Online Custom 3d printing Service In China

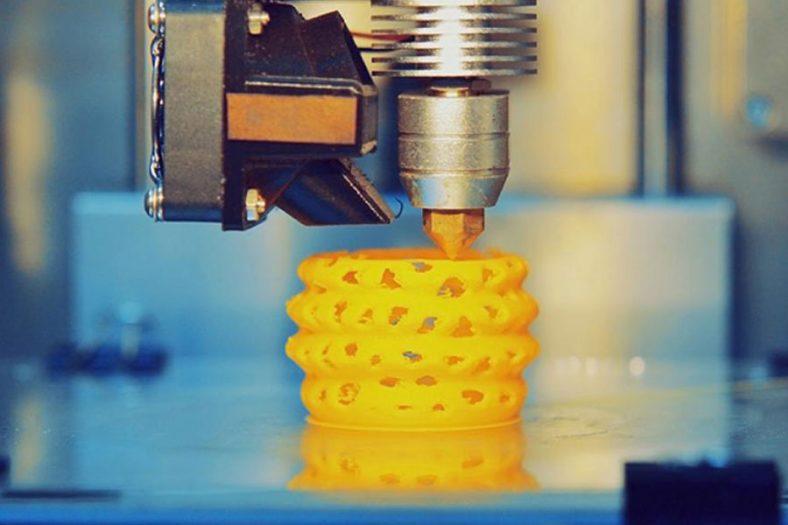

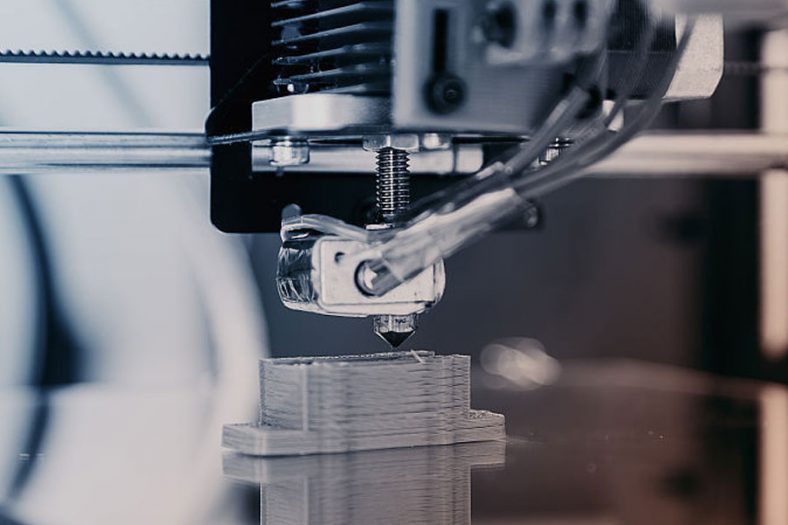

3d printing is a technology that builds objects based on digital model files, using bondable materials such as metal powder or plastic, and printing them layer by layer. It is also an emerging molding technology involving various high-tech comprehensive applications such as CAD, CAM technology, data processing technology, material technology, CNC technology, testing sensor technology and computer software technology.

The Advantages Of 3D Printing

- The time and cost of building an industrial model are only 20%-35% of traditional processing methods

- No need to process machine tools and molds, precise and fast.

- Early detection finds errors in design and manufacturing, which are impossible to find on paper and computers.

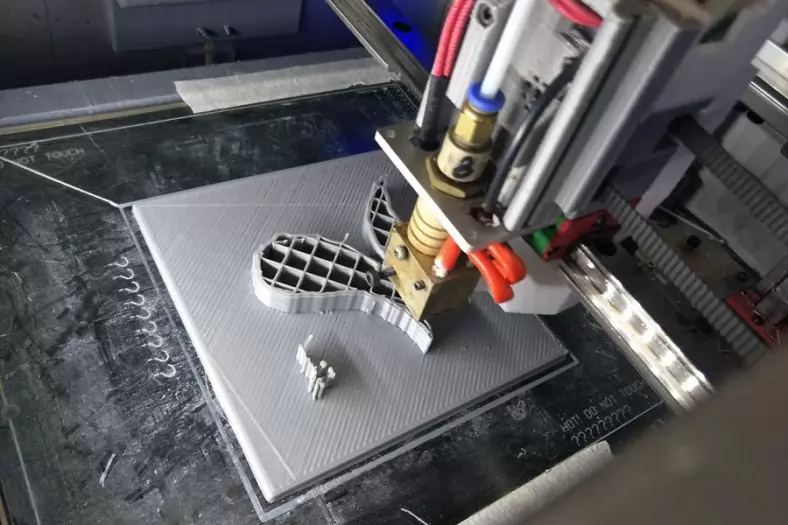

CNC 3D printing can produce parts within no time, which quickens up the prototyping process. Rapid prototyping makes allowance for each stage to finish faster. If you compare it with machining prototypes, a 3D printing service is quick and inexpensive at producing parts as the component can be finished in hours. This allows for every design modification to be finished at a more efficient rate.

