Custom Magnesium Parts

- Global delivery as fast as 30 days

- Machined prototypes in as fast as 9 days.

- Perfect Service And High Quality

- Tolerances down to +-0.005mm

- ISO 9001:2015, ITAF 16949

>>>All uploaded drawings are strictly confidential, check the confidentiality agreement

Fabrication Magnesium Parts Supplier – Custom Magnesium Components Manufacturer

In the elastic range, when magnesium alloy is subjected to impact load, the energy absorbed is half that of aluminum alloy parts, so magnesium alloy has good shock resistance and noise reduction performance. The melting point of magnesium alloy is lower than that of aluminum alloy, and the die-casting performance is good. The tensile strength of magnesium alloy castings is equivalent to that of aluminum alloy castings, generally up to 250MPA, and up to more than 600Mpa. The yield strength and elongation are not much different from those of aluminum alloys. Magnesium alloy also has good corrosion resistance, electromagnetic shielding performance, radiation protection performance, and can be 100% recycled. Magnesium alloy parts have high stability and die castings have high dimensional accuracy and can be machined with high precision.As a professional fabrication supplier,Be-cu offering magnesium alloy die casting and some magnesium cnc machining.Be-cu has been making magnesium parts of various sizes, from miniature to oversized, and various shapes, from simplest to the most complicated.

• Empowered by 100+ advanced facilities

• 10000+ case studies produced

• Serving 3000+ clients worldwide

• Supported by hundreds senior machinists with over 20 years of experience

Be-cu Shop has custom magnesium parts for over 10 years. You can design and order your parts with our free rapid quote tooling or upload your own CAD file to our email:[email protected] for a fast quote.

What Is Magnesium Parts – Magnesium Define

Magnesium Parts are actually pure magnesium or magnesium alloy parts obtained by various manufacturing methods.

Molecular formula of magnesium-aluminum alloy: Mg4Al3 Molecular weight: 178.22 The color is grayish brown, the specific gravity is about 2.15g/cm3, the melting point is 463℃, and the temperature generated during combustion reaches 2000℃-3000℃. It plays a very important role as a reducing agent in the production process of fireworks, and can also be used as a white light agent and a lighting agent. Magnesium-aluminum alloy is made by melting magnesium ingot and aluminum ingot at high temperature in protective gas. For a long time, there have been two theories about the structure of magnesium-aluminum alloys. One argument is that the magnesium-aluminum alloy is a simple physical mixture;

Another argument is that the crystal structure of the magnesium-aluminum alloy has changed, not a simple physical mixture. When the magnesium ingot and aluminum ingot are higher than 1150K, part of the aluminum reacts with oxygen in the air to generate a-Al2O3. The chemical properties of this crystal of alumina are inert and play a role of barrier and isolation. When it is lower than 1150K, it is born in B-Al2O3 and this crystal reacts with acid, which cannot protect the inner magnesium-aluminum alloy.

Magnesium alloys are widely used in portable equipment and automobile industries to achieve the purpose of lightweight. Although the specific gravity of magnesium alloys is heavier than that of plastics, the strength and elastic modulus per unit weight are higher than those of plastics. Therefore, in the case of parts with the same strength, magnesium alloy parts can be made thinner and lighter than plastics. In addition, since the specific strength of magnesium alloy is also higher than that of aluminum alloy and iron, the weight of aluminum or iron parts can be reduced without reducing the strength of the parts. Magnesium alloys have the highest relative specific strength (ratio of strength to mass). The specific stiffness (ratio of stiffness to mass) is close to aluminum alloy and steel, much higher than engineering plastics.

