Custom Brass Parts

- Global delivery as fast as 30 days

- Machined prototypes in as fast as 9 days.

- Perfect Service And High Quality

- Tolerances down to +-0.005mm

- ISO 9001:2015, ITAF 16949

>>>All uploaded drawings are strictly confidential, check the confidentiality agreement

Fabrication Brass Parts Supplier – Custom Brass Components Manufacturer

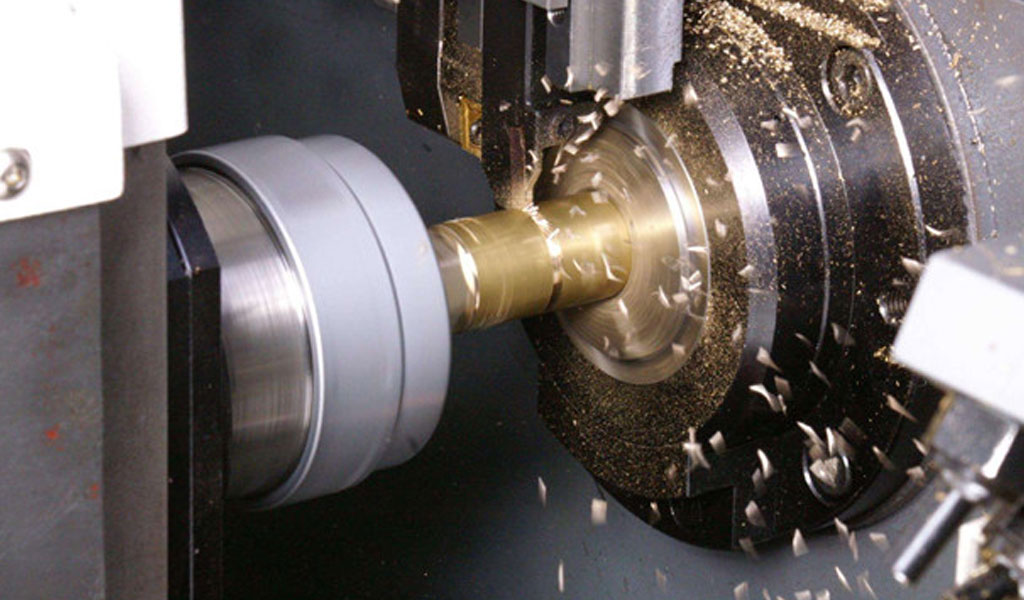

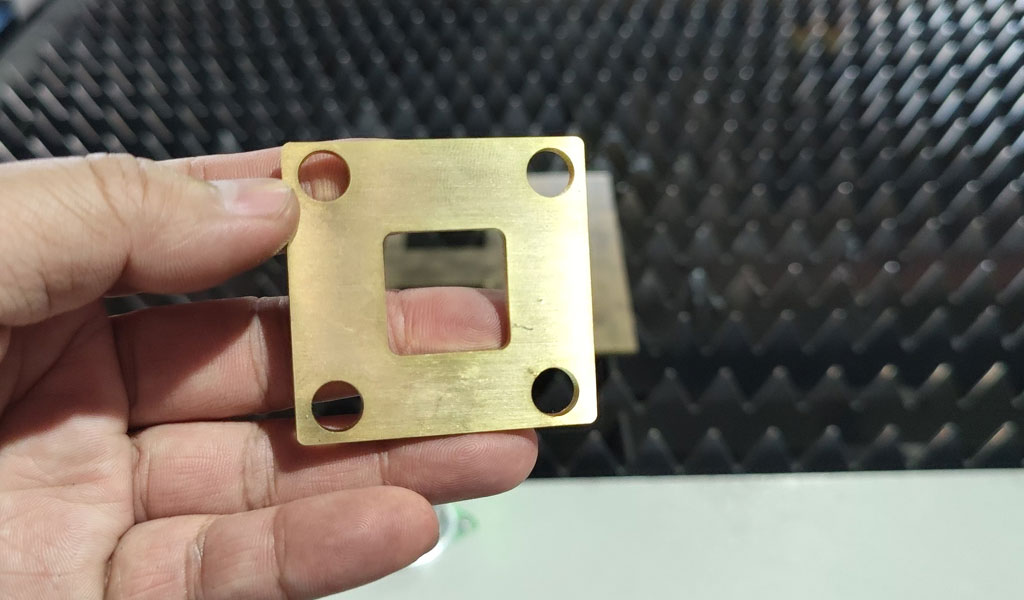

Brass is a metal alloy made from copper and zinc. Looking for custom brass parts by an experienced and reliable fabrication components manufacturer? Be-cu’s custom brass parts services can be your ideal choice. Capabilities to manufacture simple or complex brass products.All of our