Industrial Design Service

- Rapid Prototype Solutions

- Volume Manufacturing Solutions

- Mold Manufacturing Solutions

- After Sale Solutions

- OEM Solutions And More

>>>Take advantage of direct access to be-cu’s world-class technicians,

ready to help with all of your parts and project needs.

Industrial Design & Product Drawings for Your Custom Parts

Our industrial design services drive innovation by using a human-centric design focus leading to parts that are physically and digitally intuitive, easy to use, and highly functional.

Online Parts Design Services

Good industrial design considers all aspects of user experience, mechanical functionality, and manufacturing concerns, balanced with the client’s key objectives of features, cost targets, and timeline.

At Be-cu.com, industrial design starts from the very beginning of a project by understanding the user and maintaining the original design intent all the way through to manufacturing of the product.With a highly-skilled design and engineering team, our online Parts Design Services can turn your concept into reality, ranging from mechanical components to parts used in aerospace, automotive, machinery, electronics, military, medical, led, and more industries.

Even if you just have an idea of the final parts, please tell us your detailed requirements or submit a sample, we’ll deliver a professional product design drawing based on your customization. The parts design can also be converted into exact objects as required at our factory.With years of manufacturing and parts design experience, our design experts offer the best solution for all your rapid manufacturing needs.

Capabilities of Be-cu Online Parts Design Services

| Research | Our industrial design process starts with research to understand the client’s key objectives, client’s voice of customer (VOC), the competitive product landscape and market trends. |

| Brainstorming and early concept generation | Then we start our brainstorming process to find innovations and start early concept development. |

| User interface studies | We will work with our Experience Design (XD) group to immerse ourselves in the User’s experience. Then start concept sketching and building rough 3D mockup to test with Users. This iterative concept development will go through many cycles. |

| Instrument concept sketching | As the concepts begin to take shape, we continue to sketch out and refine them taking into account findings from the user experience studies. Simultaneously, we are working with the engineering team to ensure we are aligned, helping to drive internal component layout with the User in mind. |

| Concept refinement | Further refinement includes CMF study to evaluate colors, materials and finishes where appropriate for the market as well as maintaining cost targets. |

| 3D mock-ups | We will also continue to build full-size 3D mock-ups to evaluate ergonomic user interface, form and proportion and as a communication tool with engineering. |

| 3D CAD models | From there we’ll start to build 3D CAD models to ensure the mechanical components are well integrated. In addition, we will create photoreal CAD renderings to further evaluate CMF options. |

| Appearance models | If needed by the client for tradeshow or investor purposes, we will create appearance models that very closely resemble the actual product design |

| Maintain original design intent through production | Finally, we maintain the client’s agreed upon original design intent through the many months of technical development that occurs prior to final manufacturing production. |

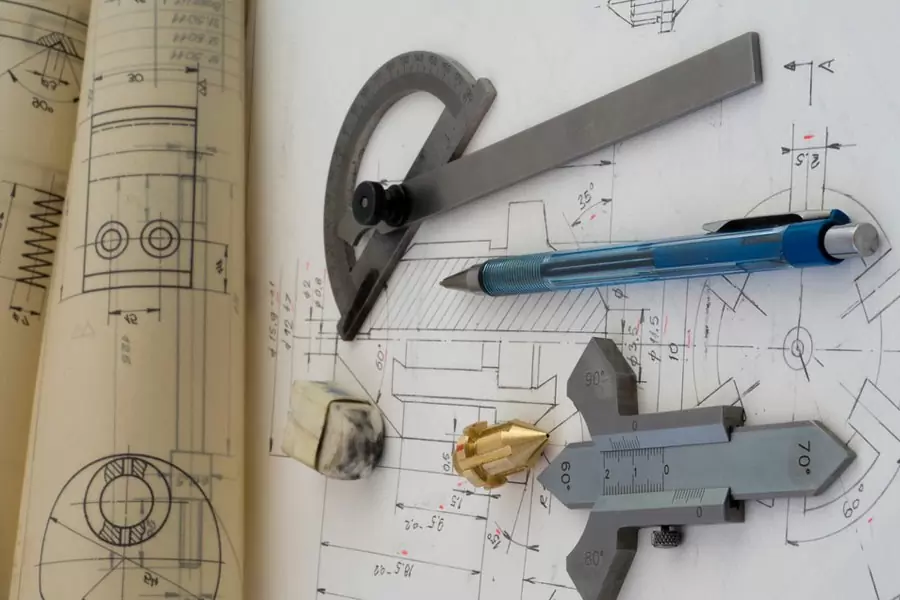

What Is Part Drawing?

Part drawing is a drawing that expresses the shape, size and characteristics of a single part, and is also a drawing used in the manufacture and inspection of machine parts, also known as a part working drawing. In the production process, production preparation, manufacturing and inspection are carried out according to the technical requirements of the part drawings and drawings. Therefore, it is an important technical document to guide the production of parts.

The basic requirements of the part drawing should follow the provisions of GB/T 17451-1998 “Technical Drawing – Drawing Method – View”. The standard clearly states that when drawing technical drawings, the first consideration should be given to the convenience of viewing the drawings. According to the structural characteristics of the object, the appropriate expression method is selected, and on the premise of expressing the shape of the object completely and clearly, we strive to make the drawing simple.

View Selection

- The view selection of the part is to choose a set of suitable views to express the internal and external structural shape of the part and the relative positional relationship of each part.

- A good part view expression scheme is: the expression is correct, complete, clear, concise, and easy to see.

