Stainless Steel Parts

- Global delivery as fast as 30 days

- Machined prototypes in as fast as 9 days.

- Perfect Service And High Quality

- Tolerances down to +-0.005mm

- ISO 9001:2015, ITAF 16949

>>>All uploaded drawings are strictly confidential, check the confidentiality agreement

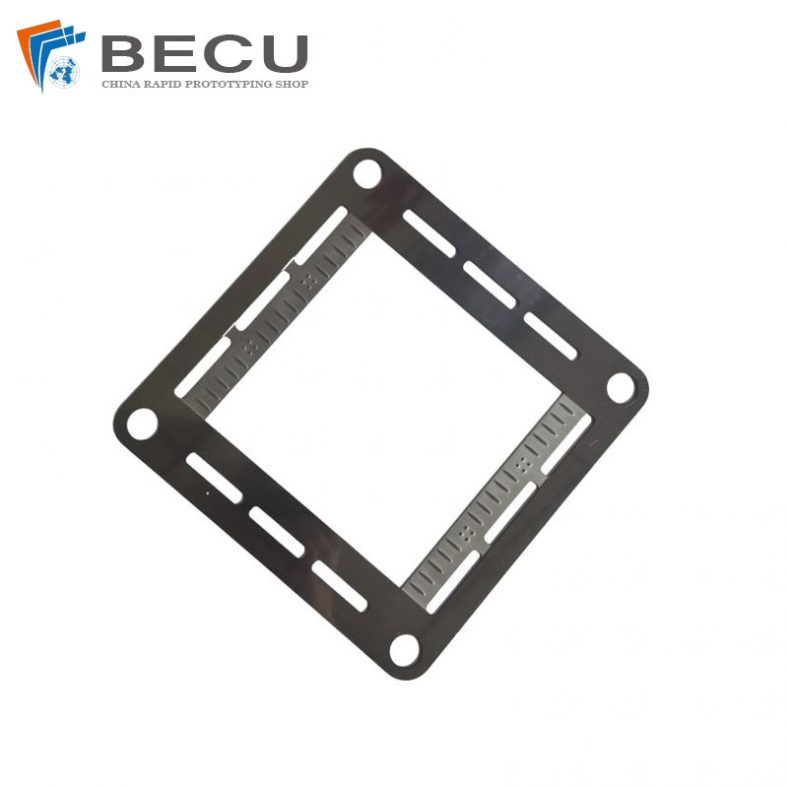

Custom Stainless Steel Parts Supplier – Fabrication Stainless Steel Parts Manufacturer

