Femtosecond Laser Cutting

- Firstly, the duration of femtosecond laser pulses is extremely short, only a few femtoseconds, making them thousands of times shorter than the shortest pulses obtained using electronic methods, representing the shortest pulses achievable by humans under experimental conditions.

- Secondly, femtosecond lasers have extremely high instantaneous power, reaching trillions of watts, which is hundreds of times more than the total power generation of the entire world.

- Thirdly, femtosecond lasers can be focused into spatial regions smaller than the diameter of a hair, creating electromagnetic field intensities several times higher than the forces acting on electrons around atomic nuclei, many of which are extreme physical conditions that do not exist on Earth and cannot be obtained by other methods.

Due to the ultra-high peak power of femtosecond lasers, after focusing, the light intensity can reach the order of 10^22 watts per square centimeter. Such intensity far exceeds the Coulomb field of interaction within atoms, so femtosecond laser pulses can easily liberate electrons from atomic confinement, forming a plasma. For example, the Coulomb field strength of a hydrogen atom is 5×10^11 volts per meter, while a femtosecond laser pulse of 1 millijoule, after focusing, can reach the order of 10^12 volts per meter, allowing it to ionize hydrogen atoms.

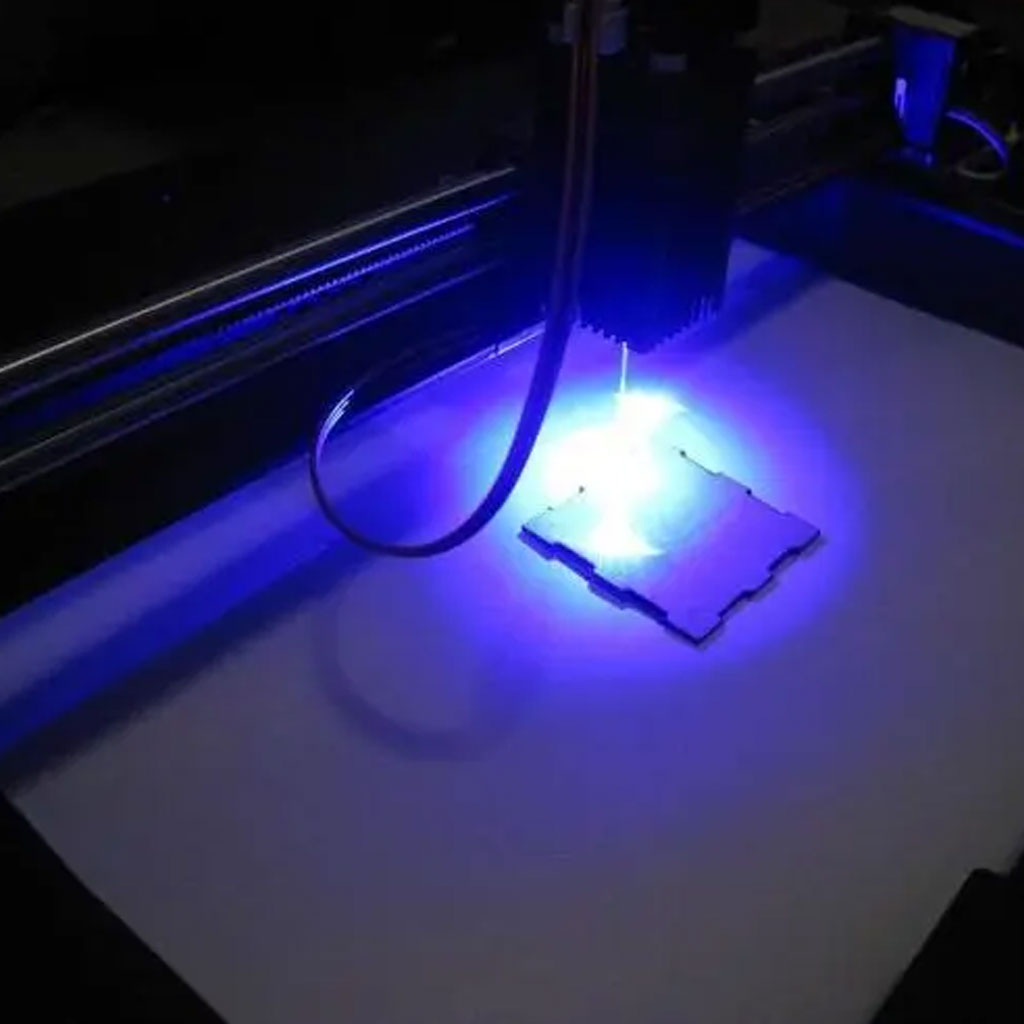

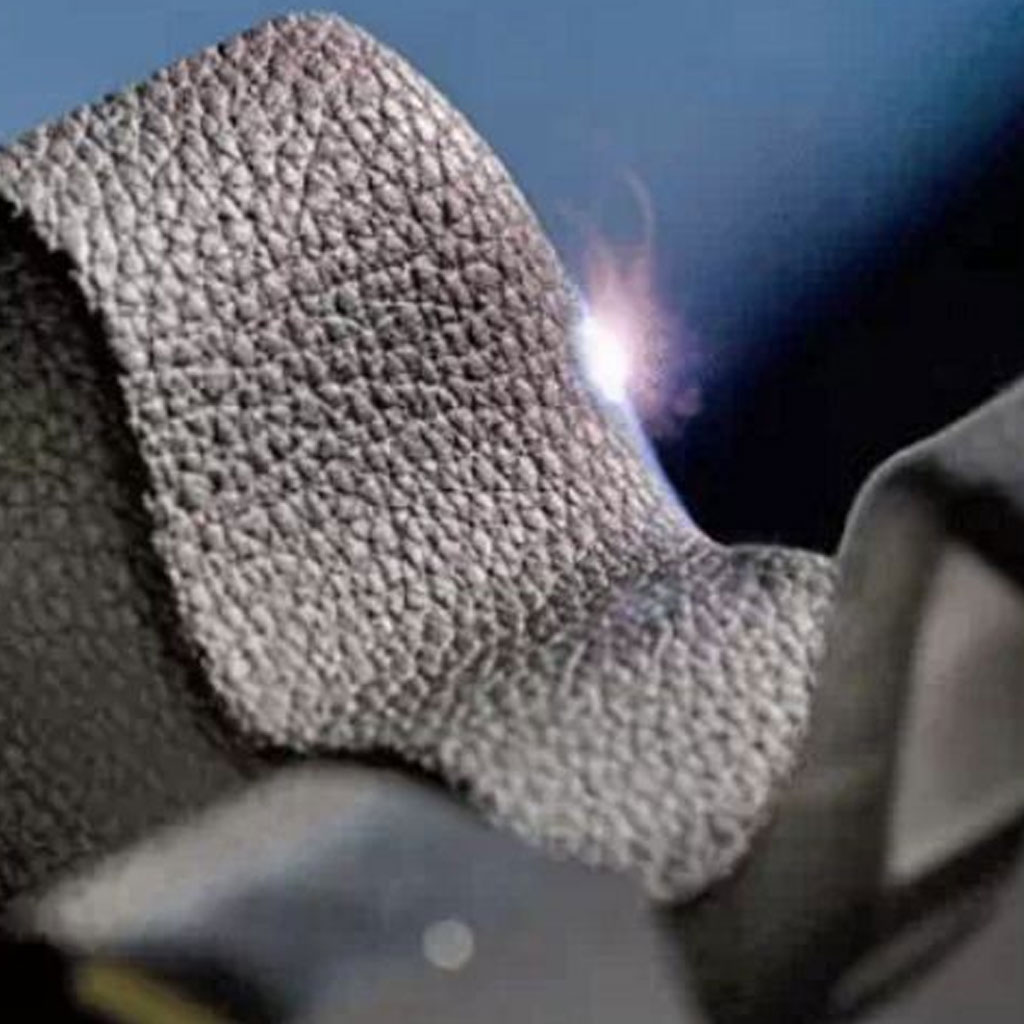

Femtosecond laser cutting is a cutting-edge technique used in various industries, including manufacturing, electronics, and medical devices. It involves using an ultrafast laser, typically operating in the femtosecond (10^-15 seconds) range, to precisely cut materials with extremely high accuracy and minimal heat damage.