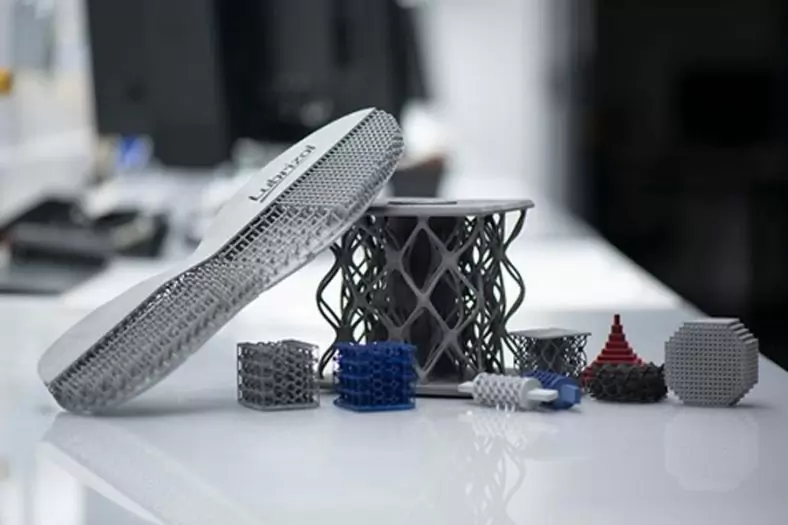

Be-cu have been providing online 3D printing solutions for over 10 years,used for rapid prototyping and production in volume. Our clients are across a wide variety of industries and companies, including automotive, construction, aerospace, defense, electronics, machinery, industrial automation, medical, healthcare, consumer production, oil & gas, etc. Accelerate your product development and manufacturing process with our industry-leading metal & plastic 3D printing service and 3D printed parts. We’ll find the best 3D printing solution for your projects, to lower your cost and shorten the lead time based on your needs, while maintaining the quality. From 3D prototyping to end-use parts production, multiple materials are available for custom 3D printing parts.

The Advantage Of BE-CU 3D Printing Service

Gather the world’s cutting-edge 3D printing technology, 3D printer, 3D scanner, a variety of 3D printing materials to choose from, 24 hours Online 3D printing service!

- Excellent precision, smooth surface, complex geometric shapes, small moving parts, good details, prominent text and any other design requirements.

- Forming ultra-thin thickness of 16-30um,

- The highest accuracy can reach 0.02mm;

- Forming resolution: 600600900~1600dpi

- No minimum order quantity

- Metal or plastic 3D printed prototype and production parts in 7-10 days

- Precision custom 3D printing parts at affordable prices

- Online free quote in the shortest time

- Single prototypes or complex shapes are both allowed

- A wide selection of metal or plastic materials

- Commercial and industrial-grade 3D printers

- Cooperative supplier assistance project

- Provide a quick solution for small batches of complex prototypes

- We provide with our partner

- 3D printing services for metals and plastics

- Meet the rapid needs of complex prototype designers

The Materials Of 3D Printing

- – Including photosensitive resin, ABS, nylon, paraffin, 390,000-color full-color composite materials for optional applications, meeting various tests and verifications.

- – It can be drilled, screwed, assembled, press-fitted, hinged and elastic.

- – It can be sprayed, painted, electroplated, etc.

| Thermoplastic Materials | ABS-M30, PC, POM-like, HDPE and other high-hardness, flame-retardant, high-temperature-resistant series production-grade thermoplastic materials. |

| Nylon | PA12 nylon series has the material properties of high strength and rigidity, high temperature resistance, chemical resistance, invariance, and excellent wear resistance. |

| Resin | Photosensitive resin is a kind of ABS-like white engineering plastic, which is easy for surface polishing and laser seamless stitching of super large objects. |

| Metal Material | Ti64 titanium alloy, MS1 mold steel, GP1 stainless steel, aluminum-magnesium alloy, cobalt-chromium alloy. |

| ABS | Similar to ABS white and red wax 3D printing materials, it is very suitable for manufacturing accurate, high-definition and ultra-fine details of models and prototypes. |

| Wax Material | Wax material has extremely high resolution and fine details, suitable for high-end lost wax casting of jewelry, clocks and micro-medical and electrical equipment |

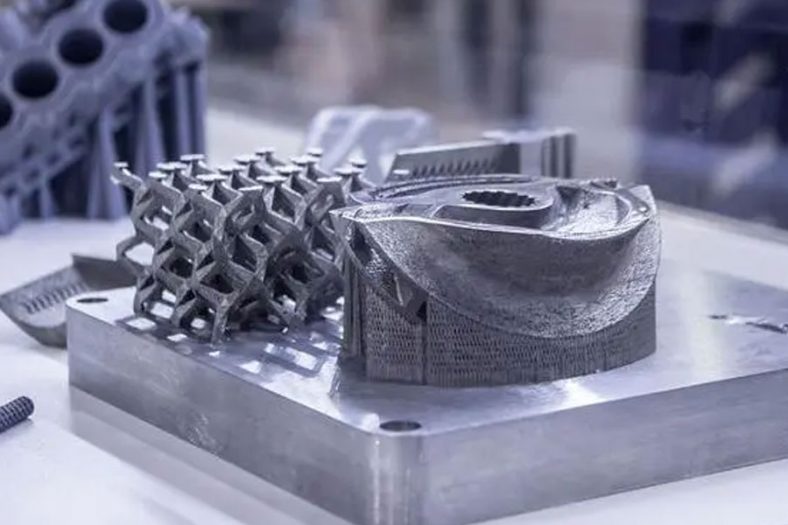

Metal 3D Printing Services

Be-Cu offers a rapid metal 3D Printing service for custom production of your prototype parts, unit parts, or small series (from 1 to 1000+ parts). Metal 3D printing is ideal for creating fully functional prototypes and end-use parts that may be impossible to produce using conventional manufacturing methods,our capabilities allow us to produce your functional metal parts very quickly in as little as one working day.

