China Online Custom Powder Metallurgy Services

Efficient and consistent, powder metallurgy (PM) is a value-added engineering process that provides a host of advantages over competing metal-forming technologies. Powder metallurgy has similarities with the production of ceramics, and both belong to powder sintering technology. Therefore, a series of new powder metallurgy technologies can also be used for the preparation of ceramic materials. As unique, highly developed method of manufacturing ferrous and nonferrous parts,It is a versatile, cost-effective, and constantly expanding technology that is rapidly gaining worldwide popularity. The powder metallurgy products often go far beyond the scope of materials and metallurgy, Be-cu has been using metal powder injection molding (MIM) technology and ceramic powder injection molding (CIM) technology to produce precision stainless steel part, iron based parts, ceramic products, tungsten parts etc

With years of experience in powder injection molding and powder injection molding, BE-CU has the expertise to produce custom PM with various powder metallurgy processes and techniques. From designs to production to shipping, we can meet your requirements at each stage. Capable of sintering parts less than 1/8 in. to 10 in. sq. surface area. Press capacity ranges from 2 to 300 tons. Secondary services such as turning, milling, tapping, honing, deburring and ball burnishing provided. Whether you want to find the manufacturers of MIM powder metallurgy parts, CIM powder metallurgy parts, powder metallurgy mold, or other types of powder metallurgy, we’ll deliver top-quality products with a fast turnaround. From ceramic to hard metals, a wide selection of materials with excellent properties are provided. We can also help you in the design and review of almost all types of PM parts to enhance their functionality and manufacturability.

Powder Metallurgy Process

- Product design

- Powder metallurgy mold design

- Powder metallurgy mold manufacturing

- Metal Powder

- Binder

- Metal Feeding

- Injection molding

- Degreasing

- Sintering

- Reprocessing (parts)

- Inspection

- Finished Product

MIM PM Process

- Metal Powder

- Mix

- Injection Molding

- Degreasing

- Sintering

- Post-Processing

Powder Metallurgy Material

- Metal

- Ceramics

- Intermetallic Compound

- Cermet

- Magnetic Material(Soft Magnetic Materials And Hard Magnetic Materials)

- Composite and functional materials

- Thermoelectric material

- Functionally graded materials

- Composite functional materials

The Advantage Of BE-CU Powder Metallurgy Service

BE-CU Prototype has 14 years of experience in powder metallurgy R&D and application, masters advanced process technologies such as MIM and PM to help partners solve new material problems, provides technical support for many fields and disciplines, and focuses on metal powder press forming and metal powder injection Molding technology, has independent research and development patent results, passed the ISO9001 quality system certification, adhering to the concept of excellence, and the products are selling well all over the world.

- – Each service provides an in-depth understanding of customer needs, product application environment, current problems and difficulties, and provides overall solutions.

- – Product design customization, proofing and confirmation, combined with the strong production capacity and advanced equipment technology of the two major R&D and manufacturing bases, escort the quality of customers’ products, and 99% of the products are delivered within the specified deadline.

- – More than 20 professional R&D technical teams with returnees as the core provide professional advice to customers, participate in customer product design, and help plan optimization.

Welcome to send your inquiry or custom designs of Powder Metallurgy parts to be made, we’ll send you a free quote within 24 hours in working days and work out a schedule for recording the progress.

