Frequently Asked Questions From BE-CU.COM

Q1:Are you trading company or manufacturer ?position?

Q2:Can You Strictly Follow The Tolerance on The Drawing And Meet The High Precision?

Q3:Can you change the design of the sample?

professionally.

Q4:Is there any MOQ required?

Q5:If I don’t have drawing, how can I get sample ?

Q6:How to ensure that every process’s quality?

At the same time, the sales staff will follow up your order on the production line.

If you still have questions, you can check our quality page

Q7:What is your main products?

Q8:How about certificate?

Q9:What about the leading time for mass production?

Q10:What if the parts are not good?

Q11:What is your terms of payment ?

Q12:What’s your MOQ?

In general 1000pcs,but can accept low quantity in some special conditions.

Depand on which process do you choose ,

For die casting : Flexible volume is accepted by us in view of this new project growing. general guality :500 pcs

For investment casting:Flexible volume is accepted by us in view of this new project growing. general guality :100 pcs

For sand casting:Flexible volume is accepted by us in view of this new project growing. general guality :100 pcs

Q13:What is your lead time for production ?

Q14:Do you provide samples ? is it free or extra ?

Q15:How long is your delivery time?

2) Lead time for making sample:about 2-7 days.

Q16:How long if your offer qutation ?

Q17:Is The Anodized Parts Conductive?

Q18:What is the difference between aluminum profile anodizing and natural oxidation?

Q19:New Die Casting Tooling Acceptance Content

>Is the mold number clear and correct?

> Mold size?

> What is the diameter of the material cylinder?

> What is the eccentricity under the mold?

> What is the spacing of the ejector holes?

> What is the size and spacing of the tie rod holes?

> Mold cavity error value ≤ 0.1mm (check the indentation around the cavity)?

> Surface roughness Ra≤0.4μm?

> There are no damages, scratches or cracks on the surface of the cavity?

> Can the thimble and slider be free from jamming?

> The movable and fixed mold core is 0.02~0.06mm higher than the mold base?

> Is the arrangement of the ring holes on the mold base, top plate, thimble fixing plate and mold foot reasonable and convenient?

> Are the cooling water inlet and outlet marked clearly?

> Does the cooling water mold end interface match the specifications of the company’s common water pipes?

> Does the hydraulic cylinder mold end interface match the specifications of the company’s common oil pipe interface?

> Does the supplier provide tie rods and top rods?

> Does the supplier provide core spare parts?

> Does the supplier provide spare parts drawings?

> Does the supplier provide the material certificate and heat treatment report?

Q20:Your price is very high and i can get lower price from other supplier.

Of course, if you could bear various kinds of bad problems and invalid commitment of cheaper productions. Their price is cheaper $ 1 than us and you can earn 10000 USD on 10000 pcs parts. But you will lose more than 10000 USD, even more lose a faithful customer if it happened a mechanical mishap occur. At the same time, I don’t think you can get more higher efficiency of the supply when you get a price which is lower 0.5-1 USD because price elasticity depends on different service.

Finally, you are an expert in the filed, if they can give you an offer which is even lower than the cost. What will you think about it.

What you will get is what you paid for.

You can call me if you have any questions ,we will reply you as soon as possible!

Q21:What Kind Of Aluminum Or Zinc Material Do You Die Casting With?

A360

A380

ADC6

ADC10

ADC12

ALSi12

ALSi9Cu3

For Zinc Parts:

Zamak3

Zamak5

Zamak8

Zamak12

Q22:What Can We Do For You?(Die Casting And Cnc Machining etc.,)

Q23:How to save the die casting cost ?

maybe there’s a scratch.it’s perfectly good and doesn’t deserve to be thrown in the furnace

if you can agree Non fatal problem, keep millions of kilos of materials from being wasted

and help many customer like you save piles of money

Q24:Do you show the new style part ?

Sorry ,I only show the part that approved by customer ,or some oldest style part .

Because I signed the NDA and only show the ability of Fabrication and Mechanical Service–die casting china ,CNC machining china,Assembly

welcome visit be-cu.com ,Thank

Q25:How to visit us ?

Find die casting supplier , cnc machining fatory .

Welcome to visit us, it is very convenient from Hk to dongguan.

It is also our pleasure to help you on pick-up and hotel booking.

Q26:Why your die casting price is more reasonable than other china supplier?

2. Die Casting machine:LK GROUP , YIZHIMI Group,lijie

3.Use Green Energy ,Save the world : Huawei,Natural gas,Electricity ——choose us , for the Minghe Casting.thanks

4, Die Casting Mold :Bigger Size ,and more than 50000 shots mold life.

5.Inspection equipment:CMM

Q27:Types of Dies

A single cavity die requires no explanation. Multiple cavity dies have several cavities which are all identical. If a die has cavities of different shapes, it’s called a combination or family die. A combination die is used to produce several parts for an assembly. For simple parts, unit dies might be used to effect tooling and production economies. Several parts for an assembly, or for different customers, might be cast at the same time with unit dies. One or more unit dies are assembled in a common holder and connected by runners to a common opening or sprue hole. This permits simultaneous filling of all cavities.

