most of the secondary process for bike parts have anodizing, powder coating, of course,BE-CU.COM provide these after machining process,these are completed under our strictly standard, make your project better.

Also,Be-cu.com offers the low-volume manufacturing for your projects after your prototype completed, will fast delivery them to you for assembling testing, we do best one-stop services in here, Our engineer will work with you on these machining details, using our larger CNC lathe to machining outline then have 5 axis CNC machining center(DMU Or Mazak) to making its details to achieve final parts,whatever your orders quantities are single set or 30 sets or more 200 sets, We can complete them for you quickly.

Why Choose Our Bicycle Machining Service?

- Save time and money for your Bicycle project but quality guaranteed.

- High productivity, outstanding efficiency and high accuracy

- A wide range of material grades and alloy materials can be machined

- Custom complex Bicycle machined parts and components at specific tolerances

- High speed machining for prototyping and low to high volume production runs

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for Bicycle customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

Top China Bicycle Cnc Machining Parts & Case Studies

With the continuous maturity and development of CNC Machining technology, more and more bike manufacturers have introduced this technology for prototype testing, design proofing, parts customization and other applications. By exploring our success stories, you can learn about: the development of CNC Machining in the Bicycle industry, the application of CNC Machining in Bicycle forging molds, how CNC Machining changes the Bicycle manufacturing supply chain, and more.