brass parts are subject to our rigorous inspection regime with designated inspectors, in-process inspection and a full final inspection completed on every part.Be-cu has been fabrication brass parts of various sizes, from miniature to oversized, and various shapes, from simplest to the most complicated.

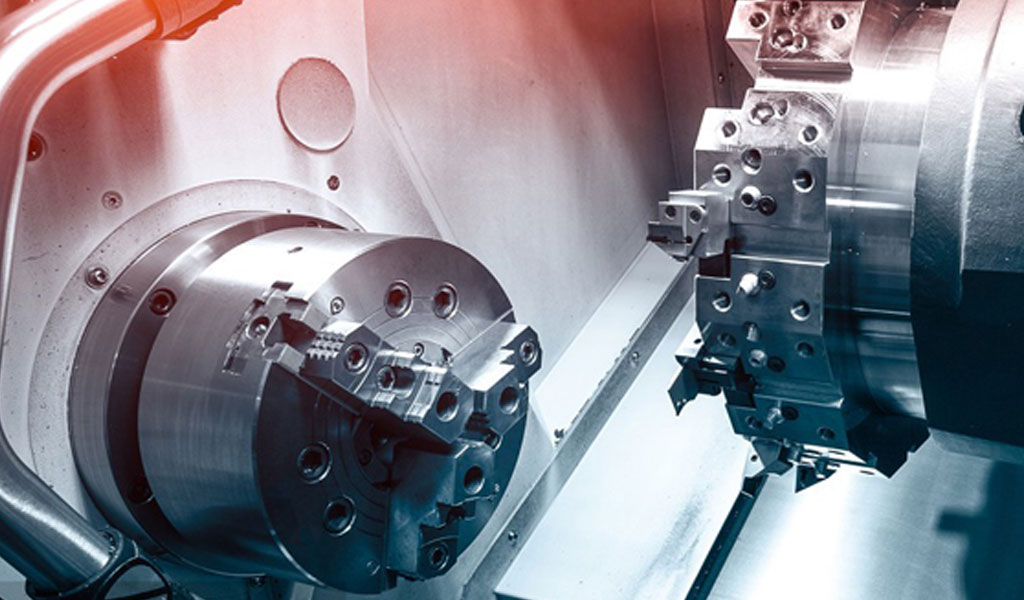

• Empowered by 100+ advanced facilities

• 10000+ case studies produced

• Serving 3000+ clients worldwide

• Supported by hundreds senior machinists with over 20 years of experience

Be-cu Shop has custom brass parts for over 30 years. You can design and order your parts with our free rapid quote tooling or upload your own CAD file to our email:[email protected] for a fast quote.