Q28:Casting Dies and their Construction

The fixed die half of the die is designed to contain the sprue hole through which molten metal enters the die. The ejector half usually contains the runners (passage ways) and gates (inlets) which route molten metal to the cavity (or cavities) of the die. The ejector half is also connected to an ejector box which houses the mechanism for ejecting the casting from the die. Ejection occurs when pins connected to the ejector plate move forward to force the casting from the cavity. This usually occurs as part of the opening stroke of the machine. Placement of ejector pins must be carefully arranged so force placed upon the casting during ejection will not cause deformation. Return pins attached to the ejector plate return this plate to its casting position as the die closes.

Fixed and moveable cores are often used in dies. If fixed, the core axis must be parallel to the direction of die opening. If moveable, they are often attached to core slides. Should the side of a die casting design require a depression, the die can be made with one or more slides to obtain the desired result without affecting ejection of the casting from the die cavity. All moveable slides and cores must be carefully fitted, and have the ability to be securely locked into position during the casting cycle. Otherwise, molten metal could be forced into their slideways causing a disruption of operations. Although slides and cores add to the complexity and cost of die construction, they make it possible to produce die castings in a wide variety of configurations, and usually more economically than any other metalworking process.

Q29:How do I know what process is best for my needs?

Q30:I want to know more manufacturing knowledge

Many Technologies, One Standard: On-Time Quality

At BE-CU, we have implemented a Strict Quality Inspection Standard for our fabrication services to inspect parts and ensure the consistency of cosmetic appearance.Our custom parts services are bolstered by our extensive be-cu machine library and general breadth of fabricate technology. Few can match be-cu in adherence to exacting specifications, or in the re-creation of complex geometries for high volume fabrication of all types of specialized material parts.

We are proud to be fully certified. This demonstrates our commitment to continuous quality improvement, respect for our workers and for the environment.See examples of our case studies on our Products Page

