CNC Machining For Medical Industry

Precision CNC Machining improves medical care. Medical products, equipment and accessories are becoming increasingly sophisticated as new technologies emerge to improve human health and patient outcomes. They can be found everywhere, from surgical wards to rehabilitation centres, from small town clinics to home medicine kits.

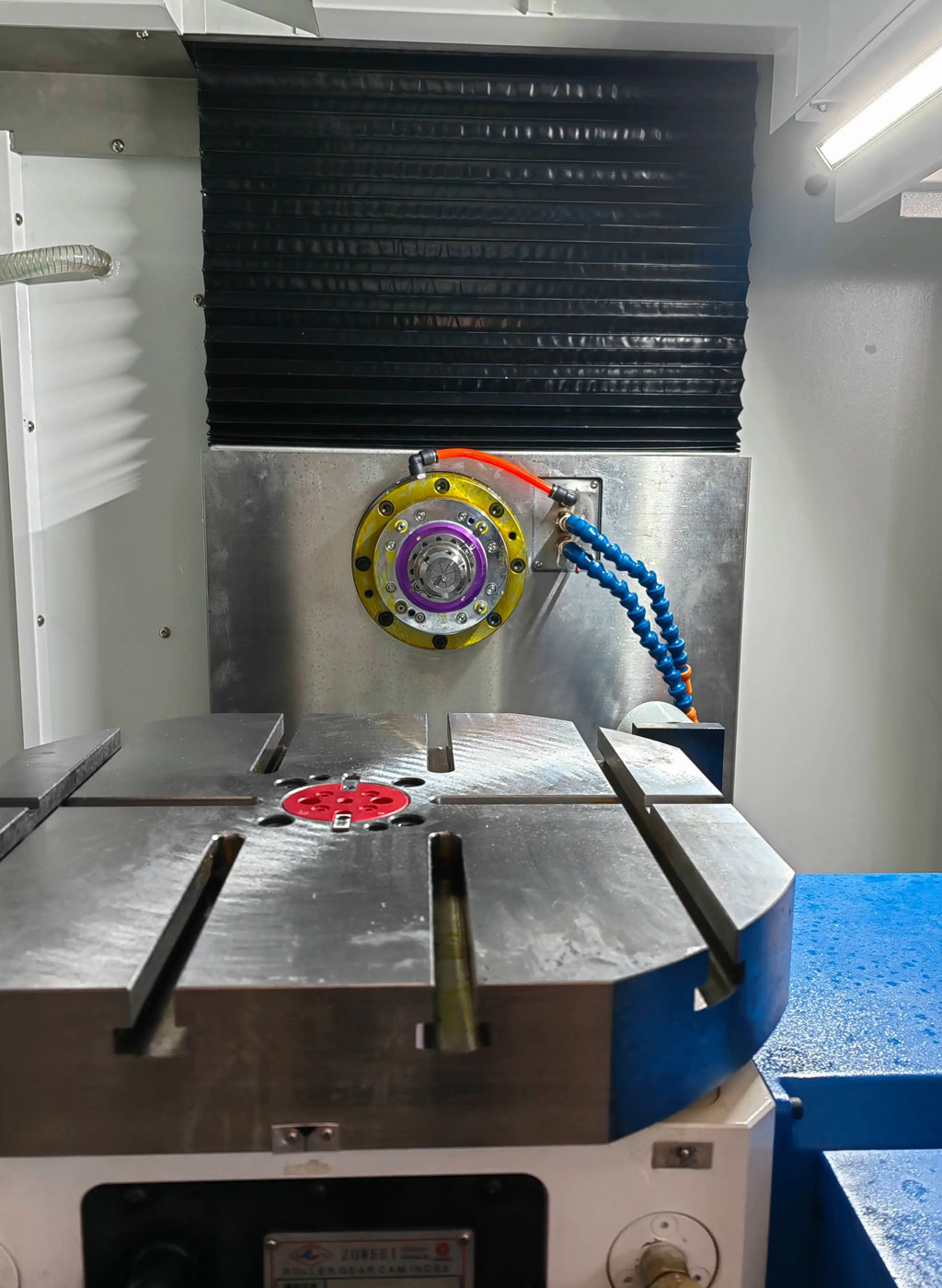

Sophisticated software and specialist cutting tools are improving the accuracy, repeatability and scalability of CNC machining. Regardless of the type of product, all have some common characteristics.

