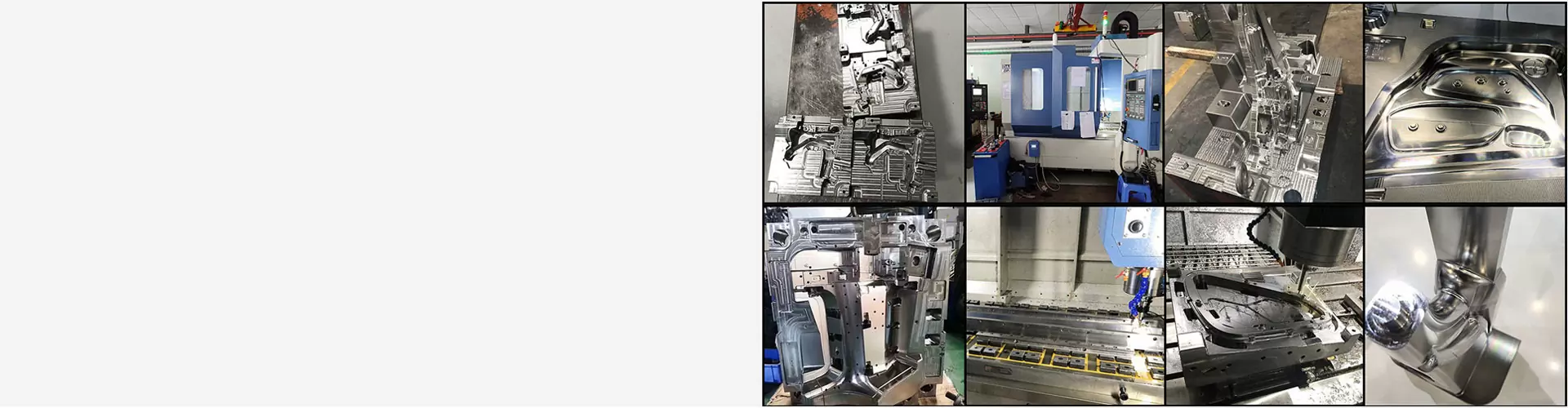

Mold Manufacturing

- Build molds with tight tolerances.

- Accurately and continuously which increases mold and part quality

- Reduces mold build leadtime and mold cost.

- Each new mold project is assigned a Project Manager for single point of contact.

- All molds are 100% guaranteed while running production in our facility.

>>>All uploaded drawings are strictly confidential, check the confidentiality agreement

Advance Mold Making In China – Die Machining And Mold Manufacturer

The mold manufacturing is of significant importance in project operations, whether for metal parts mold or plastic mould.Be-cu is a die machining and mold manufacturer that is specialized in the manufacturing of precision mould used for different applications. Cr12、Cr12MoV、S-136、SLD、NAK80、GCr15、T8、T10、5CrMnMo、3Cr2W8、9CrSi、W18Cr4V、5CrNiMo、W6Mo5Cr4V2、M2 and more are popular mold material options. Our custom mold manufacturing services can deliver durable service life,coupled with our team’s collective experience in the field, have earned us lasting customer loyalty,most importantly, can perfectly match your requirements. From Big nozzle mold to Sprue Mould to Hot runner mold, trust professional experts and engineers at Be-cu.com to help you in mold design and machining, as well as spinning die and other dies manufacturing. We’ll minimize the downtime costs and improve the efficiency to provide a cost-effective solution with a short lead time. Fast to upload your CAD files or send us your inquiry to get a quick response online.

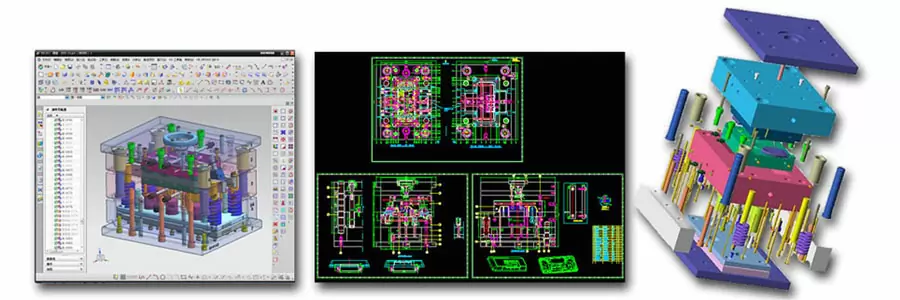

Mould Design Engineering

- The design is the foundation of the product.Our experienced engineers will use CAE/CAD to make your dream come true,We are the most suitable midwife of your great ideas!