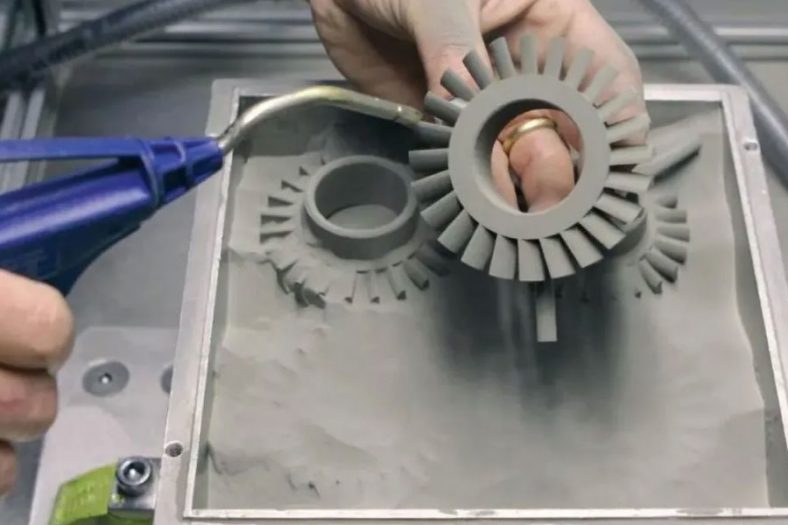

DMLS/SLM/EBM process is the best choice for prototyping and rapid production of small and large metal parts. You receive high dimensional precision parts made from a wide choice of ‘right materials’:

More 3D Printing Capabilities At Be-cu.com

3D Modeling Software

3D modeling is a key step in the realization of 3D printing technology. Whether in cultural creativity, animation and film, medical industry, construction industry, industrial manufacturing, food industry, etc., if you want to print something, you must perform 3D modeling before you can use it. The 3D printer prints the modeling data. Any 3D design software can be used to design a 3D model. As long as it is modeled with software with suitable 3D printing technology characteristics, it can be exported or converted into STL format software to achieve the best results.

3D modeling software is divided into two main types:

- One is for artistic creation and design, such as decorative artwork, movie special effects prototypes, animation figures, dolls, cultural creativity;

- The other is industrial product design. Of course, there is also a 3D modeling software with special value, Rhion, which is not only used for industrial design and mechanical design such as CAD, CAM, but also can create excellent 3D models for cartoon design, movie special effects, and three-dimensional animation production.

Industrial Product Design

Industrial product design 3D modeling software is well known: Sketchup, Solidworks, PROE, UG, through the parametric analysis of the object modeling, through the design of the parameters, directly generate 3D models.

- (1) Blender is an open source free 3D drawing software with powerful functions and cross-platform support for all major operating systems. Provides a comprehensive 3D creation tool; cross-platform support; high-quality 3D architecture brings a fast and efficient creation process;

- (2) Sketchup is a free interactive 3D model program of Google, which is not only suitable for advanced users, but also suitable for beginners. Compared with the CAD program, it is more intuitive and simple, and beginners can choose Sketchup.

- (3) SolidWorks is powerful, easy to learn and easy to use, and technological innovation is the three major characteristics of Solidworks.

- (4) UG and PROE UG are high-end CAD/CAE/CAM software for the manufacturing industry. Used to engage in industrial design, detailed mechanical design, and engineering manufacturing. PROE is slightly weaker than UG. PROE can do it, UG can definitely do it. UG is very good for precise surface.

Anime Art Figure Design

Medical 3D Modeling

Traditionally, doctors can obtain CT two-dimensional image information through CT scans. However, for the understanding of CT two-dimensional images, doctors need to abstract into 3D images in their minds with experience to further diagnose and treat liver tumors and other medical diseases. This experience is often Not reliable enough, deviations may occur.

3D printing technology can realize that the data provided by medical institutions can be processed by professional doctors. The image data obtained by the provided X-ray CT machine and MRI MRI scan can be converted into CAD data required by the input 3D printer for 3D printing model. The 3D printing model not only has the same three-dimensional visual function and individualized characteristics as the digital three-dimensional model, but also has the function of manually touching and marking important anatomical structures, which provides a new method for medical teaching, clinical and scientific research.

3D printing technology will have a wider range of medical applications in the construction of medical models, artificial bones, the manufacture of biological organs, teeth, and plastic surgery.

3D Scanning

The U-level high-resolution 3D scanner imported from Germany has an accuracy of up to 0.007mm and can measure parts of different sizes. When using the highest resolution, it reflects the details of small parts measuring as small as 38 mm, or extremely fast scanning processing measures large objects as large as 2 meters. It can even measure objects as large as 30 meters while maintaining extremely high local resolution.

Can do: 3D scanning of toy figurines, 3D scanning of artwork, 3D scanning of Buddha statues, 3D scanning of cultural relics, 3D scanning of mud sculpture works, 3D scanning of ivory sculptures, 3D scanning of mobile phones, 3D scanning of cars, body scanning, precision 3D scanning and counting. Directly generate .stl data files, which can be directly used for 3D printing or fine carving.

- Measuring point: 2x5000 000

- Measuring area: 38x29-2000x1500mm2

- Measuring point distance 0.01-0.62mm

Copy Number

Use the most advanced non-contact three-coordinate scanning equipment system imported from Germany on the market to measure the surface of the product and obtain point data to directly generate .stl data files. Advanced blue light technology and precision equipment up to 16 million pixels can avoid errors caused by point cloud calculations, with high accuracy and fast speed. Can do full-size inspection, size verification and comparison.

- 1. Calculate 3D coordinate conversion and 3D shape deviation;

- 2. It can accurately define the coordinates of the object points under quasi-static conditions, and calculate the three-dimensional displacement and deformation of various objects and components from this;

- 3. Quality control of gap deformation, flatness testing, component deformation and testing (CAV comparison);

To meet high-end customers, high-precision product design and testing. Be able to detect deviations in the production process in a timely and accurate manner. Save time and money and improve production efficiency.