-

CNC Machining Bakelite Circuit Board Test Fixture

-

Precision Grinding Tungsten Steel Mold Parts

-

5 Axis CNC Machining Medical Olecranon Plate

-

Special-Shaped Non-Standard Medical Device Needles

-

High-Speed Steel (HSS) Die Punching Needles

-

Precision Tungsten Copper Alloy Eccentric Insert

-

5 Axis CNC Machining Spiral Bevel Gear Mold

-

Small Precision Injection Molding Inserts

-

5 Axis Machining Aluminum-Magnesium Alloy Water Aerator Impeller

-

Large CNC Turning Inconel 625 Automobile Engine Camshafts

-

Swiss Machining And Bending 304 Hand Sewing Needle For Textile Machinery

-

Automatic Swiss Turning Stainless Steel 316L U-bolt

-

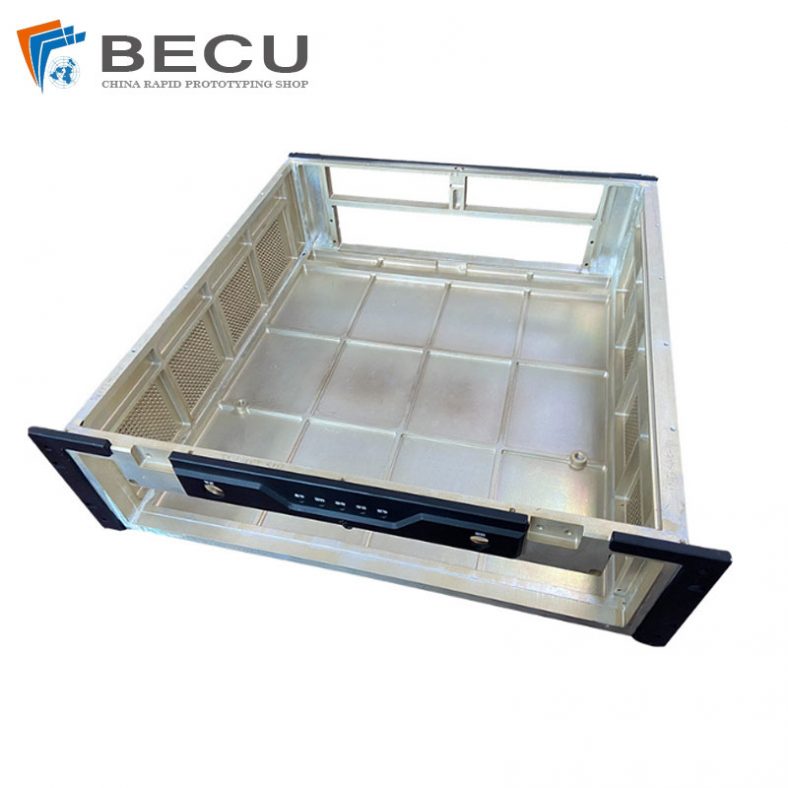

Precision Machining 6063 Aluminum Military Computer Server Chassis

-

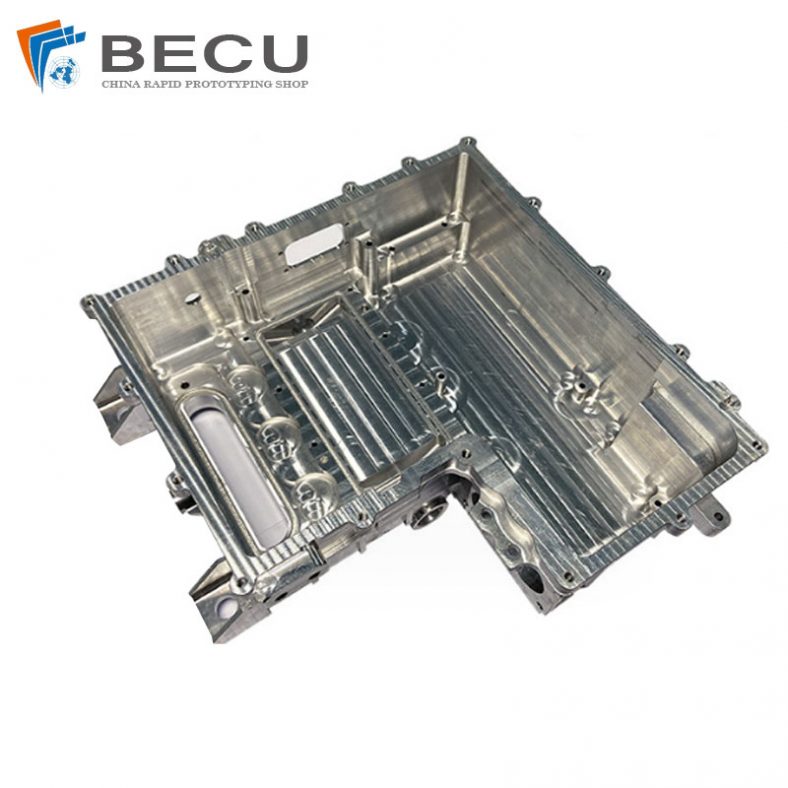

CNC 6063 Aluminum Automotive Motor End Cover

-

4 Axis CNC Machining Titanium Grade 5 Mobile Phone Buttons

-

CNC Machining Anti-static Translucent PC Optical Parts

-

Precision Turning 20° Acrylic Downlight Reflector

-

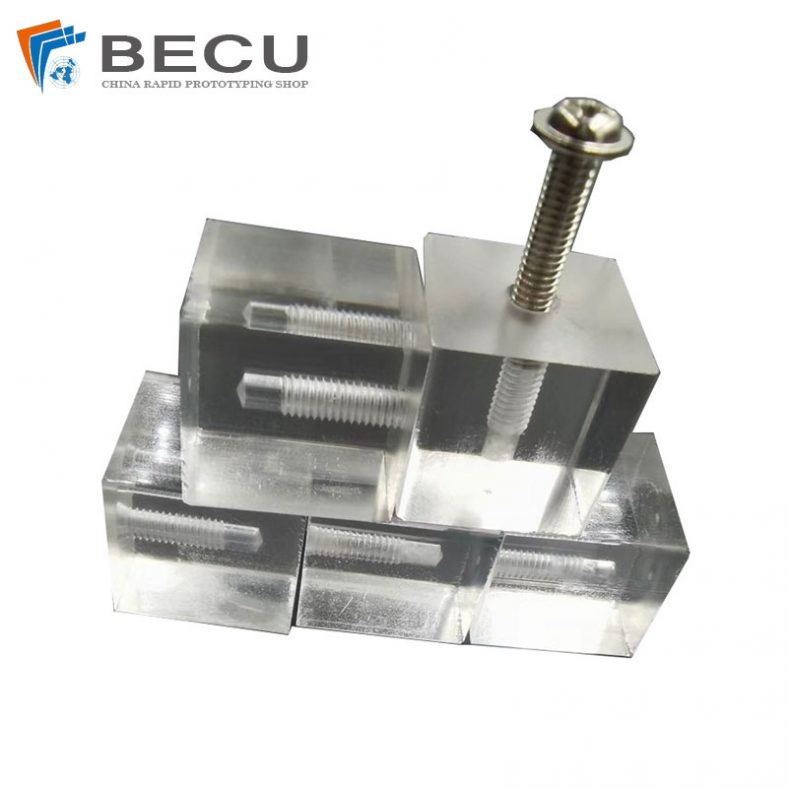

Transparent Acrylic Faceted Cube Threaded Clamp

-

CNC Turning Transparent PMMA Wear-Resistant Mechanical Parts

-

4 Axis Machining Highly Transparent Acrylic LED Tunnel Light Lens