Electronic Sheet Metal Fabrication

The genesis of electronic sheet metal fabrication can be traced back to the burgeoning electronics industry.

As electronic devices shrank in size and complexity, the need for custom-fabricated enclosures and components became increasingly apparent. This led to the development of specialized techniques and processes tailored to the unique demands of electronics manufacturing.

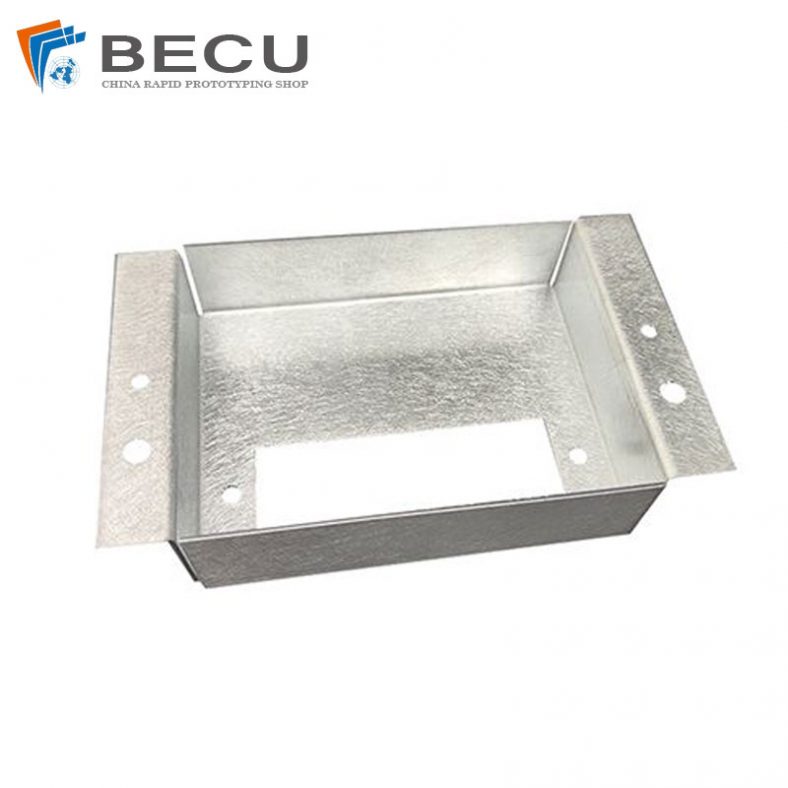

Electronic sheet metal fabrication, often referred to as electronic sheet metal manufacturing or electronic sheet metal design and fabrication, is a specialized branch of sheet metal fabrication that focuses on producing custom sheet metal components and enclosures for electronic devices and equipment. This process involves the design, cutting, bending, and assembly of sheet metal to create parts and enclosures that house electronic components such as printed circuit boards (PCBs), connectors, wiring, and other electronic elements.

Electronic sheet metal fabrication plays a crucial role in the manufacturing of a wide range of electronic devices, including computers, telecommunications equipment, medical devices, industrial control panels, and consumer electronics. The precise fabrication of sheet metal components ensures that electronic equipment functions reliably while also meeting regulatory and safety requirements.

Electronics Sheet Metal Fabrication Services – Electronic Sheet Metal Parts Manufacturer

Be-Cu prototype is a leading Electronic Sheet Metal Parts Manufacturer with a reputation for excellence and innovation in the industry. With 30 years of experience, we have become a trusted partner for companies seeking high-quality precision sheet metal components for electronic applications.From electronic devices and equipment projects to electronic accessories, our electronics sheet metal fabrication services will deliver custom sheet metal parts that fit your exact standards.

At Be-Cu, your electronics sheet metal is custom built for you, meaning you can specify just about any cutout you wish. These typically include functional cutouts for connectors, displays, switches, etc. However, we often see creative cutout designs, including company logos, brands, or product names, and creativity around ventilation cutouts, thereby combining form and function.

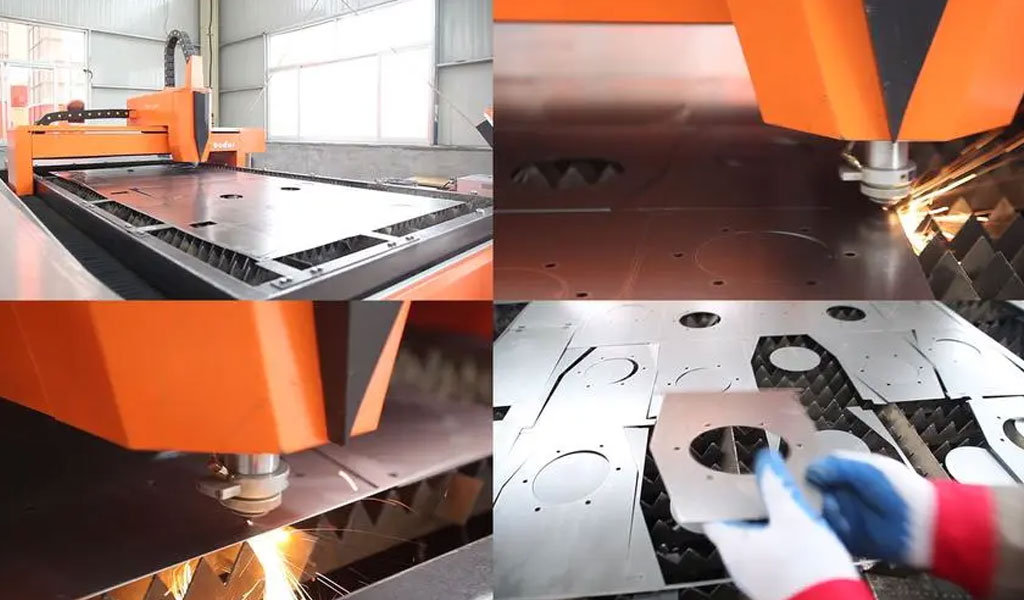

Electronics sheet metal parts are generally fabricated through processes including bending, cutting, joining, annealing, drawing, folding, welding, roll forming, brazing, punching, pressing, etc. Be-Cu will also offer a full array of surface finishing services to achieve a unique appearance and effect according to your needs.

