Post Processing

- Post Processing For Die Casting

- Post Processing For CNC Machining

- Post Processing For 3D Printing

- Post Processing For Mold Manufacturing

- Post Processing For More Services

>>>All uploaded drawings are strictly confidential, check the confidentiality agreement

What is Post Processing & How Does it Work – Post Processing Services

Post-processing corresponds to pre-processing, which refers to the next step after pre-processing, the work performed before final processing and perfection, or the steps performed after a certain stage of work. Industry or field, there will be different interpretations.

| Classification | Process | Effect |

|---|---|---|

| Surface Treatment By Machining | Frosted 、 Polished | Make The Surface Smooth And Bright And Beautiful |

| Surface Decoration Treatment | Finishing 、 Printing 、 Filming 、 Hot Stamping | DecoratIon, BeautifiCation, Anti-Aging And Anti-Corrosion |

| Surface Treatment | Thermal Spraying 、 Electroplating 、Ion Plating; | Make The Surface Wear-Resistant, Anti-Aging And Metallic luster |

Generally speaking, rapid prototyping parts produced by 3D printing technology, CNC machining technology, and silicone complex molding technology can be directly used for assembly testing, functional verification and other purposes. A series of surface treatments can also be carried out on the processed parts to improve the appearance, touch and texture of the parts surface, and play the role of beauty, anti-corrosion, anti-aging, anti-skid and so on. The prototype parts in the road test stage of automobile research and development all require a series of surface treatments for the rapid prototyping parts produced by 3D printing technology, CNC processing technology, and silicone mold technology, so that the performance of the prototype parts is closer. Mass-produced parts. Common surface treatments of non-metallic rapid prototyping parts include grinding and polishing, spraying, electroplating, silk screen printing, laser engraving, etc.

Car air conditioning shell quick sample sandblasting effect Car dashboard quick sample frosting effect transparent part polishing effect

The common surface decoration treatment methods of non-metal rapid prototyping parts are: spraying, printing (silk screen transfer hot stamping), film, laser engraving, etc. Mainly to improve the visual effect and tactile feel of parts, and play the role of beauty, corrosion resistance, anti-aging and so on.

BE-CU (PTJ Group) has established a dust-free paint spraying room and a low-temperature paint baking room, which can spray paint the rapid prototyping parts produced by 3D printing technology, Die Casting technology, CNC Machining technology, and silicone complex molding technology.

Effects of Spray Coating Process

- Matte Lacquer: Apply the paint finish according to the shade provided for a matte finish.

- Gloss paint: spray paint surface according to the color number provided, bright effect.

- Imitation electroplating paint: The surface of electroplating paint has a certain metallic luster effect through the modulation of special materials.

- Rubber paint: spray rubber paint to simulate the effect of rubber coating on the surface of the sample.

- Varnish: Transparent parts can improve transparency by spraying varnish.

- Leather texture paint: spray leather texture paint, the surface of the sample has a leather texture effect, and the texture thickness can be adjusted.

Post Processing Of Cnc Machining

At present, in the machining process of mechanical parts, it usually includes: the blank formed by the previous mechanical rough processing, and then, the post-processing process of coloring, mechanical processing and electrostatic powder spraying is performed in sequence. The mechanical parts formed by this post-treatment process will have powder residues on the surface; it will be very difficult to remove the powder remaining on the surface, the cleaning effect will not be good, and it will directly damage the machine. The size of the part.Therefore, if the mechanical part has an assembly relationship with other parts, in other words, the mechanical part has at least one mounting surface, then the powder remaining on the mounting surface will make the flatness of the mounting surface poor, and the installation cannot be achieved. requirements, the installation accuracy of the component cannot be guaranteed, which directly affects the quality of the product formed by the component.The measures to control the surface quality of the workpiece are as follows:

- ①Improve the vibration resistance of the system, select the cutting depth and cutting speed reasonably, and reduce the impact of vibration.

- ②For different workpiece materials, choose different cutting fluids.

