CNC Machining For Aerospace Industry

In the world of aerospace engineering, where every millimeter can make the difference between success and failure, precision is paramount. The aerospace industry relies heavily on cutting-edge technology and expertise to produce components that meet the rigorous demands of flight. At the heart of this precision-driven endeavor lies the machine shop, a crucial player in the aerospace manufacturing process.

The aerospace industry operates in an environment of extreme conditions, from the frigid cold of high altitudes to the scorching heat generated during reentry. In this unforgiving realm, the materials and components used must exhibit unmatched quality, strength, and durability. This is where machine shops come into play.

Be-Cu is dedicated to producing precision aerospace components machined to the highest accuracy for their specific application.Machine shops dedicated to aerospace engineering are more than just workshops; they are centers of innovation and precision. These specialized facilities house an array of advanced machinery, such as Computer Numerical Control (CNC) machines, which use computer programs to control machining tools with remarkable accuracy. These machines can sculpt intricate components from various materials, ranging from lightweight composites to high-strength metals like titanium and Inconel.

Superior Aerospace Machining Shop – Aerospace Cnc Machining Companies

Be-Cu prototype uses a variety of materials to make aerospace parts & components, but we has extensive experience in aerospace CNC machining small, medium and large components with high accuracies to ±.0001″. Some aerospace machining include impeller cnc machining, aircraft machining and more. We offer a full complement of aerospace parts manufacturing services, from prototype to production. Whether your requirement is for small, ultra-precise machined components, intricate structure projects or high production of established products.There are a number of different types of material used in manufacturing, and each one has different qualities, benefits, and needs when being used in the manufacturing process.At Be-Cu prototype, we have decades of experience in aerospace machining using:

- Aluminum Alloys: Aluminum and its alloys are widely used in aerospace due to their lightweight nature and good strength-to-weight ratio. They are commonly used for parts such as aircraft frames, skins, and structural components.

- Titanium Alloys: Titanium alloys are known for their high strength-to-weight ratio, corrosion resistance, and ability to withstand high temperatures. They are used in components such as aircraft engine parts, landing gear, and structural components.

- Stainless Steel: Certain stainless steel alloys are chosen for their corrosion resistance and strength. They can be found in components such as aircraft exhaust systems and fasteners.

- Nickel-Based Alloys: Nickel-based superalloys are used in high-temperature environments like aircraft engines, where they offer excellent creep resistance and thermal stability.

- Composites: Composite materials, such as carbon fiber-reinforced polymers (CFRP) and fiberglass-reinforced polymers (GFRP), are used to create lightweight yet strong structures. They’re commonly used in aerospace for parts like aircraft wings, fuselage sections, and rotor blades.

- Superalloys: Superalloys are used in extreme conditions where high-temperature resistance and strength are crucial. They find applications in turbine blades, combustion chambers, and other engine components.

- Copper Alloys: Copper alloys are used for their electrical conductivity and thermal properties. They can be found in electrical connectors and conductive components.

- Magnesium Alloys: Magnesium alloys are used in aerospace due to their lightweight properties, although they are less common than aluminum and titanium alloys. They are used in non-critical components to save weight.

- Plastics and Polymers: Certain plastics and polymers are used for non-structural parts or components that require specific properties, such as insulation, vibration dampening, or chemical resistance.

- Ceramic Matrix Composites (CMCs): CMCs are designed to withstand extremely high temperatures and are used in components like heat shields and parts within the hot sections of jet engines.

There are many applications for precision machined parts within the various aerospace industry markets. Some of the most common component applications include:

- PARTS FOR OXYGEN GENERATION

- SEATS

- TURBINE BLADES

- SHAFTS

- VALVE COMPONENTS

- ELECTRICAL CONNECTORS

- HOUSINGS

- CASTINGS

- STRUCTURAL COMPONENTS

- FILTER BODIES

- AEROSPACE COUPLERS

- FLANGES

- RETAINER RINGS

- GUIDANCE FINES

- AND MUCH MORE

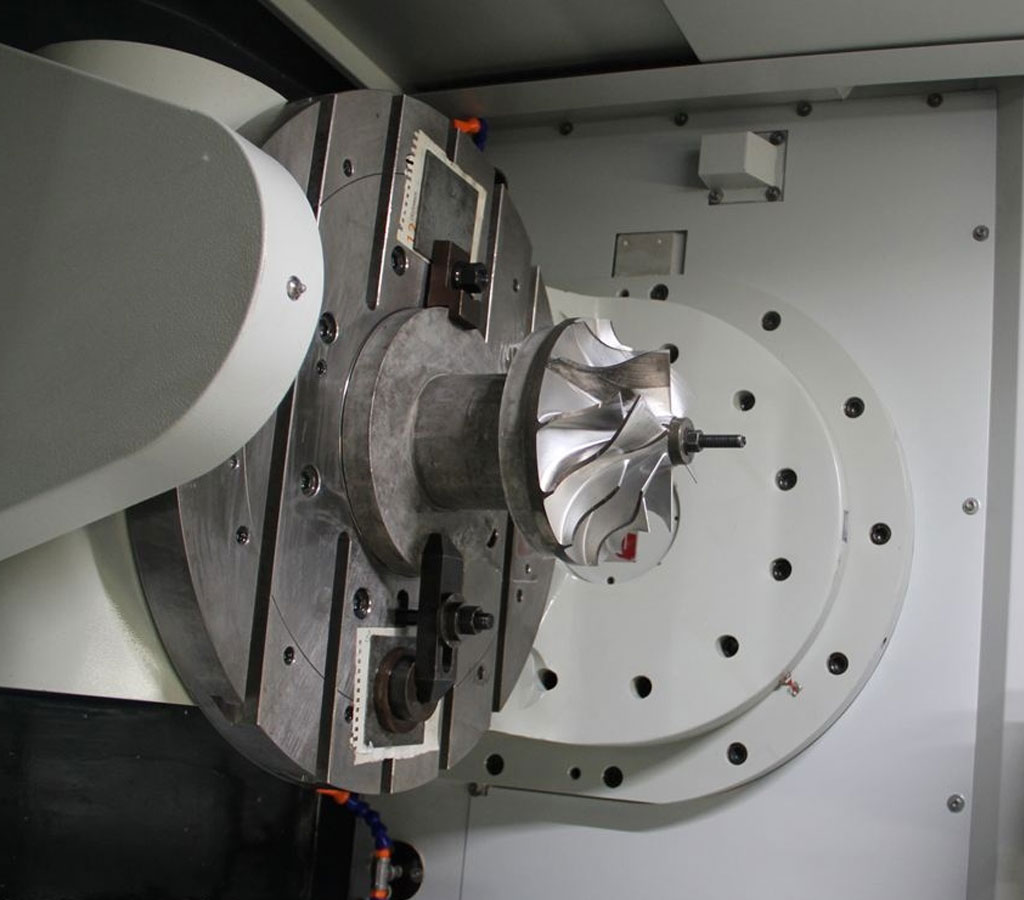

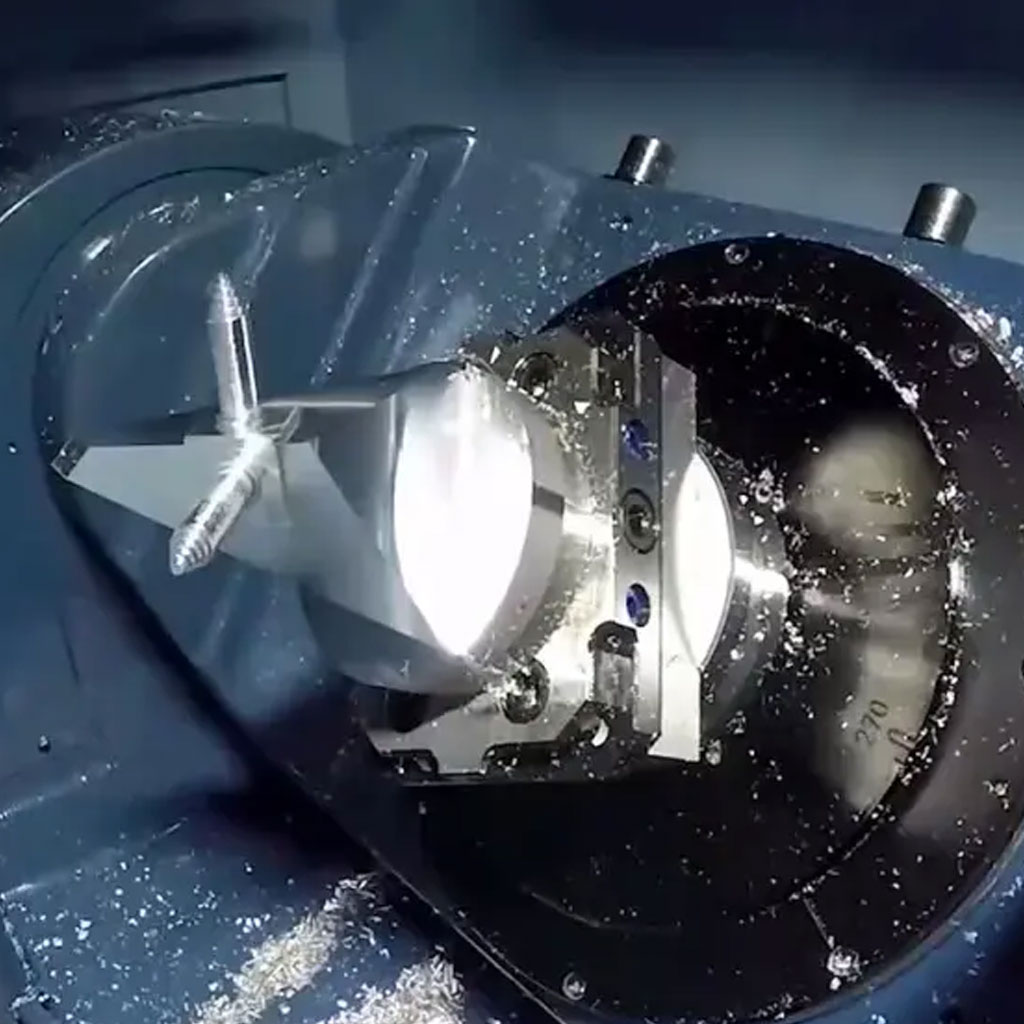

5-Axis Milling Machining for Aerospace

Aerospace Parts makers require the most exact production to do their job right. 5-axis milling allows the tool to approach the workpiece from different directions, enabling the creation of intricate shapes and contours.And it allows for continuous tool engagement with the workpiece, resulting in smoother surface finishes and reduced tool marks.Be-Cu use 5-axis Milling to fabricate custom parts for use in Aerospace.

With 5-axis machining, we can significantly reduce setup times and execute multi-sided machining in a single operation. This efficiency not only accelerates the manufacturing process but also minimizes the possibility of errors during setup changes.Of course, your micromachining, 5-axis or Swiss CNC machining precision parts are only as good as the operators behind them, which is why you need Be-Cu prototype.

Precision Aerospace Machining

Precision aerospace machining is a specialized manufacturing process that involves the use of advanced machining techniques and technologies to create high-precision components for the aerospace industry. Aerospace components often require extremely tight tolerances to ensure proper fit, performance, and safety. Precision machining techniques are employed to achieve these tight tolerances, sometimes measured in micrometers or even sub-micrometer levels.

Be-Cu employs advanced techniques such as Computer Numerical Control (CNC) machining, multi-axis machining, and high-speed machining. These techniques can rotate and tilt the workpiece,allow for complex shapes, contours, and features to be accurately produced.Rigorous quality control and inspection processes are integral to precision aerospace machining. Be-Cu prototype offering advanced measurement service, such as Coordinate Measuring Machines (CMMs), laser scanners, and optical comparators, are used to verify component dimensions and tolerances.

