Custom Titanium Parts

- Global delivery as fast as 30 days

- Machined prototypes in as fast as 9 days.

- Perfect Service And High Quality

- Tolerances down to +-0.005mm

- ISO 9001:2015, ITAF 16949

>>>All uploaded drawings are strictly confidential, check the confidentiality agreement

What Is Titanium Parts – Titanium Define

Titanium parts are actually pure titanium or titanium alloy parts obtained by various fabrication methods.

- Titanium is a new type of metal. The performance of titanium is related to the content of impurities such as carbon, nitrogen, hydrogen, and oxygen. The purest titanium iodide has an impurity content of no more than 0.1%, but its strength is low and its plasticity is high. The properties of 99.5% industrial pure titanium are: density ρ=4.5g/cm3, melting point 1725℃, thermal conductivity λ=15.24W/(mK), tensile strength σb=539MPa, elongation δ=25%, section shrinkage Rate ψ=25%, elastic modulus E=1.078×105MPa, hardness HB195.

- The density of titanium alloys is generally around 4.51g/cm3, which is only 60% of that of steel. Some high-strength titanium alloys exceed the strength of many alloy structural steels. Therefore, the specific strength (strength/density) of titanium alloy is much greater than that of other metal structural materials, and parts with high unit strength, good rigidity and light weight can be produced. Titanium alloys are used in aircraft engine components, skeletons, skins, fasteners and landing gear.

- The operating temperature is several hundred degrees higher than that of aluminum alloys, and the required strength can still be maintained at moderate temperatures, and it can work for a long time at a temperature of 450 to 500 °C. The specific strength of aluminum alloy decreases significantly at 150 °C. The working temperature of titanium alloy can reach 500 ℃, and the working temperature of aluminum alloy is below 200 ℃.

- Titanium alloy works in humid atmosphere and seawater medium, and its corrosion resistance is much better than stainless steel; it is particularly resistant to pitting corrosion, acid corrosion, and stress corrosion; it is resistant to alkali, chloride, chlorine, organic substances, nitric acid, sulfuric acid etc. have excellent corrosion resistance. However, titanium has poor corrosion resistance to media with reducing oxygen and chromium salts.

- Titanium alloys can still maintain their mechanical properties at low and ultra-low temperatures. Titanium alloys with good low temperature performance and extremely low interstitial elements, such as TA7, can maintain a certain plasticity at -253 °C. Therefore, titanium alloy is also an important low-temperature structural material.

- Titanium has high chemical activity and produces strong chemical reactions with O2, N2, H2, CO, CO2, water vapor, and ammonia in the atmosphere. When the carbon content is greater than 0.2%, a hard TiC will be formed in the titanium alloy; when the temperature is high, a hard surface layer of TiN will also be formed when it interacts with N; when the temperature is above 600 ℃, titanium absorbs oxygen to form a hardened layer with high hardness ; Increased hydrogen content will also form an embrittlement layer. The depth of the hard and brittle surface layer produced by absorbing gas can reach 0.1 to 0.15 mm, and the degree of hardening is 20% to 30%. The chemical affinity of titanium is also large, and it is easy to adhere to the friction surface.

- The thermal conductivity of titanium λ=15.24W/(m·K) is about 1/4 of nickel, 1/5 of iron, and 1/14 of aluminum, and the thermal conductivity of various titanium alloys is about 50 lower than that of titanium. %. The elastic modulus of titanium alloy is about 1/2 of that of steel, so its rigidity is poor and it is easy to deform. It is not suitable to make slender rods and thin-walled parts. times, resulting in severe friction, adhesion and bond wear on the flank of the tool.

