3D Printing For Jewelry

From getting acquainted and falling in love to achieving a positive result, every happy couple regards each other as the only one, and for the couples who are about to enter the wedding scene, if a wedding ring that will accompany you for a lifetime and be engraved forever, if it can be unique, The meaning is self-evident. The powerful and affordable customization capabilities of 3D printers make the popularization of similar exclusive customization a reality.

Although jewelry is small, it needs to go through a delicate and cumbersome production process from design to finished product. The cost of exclusive customization is beyond the reach of most ordinary consumers. The application of 3D printing technology solves the most critical problem in jewelry manufacturing.

The limitations and cost issues of wax model making make private customization possible. Today, individual designers can also easily start their own business with 3D printers, and the public can also choose designs according to their wishes at home, add personality and commemorative elements to wedding rings, and jewelry manufacturing is in progress.

3D Printing Jewelry In China

China is the largest jewelry production country in the world. With the rise of the middle class and high-income class in China and the awakening and pursuit of beauty, the sales of jewelry in China are showing an explosive trend year by year. Today, when 3D printing technology has entered various segments of the Chinese market, 3D printing accessories have become a new fashion pursued by fashion lovers, and art designers are also making full use of this technology to continuously explore innovative designs.

Using 3D printing to complete their design works will no longer limit the creative thinking of the wild and unconstrained style, and 3D printing can help designers to see their ideas from the drawings, so that designers and customers can communicate creative ideas more directly, and To shorten the design period and reduce labor, more and more designers use the advancement of this technology to produce high-quality, precise objects with complex geometric structures and elusive shapes.

The Application Of Jewelry 3D Printing

3D printing is being widely used in various fields due to its technical advantages of rapid prototyping, including the jewelry advanced customization industry. Today, 3D printing technology is becoming more and more mature, making jewelry customization, which has always maintained a cold attitude in the past, more down-to-earth. At the same time, 3D printing also solves many production problems that cannot be quickly and accurately displayed due to the design being too complex. Despite this, 3D printed jewelry is still too mysterious for most people.

The Advantage Of Jewelry 3D Printing

Compared with the traditional jewelry production process, the advantages of 3D printing jewelry are:

- Faster: Traditional handmade custom jewelry requires experienced craftsmen to open molds and polish it manually, which is time-consuming and labor-intensive. 3D printed jewelry is more accurate and less time-consuming.

- Cheaper: Traditional handmade jewelry is expensive, and 3D printer jewelry can be mass-produced, which reduces production costs and prices.

- More freedom: Compared with traditional manufacturing, 3D printing technology for complex structures that cannot be completed by hand only needs to be programmed, and even difficult and complex shapes can be printed by computer settings. Therefore, 3D printing technology makes up for This artificial “mishap”.

- More unique: 3D printing has more advantages in jewelry design, and can better meet customers’ personalized customization needs.

Jewelry 3D Printing provides jewelers with enhanced precision, flexibility, and customization options in their manufacturing processes. It enables the creation of intricate designs, personalization, stone setting, prototyping, assembly, surface texturing, and material removal, contributing to the advancement and creativity in the jewelry industry.

Jewelry 3D Printing Service – Jewelry Printing Manufacturer

Jewelry is usually formulated to match the desired final product prototype, requiring three key points:

- Firstly, fine details are necessary to correctly depict the desired product due to the typical small size of jewelry products.

- Second, the problem of smooth surface prototyping becomes critical. The main reason for this is to appreciate the beauty of the part, but also requires post-processing (such as silicon molding, jewelry molds, processing with VLT rubber, and others).

- Finally, tolerances are critical when producing prototypes for the jewelry market as parts are small and need to be an almost perfect match to the CAD drawing desired product. The film layer thickness of BE-CU’s rapid prototyping technology is 16μ, its special smooth surface, and its printing precision, provide a solid and attractive solution.

Push the boundaries of the technology, explore new materials and design applications with us – we love to get involved.

We can advise on materials, designs and even hole placement. We are lucky to work with some excellent jewellery designers and labels, providing them with fantastic quality jewellery and the packaging to.

Metal 3D Printing Service For Jewelry

Metal 3D Printing Jewelry is an innovative precision manufacturing process. 3D printing is a complex and delicate building process where thousands of thin layers are combined to achieve a strength comparable to forging.

It can not only realize the designer’s unconstrained ideas, but also realize these ideas through specific processes. In recent years, with the rapid development of global technology and the increasing demand for personalized and customized products, metal 3D printing jewelry has become an increasingly popular process.

As a leading metal 3D printing manufacturing company, Be-Cu has been committed to providing customers with the most advanced manufacturing solutions and the highest quality products. Through our unique full-process solutions such as raw material selection, component design, equipment technology, heat treatment, stress relief, machining, inspection and testing, we can meet the various needs of customers, whether it is customized single products or mass production.