- We can also put out a complete 2D and 3D mold blueprint according to the products provided by our customers.

- All of our tools are constructed to rigid DME and Hasco mold standards.We utilize only high-grade mold steels from companies such as Uddeholm and International mold steel(P20,H13,2344,420,S-7,718H,S136,etc).For the hot runner system,we use MoldMaster,DME, Husky,Yudo,etc.

What is a Mold Manufacturing?

The Mold Manufacturing refers high value-added and technology-intensive product,various molds and tools used in industrial production to obtain the desired products by injection molding, blow molding, extrusion, die casting or forging, smelting, stamping and other methods. In short, a mold is a tool used to make a shaped item, this tool is made up of various parts, and different molds are made up of different parts,and its own technical level has become one of the signs reflecting the strength of a country’s manufacturing capacity. To a large extent, the mold determines the quality, efficiency and development capability of the product, and the quality of the mold mainly depends on the level of craftsmanship in the manufacturing process.Cnc Machining And EDM technology is key technology in the field of mold manufacturing technology. EDM is a non-contact fabrication method with very small macro manufacturing force, which makes it play an important role in finishing.

Why Choose Mold Making Service At Be-cu?

- Years of experience and knowledge enable us to handle multiple levels of complexity

- Capabilities including mold manufacturing, assembly tooling, special machinery and more

- Safety and quality are our top priorities, implementation of inspection is a must step

- Reasonable prices based on your specifications, quality requirements and budget limitations.

- In addition,we supply components with DME and Hasco standard to meet the clients requirements to mold interchange,quality and delivery.

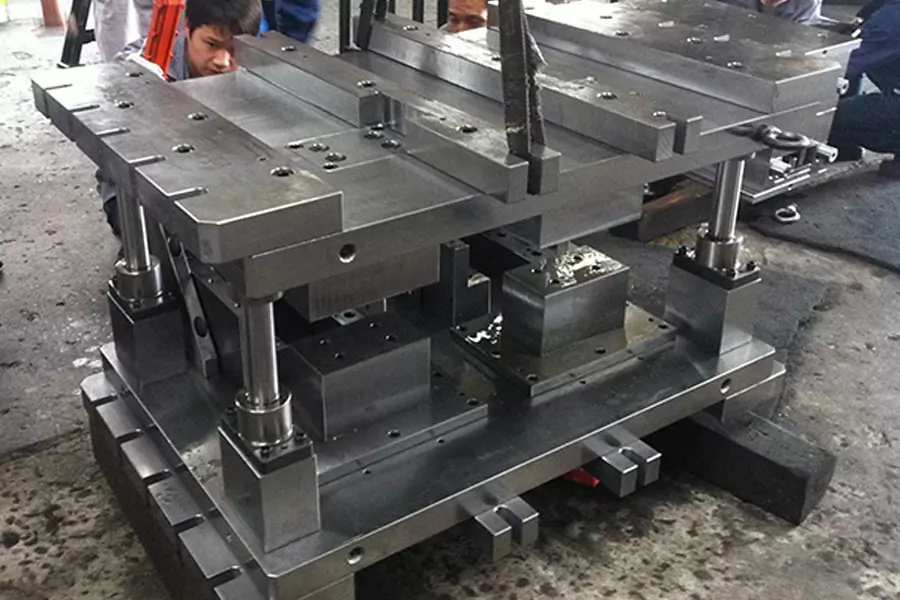

- We can build molds which being dimensioned within 1.5M and being weighed less than 10T.

- Our Mold Division is one of our biggest strength. Sixty percent (50%) of our Molds are exported mainly to U.S., Brazil, Italy, Germany, France, Japan and UK.

- We have complete manufacturing facilities from CNC, EDM, Wire Cutting, Milling, Drilling all located in one roof.

- Our Mold Flow Analysis program ensures that potential processing problems are highlighted at an early stage just before we start building our molds.