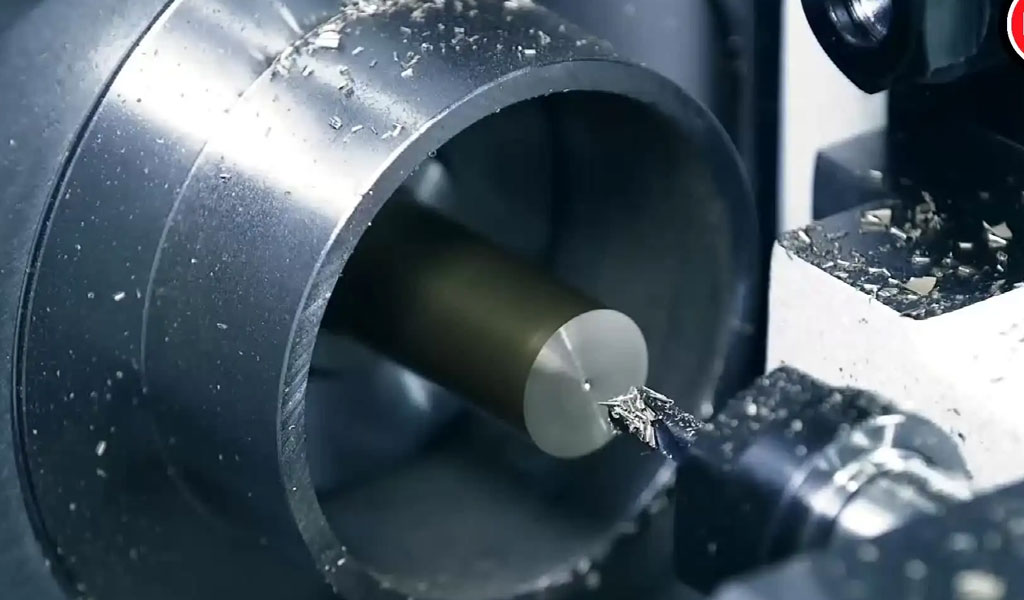

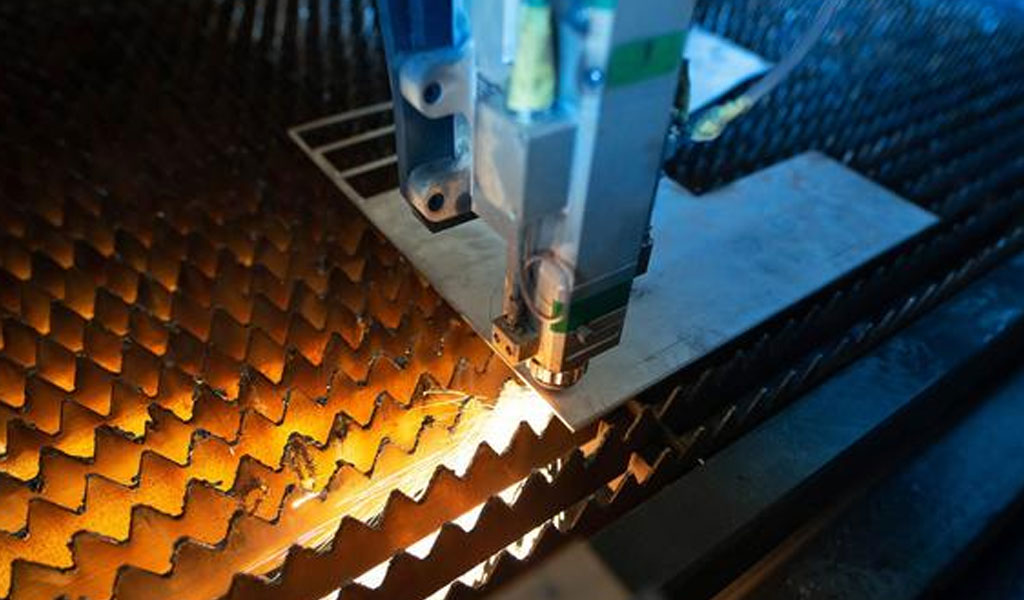

Stainless steel are generally more challenging to metal parts manufacturing than standard carbon steel and a general rule is that the higher a steel’s alloying content, the more difficult it is to fabrication. Looking for low cost custom stainless steel parts with unparalleled quality?As a China-leading stainless steel fabrication company, we can employ multi fabrication custom stainless steel parts to ensure efficiency and accuracy, even the most complex geometries and tight tolerances are required. Fabrication stainless steel parts are fabricated based on customer requirements or CAD drawings submitted, our engineers and designers will help you improve the models to gain the best outcomes and reduce costs.

• Empowered by 100+ advanced facilities

• 10000+ case studies produced

• Serving 3000+ clients worldwide

• Supported by hundreds senior machinists with over 20 years of experience

Be-cu Shop has custom stainless steel parts for over 30 years. You can design and order your parts with our free rapid quote tooling or upload your own CAD file to our email:[email protected] for a fast quote.

What Is Stainless Steel Parts – Stainless Steel Define

Stainless steel (Stainless Steel) is defined in GB/T20878-2007 as a steel with stainless steel and corrosion resistance as its main characteristics, with a chromium content of at least 10.5% and a carbon content of not more than 1.2%.Stainless Steel parts are actually pure stainless steel or stainless steel alloy parts obtained by various manufacturing methods.

