Investment Casting For Bicycle Industry

Despite its misleading name, investment casting has nothing to do with the stock market. The name is derived from the pattern invested or surrounded by a material, usually wax or some refractory material.

The wax imprint is then encased in a material such as a ceramic slurry, which is then melted and burned off in a furnace, giving investment casting another common name, “lost wax casting.” The remaining molds are then used to cast the final metal part. This technique is common in the bicycle parts industry.

The surface finish of bicycle investment castings is higher than that of ordinary castings, generally up to Ra.1.63.2μm. The biggest advantage of investment casting is that due to the high dimensional accuracy and surface finish of investment castings, machining work can be reduced.

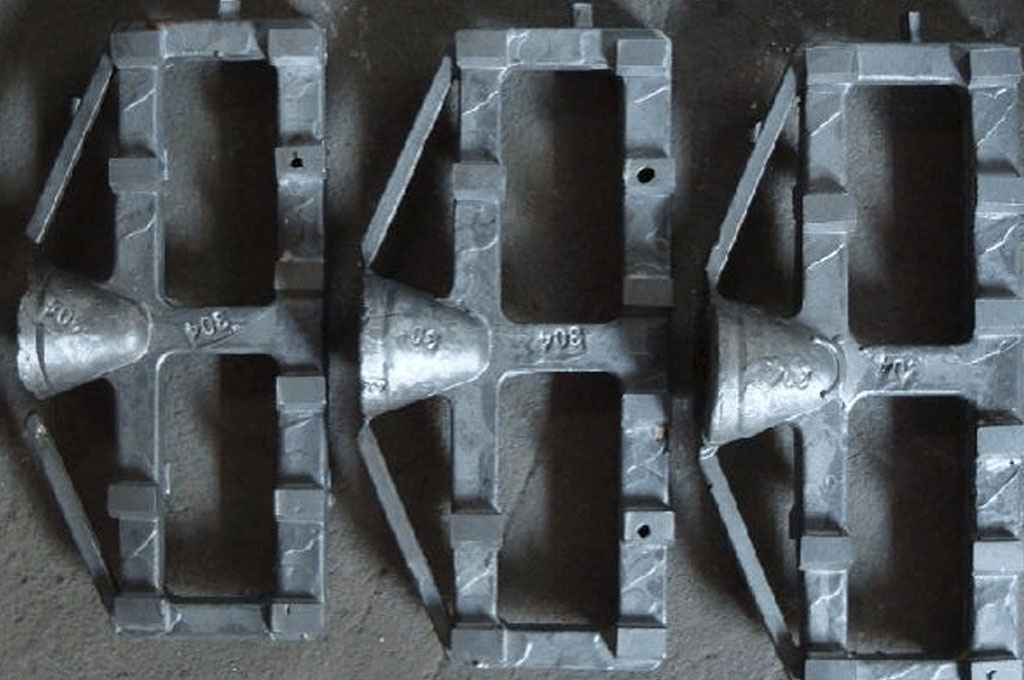

Be-cu.com has produced hundreds of thousands of “middle joints” by lost wax casting method for two bicycle factories. The material of this casting is ZG25, and it is also replaced by ZG35. The weight of the blank is 0.31kg, and the geometric shape is relatively complicated. More importantly, the wall is thin (the wall thickness is generally between 2.5-3.75 mm, and the thinnest part is 1.5 mm).

3D Printing Investment Castings For Bicycle

Metal tools are often prohibitively expensive, especially for smaller companies. 3D printing even opens the door for them to get highly customizable metal parts at a reasonable price.

Take, for example, the production of parts for custom bicycles. Using 3D printed patterns makes it possible to create custom small metal parts using modern materials without expensive tooling processes. For very low-volume production or one-off unique metal tools, companies are turning to direct 3D printing of metal.

Sand casting molds and cores produced with 3D printers have been the standard for many foundries for many years. This technique is well established in the field of steel casting and is used where it helps. Although these applications are primarily in the realm of prototyping and low-volume runs, the limits tend to become larger and larger as the performance of 3D printing systems continues to improve. In terms of total cost, 3D printing is always a more economical alternative to traditional processes up to a certain volume due to the elimination of tooling costs. The smaller the batch size, the greater the cost advantage provided by 3DP+Investment casting technology. Especially for complex geometries, 3D printing in batches of even a few hundred units is the most economical option, if not possible.

Bicycle Parts Investment Casting Supplier – Precision Investment Castings For Bike Parts

An investment casting for bicycle parts uses expandable patterns created from a wax-like material to assemble a complex component. A step-by-step near-net shape operation with phenomenal surface qualities that resulted from utilizing ceramic molds with the best thermal characteristics.

Most engineers prefer to utilize investment casting for multiple bike industries as it offers countless qualities and benefits. It is the most diverse process that aids in generating precise, intricate, and structurally durable designed components for bicycle applications.

We have extensive experience in the bicycle sector, and are a supplier of choice for bicycle parts.

The Bicycle Component Of Investment Casting

Typical parts of a bicycle which can be investment-cast are:

- Head lugs

- Dropouts

- Seat clusters

- Bottom bracket shells

- Seat-stay and chain-stay bridges

- Fork crowns

- More

The experience we have of huge range of alloys in casting ,including aluminum, CF8/CF8M & Non ferrous means we can get almost any bicycle casting completed on time and to budget. We also have a track record of providing solutions for new, previously un-castable materials.When parts programs call for ready-to-use or fully finished and assembled investment castings in high, moderate, or low volumes, Be-cu.com has the capabilities to meet customers’ needs.

The Tolerance Of Investment Castings

The dimensional accuracy of Investment castings is one of the important quality indicators of castings. The dimensional tolerance standards of investment castings are the objective basis for measuring the dimensional accuracy of castings. Be-cu strictly follows the national standard GB/T6414-2017.For investment castings, select the following corresponding tolerance classes according to their maximum nominal size:

- When the maximum nominal size is less than or equal to 100, choose DCTG4~DCTG6 grade;

- 100<maximum nominal size≤400, choose DCTG4~DCTG8 grade;

- When the maximum nominal size is greater than 400, select DCTG4~DCTG9 grade.

The Case Studies Of Bicycle Investment Castings

You have a complex part design, Our investment casting service can help you turn it into a reality. With the right equipment, strong technical knowledge, and a focus on quality.. From tool design to finishing and then on to shipment, Be-cu prototpe ensure that every project is completed to a high standard and that your orders are delivered on time, every time.