Once the customer confirms our mold designing or provides us a designed mold,our workshop provides all kinds of technology and techniques for the whole manufacturing required,including rough machining,half fabrication and precise manufacturing.The mold will be completed,respectively according to your requirements on the mold materials,structures,equipment and delivering time.These procedures include Lathe,Milling,Drill,Grinding,EDM,EDM Wire Cutting,CNC,Heat treatment and Mold Finish.Each procedure in the whole process will be filed in a record card and be put through a quality-control section to assure good quality and on time delivery,and consequently the smooth assembly of the molds.In the ultimate procedure,we will mail the qualified sample which has passed the tool trial along with the improved mold to the clients.

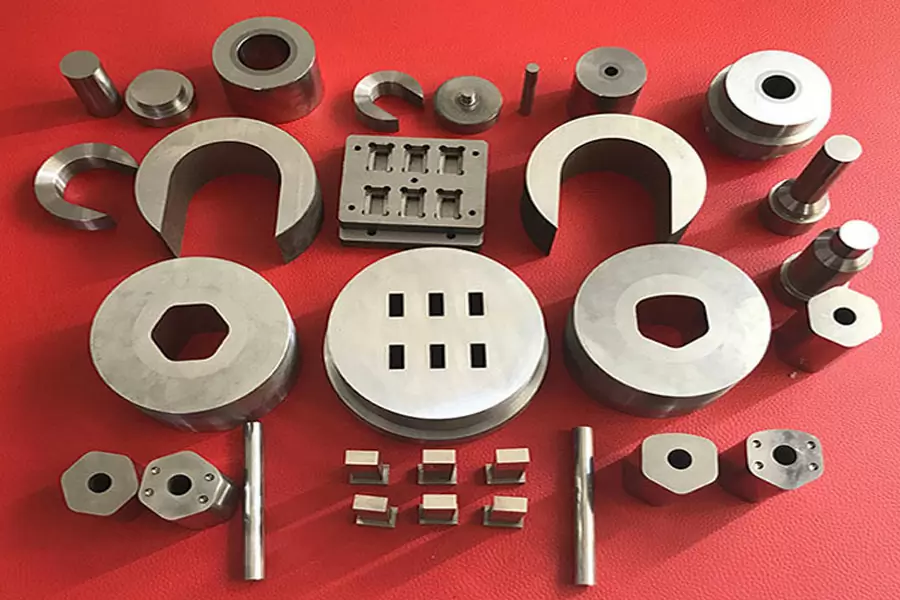

Powder Metallurgy Mold

The molds are widely covered metal, nonmetal product molds, automobile, motorcycle molds, precision stamping dies, precision cavity dies, jigs, fixtures and the standard parts of the mold. And the products are made by the mold widely used in the below industry come to powder metallurgy ,auto part, precision electric , precision ceramic ,magnetic material, plastics, rubber products as well as injection molding, die-casting, forging and so on. The precision of the mold is very high, it can reach within 0.002mm, the class of precision gear mold can reach DIN(ISO)4, also the precision of the finished gear parts can reach the standard DIN(ISO) 5, sure, it has a very high and advanced standard in the inland.

Die Casting Mold

We offering include thin wall or more die casting mold manufacturing,mold design, as well as with die casting mold cnc machining. With more than 30 years of experience, we are able to produce custom affordable aluminum die casting parts,zinc die casting parts and magnesium parts according to customers’ specifications, drawings or samples. We own advanced techniques, highly skilled staff that employ superior tooling and high pressure die cast processes to ensure that the mold parts are of the cheapest price and highest quality. Whether you need rapid tooling, mass production mold making with tight tolerances, our team of experienced specialists can offer a cost-effective solution at each stage.

