Electronic CNC Machining Solutions

CNC machining has significantly transformed the way electronic parts are designed and produced. Its precision, versatility, and automation capabilities make it an indispensable tool in the modern electronics manufacturing landscape.CNC machining involves the use of computer-controlled machines to precisely cut, shape, and form materials into desired shapes and sizes.As technology continues to advance, CNC machining will continue to drive innovation, enabling the creation of increasingly intricate and efficient electronic components. Embracing this technology ensures that the electronics industry remains at the forefront of precision manufacturing in the digital age.

Applications of CNC Machining in Electronics

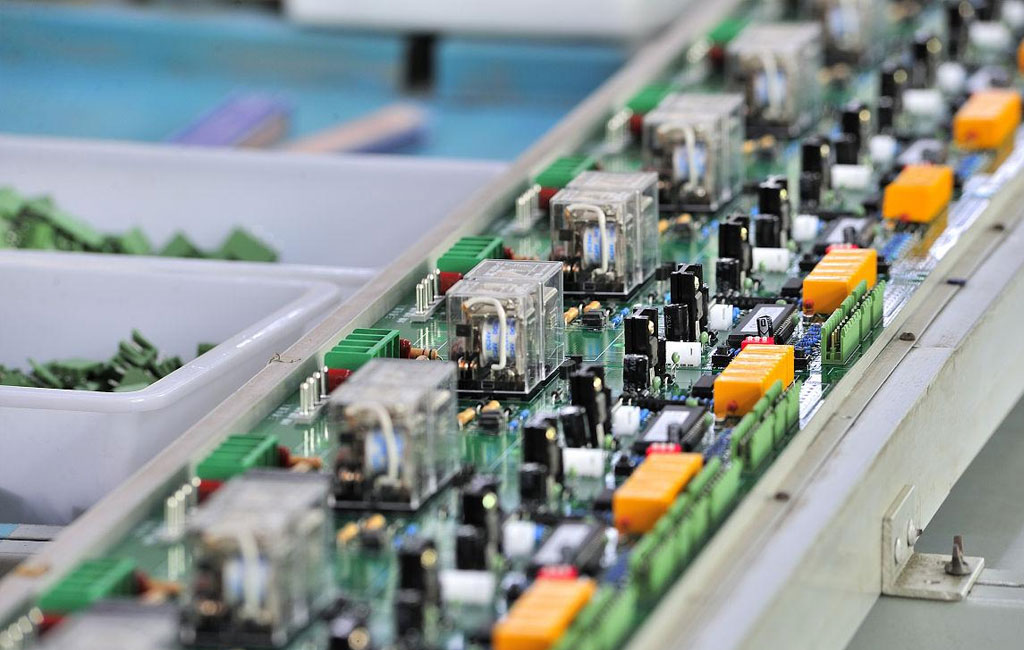

CNC machining has found a multitude of applications within the electronics industry, where precision, consistency, and intricate designs are paramount. From creating complex printed circuit boards (PCBs) to crafting custom enclosures, CNC machining plays a pivotal role in ensuring the functionality and reliability of electronic devices. Here are some key applications of CNC machining in electronics:

Printed Circuit Boards (PCBs)