Fabrication Titanium Parts Supplier – Custom Titanium Components Manufacturer

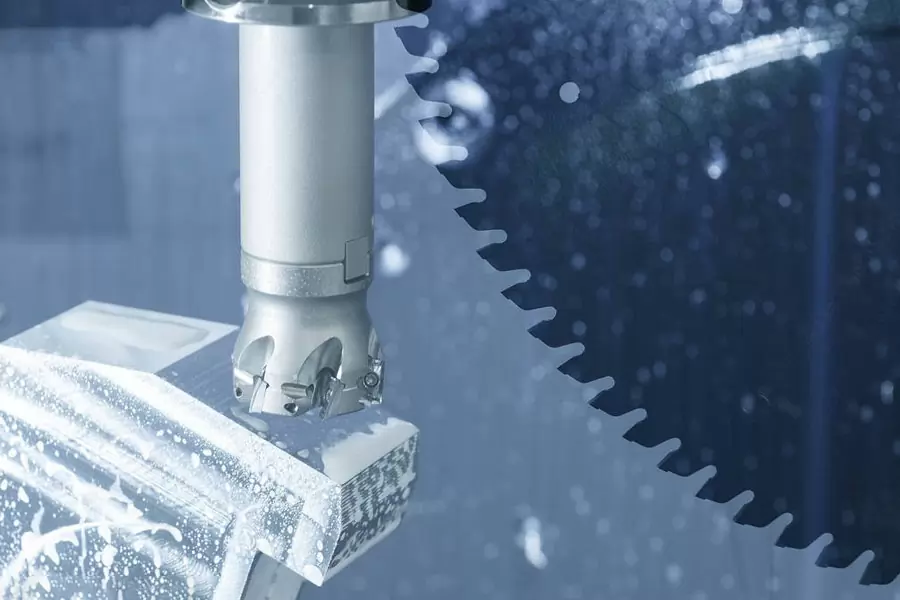

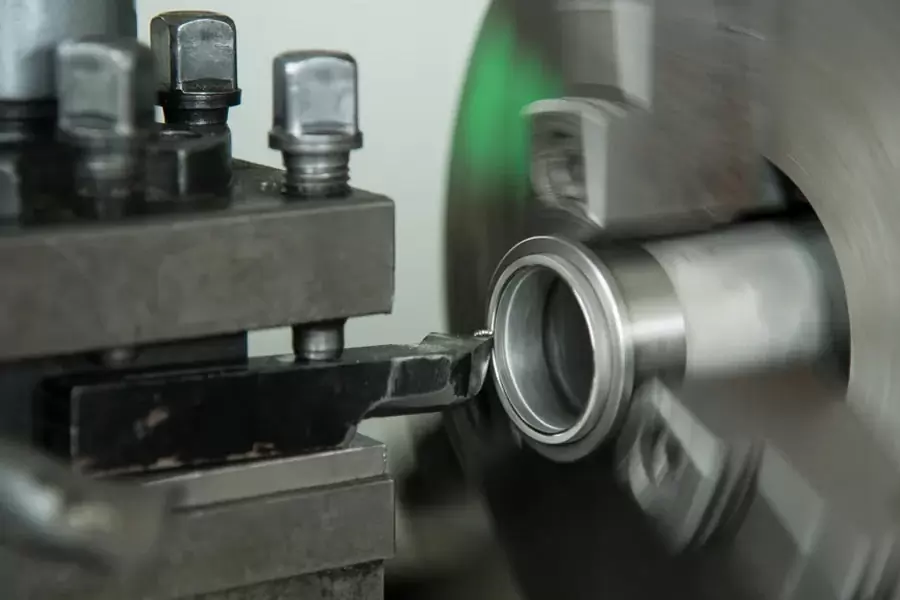

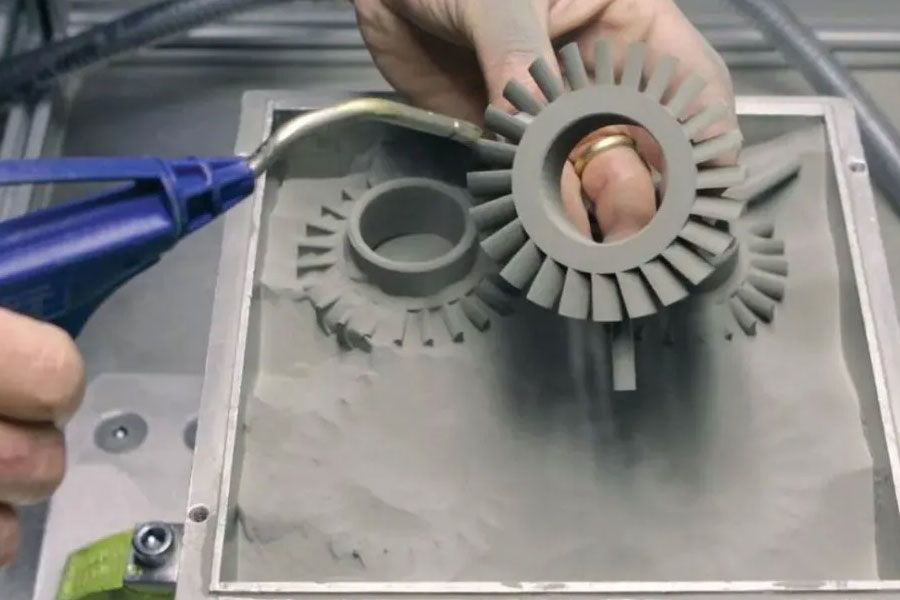

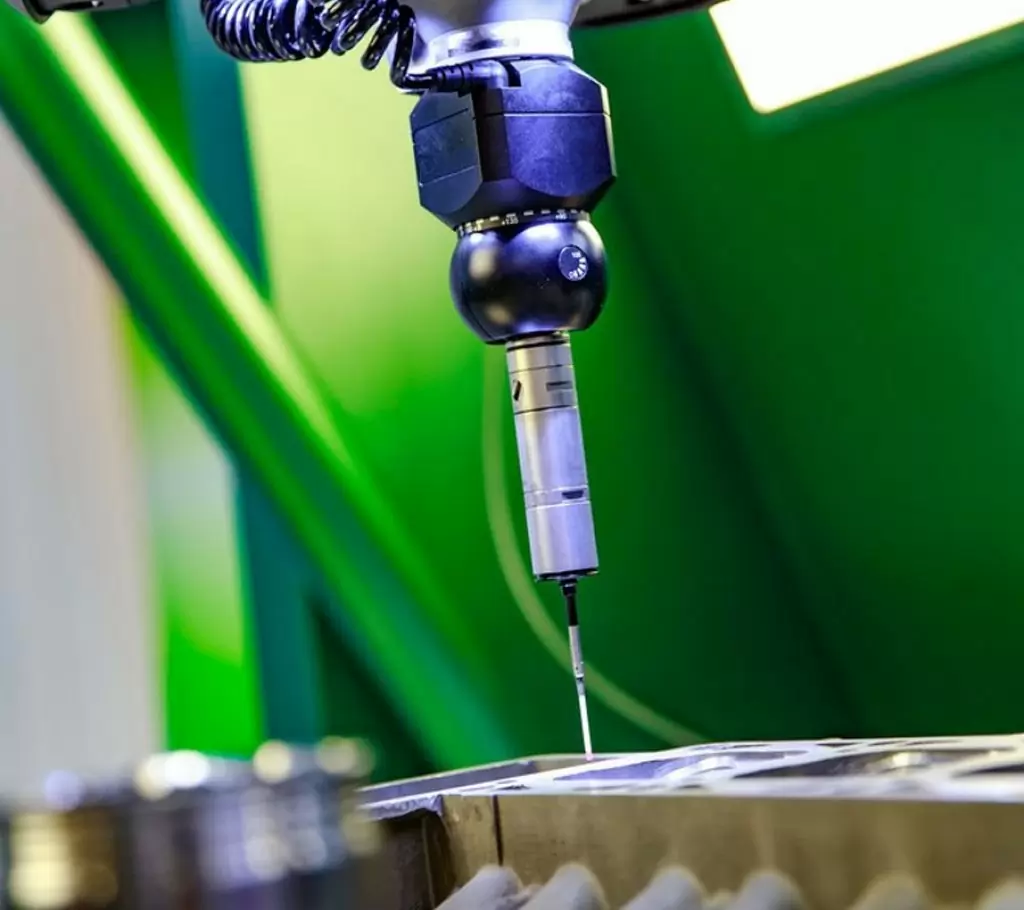

Titanium is a transition metal often used in the aerospace, medical, and military industries.Fabrication titanium is the specialized precision manufacturing of customer designed titanium components from cold headed blanks, titanium blanks, or solid titanium bars. Titanium is a very difficult metal to machine and requires specialized process knowledge for manufacturing. If you are seeking a professional fabrication supplier to provide high quality custom titanium parts, BE-CU is one of the most affordable and capable manufacturer, specializing in titanium fabrication process on advanced titanium CNC machining,titanium investment casting and more. All our clients are satisfied with our products and service, especially the advanced technique of cnc machining and efficient preparation of samples.Be-cu has been making titanium parts of various sizes, from miniature to oversized, and various shapes, from simplest to the most complicated.