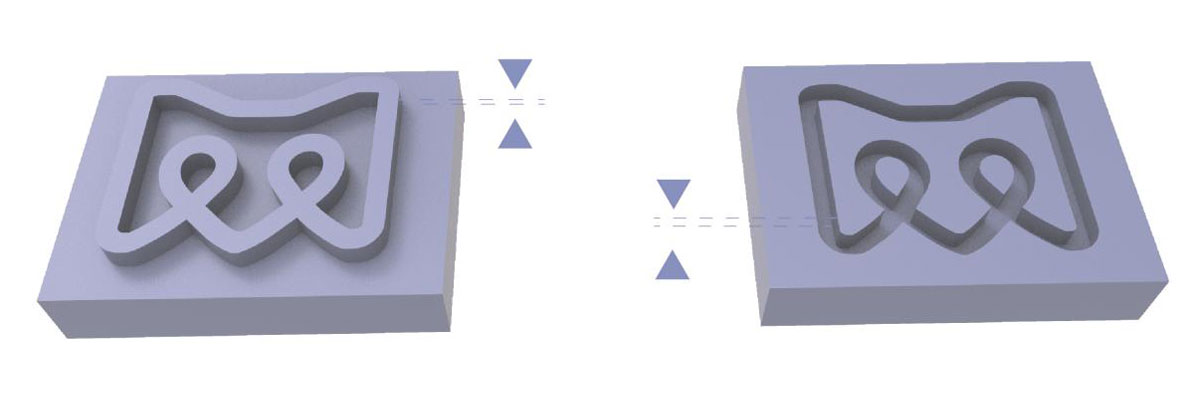

Especially in the mold manufacturing process, it is often necessary to repeatedly try and modify the mold surface. If the mold that meets the requirements is measured and its digital model is reversed, this spare digital model can be used to generate the processing program when the mold is repeatedly manufactured, which can greatly improve mold production efficiency and reduce mold manufacturing costs.