Applications of femtosecond laser cutting include microelectronics manufacturing, medical device fabrication, precision machining, and microfluidics, among others. It’s a cutting-edge technology that continues to push the boundaries of what’s possible in terms of precision manufacturing.

Best Femtosecond Laser Cutting In China- Femto Laser Cutting Company

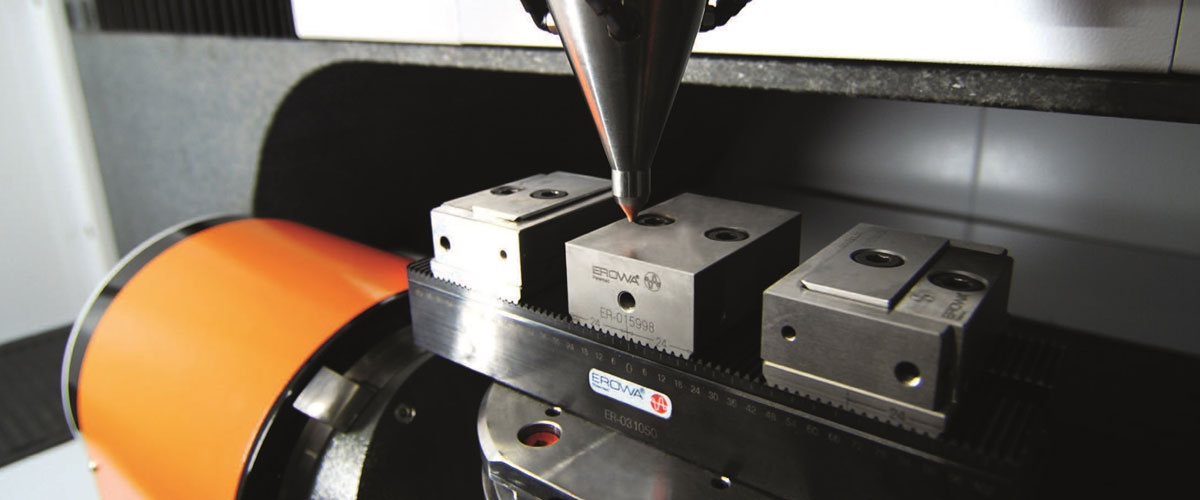

China Be-Cu Prototype Inc. utilizes proprietary patented technology, including a femtosecond laser spiral drilling system and unique ELID (Electrolytic In-Process Dressing) technology for grinding wheels, femtosecond laser polishing technology, to produce various ultra-precision components.