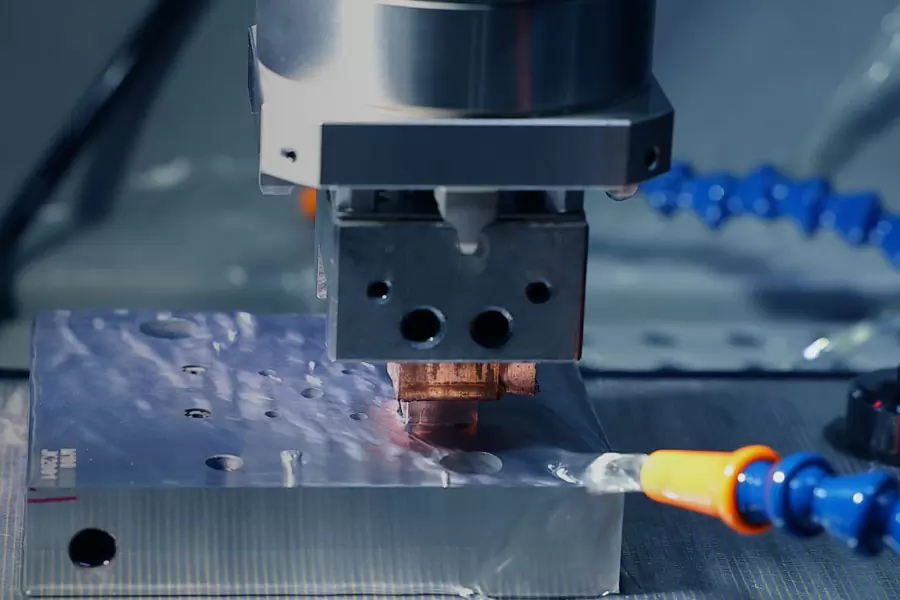

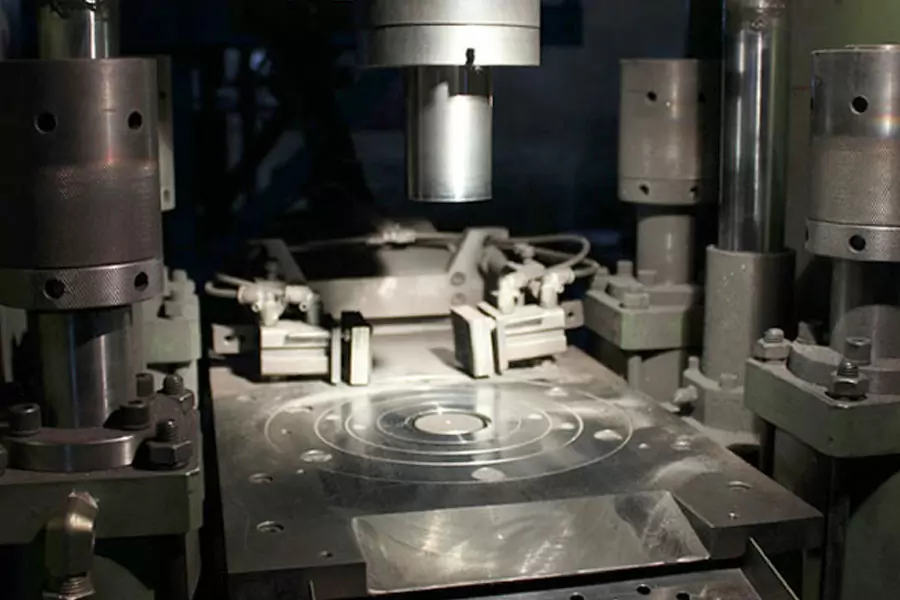

Our Outstanding Powder Metallurgy Equipment

- Powder Metallurgy Molding Machine

- Continuous Mesh Belt Sintering Furnace

- Vacuum Sintering Furnace

- Punching Machine

- Gear Meshing Instrument

- CMM Measuring Machine

- Cnc Machining Center

- Tensile Testing Machine

- Check Out BE-CU Equipment List

-

Carbide Tungsten Valve Seat For Oil And Gas Industry

-

Custom Hexahedron Tungsten Dnd Dice

-

Tungsten Carbide 3D Printer Nozzle

-

Sintering YG6 Tungsten Alloy Non-Slip Thread Screw

-

YG15 Tungsten Cobalt Cemented Carbide Parts

-

CNC Machining Tungsten Cobalt Carbide Punch

-

Powder Metallurgy Sector Gear

-

High-Strength Small Powder Metallurgy Gears

-

SMF5040 Powder Metallurgy Parts

-

Powder Metallurgy Automotive Shock Absorber Guide Parts

-

Tin Bronze Motor Spherical Oil Bearing

-

High-Precision Hydraulic Vane Oil Pump Rotor