Stainless Steel is the abbreviation of stainless and acid-resistant steel. The steel that is resistant to weak corrosive media such as air, steam and water or has stainless steel is called stainless steel; Corroded steel is called acid-resistant steel.Due to the difference in chemical composition of the two, their corrosion resistance is different. Ordinary stainless steel is generally not resistant to chemical medium corrosion, while acid-resistant steel is generally stainless. The term “stainless steel” does not simply refer to one type of stainless steel, but to more than one hundred industrial stainless steels, each developed to perform well in its specific field of application. The key to success is to first understand the application and then determine the correct steel grade. There are usually only six steel grades associated with building construction applications. They all contain 17-22% chromium, and the better grades also contain nickel. The addition of molybdenum can further improve atmospheric corrosion, especially corrosion resistance to chloride-containing atmospheres. Generally speaking, the hardness of stainless steel is higher than that of aluminum alloy, and the cost of stainless steel is higher than that of aluminum alloy.

Stainless steel is often divided into: martensitic steel, ferritic steel, austenitic steel, austenitic-ferritic (duplex) stainless steel and precipitation hardening stainless steel according to the structure state. In addition, it can be divided into: chromium stainless steel, chromium-nickel stainless steel and chromium-manganese-nitrogen stainless steel according to the composition.

The corrosion resistance of stainless steel decreases with the increase of carbon content. Therefore, the carbon content of most stainless steels is low, the maximum is not more than 1.2%, and the ωc (carbon content) of some steels is even lower than 0.03% (such as 00Cr12 ). The main alloying element in stainless steel is Cr (chromium). Only when the Cr content reaches a certain value, the steel has corrosion resistance. Therefore, stainless steel generally has a Cr (chromium) content of at least 10.5%. Stainless steel also contains elements such as Ni, Ti, Mn, N, Nb, Mo, Si, and Cu.

Experienced To Offer More Manufacturing Options

Upholding this standard requires an exceptional commitment to manufacturing resources. The wide variety of machining technology options in the Pintejin Group machine library is supported by an in-house tooling capability that adapts tools to the unique characteristics of each material.Our stainless steel science engineers will help you choose suitable metal alloys and machining processes(include stainless steel cnc machining and more) to address your part-making needs.

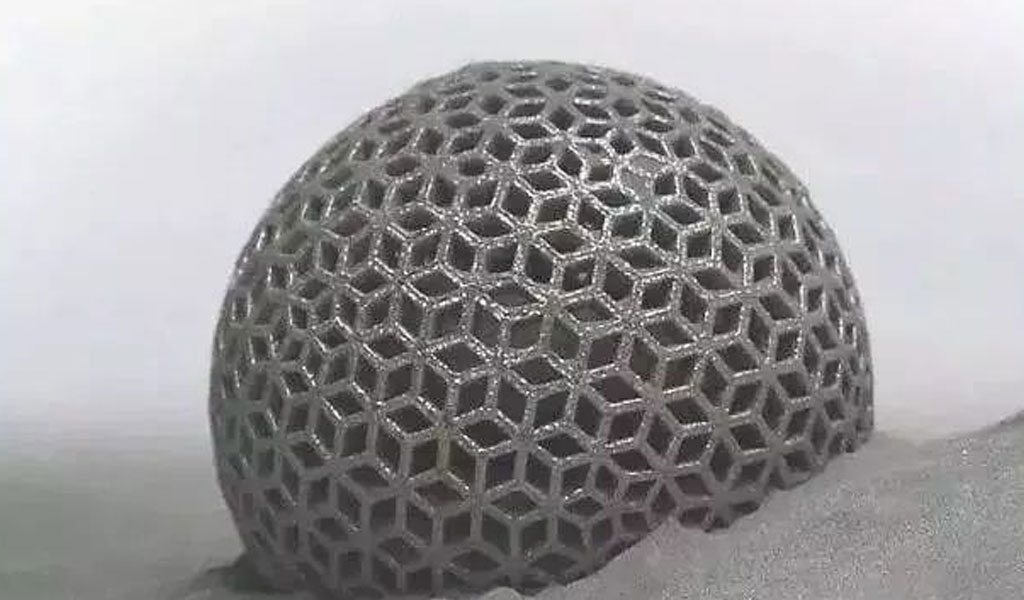

Stainless Steel 3D Printing

Stainless Steel Sand Casting

Stainless Steel Parts Applications – What is Custom Stainless Steel Parts Used for