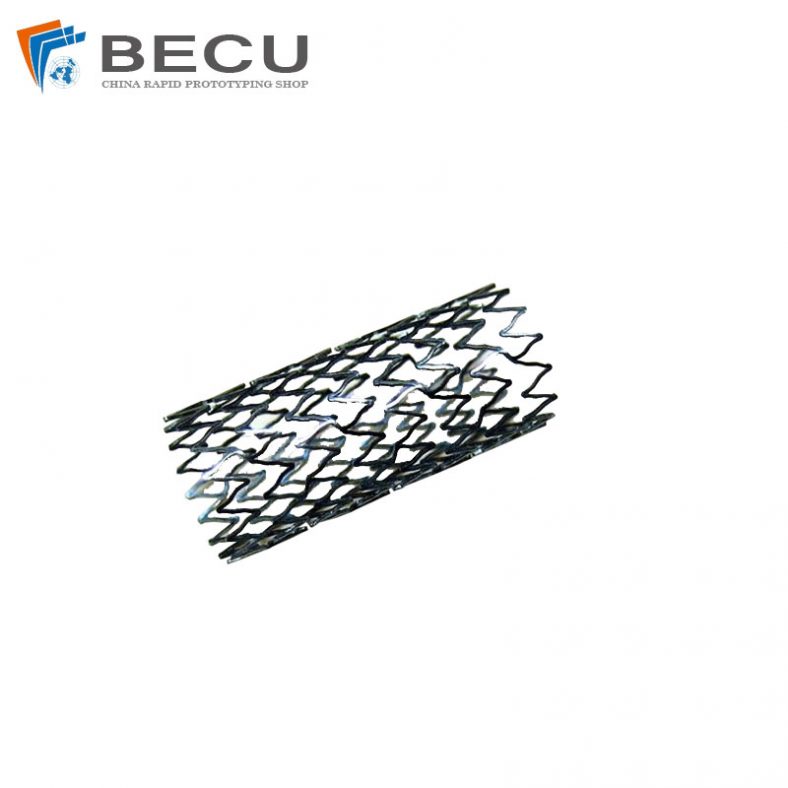

Femtosecond Laser Cutting For ∅4.5mm Disposable Biliary Cobra Bone

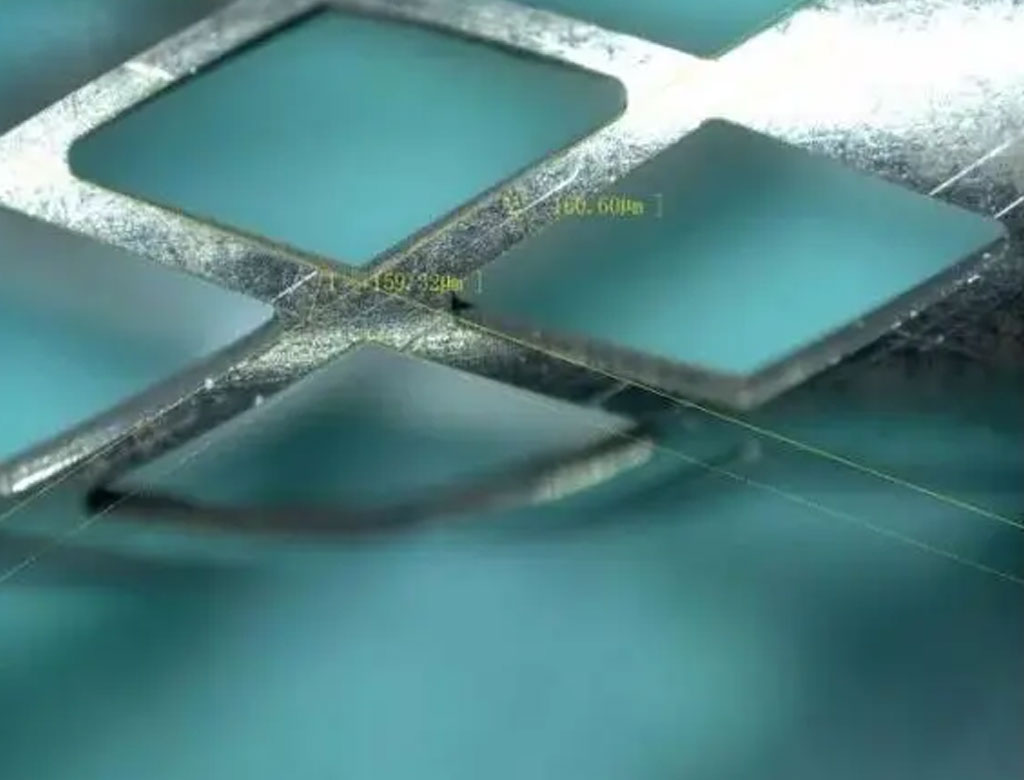

With a track record including Huawei, Samsung Electronics, and WuXi AppTec, among other well-known enterprises, we specialize in producing ultra-precision components with dimensions as follows: a 440-millimeter flat square panel with a flatness achievable to 5 micrometers or less, surface roughness of RA reaching 0.01 micrometers or less, capable of drilling holes as small as 20 micrometers, achieving a roundness of over 95%, and capable of processing micro-holes of different shapes and sizes, with a maximum capacity of processing up to 800,000 micro-holes.