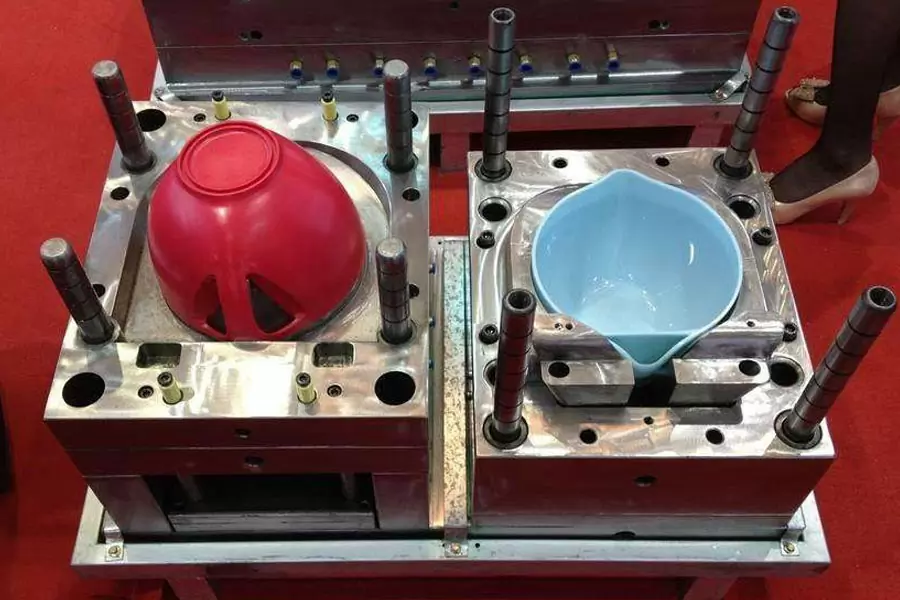

Plastic Mould

Our cooperate plastic molding company has injection molding machines from 60 tons to 2000 tons to suit your different requirements, 3 sets of machines are 2K injection molding machines which are for two-color molding parts service, we produce two/single color mold, multiple cavities mold, over-molding, 2K molding, insert molding, gas assist mold, transparent plastic injection molding etc.We do not only offer plastic mold making services, but also have silk-screen, pad printing, painting, and assembly service. Quality is a hallmark of our operation, special tight lead time (15 days) which is offered for some special case, with ISO-9001:2015 quality system in place to control the quality of the product.

Stamping Mold

Stamping is really cost effective and it’s suitable for the mass production of complex shape parts.Through the use of quick-change inserts, standard dies, single-station fixtures, and know-how gained from over variours years of precision stamping experience, we can provide both the high quality you require along with a reduction of costs by as much as 85% when compared to conventional methods.Precision-built tooling is manufactured to make sure your parts and assemblies meet or exceed your most critical performance requirements and hold tight tolerances.Be-cu provide high quality and affordable metal stamping mold and tooling for prototypes and production parts with quick turnaround times.

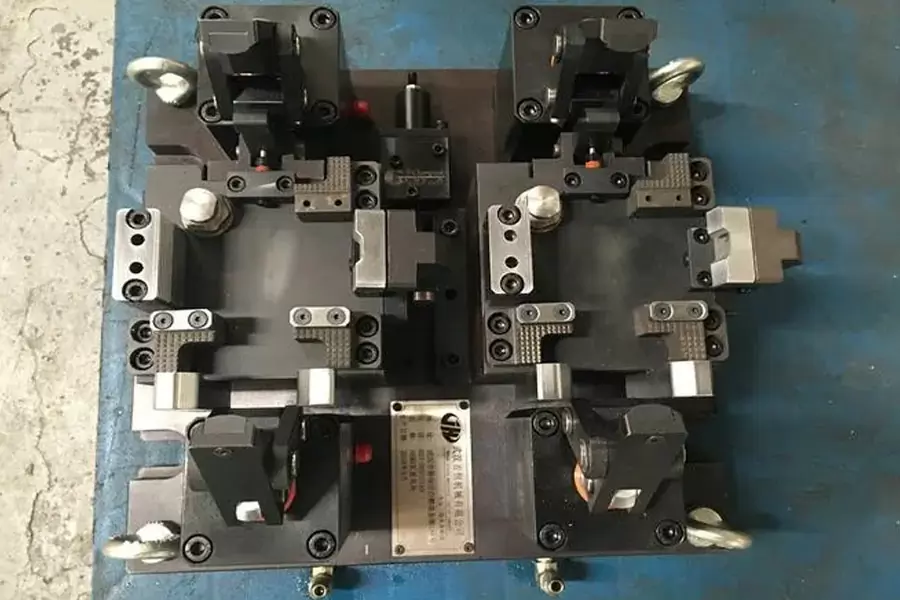

Custom Fixture

Be-cu is a CNC part and tooling manufacturer that is specialized in the manufacturing of CNC fixtures and clamping systems used for different applications. Cast iron, stainless steel, and mild steel are popular fixture material options. Our custom fixture machining services can deliver CNC clamping systems with high functionality and ease of exchange, most importantly, can perfectly match your requirements.

Silicone Rubber Mold

Our rewards are lower costs,dynamic profits team,specialised QC,potent factories,high-quality services for Silicone Rubber Mold, 5mm Rubber O Rings, Round Silicone Rubber Gasket, Thick Wall Silicone Tubing,Buy Medical Grade Silicone. We sincerely hope to provide you and your company with a great start. If there is anything we will do to suit your needs, we shall be additional than pleased to do so.