Because the fabrication allows a very high precision without altering the structure of the material with a good rate of manufacture, fabrication is becoming increasingly common as its machine range, control systems and cutting tools are just growing. Our fabrication service is used to produce a variety of custom-designed fabrication parts and products in all areas of the industry:

The Case Studies Of Custom Stainless Steel Parts

You have a complex stainless steel parts design, Our fabrication service can help you turn it into a reality. With the right equipment, strong technical knowledge, and a focus on quality.. From tool design to finishing and then on to shipment, Be-cu prototpe ensure that every project is completed to a high standard and that your orders are delivered on time, every time.

-

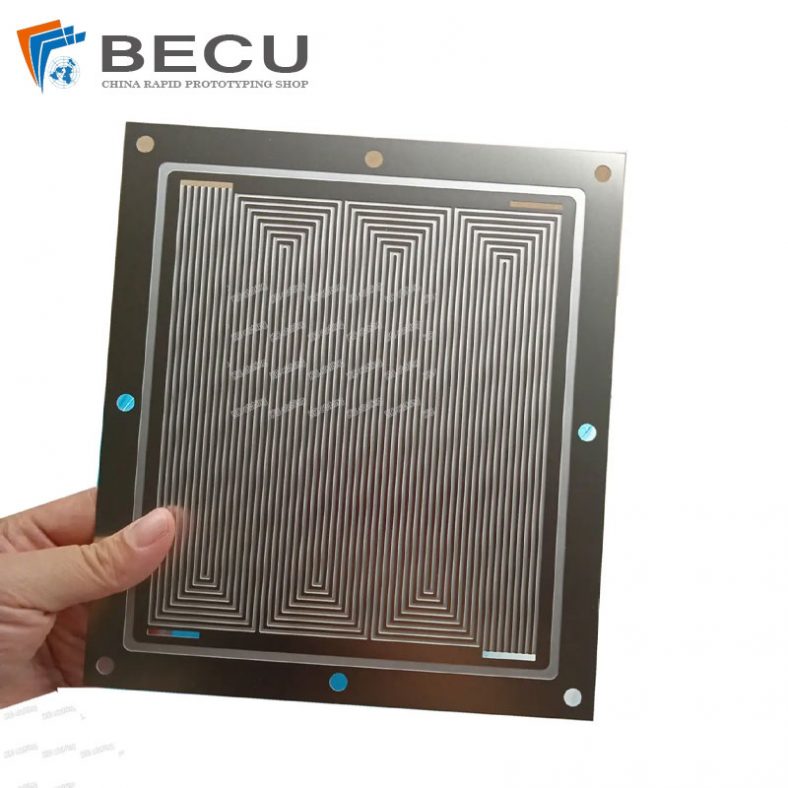

Metal Etched Hydrogen Fuel Cell Metal Bipolar Plates

-

Prototype CNC Spinning Stainless Steel 316L Outdoor Camping Pot

-

Precise Etching Stainless Steel 316 High-Speed Hair Dryer Networks

-

Chemical Etching Stainless Steel 316 Bipolar Flow Plates

-

Swiss Machining And Bending 304 Hand Sewing Needle For Textile Machinery

-

Automatic Swiss Turning Stainless Steel 316L U-bolt

-

CNC Machining Metal Chess Pieces,Board And Sets

-

CNC Machined Fidget Spinner

-

Custom Stainless Steel 316 Goblet By Turning

-

CNC Turning Stainless Steel 316 Grinding Core For Coffee Mill

-

Precision 316 Stainless Steel Cookware Boiler Cover For Kitchen

-

Precision Turning Stainless Steel 4 Minute Extra Thread Faucet