Medical Sheet Metal Fabrication

Medical sheet metal fabrication is a specialized manufacturing process used in the healthcare industry to produce various components and equipment made from sheet metal materials. Sheet metal fabrication involves cutting, bending, and shaping thin sheets of metal to create custom parts and products used in medical devices, equipment, and facilities.Commonly used sheet metal materials in medical fabrication include stainless steel, aluminum, and various alloys. These materials are chosen for their corrosion resistance, durability, and compatibility with sterilization processes.

These components are critical for the healthcare industry, as they are used in a wide range of applications, including medical devices, hospital furniture, surgical instruments, and more. The precision, quality, and compatibility requirements make it a crucial aspect of medical device and equipment production.

ISO:9001 Sheet Metal Fabrication For The Medical Industry

When medical devices manufacturers need custom Critical Healthcare parts and components for hospital and medical equipment factory, Be-Cu prototype has been here to fill that need for the last 20 years. We have manufactured medical parts with precise medical CNC Machining Services and medical Sheet Metal Fabrication Services to help meet the demands of the increased market for medical.

Located just China, we are a metal fabrication company ready for low-volume prototypes to large production orders. Medical Sheet metal manufacturing starts with a design. Each one carefully crafted and thought out to produce optimum results. Using this technique, we turn flat metal sheets into different parts by bending, perforating, cutting, and designing. Every sheet metal can be transformed into many different forms. However, we carefully select the materials. We used high-end aluminum sheets, steel sheets, stainless steel, brass, and more. According to your exact specifications, we guarantee high-precision car sheet metal parts.The end-result being a high-quality, performance enhancing component manufactured by some of our top engineers in the world of metal fabrication.

We would be delighted to collaborate with you on your upcoming projects and provide you with solutions that align with your needs. Our team is available to discuss your requirements, answer any questions you may have, and provide you with a detailed proposal tailored to your project’s specifications.

Please feel free to contact us at [email protected] to schedule a consultation or to request more information about our services.

Medical Sheet Metal Techniques

- Cutting: Shearing, laser cutting, plasma cutting, and waterjet cutting are common methods used to cut sheet metal into desired shapes and sizes.

- Bending: Press brakes and other bending equipment are utilized to bend sheet metal into angles and shapes according to design specifications.

- Forming: Roll forming and stamping are techniques employed to shape sheet metal into complex geometries.

- Welding: Welding joins separate pieces of sheet metal together using various methods such as MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding.

- Assembly: Assembly involves joining different components created through sheet metal fabrication to create a final product or structure.

Medical Sheet Metal Materials

Sheet metal is a widely used form of raw material, usually 0.006 and 0.25 inches thick sheet used in sheet metal fabrication. Sheet metal enclosures are typically constructed from thin metal sheets, such as steel, aluminum, or stainless steel. The choice of material depends on factors like the desired strength, durability, corrosion resistance, and weight requirements.

- Aluminum: Al 5052, 6061,6063 etc

- Copper: C101, C110, brass (C260) etc

- Stainless Steel: SS 301, 304, 316/316L etc

- Steel: low carbon steel etc

-

Stainless Steel Sheet Metal Fabrication

-

Aluminum Sheet Metal Fabrication

-

Copper Sheet Metal Fabrication

-

Brass Sheet Metal Fabrication

-

Steel Sheet Metal Fabrication

-

Titanium Sheet Metal Fabrication

-

Galvanized Steel Sheet Metal Fabrication

-

Mild Steel Sheet Metal Fabrication

-

Bronze Sheet Metal Fabrication

Medical Sheet Metal Fabrication By Surface Finish

The fabricated enclosure may undergo various surface treatments and finishes, such as powder coating, painting, anodizing, or plating. These processes enhance the aesthetics, provide protection against corrosion, and improve the overall durability of the enclosure. Here are some common surface finishes used in medical sheet metal fabrication:

Anodizing Medical Sheet Metal Fabrication

Brushed Medical Sheet Metal Fabrication

Galvanized Medical Sheet Metal Fabrication

Plating Medical Sheet Metal Fabrication

Polishing Medical Sheet Metal Fabrication

Powder Coated Medical Sheet Metal Fabrication

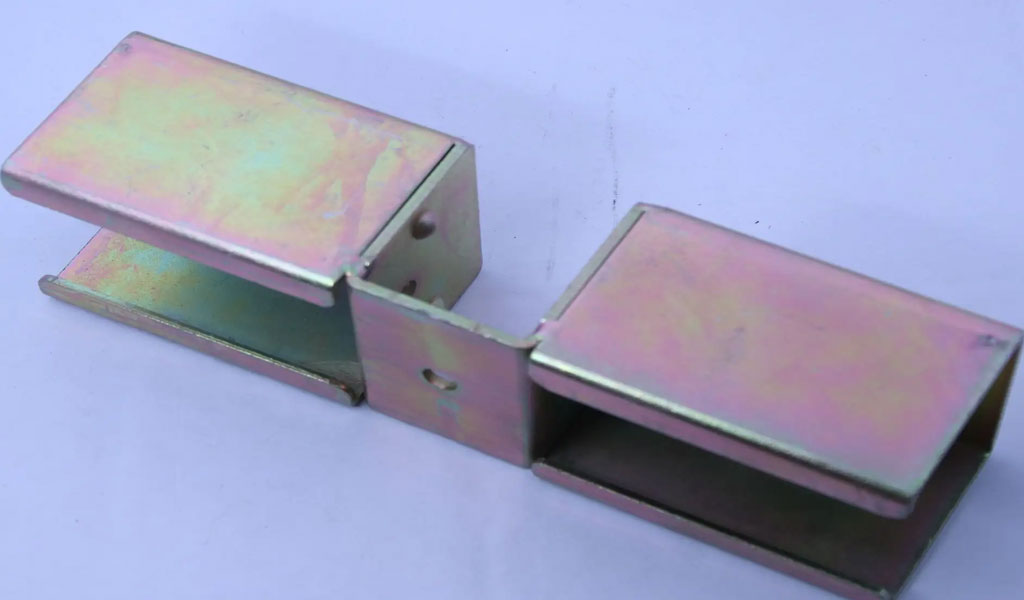

Custom Medical Sheet Metal Fabrication Parts Gallery

BE-CU prototype performed complete medical sheet metal fabrication services. Cutting, punching, bending, welding, and assembling are among our operations. Sheet metal boxes are useful in numerous industries. Such as electronics, automotive and offshore industries, and more. Moreover, BE-CU can create Medical Sheet Metal Fabrication parts to meet your specifications. Whatever your application is, we have sheet metal that will work best for its fabrication.

BE-CU prototype provides Medical Sheet Metal Fabrication and several secondary and support service to take your project from start to finish. Request a quote for your Medical Sheet Metal Fabrication project today or contact us to learn more about our Medical Sheet Metal Fabrication process.

The Application Of Medical Sheet Metal Fabrication

Medical sheet metal fabrication is a specialized manufacturing process used to create a wide range of critical components and equipment for the healthcare industry.Here are some examples of products that can be produced through this process:

Surgical Instruments

Medical Carts

Hospital Beds

Diagnostic Equipment Housings

Medical Device Components

Laboratory Equipment

Sterilization Containers

Medical Cabinets and Shelving

Dental Equipment

Medical Enclosures

Operating Room Fixtures

Medical Equipment Panels

These examples illustrate the diverse range of products and components that can be created through medical sheet metal fabrication, all of which are essential to the functioning of healthcare facilities and the delivery of medical care.