Forging Die

Forging dies are fabricated in different materials such as cold rolled steel, stainless steel, copper, brass & nickel. Capabilities include CAD/CAM designing, prototyping, machining, milling, welding, tapping, forming & assembling. Other dies such as single-station dies, progressive dies, slide-forming dies, embossing dies, extrusion dies, stamping dies, fourslide dies, multislide dies & vertislide dies are also fabricated.

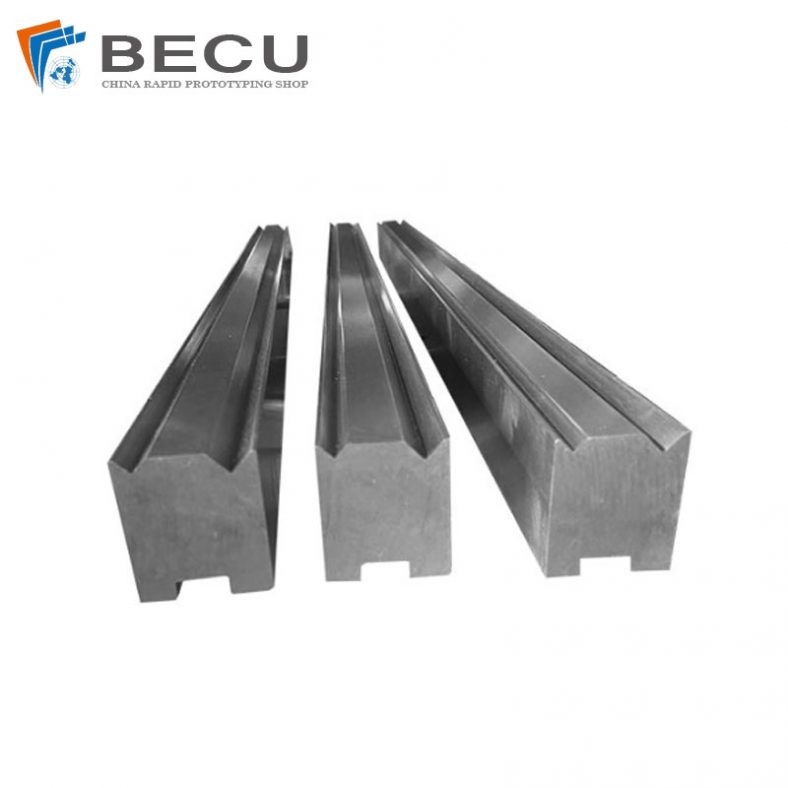

Mold Parts

China Be-cu company devote to make custom, durable and high quality precision mold parts. Many of our skilled engineers have over ten years experience. Under their leading of precision machining processes, the customer is able to get more efficient, high accuracy, economic design and products. Precision mouldings we provide always meet or exceed the industry standard tolerances and can reach ±0.002mm.

Strong Collaborative Manufacturing Network

Be-cu has 8 self-operated factories, serving 10,000+ customers in more than 30 countries and regions around the world.

In the future, Be-cu will continue to empower traditional manufacturing and create a full industrial chain for manufacturing OEM parts

Fast proofing and mass production of parts, 24-hour quotation system, minimum order of 1 piece, delivery in the fastest 2 days, 100% full inspection.

Under the control of ISO9001 and TS 16949,All processes are carried out through hundreds of advanced die casting machines, 5-axis machining, and other facilities, ranging from blasters to Ultra Sonic washing machines

Strict follow-up and control of the entire process from quotation to delivery.Other Serviced Include Sheet metal rapid proofing, stamping die manufacturing and high-speed stamping, forging die manufacturing, etc.,

-

Precision Grinding Tungsten Steel Mold Parts

-

5 Axis CNC Machining Medical Olecranon Plate

-

Special-Shaped Non-Standard Medical Device Needles

-

High-Speed Steel (HSS) Die Punching Needles

-

Precision Tungsten Copper Alloy Eccentric Insert

-

5 Axis CNC Machining Spiral Bevel Gear Mold

-

Small Precision Injection Molding Inserts

-

OEM Stainless Steel Press Brake Tooling

-

42CrMo Steel CNC Machining Bender Dies

-

Carbide Tungsten Valve Seat For Oil And Gas Industry