Connectors and Terminals

Enclosures and Housings

Heat Sinks

Custom Components

Antennas and Waveguides

Insulating and Conductive Gaskets

More Electronic Parts

Custom Electronic Machining & Electronic CNC Machined Parts

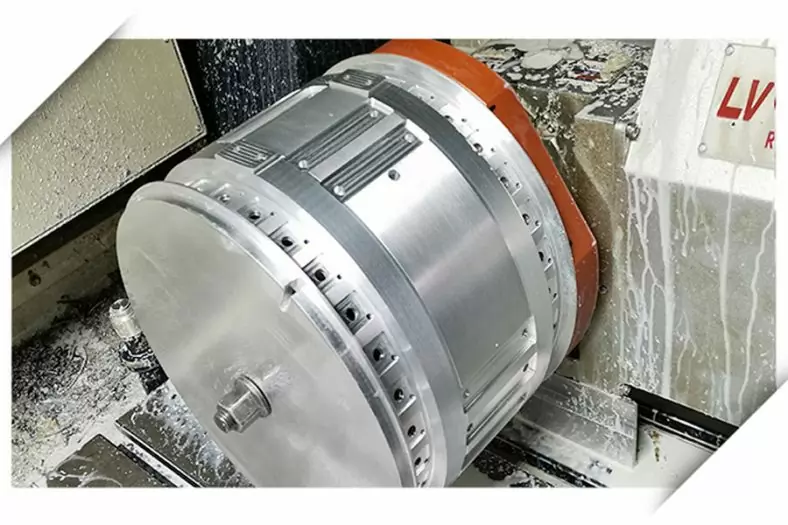

With our roots deeply embedded in the electronic industry, we have created systems around part handling, automated deburring/surface finishing, non-contact dimensional inspection, and QC inspection in relation to standardized aesthetics and components. Our dmu 5 axis machines and swiss machines enable us to form mission-critical components with tight tolerances at high repeatability, and our experience working with large electronic parts company has given us the knowledge required to form parts to meet your expectations.

Be-Cu uses ISO9001:2015 REV D-certified, ITAR-registered machining processes to manufacture electronic parts. We have worked hard to develop a robust ISO9001:2015 certified Quality System, which includes companywide utilization of Custom ERP system for increased quality control.

In addition to our machining centers, we also have CNC lathes for CNC turning options for high-quality machined electronic parts. We utilize a full 5-axis HyperMill CAM system with machine simulation featuring multi-axis machining, hole feature recognition. This system also allows for milling and turning to take place in one operation, saving set up time during high volume projects.

Our following machining capabilities were developed over 30 years. These capabilities have helped us establish a brilliant reputation in the industry.

- CNC Turning,CNC Milling and 5 Axis Machining For Electronic Parts:CNC milling and turning has become an integral part of Electronic machining due to various advantages offered by them. We provide end-to-end CNC milling and turning services to our Electronic customers. Customers regularly approach us for their specific boring, hard turning, peripheral milling, parting, and drilling requirements.

- EDM Machining For Electronic Parts: Our advanced EDM machines allow us to complete complex projects at quick turnarounds, and in tight tolerances up to +/_ 0.0001. We employ 4-axis machining to produce high-quality products. We use various advanced CAM software, which helps us import parts, files, and drawings easily.

- Threading and Tapping For Electronic Parts:Many electronic components require threaded holes or tapped features for mounting screws, fasteners, or connectors. Our Electronic machining service offers precise threading and tapping capabilities, ensuring that these essential features are accurately created to the required specifications. This is particularly important in maintaining the integrity and stability of assembled electronic devices.

- High-Speed Drilling For Electronic Parts:Electronics manufacturing often involves drilling precise holes for components, connectors, and fasteners. Our High-speed dril with CNC machines guarantees accurate hole placement, diameter, and depth. This capability is essential for producing consistent and reliable connections between components in various electronic assemblies.

Our state-of-the-art machining facility combined with our vast industry experience, and expertise makes us one of the preferred vendors for electronic machining projects. Our experts work closely with customers to understand their specific requirements. Also, they can suggest appropriate building materials, and designs according to diverse working conditions. Our world-class customer service and guaranteed quality assurance have won us lots of satisfied clients. To know more, please contact us at the earliest. You can also request a quote for CNC machining in the electronic industry.

Materials We Work With

We have helped our electronic industry clients to machine parts, and components made from the following materials:

Why Choose Our Electronic Machining Service?

- Save time and money for your electronic project but quality guaranteed.