We know that the electronics industry relies on high-precision and high-efficiency sheet metal manufacturing parts. In many cases, electronic sheet metal parts are extremely small, complex in structure, and customized with special materials.

At Be-Cu, we have a wide range of manufacturing capabilities to actively advance your product manufacturing plans, combining sheet metal bending, precision progressive die stamping, Laser cutting, surface coating and other processes to provide high precision, low cost and cost-effective A manufacturing solution that ensures fast delivery and superior product quality that exceeds your expectations.Would you like to receive the assembled sheet metal fabrication product? Whether it is complex structure, strict standards of products, or a small number of orders.Be-Cu can be solved smoothly, you do not need to bear any risk, protect your investment security.

Please feel free to contact us at [email protected] to schedule a consultation or to request more information about our services.

Electronics Sheet Metal Materials

Sheet metal is a widely used form of raw material, usually 0.006 and 0.25 inches thick sheet used in sheet metal fabrication. Sheet metal electronics are typically constructed from thin metal sheets, such as steel, aluminum, or stainless steel. The choice of material depends on factors like the desired strength, durability, corrosion resistance, and weight requirements.

- Aluminum: Al 5052, 6061,6063 etc

- Copper: C101, C110, brass (C260) etc

- Stainless Steel: SS 301, 304, 316/316L etc

- Steel: low carbon steel etc

-

Stainless Steel Sheet Metal Fabrication

-

Aluminum Sheet Metal Fabrication

-

Copper Sheet Metal Fabrication

-

Brass Sheet Metal Fabrication

-

Steel Sheet Metal Fabrication

-

Titanium Sheet Metal Fabrication

-

Galvanized Steel Sheet Metal Fabrication

-

Mild Steel Sheet Metal Fabrication

-

Bronze Sheet Metal Fabrication

Electronics Sheet Metal Fabrication By Surface Finish

The fabricated enclosure may undergo various surface treatments and finishes, such as powder coating, painting, anodizing, or plating. These processes enhance the aesthetics, provide protection against corrosion, and improve the overall durability of the electronics. Here are some common surface finishes used in electronics sheet metal fabrication:

Powder-Coated-Electronic-Sheet-Metal-Fabrication

Polishing-Electronic-Sheet-Metal-Fabrication

Plating-Electronic-Sheet-Metal-Fabrication

Galvanized-Medical-Sheet-Metal-Fabrication-1

Brushed-Electronic-Sheet-Metal-Fabrication

Anodizing-Electronic-Sheet-Metal-Fabrication

Custom Electronic Sheet Metal Fabrication Parts Gallery

BE-CU prototype performed complete electronics sheet metal fabrication services. Cutting, punching, bending, welding, and assembling are among our operations. Sheet metal electronics are useful in numerous industries. Moreover, BE-CU can create Electronics Sheet Metal Fabrication parts to meet your specifications. Whatever your application is, we have sheet metal that will work best for its fabrication.

BE-CU prototype provides Electronics Sheet Metal Fabrication and several secondary and support service to take your project from start to finish. Request a quote for your Electronics Sheet Metal Fabrication project today or contact us to learn more about our Electronics Sheet Metal Fabrication process.

-

Precision Fabrication Green Energy EV Charging Station Cabinet

-

Outdoor Rainproof Weak Current Communication Network Sheet Metal Cabinet

-

Sheet Metal Fabrication POS Machine Box Shell

-

Sheet Metal Fabrication Industrial Computer Bottom Cover

-

Sheet Metal Fabrication Strongbox Enclosure

-

Sheet Metal Fabrication Distribution Electric Cabinet

-

Sheet Metal Manufacturing 10.1 Inch Hardware Monitor Enclosure

-

32-Inch Medical Sheet Metal All-In-One Machine Cabinet

-

Precision Fabrication Wall Mount Gaming Computer Case Chassis

-

0.8MM All Aluminum Sheet Metal Mini Host Computer Chassis

-

3MM Fabrication Aluminum 5052 Brushed Battery Box

-

12.1 Inch Vertical Inquiry Kiosks

-

65-Inch Vertical Touch All-in-one Advertising Machine Sheet Metal Shell

-

LCD Display Advertising Machine Sheet Metal Frame

-

Custom 32 Inch Ordering Machine Kiosk Chassis

-

SPCC Sheet Metal Fabrication Financial Device Enclosure

The Application Of Electronics Sheet Metal Fabrication

Electronics sheet metal fabrication involves the manufacturing of various sheet metal components and enclosures specifically designed for electronic devices and equipment. This process is essential in the production of electronics as it provides a protective and structural housing for electronic components, ensuring their functionality, safety, and reliability. Here are some common types of electronics sheet metal fabrication:

Electronic Enclosures

Racks and Cabinets

Electronic Chassis

Faceplates and Panels

Brackets and Mounts

Covers and Lids

Heat Sinks

Connectors and Backplanes

Cable Management

Customized Components

The choice of materials, manufacturing processes, and design considerations in electronics sheet metal fabrication can vary widely depending on factors such as the application, environmental conditions, and regulatory requirements. Manufacturers may use techniques like laser cutting, CNC machining, welding, and powder coating to create high-quality, precise, and durable sheet metal components for electronics.