Whether your own CNC machines are having trouble achieving the tight tolerances or detailed intricacies your product requires, you’re in need of high-quality parts manufactured on a mass level or you just need a few aerospace parts made for your project company; Be-Cu prototype offers ultra-precision CNC from cnc machining industry leaders. As an ISO 9001:2015 Certified CNC Machine Shop that only employs the highest trained professionals, you’re assured that each and every one of our services exceeds industry quality standards. We are equipped to successfully machine complex aerospace parts.Contact [email protected] today to learn more about how our precision cnc machining process is the right choice for your aerospace manufacturing needs.

Why Choose Our Aerospace Machining Service?

- Save time and money for your Aerospace project but quality guaranteed.

- High productivity, outstanding efficiency and high accuracy

- A wide range of material grades and alloy materials can be machined

- Custom complex Aerospace machined parts and components at specific tolerances

- High speed machining for prototyping and low to high volume production runs

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

Top China Aerospace Cnc Machining Parts & Components

With the continuous maturity and development of CNC Machining technology, more and more Aerospace manufacturers have introduced this technology for prototype testing, design proofing, parts customization and other applications. By exploring our success stories, you can learn about: the development of CNC Machining in the Aerospace industry, the application of CNC Machining in Aerospace molds, how CNC Machining changes the Aerospace manufacturing supply chain, and more.