- Because the structure and shape of the parts are various, the structure and shape of the parts should be analyzed before drawing, and the main view and other views should be selected according to the characteristics of different parts to determine the best expression scheme.

- The principle of choosing a view is: on the premise of expressing the inner and outer shape of the part completely and clearly, the number of graphics should be reduced as much as possible to facilitate drawing and viewing.

In order to meet production needs, a complete part drawing should include the following basic content:

- A set of views: To comprehensively use views, sections, sections and other prescribed and simplified drawing methods, select a set of views that can clearly express the internal and external structural shapes of the parts.

- Complete Dimensions: Used to determine the size and location of parts of a part. The part drawing should indicate all the dimensions required for the completion of processing and inspection of the parts for conformity.

- Title bar: indicate the name, material, quantity, date, number, scale and description of the part, signature of the reviewer, etc. According to national standards, there are fixed forms and sizes, and the drawings should be drawn according to the standards.

- Technical requirements: Annotate with some prescribed symbols, numbers, letters and words to concisely and accurately give some technical requirements that the parts should meet during use, manufacture and inspection (including surface roughness, dimensional tolerances, shape and position tolerances, surface treatment and material handling requirements).

Why Choose Our Online Parts Design Services

- Many industrial design firms create attractive product designs based on a customer-centric approach. And many engineering firms create functional instruments that perform well. But few firms combine intuitive designs with high functionality and reliability. Be-cu provides both.

- Our designers work collaboratively with team members across the full product development spectrum, from user experience design to mechanical and electrical engineering, medical scientists, software developers and contract manufacturing to creatively problem solve and arrive at innovative solutions.

- By seeking constant feedback from all project team members throughout the product development process, we are able to avoid the snarl of conflicting compliance demands, communication misfires, and the consequent increase in development time that could happen when design and development are more siloed.

- Be-cu ’s key advantage is this seamless merging of distinct teams, and our process of continual collaboration throughout the project, delivering intuitive, elegant and functional design. This dynamic communication between teams ensures all perspectives are represented, improving efficiency, ensuring compliance, and guaranteeing customer satisfaction.

Many Technologies, One Standard: On-Time Quality

Our custom parts services are bolstered by our extensive be-cu machine library and general breadth of fabricate technology. Few can match be-cu in adherence to exacting specifications, or in the re-creation of complex geometries for high volume fabrication of all types of specialized material parts.See examples of our case studies on our Products Page

At BE-CU, we have implemented a Strict Quality Inspection Standard for our fabrication services to inspect parts and ensure the consistency of cosmetic appearance. We are proud to be fully certified. This demonstrates our commitment to continuous quality improvement, respect for our workers and for the environment.

-

Precision Grinding Tungsten Steel Mold Parts

-

5 Axis CNC Machining Medical Olecranon Plate

-

Special-Shaped Non-Standard Medical Device Needles

-

High-Speed Steel (HSS) Die Punching Needles

-

Precision Tungsten Copper Alloy Eccentric Insert

-

5 Axis CNC Machining Spiral Bevel Gear Mold

-

Small Precision Injection Molding Inserts

-

5 Axis Machining Aluminum-Magnesium Alloy Water Aerator Impeller

-

Large CNC Turning Inconel 625 Automobile Engine Camshafts

-

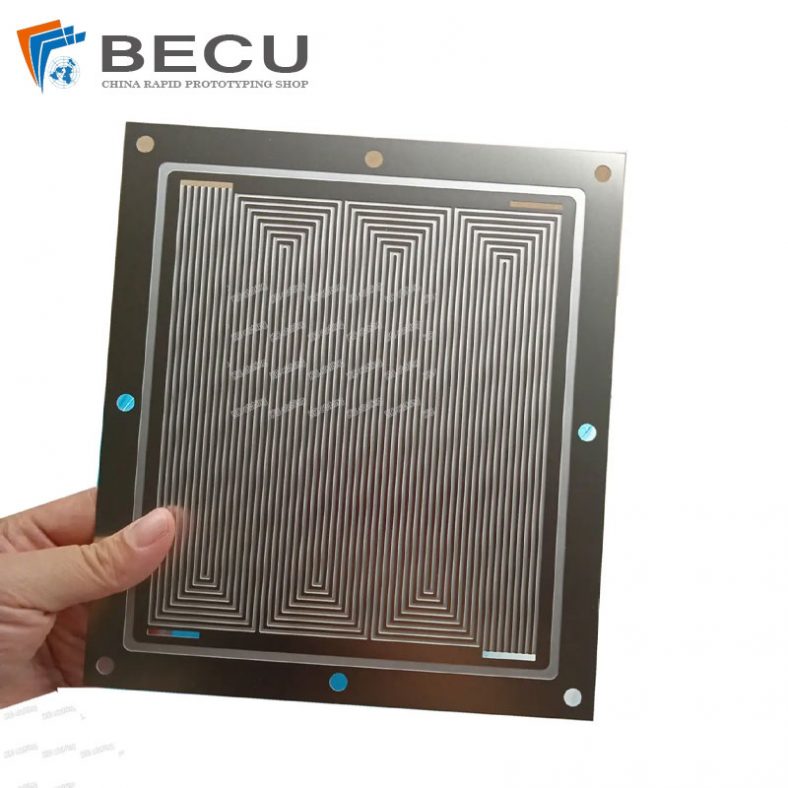

Metal Etched Hydrogen Fuel Cell Metal Bipolar Plates

-

Prototype CNC Spinning Stainless Steel 316L Outdoor Camping Pot

-

Precise Etching Stainless Steel 316 High-Speed Hair Dryer Networks