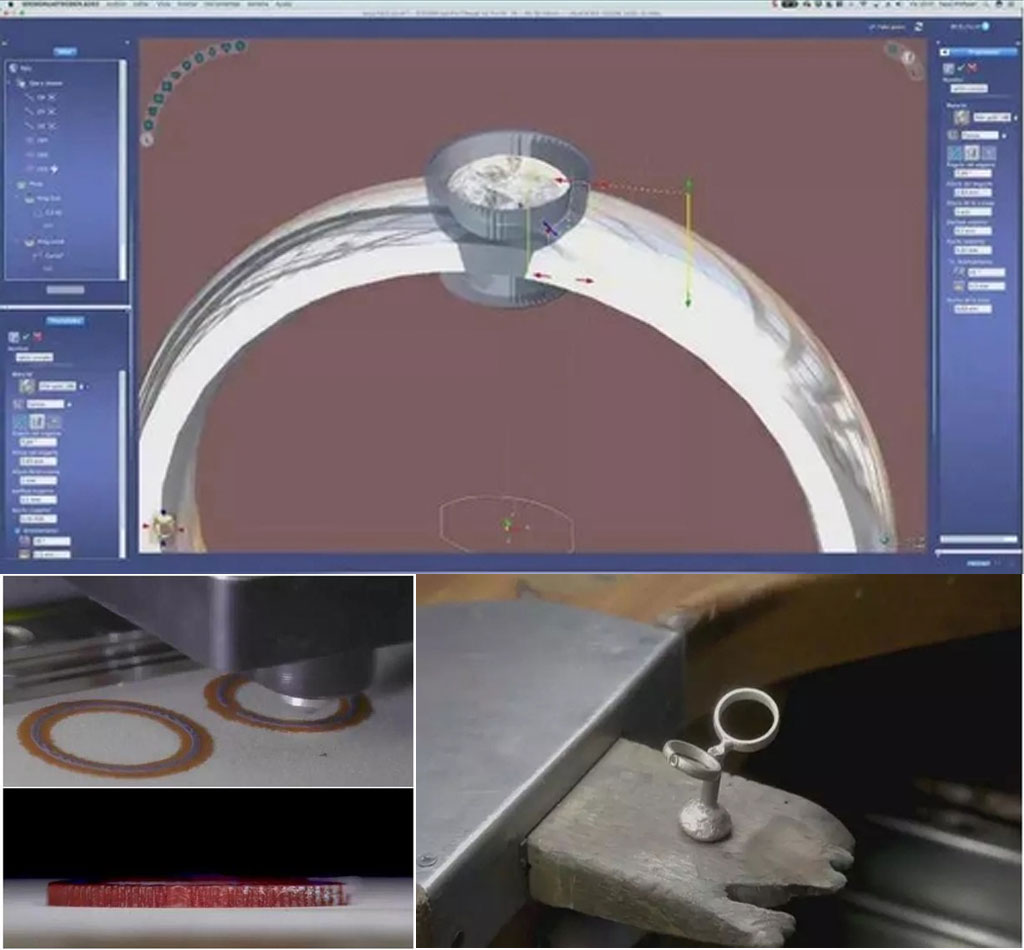

Step-To-Step Process From R&D Design To Volume 3D Printing Jewelry

Design Jewelry

Scan The Jewelry

3D Scanning To Create An Accurate Jewelry Digital Model

Create A Virtual Model

3D Printing Model

Afterwards, the design team carefully inspects the 3D printed diamond ring wax model to ensure that it accurately reflects the original design. This link is a key point for quality control because this is the first sample in the manufacturing process. If the diamond ring If the wax-up copy does not match exactly, the design team will go back to the drawing board to create another usable design.

Casting The Model

Foundry Furnace

The casting bracket is put into the casting furnace for heating

A plaster mold is created around the wax tree, which is vacuumed to remove air bubbles. As the model dries, the inner layer of wax burns, leaving a negative mold of the jewelry, into which molten gold or platinum is poured and allowed to cool.

A ring and its casting model

The final step is to strip the plaster mold from the surrounding gold or platinum and add various jewelry knots to the tree

Assemble Decorations

Setting Gems

Polishing and Engraving

Jewelry Quality Inspection

Jewelry Quality Evaluation

In this way, a piece of 3D printed jewelry is considered complete. 3D printing technology makes up for the “flaws” such as complex lines and hollowing out that craftsmen cannot complete. All plaster molds and wax molds can be operated mechanically with high precision after setting the program, and even complex and changeable shapes can be printed out through computer settings. In addition, compared with those expensive high-end jewelry customization, 3D printing jewelry is undoubtedly affordable for ordinary people.

The Case Studies Of Jewelry 3D Printing

You have a complex jewelry design, Our Jewelry 3D Printing Service can help you turn it into a reality. With the right equipment, strong technical knowledge, and a focus on quality.. From tool design to finishing and then on to shipment, Be-cu prototpe ensure that every project is completed to a high standard and that your orders are delivered on time, every time.

-

3D Scan And SLA Printing Money Tree Ornaments

-

3D Printed Octopus

-

SLA 3D Printing ABS Plastic Flower Bud

-

3D Printing Small Stainless Steel Crafts

-

3D Printing TC4 Metal Globe Table Decoration

-

SLA 3D Printing Black Panther Trophy By Spray Paint

-

Aluminum 3D Printed Dragon Head Chinese Style Man’s Ring

-

SLA 3D Printing ABS Simulation Rattlesnake Car Jewelry

-

SLA 3D Printing ABS Chinese Dragon Arthrosis Jewelry

-

MJF 3D Printing Handicraft Prototype

Online Cooperate With Jewelry 3D Printing Company

Be-cu works with customers all over the world to bring customers ideas to life with the highest quality precision engineered metal components on the planet. We have both precision laser cutting and molds making capabilities that include both conventional and modernized production line. If you are looking for a partnership to help you apply new tools and technologies, or help you fully realize your design vision, let us help you move your business forward, contact our team ([email protected])or quote online today to get the conversation started.