Reverse Engineering

More Capabilities

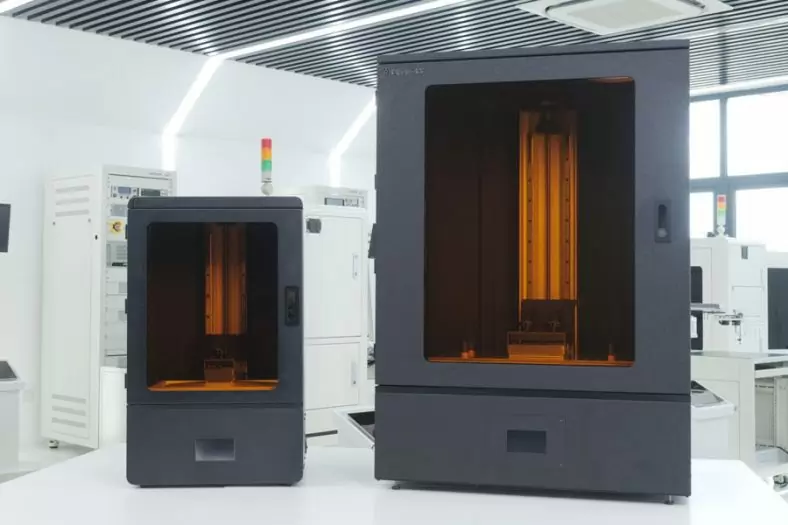

Our Outstanding 3D Printing Equipment

- P200 Industrial DLP 3D Printer

- ProJet MJP 5500X

- TPM ELITE P5000 SLS 3D Printer

- P480DL SLS 3D Printer

- ASM1500H SLA 3D Printer

- ASM-1200 SLS Molding Machine

- M400-4—SLM Metal 3D Printer

- DQ1200 FDM 3D printer

- Check Out BE-CU Equipment List

-

3D Printing Pool Pressure Cleaner Parts and Accessories

-

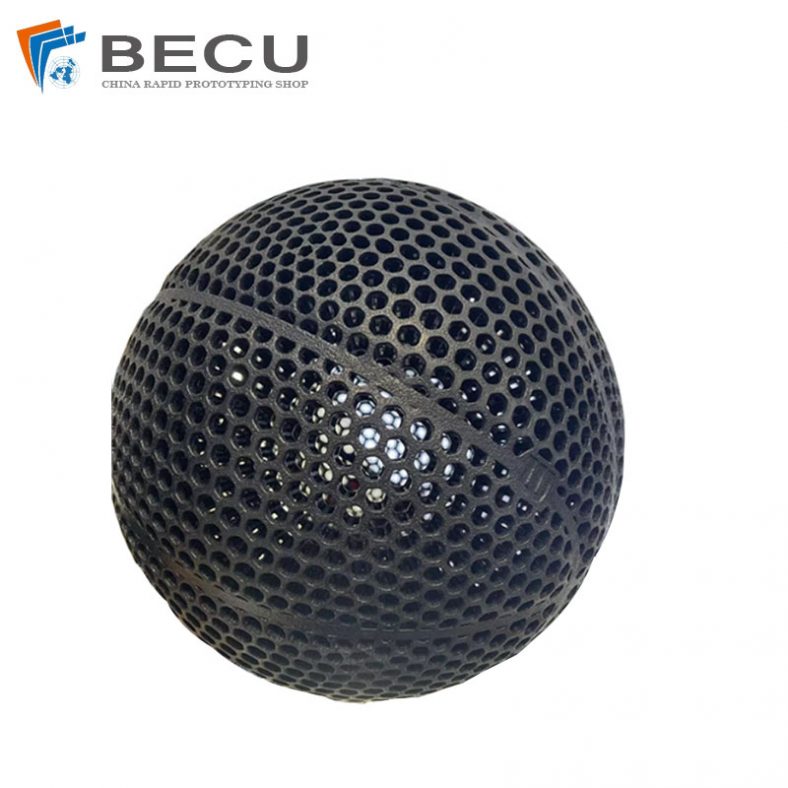

Nylon 3D Printed Size 5 Basketball

-

Black Nylon Medical Threaded Screw By MJF 3D Printing

-

MJF 3D Printing Black Nylon Red Dot Sighting For Medical

-

jetFusion 3D Printing Triceratops Mother and Child Sculpture

-

6061 Aluminum Alloy 3D Printing Black Dusting Parts

-

Development Resin Samples For Sports Shoes

-

3D Printed Sports Shoes Sole Model

-

Powder Sintering 3D Printed Shoe Midsole Sample

-

FFF Fused Wire Extrusion 3D Printed Pure Copper Parts

-

DLP 3D Printing DragonBall Dragon Desktop Ornaments

-

3D Printing Brown Wax Anime Doll

The Flow Chart Of 3D Printing

The Design Specification Classification Of 3D Printing

Dear user, in order to ensure that your design can be printed smoothly, please follow the steps in sequence:

- According to the actual use requirements, select the material. View material parameters

- Check the wall thickness of your design, be sure to meet the minimum wall thickness requirements. Check the wall thickness design requirements for different materials

- If your design is hollow, be sure to design a large enough escape hole. Check Out Escape Hole Design Requirements

- If you have freestanding columns in your design, be sure to meet the minimum wall thickness requirements. View Wall Thickness Design Requirements for Freestanding Columns

- If there are convex or concave details (such as embossed or indented characters, etc.) in your design, be sure to meet the minimum width and height requirements. View convex/concave design requirements

- If there is a sharp part in your design, the angle of the part needs to meet the minimum requirements. View sharp part design requirements

- If your design includes multiple parts, be sure to meet the minimum clearance requirements between parts. View part clearance design requirements

- If there are threads in your design, the profile angle and pitch must meet the minimum requirements. View thread design requirements

- If there are holes in your design, their inner diameter and depth must meet the minimum hole requirements. View hole design requirements

- If your design is more complex, 3D intelligent manufacturing network may be judged as special-shaped parts, and the quotation will be made according to special specifications.

The Requirements Of Document Entity Design

When rendering renderings, you don’t need to consider the thickness, just the appearance, but if you need to print out the real thing, you need to think about this during the modeling process. The created model needs to be all closed solids, not surfaces or one-sided faces with no thickness.

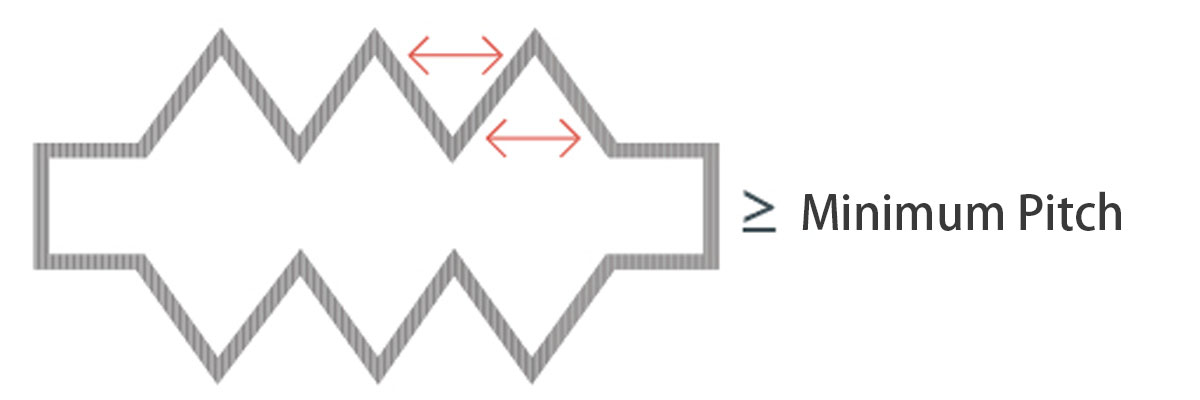

The Design Requirements Of Thread

The pitch refers to the axial distance between the corresponding points of two adjacent teeth on the thread, as shown in the following figure:

The profile angle refers to the angle between the two sides of the thread profile.

The accuracy of the printer will affect the pitch and profile angle.

Depending on the material selection, your design needs to meet the minimum pitch and minimum profile angle requirements, as follows:

| Material | 8000 photosensitive resin | Transparent photosensitive resin | HP High Performance Nylon ( Black ) | Nylon fiber-reinforced ( black ) |

|---|---|---|---|---|

| Pitch | 0.6mm | 0.6mm | 0.5mm | 0.6mm |

| Tooth Angle | 20° | 20° | 20° | 20° |

The Requirements Of Deep Hole/Bent Hole Design

The inner diameter of the hole needs to be larger than the minimum hole diameter requirement. The minimum hole diameter requirements for different materials are as follows:

| Material | 8000 Sensitive Resin | 8100 Tough Resin | Transparent Photosensitive Resin | Nylon ( White) | Nylon ( Black ) |

| Minimum Aperture | 1.2mm | 1.2mm | 1.2mm | 1.5mm | 1.5mm |

The Requirements Of Model Minimum Wall Thickness Design

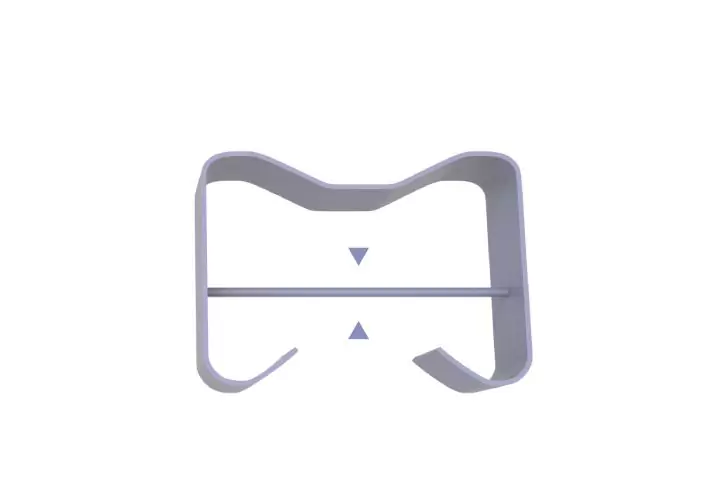

On the designed 3D digital model, the inner and outer surfaces of the model are closed to form thin walls.The thin wall is divided into supporting thin wall and non-supporting thin wall.