Regarding tooling, blade edges can be processed to a thickness of 0.2 micrometers, with blade symmetry reaching 3 micrometers or less, and blade edge linearity below 5 micrometers.

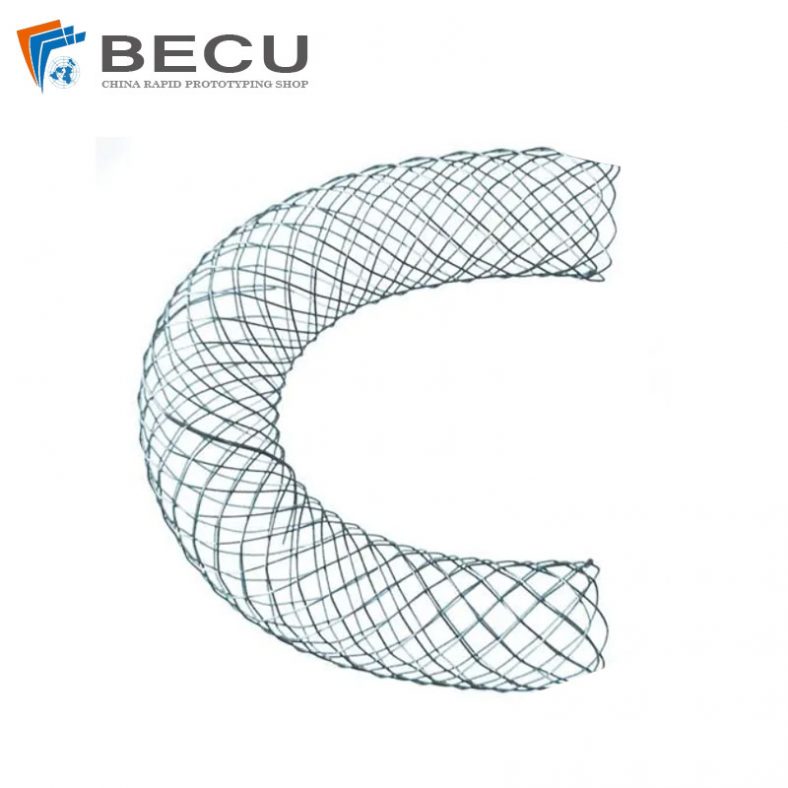

We specialize in the production of products requiring high difficulty, high geometric complexity, including dissipative components, nozzles, indexing tables, clamps, as well as various precision components for MLCCs, medical, and semiconductor fields, vacuum plates. We can process and manufacture various materials, including stainless steel, hard alloys, zirconia, and ceramics, tooling, blades, ultra-high precision jigs, medical stent, lens cutters, and tooling for C L cutters, TCB pick tools, folding chip molds, and camera module pick tools, fixtures. Particularly, ultra-thin, ultra-sharp lens cutters, smooth edge cutting of plastic lens molds, which occupy over 90% of the market share in Guangdong, China for plastic lens cutting tools, and precision fixtures for hot-press bonding of camera sensors with ICs and PCBs, also capturing over 90% of the market share in the southern China region.

In addition to vacuum suction plates, femtosecond laser micro-drilling technology can be applied in various fields. For example, fuel injectors, synthetic fiber spinning nozzles, melt-blown nozzles, spunbond nozzles, special alignment/carbide, micro-holes in biological chips, valve types, and special processing of shaped/carbide tungsten.