- High productivity, outstanding efficiency and high accuracy

- A wide range of material grades and alloy materials can be machined

- Custom complex electronic machined parts and components at specific tolerances

- High speed machining for prototyping and low to high volume production runs

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

Top China Electronic Cnc Machining Parts & Components

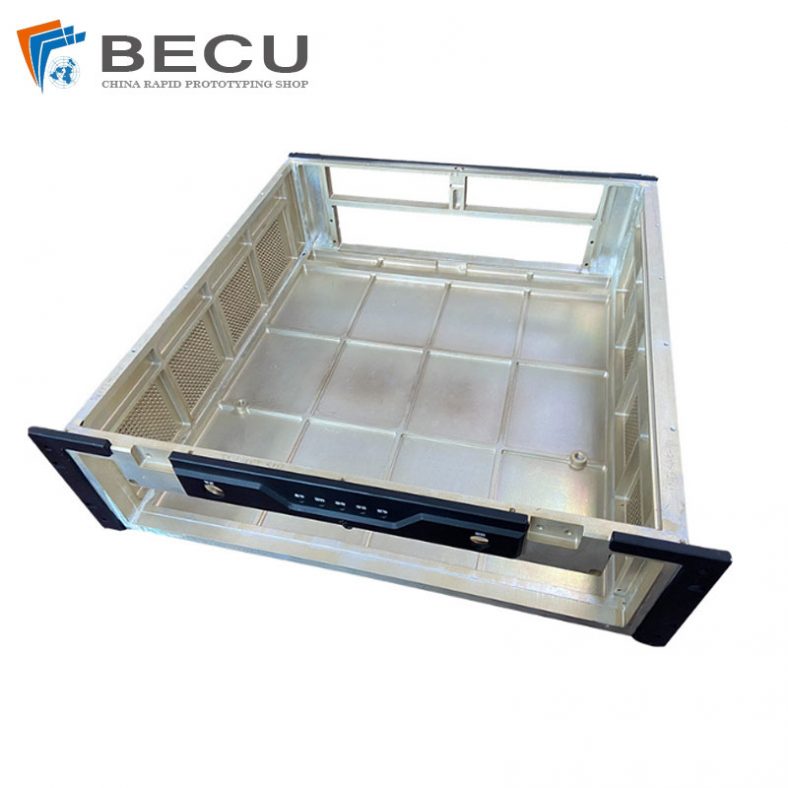

With the continuous maturity and development of CNC Machining technology, more and more electronic manufacturers have introduced this technology for prototype testing, design proofing, parts customization and other applications. By exploring our success stories, you can learn about: the development of CNC Machining in the electronic industry, the application of CNC Machining in electronic molds, how CNC Machining changes the electronic manufacturing supply chain, and more.

-

Precision Machining 6063 Aluminum Military Computer Server Chassis

-

4 Axis CNC Machining Titanium Grade 5 Mobile Phone Buttons

-

Precision Turning 20° Acrylic Downlight Reflector

-

4 Axis Machining Highly Transparent Acrylic LED Tunnel Light Lens

-

CNC Turn-Mill Machining Hastelloy c276 Parts

-

Precision CNC Machining Inconel 718 Cast Impeller

-

Precision Engraving Special-Shaped Natural Color PEEK Parts

-

CNC Turning-Milling Machining Copper Facial Massage Roller

-

Swiss Turning Stainless Steel 17-4 PH Positioning Bushing

-

Screw CNC Machining Non-Standard Mandrel Tube Shaft

-

Turn-Mill Machining Electronic Connector Components

-

Brass Turning Welding Machine Plug

-

Precision Turning Electrostatic Dissipative (ESD) ABS Parts

-

Custom CNC Turning UV-resistant ABS Parts

-

Tungsten Carbide 3D Printer Nozzle

-

Sintering YG6 Tungsten Alloy Non-Slip Thread Screw

-

YG15 Tungsten Cobalt Cemented Carbide Parts

-

CNC Machining Cast Iron Explosion Proof Junction Base

-

CNC Machining Tungsten Cobalt Carbide Punch

-

CNC Machining For Camera L Bracket

-

CNC Machining 6061-T1 Electromagnetic Clutch Parts

-

Precision Machining Security Door Lock Guard Housing

-

Custom Electron Optical Instrument Sight Bracket

-

Customized Optical Instrument Projector Components By 4 Axis Mill

-

Precision Milling Astronomical Telescope Wide-angle Lens Eyepiece Element