The supporting thin wall connects the structural features of at least two surfaces, as shown in the following figure:

Unsupported Thin Wall: Structural features that connect less than two faces, as shown below:

The wall thickness of the model determines the strength of the product, which also determines whether the model can be printed.

After the model is printed, it needs to go through support removal, grinding, sandblasting, etc. These processes determine the minimum wall thickness of different molding methods.

The minimum wall thickness requirements for different printing methods are as follows:

| 3D Printing Method | Minimum Wall Thickness Requirements |

|---|---|

| SLA 3D Printing Services | 0.6mm |

| SLS 3D Printing Services | 0.8mm |

The model is printable only when the wall thickness reaches the minimum wall thickness requirement. If there is a thin-walled structure in your model design, we recommend that you design a wall thickness of more than 1mm.

The wall thickness needs to increase with the size of the model. If the wall thickness of the product is insufficient, Be-cu.com’s sales service will communicate with you according to the actual situation and give you suggestions for modification.

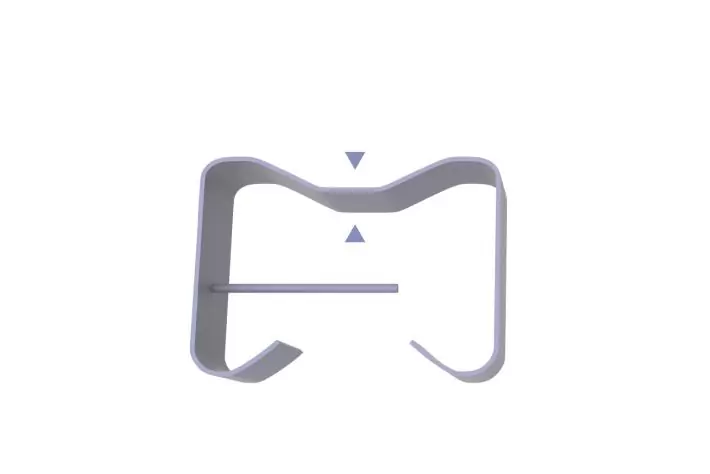

Minimum Wall Thickness Design Requirements for Columns

Supported column: In the model, if a protruding structure has a length that is twice or more than its width.

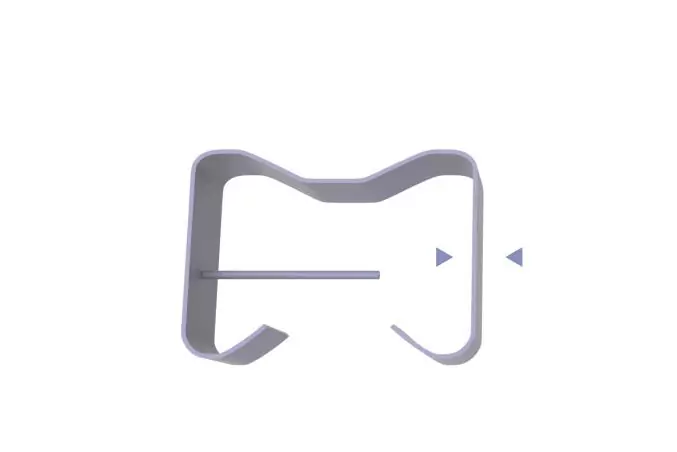

Among them, the structure where both ends are connected to the thin wall, as shown below:

Unsupported column: a structure with only one end connected to a thin wall, as shown below:

Processes such as support removal, grinding, and sandblasting determine the minimum column wall thickness requirements.

The minimum wall thickness requirements of different molding methods are as follows:

| 3D Printing Method | Support Column | Unsupported Column |

|---|---|---|

| SLA 3D Printing | 1.2mm | 1.5mm |

| SLS 3D Printing | 1.0mm | 1.0mm |

The wall thickness of the column needs to be larger than the minimum wall thickness requirement to print. If your design does not meet the minimum wall thickness requirement, it is recommended that you increase the wall thickness.

If the model cannot be printed due to the problem of wall thickness, the official customer service of Be-cu.com will communicate with you according to the actual situation and give you suggestions for modification.

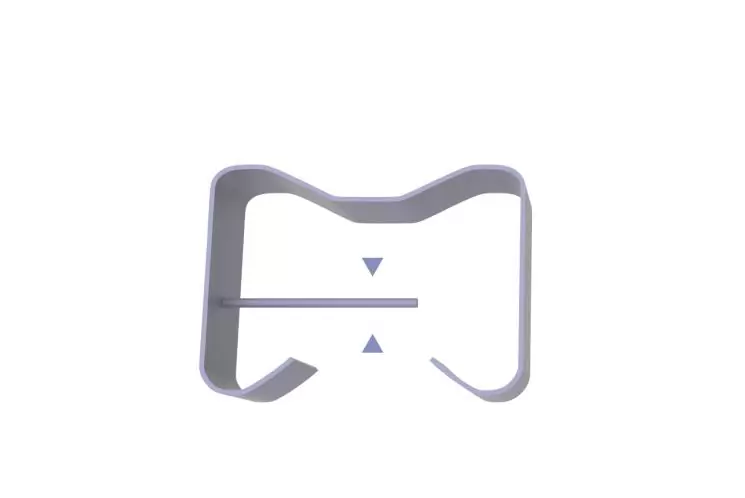

The Requirements Of Concave And Convex Detail Design

The bump detail is the part that is raised or recessed on the model, as shown in the image below.