21st Century Company has collaborated with dozens of global partners in various fields including the medical industry,electronics industry, materials industry, and automotive industry. Additionally, the company possesses a variety of technological equipment, including laser processing equipment, cutting equipment, grinding equipment, etc., and has obtained various licenses and patent privileges.

To enhance the lifespan and performance of high-quality consumable tools and accessories used across industries, 21st Century Company continues to research new laser processing technologies, increase investment in product development, and provide customers with more stable technology and higher-quality services.

Our Femto Laser Cutting Specification

- Minumum Width Of Cut:Typically 5µm

- Maximum Material Thickness:Typically 1mm (dependant on speed requirements)

- We has demonstrated .5 micron accuracy on Femto laser features.

Our Femto Laser Cutting Material

The Femtosecond Laser is very effective on a wide range of materials. Be-Cu has completed a case study to exemplify the flexibility of the Femto Laser in processing a variety of materials for micro circuit applications including both polymers and metallic materials with identical results.

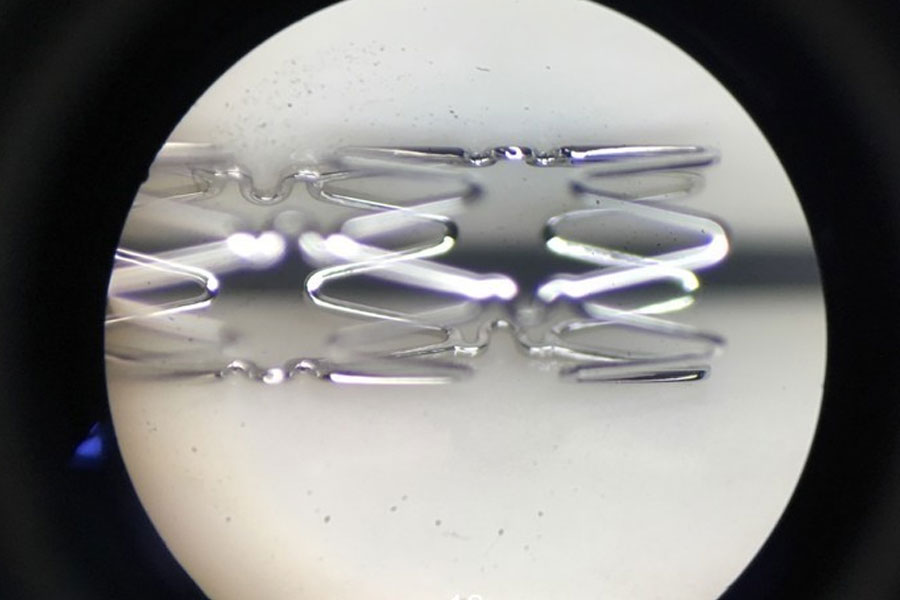

Be-Cu’s process engineers have experience in processing a wide range of metals with the Femtosecond Laser. Examples include nitinol alloy, stainless steel, MP35N, Inconel, ferrous materials, aluminum, brass, tungsten, and tungsten alloys, including carbide. In addition, they have experience processing precious metals such as gold, platinum, silver, etc. They also have experience working with polymers, such as silicone, pebax, polyimide, garolite, etc, as well as PEEK, polyethylene, and many others.

The Femtosecond Laser cutting makes it possible to machine with no tool wear, and no heat affected zone, which enables ultra-high surface and edge quality. The machining platform is extremely stable and allows for highly accurate 5-axis manipulation of the workpiece. Machine movements in the Femto Laser are controlled to sub-micron accuracy.