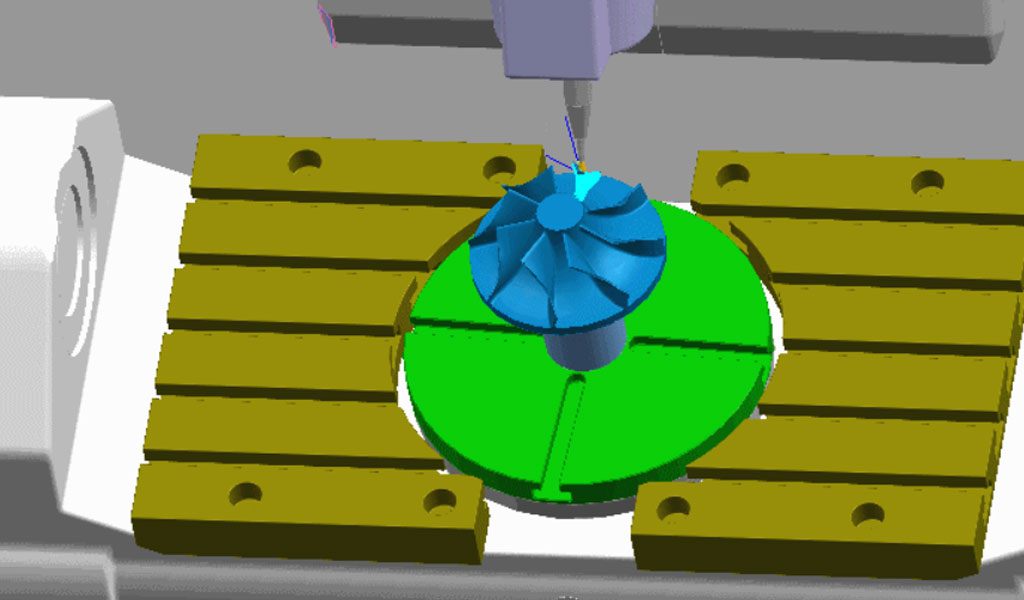

Experienced To Offer More Manufacturing Options

Upholding this standard requires an exceptional commitment to manufacturing resources. The wide variety of machining technology options in the Be-Cu prototype machine library is supported by an in-house tooling capability that adapts tools to the unique characteristics of each material.Our brass science engineers will help you choose suitable metal alloys and machining processes(include brass cnc machining and more) to address your part-making needs.

What Is Brass Parts – Brass Define

Brass Parts are actually pure brass or brass alloy parts obtained by various fabrication methods.Brass is an alloy composed of copper and zinc. Brass composed of copper and zinc is called ordinary brass. If it is a variety of alloys composed of two or more elements, it is called special brass. Brass has strong wear resistance, and ordinary brass is widely used, such as water tank belts, water supply and drainage pipes, medals, bellows, serpentine pipes, condenser pipes, bullet casings and various complex shaped stampings, small hardware, etc. . With the increase of zinc content from H63 to H59, they can withstand hot processing well, and are mostly used in various parts of machinery and electrical appliances, stamping parts and musical instruments.

Ordinary brass is a copper-zinc binary alloy, and its zinc content varies widely, so its room temperature structure is also very different. According to the Cu-Zn binary state diagram, there are three types of brass at room temperature: brass with a zinc content of less than 35%, the microstructure at room temperature is composed of a single-phase α solid solution, called α brass; zinc-containing Brass with an amount in the range of 36% to 46%, the microstructure at room temperature is composed of (α+β) two-phase, called (α+β) brass (two-phase brass); the zinc content exceeds 46 %~50% of brass, the microstructure at room temperature is only composed of β phase, which is called β brass.

α single-phase brass (from H96 to H65) has good plasticity and can withstand hot and cold fabrication, but α single-phase brass is prone to medium temperature brittleness during hot fabrication such as forging, and its specific temperature range varies with the content of Zn. The change is generally between 200 and 700 °C. Therefore, the temperature during hot working should be higher than 700°C. The reason for the formation of the medium-temperature brittle zone in single-phase α-brass is mainly due to the existence of two ordered compounds, Cu3Zn and Cu9Zn, in the α-phase region of the Cu-Zn alloy system, which undergoes an orderly transformation when heated at medium and low temperatures, making the alloy brittle; , There are trace amounts of harmful impurities of lead and bismuth in the alloy and copper to form a low-melting eutectic film distributed on the grain boundary, resulting in intergranular cracking during thermal fabrication. Practice shows that adding a small amount of cerium can effectively eliminate the brittleness at medium temperature.