The smallest bump detail is usually determined by the precision of the printer.

The minimum height and width requirements of bump details of different materials are as follows:

| 3D Printing Method | Minimum Feature |

|---|---|

| SLA 3D Printing | 0.3mm width and height (depth) |

| SLS 3D Printing | 0.7mm wide and 0.4mm high (deep) |

When the depth or width of the bump detail is smaller than the minimum bump detail requirement, it will not be able to print accurately, and it will not be possible to perform post-processing such as sanding and sandblasting.

At this point, we recommend that you increase the depth, width, and remove this part.

If it cannot be printed due to wall thickness problems, Be-cu.com customer service will communicate with you according to the actual situation and give you suggestions for modification.

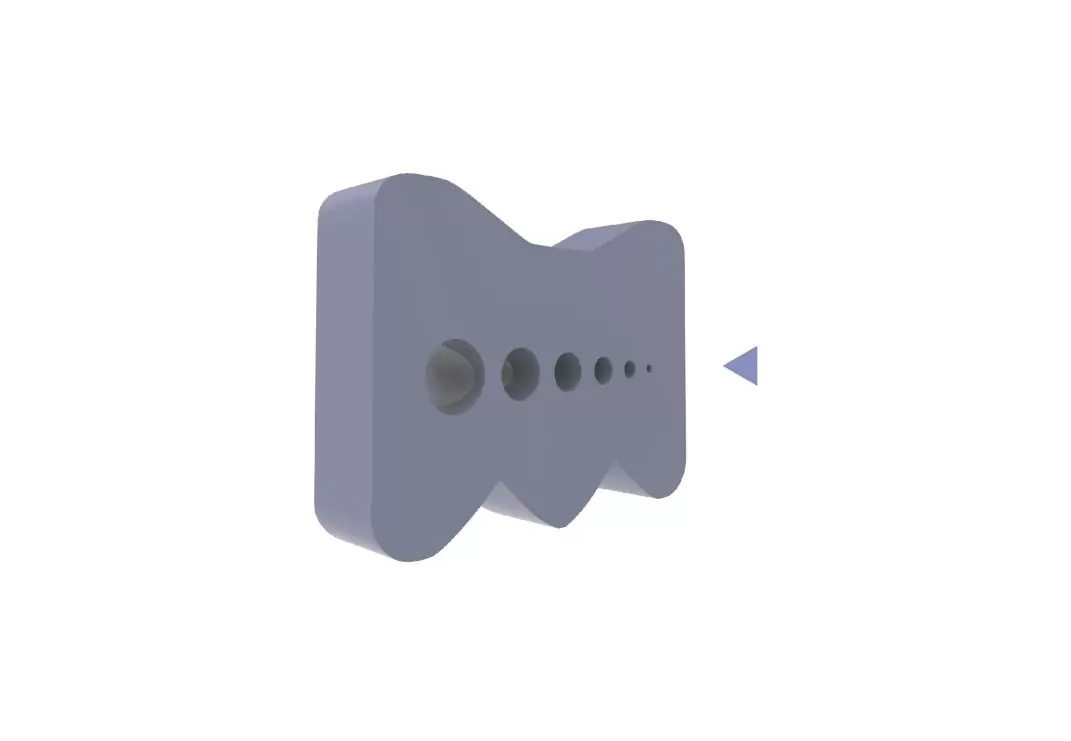

The Requirements Of Escape Aperture Design

If you are designing a hollow part, you need to design escape holes in appropriate parts to remove unused material in the printed product, as shown below:

The design of the escape hole needs to ensure that the hollow part is large enough, and its hole should be greater than 2mm, so that the hollow part diameter can be cleaned.

If the escape holes do not meet the minimum requirements, it is recommended that you increase the size of the existing escape holes, increase the number of escape holes, or fill in the hollow parts.

If it cannot be printed due to the problem of escape aperture, Be-cu sales service will communicate with you according to the actual situation and give you suggestions for modification.

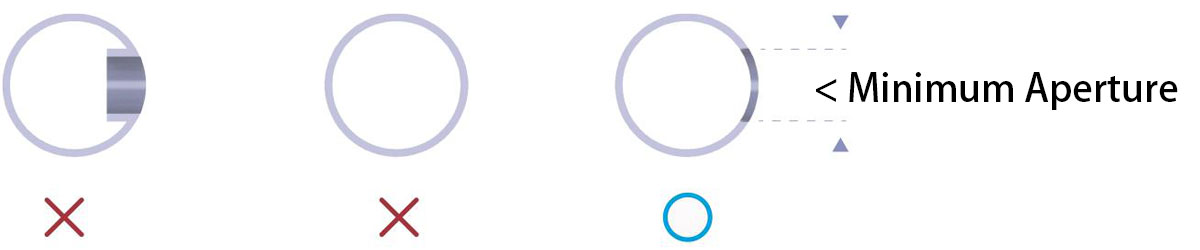

The Requirements Of Minimum Bore Design

When there is a small hole-like structure on the surface of the model, as shown in the figure below

The minimum hole diameter requirements for different molding methods are as follows:

| 3D Printing Method | Minimum Diameter |

|---|---|

| SLA | 0.5mm |

| SLS | 1.0mm |

The designed aperture does not meet the minimum diameter requirement, and the hole may be blocked during the printing process.If you need the exact hole design, make sure each hole meets the minimum hole diameter requirement.