Certifications & Quality Cutting

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

Top China Leading Femtosecond Laser Cutting Case Studies

With Be-Cu’s state-of-the-art technology and laser cutting equipment, we can oversee our laser process with a full 3-D visualization, making our process fast, smooth, and efficient. For example, when laser cutting a cogwheel for a watch manufacturing client, it only takes Be-Cu about 30 seconds to complete the precision cutting. Precision is the key to such small and intricate components, where the functionality of the product depends on it.Couldn’t find the case studies you want? Contact us now, we have a strong in-housing supply chain, can Femtosecond Laser Cutting any prototype project and parts for you.

Capabilities of Our Femtosecond Laser Cutting Services

Our reputation for precision and innovation has earned us the trust of Fortune 500 companies across a wide range of sectors. Our femto laser technology has been instrumental in advancing many industries, each with its unique challenges and requirements.Our capabilities are as follows:

- Micromachining

- Laser Hole Drilling

- Laser Resistor Trimming

- Minimal Heat Affected Zone (HAZ)

- Versatility in Material

- Compatibility

- Non-contact Processing

- High Throughput and Productivity

- Intricate and Small Feature Sizes

- Customization and Prototyping

- Clean and Burr-free Cutting

- Scalability and Production Volume

- Laser Scribing and Cutting

- Thin-Film Laser Etching

- Wafer Laser Coring, Dicing, and Resizing

Industries We Serve

Femtosecond laser cutting technology serves a wide range of industries due to its precision, versatility, and ability to work with various materials. Some of the industries that benefit from femtosecond laser cutting include:

Femtosecond Laser Cutting For Medical Device

Femtosecond Laser Cutting For Electronics

Femtosecond Laser Cutting For Automotive

Femtosecond Laser Cutting For Aerospace and Defense

Femtosecond Laser Cutting For Semiconductor

Femtosecond Laser Cutting For Biotechnology

These are just a few examples, and the versatility of femtosecond laser cutting technology continues to drive innovation across a wide range of industries, enabling the production of complex and high-quality products with unprecedented precision.

Why Use Femtosecond Laser Cutting For Extreme Precision?

Femtosecond laser cutting offers several advantages for achieving extreme precision in various applications:

- Ultrafast Pulses: Femtosecond lasers emit pulses of light with durations on the order of femtoseconds (10^-15 seconds). These ultrafast pulses enable precise material removal with minimal heat affected zones. As a result, the material can be cut or processed with extremely high spatial resolution and minimal damage to the surrounding areas.

- Non-linear Absorption: Femtosecond lasers operate in a regime where non-linear absorption processes dominate the interaction between the laser light and the material. This means that the laser energy is absorbed very efficiently and confined to a small volume, allowing for precise material removal even in transparent materials or materials that are traditionally difficult to process with conventional lasers.

- Cold Ablation: Due to the extremely short duration of femtosecond pulses, the energy deposited into the material occurs so rapidly that it effectively bypasses the thermal diffusion process. This phenomenon, known as “cold ablation,” minimizes the heat-affected zone and prevents thermal damage to the surrounding material, enabling high precision processing.

- Material Compatibility: Femtosecond lasers can process a wide range of materials, including metals, semiconductors, ceramics, polymers, and even biological tissues, with high precision. This versatility makes them valuable tools for applications ranging from microelectronics manufacturing to medical device fabrication.

- Intricate Geometries: The high precision and minimal heat affected zone of femtosecond laser processing enable the fabrication of intricate geometries and features with sub-micrometer accuracy. This makes femtosecond lasers suitable for applications requiring complex microstructures or fine details.

Overall, femtosecond laser processing offers unmatched precision, versatility, and control, making it an ideal choice for applications where extreme precision is paramount, such as microelectronics, biomedical devices, microfluidics, and photonics.

Online Cooperate With Femtosecond Laser Cutting Company

Be-cu works with customers all over the world to bring customers ideas to life with the highest quality precision engineered metal components on the planet. We have both precision Femtosecond Laser Cutting capabilities that include both conventional and modernized production line. If you are looking for a partnership to help you apply new tools and technologies, or help you fully realize your design vision, let us help you move your business forward, contact our team ([email protected])or quote online today to get the conversation started.