Custom Magnesium Parts Applications – What is Custom Magnesium Parts Used for

Because the fabrication allows a very high precision without altering the structure of the material with a good rate of manufacture, fabrication is becoming increasingly common as its machine range, control systems and cutting tools are just growing. Our fabrication service is used to produce a variety of custom-designed fabrication parts and products in all areas of the industry:

The Case Studies Of Custom Magnesium Alloy Parts

You have a complex magnesium alloy parts design, Our cnc machining and die casting magnesium alloy service can help you turn it into a reality. With the right equipment, strong technical knowledge, and a focus on quality.. From tool design to finishing and then on to shipment, Be-cu prototpe ensure that every project is completed to a high standard and that your orders are delivered on time, every time.

-

Extrusion Die-casting Magnesium Alloy Heat Sink Shell

-

Manufacturers Open Mold Casting Magnesium Alloy Shell

-

AZ61A Magnesium Alloy Die Casting Machinery Parts

-

AZ61M Magnesium Alloy Die Casting Machinery Parts

-

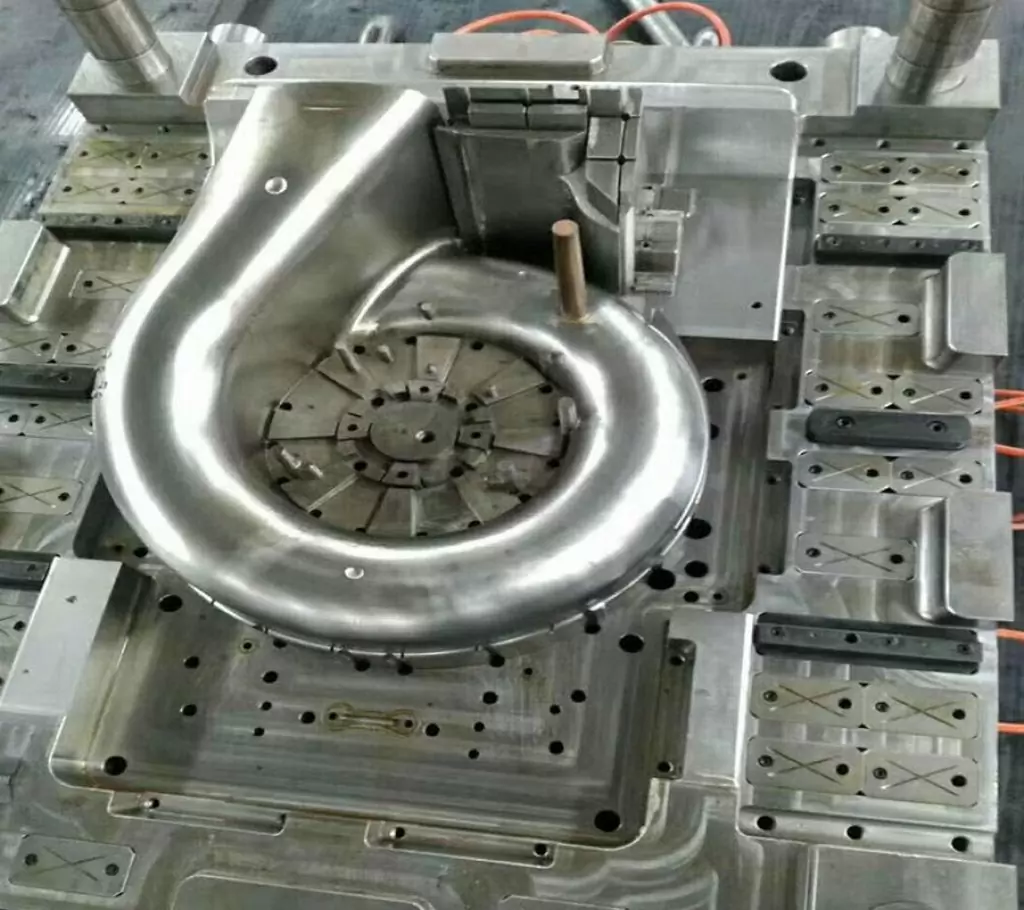

Custom Magnesium Alloy Car Steering Wheel By Die Casting

-

Magnesium Die Casting Mechanical Equipment Parts