• Empowered by 100+ advanced facilities

• 10000+ case studies produced

• Serving 3000+ clients worldwide

• Supported by hundreds senior machinists with over 20 years of experience

We produce titanium parts according to clients’ requests and provide quality products and service with competitive prices. You can design and order your parts with our free rapid quote tooling or upload your own CAD file to our email:[email protected] for a fast quote.

Experienced To Offer More Titanium Manufacturing Options

Upholding this standard requires an exceptional commitment to manufacturing resources. The wide variety of machining technology options in the Be-Cu prototype machine library is supported by an in-house tooling capability that adapts tools to the unique characteristics of each material.Our titanium science engineers will help you choose suitable metal alloys and machining processes(include titanium cnc machining and more) to address your part-making needs.

Custom Titanium Parts Applications – What is Custom Titanium Parts Used for

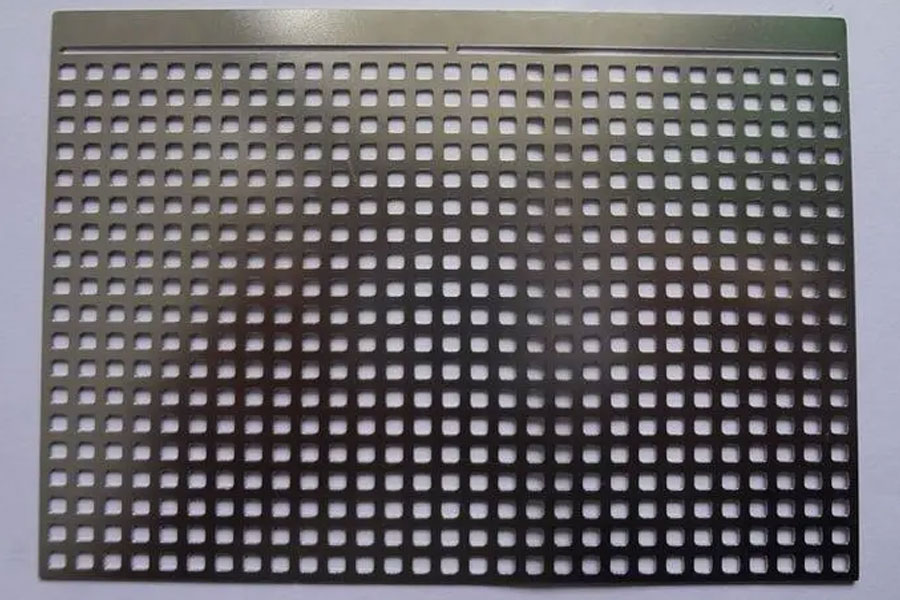

Because the fabrication allows a very high precision without altering the structure of the material with a good rate of manufacture, fabrication is becoming increasingly common as its machine range, control systems and cutting tools are just growing. Our fabrication service is used to produce a variety of custom-designed fabrication parts and products in all areas of the industry:

The Case Studies Of Titanium Parts

You have a complex titanium parts design, Our fabrication service can help you turn it into a reality. With the right equipment, strong technical knowledge, and a focus on quality.. From tool design to finishing and then on to shipment, Be-cu prototpe ensure that every project is completed to a high standard and that your orders are delivered on time, every time.