- They must be safe to use and the degree of safety includes the manufacture of their raw materials.

- They must be reliable, with the tight tolerances required for predictable and repeatable performance.

- They are often highly customised and have a unique design that makes them suitable for very specific applications related to human anatomy

- Importantly, new product ideas can be quickly prototyped, tested, approved and brought to market.

- CNC machining is the ideal manufacturing solution to meet all these criteria and more.

Cnc Machining Medical Parts – Medical Machining Specialist

CNC machining is essential in the development and production of a wide range of medical devices, including anatomical models, handheld devices and large devices.The Be-cu name is a byword in medical manufacturing. Thanks to our trusted reputation for meeting exceptional requirements for intricate and highly complex components, we deliver the supply reliability our medical customers can’t live without.

Precision 4 and 5-axis CNC swiss screw machining services including milling, wire EDM, external and internal threading, contour, form, taper and straight turning. Capabilities include contract manufacturing of complex medical parts and larger medical components. Aluminum, brass, copper, Glidcop®, titanium, stainless steel, Hastelloy®, Inconel®, Invar®, molybdenum, tungsten, PEEK, acetal, ceramic and more materials are worked with. Equipped with CAD and CAM software. Provides tolerances up to 0.0003 in. for horizontal milling, 0.0002 in. for CNC turning and 0.0001 in. for screw machining. Prototype and low to high volume production runs offered. Blanket orders also accepted.

The Appliaction Of Medical CNC Machining

Due to its versatility, CNC machining is suitable for the custom manufacture of a wide range of medical products. Examples can include stainless steel tools, forceps and clamps; surgical implants for bone repair; orthopaedic and prosthetic components; high-temperature accessories for sterilisation chambers; components for testing equipment; the list is endless. The list really is endless. However, CNC machining is not the most suitable plastic part that should be moulded.

CNC machining may be available for hospitals, clinics, medical research centres. For many applications, CNC machining is faster than 3D printing, and its parts can be produced more robustly and accurately. Even in remote areas, small, portable and large multi-axis machining centres can be easily placed to provide fast, accurate and inexpensive manufacturing solutions.