Due to the different zinc content in brass, the mechanical properties are also different, and the mechanical properties of brass vary with the zinc content. For α brass, with the increase of zinc content, both σb and δ increase continuously. For (α+β) brass, the room temperature strength increases continuously until the zinc content increases to about 45%. If the zinc content is further increased, the strength decreases sharply due to the appearance of a more brittle r-phase (solid solution based on Cu5Zn8 compound) in the alloy structure. The room temperature plasticity of (α+β) brass always decreases with the increase of zinc content. Therefore, copper-zinc alloys containing more than 45% zinc have no practical value.

Custom Brass Parts Applications – What is Custom Brass Parts Used for

Because the fabrication allows a very high precision without altering the structure of the material with a good rate of manufacture, fabrication is becoming increasingly common as its machine range, control systems and cutting tools are just growing. Our fabrication service is used to produce a variety of custom-designed fabrication parts and products in all areas of the industry:

The Case Studies Of Custom Brass Parts

You have a complex brass parts design, Our fabrication service can help you turn it into a reality. With the right equipment, strong technical knowledge, and a focus on quality.. From tool design to finishing and then on to shipment, Be-cu prototpe ensure that every project is completed to a high standard and that your orders are delivered on time, every time.

-

Custom Brass Hanging Signs For Wall Decorations

-

Precision Turning H59 Brass Dough Hooks And Beaters

-

Brass Direct Injection Flame Distributor Nozzle For Gas Stove

-

CNC Machining Brass Natural Gas Kitchen Appliance Valve Core

-

CNC Machining Double Threaded Pen Nib

-

CNC Machining Brass Solid Gourd Keychain

-

Precision Turning Solid Wenchang Pagoda Copper Ornament

-

Turn-Mill Machining Electronic Connector Components

-

Brass Turning Welding Machine Plug

-

Metal Spinning Top Toy

-

Hollow Laser Cutting Brass 360 Jewelry

-

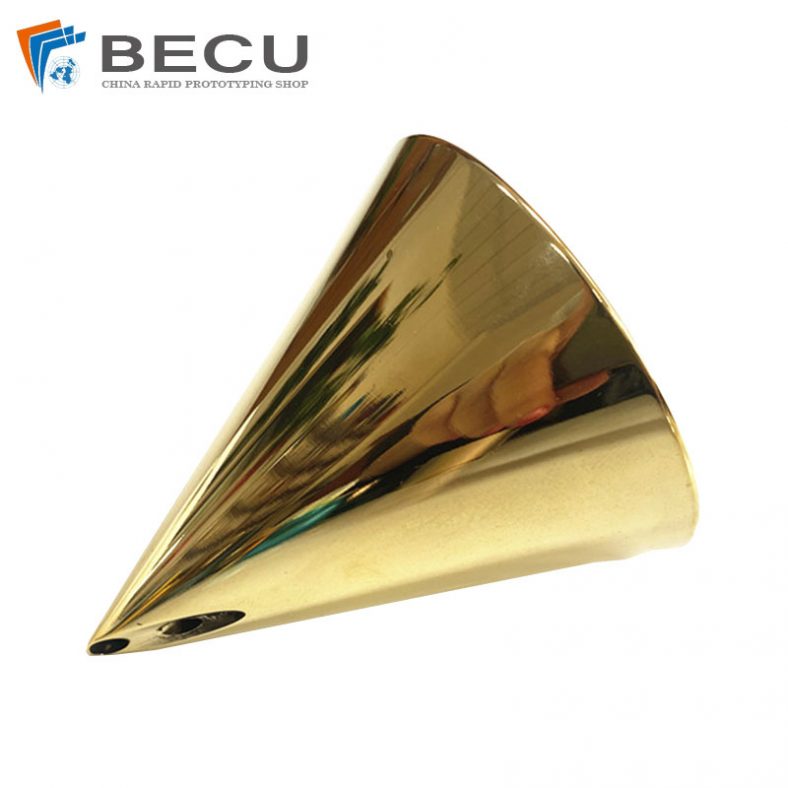

Precision Turning Brass 353 Cone Housing