-

5 Axis CNC Machining Medical Olecranon Plate

-

4 Axis CNC Machining Titanium Grade 5 Mobile Phone Buttons

-

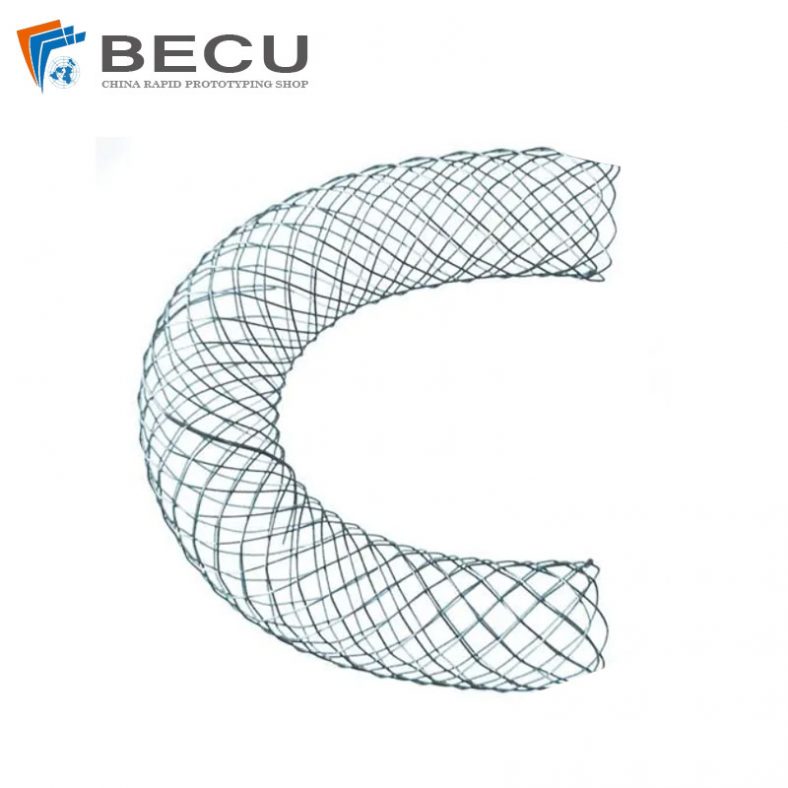

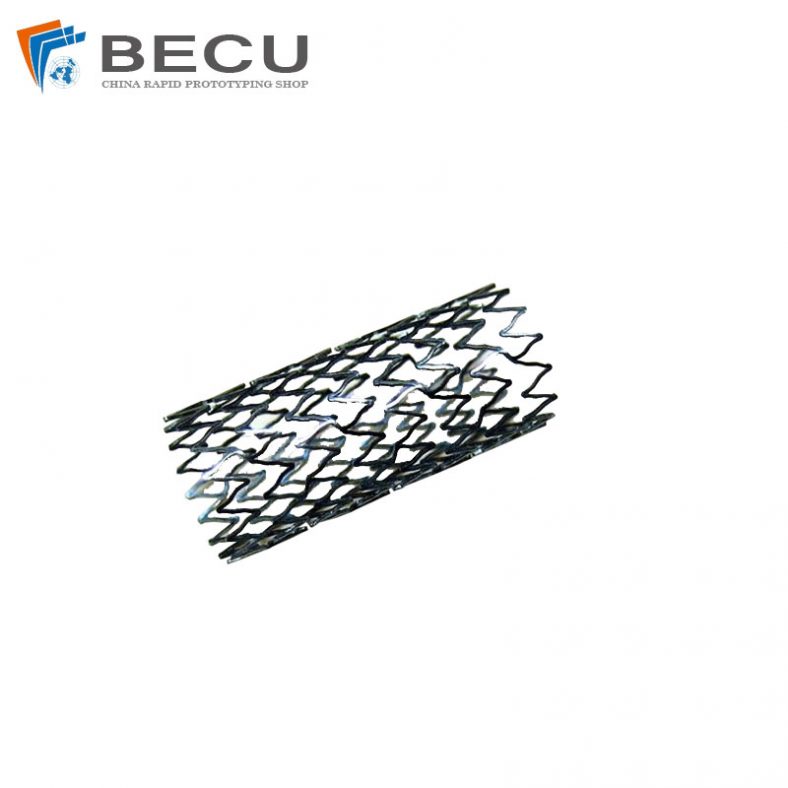

Laser Cut Nitinol Stent For Bile Duct

-

Stents For Carrying Valves And Venous Valve Replacement Devices

-

Precision Swiss Turning Titanium Alloy Medical Shaft

-

TA1TA2 Alloy Sheet Metal Manufacturing Machinery Support Parts

-

3D Printing Ti-6Al-4V Sacroiliac Screws

-

3D Printing Titanium Alloy Dental Teeth

-

3D Printing Titanium Grade 5 Medical Implants

-

Investment Casting For TC4 Golf Putter Head

-

Custom Titanium Alloy Electric Bike Folder Parts Via SLM

-

3D Printing TC4 Metal Globe Table Decoration