The Advantage Of Medical CNC Machining

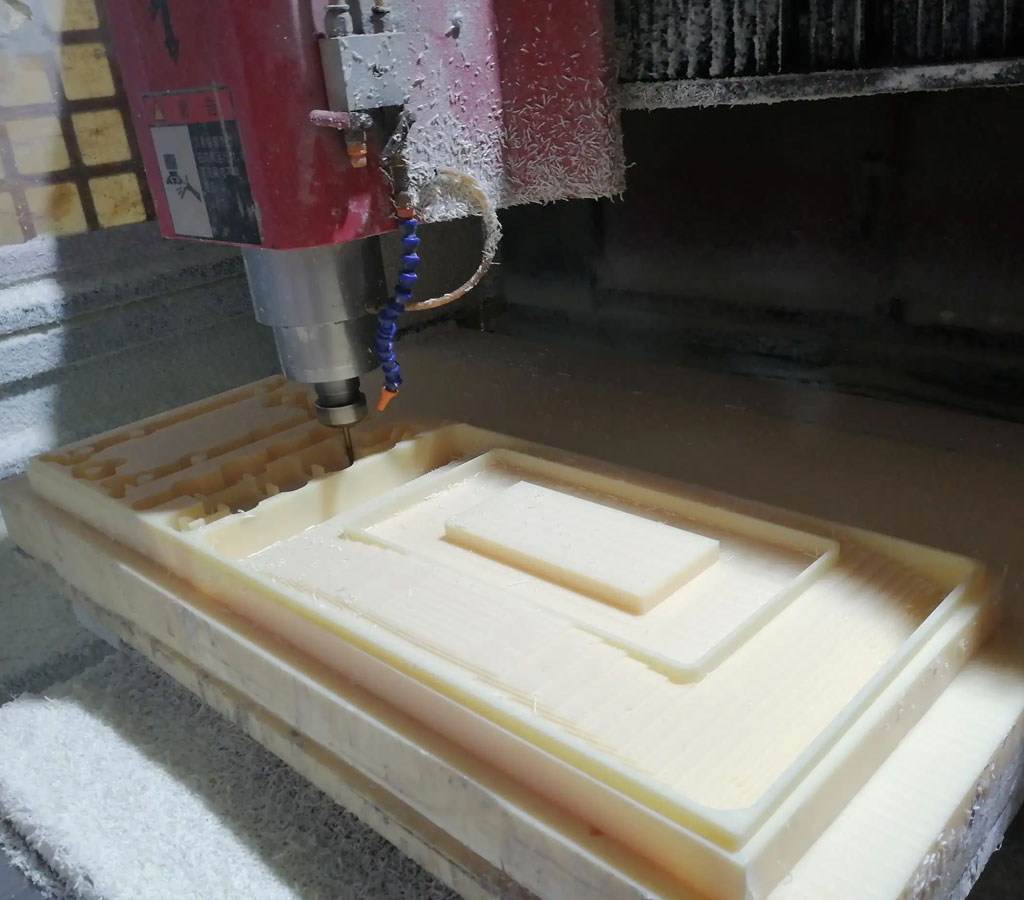

Every new product starts with a prototype. This is as true for medical technology as it is for any other industry. There are several advantages to using CNC machining for medical prototypes.

- Rapid Prototyping: Once a design has been approved, it can be programmed and processed in just one day. This allows product engineers to properly test for adaptability and functionality – key steps in the production process. The physical prototype helps to identify any potential design flaws or areas where improvements can be made. If minor changes are required, only the machine program needs to be changed accordingly.

- CNC Machining Accuracy And Repeatability: Once the design is complete, any number of repeat parts can be made on any functional CNC milling machine or lathe. Tolerances between parts are small, typically 5 microns or less. In previous times, manual machines were required to achieve this accuracy, requiring the skills of a machinist under controlled conditions, which would be much slower and more costly. Nowadays, digital motors, sophisticated software and specialist cutting tools make it easy to achieve this perfection with complete reliability. So, medical product designers no longer need to hire – to do it? Yes, you can.

- Measurability: Some mass production processes first rely on the manufacture of moulds for forming or casting, such as plastic injection moulding or investment moulding. These moulds take much longer to manufacture and require a significant upfront capital investment. From a developer’s perspective, the only way to recoup the cost of this investment is to commit to manufacturing a large number of finished products over time. But many medical designs are highly customised and will not be produced in large quantities, so investing in tooling is not a viable option. CNC machining does not require hard tooling, so individual parts can be produced cost-effectively, and production volumes will slowly increase as demand grows.

- Versatility: CNC machining does not care about the raw material being machined, as long as it is rigid enough to withstand the force of the tool. There may be some minor machine adjustments for different types of metal or plastic (speeds and feeds), but this versatile nature means that designers and medical technicians have a lot of scope to select the most suitable material for the intended application.

Why Choose Our Medical Machining Service?

- Save time and money for your Medical project but quality guaranteed.

- High productivity, outstanding efficiency and high accuracy

- A wide range of material grades and alloy materials can be machined

- Custom complex Medical machined parts and components at specific tolerances

- High speed machining for prototyping and low to high volume production runs

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

Top China Medical Cnc Machining Parts & Case Studies

With the continuous maturity and development of CNC Machining technology, more and more car manufacturers have introduced this technology for prototype testing, design proofing, parts customization and other applications. By exploring our success stories, you can learn about: the development of CNC Machining in the Medical industry, the application of CNC Machining in Medical molds, how CNC Machining changes the Medical manufacturing supply chain, and more.

-

5 Axis CNC Machining Medical Olecranon Plate

-

Automatic Swiss Turning Stainless Steel 316L U-bolt

-

Micro CNC Machining Kovar 4J29 Medical Implant

-

Precision Swiss Turning Titanium Alloy Medical Shaft

-

Swiss Turning 304 Stainless Steel Medical Threaded Rod

-

Custom Black PEEK Pet Hair Dryer Fan

-

Deep Hole CNC Turning Titanium Alloy Dispensing Needle

-

Precision Turning TC4 Alloy Medical Ultrasound Bead Needle

-

Swiss Machining Stainless Steel Alloy Medical Disposable Trocar

-

CNC Milling Machining PEEK Medical Parts

-

4-Axis CNC Machining Aluminum 2011 Medical Parts

-

Titanium Alloy Internal Fixation Plate For Medical Equipment