If the model cannot be printed due to the minimum aperture problem, Be-cu sales service will communicate with you according to the actual situation and give you suggestions for modification.

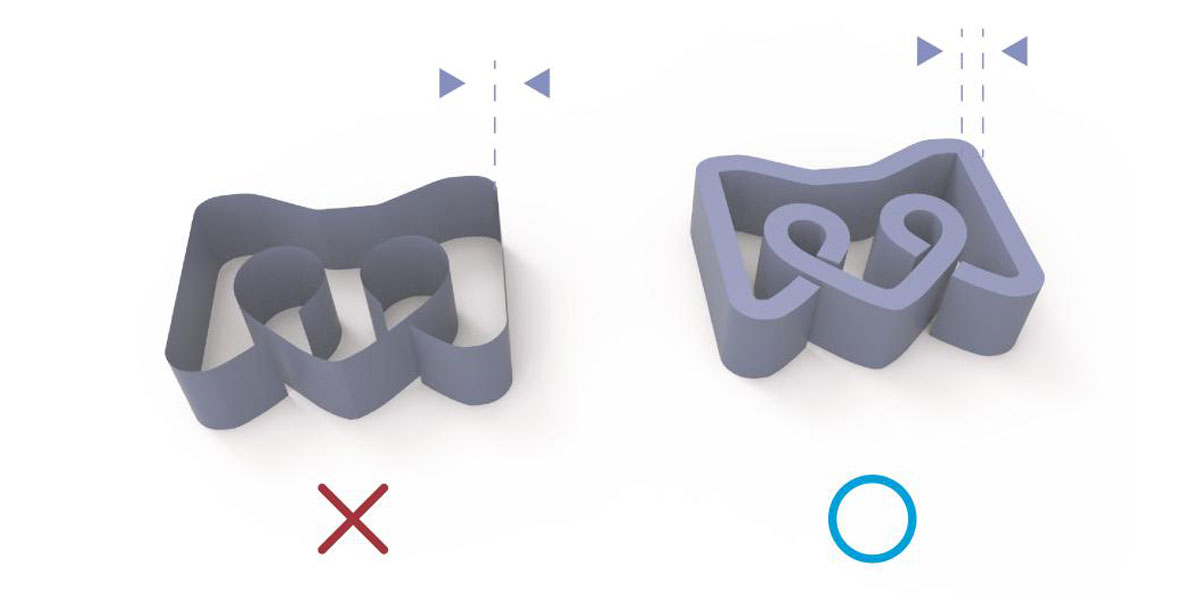

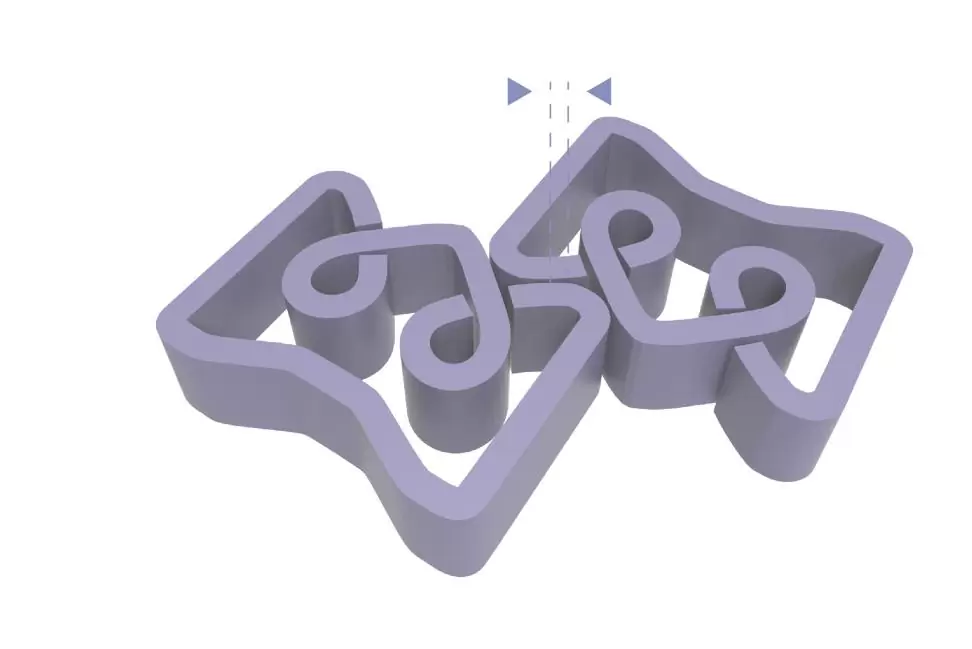

The Requirements Of Minimum Clearance Design

The printing gap refers to the distance between any two parts, thin walls or columns, as shown in the following figure:

When the designed model requires multiple parts to be printed in one piece, the minimum clearance of the SLS 3d printing process is 0.5mm.

If the gap between parts is smaller than this standard, post-processing engineers will not be able to remove the residual powder, resulting in gap failure.

At this time, it is recommended that you increase the gap size or select other materials with small gap requirements.

If the independence of the two parts of the model is not important, it is recommended that you combine the two parts into a whole.

The Assembly Design Requirements Of 3D Printing

When the model needs to design the assembly structure, it is necessary to keep the assembly clearance, which refers to the required assembly tolerance between the two assemblies of the model (for example, the distance between two gears or joints).

Generally, the minimum assembly gap is 0.2mm . If the gap is less than 0.2mm , the error of the parts will cause the two parts to fail to assemble.