- ③ Reasonably select the material of the tool and the geometric angle of the tool.

- ④Avoid the critical parameter range that is easy to produce stubble and thorns for processing.

Surface Printing Treatment

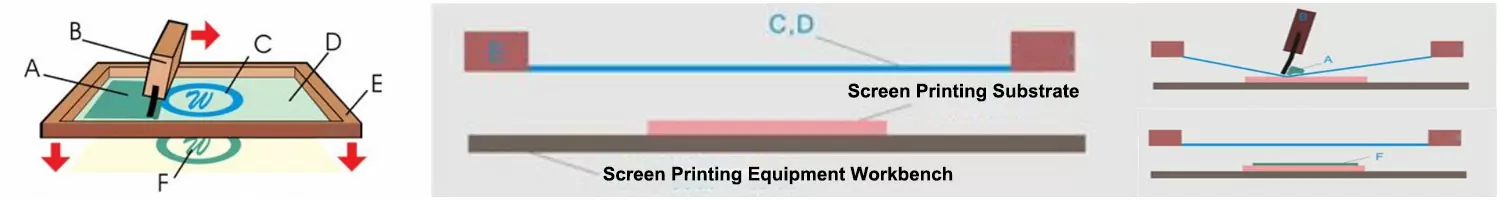

In addition to spray coating, Be-cu also provides surface printing treatment of non-metallic parts such as silk screen printing, pad printing, and laser engraving, which plays the role of functional identification, decorative appearance, and conveying product information. According to the vector file, color number, text font, printing position and other information provided by the customer, brightly colored preset patterns, logos, logos, etc. can be printed on the surface of flat or curved non-metallic parts.

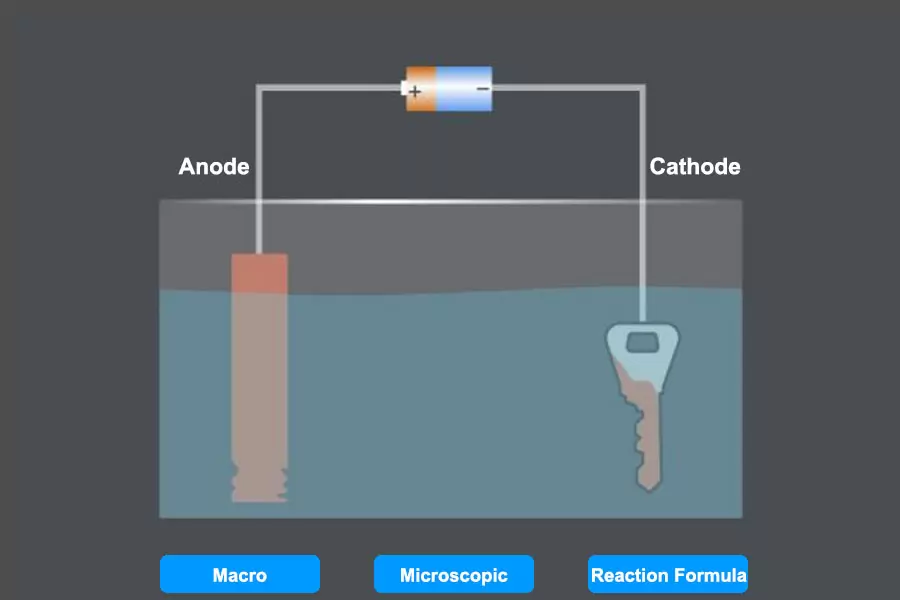

Non-Metallic Plating Treatment

Non-metal plating treatment is a process of using electrolysis to attach a layer of metal film to the surface of metal or other materials to prevent metal oxidation (such as rust), improve wear resistance, electrical conductivity, reflectivity, corrosion resistance and enhance aesthetics, etc.

Non-metal plating treatment uses the principle of electrolysis to coat a thin layer of other metals or alloys on the surface of metals and non-metals. Be-cu Prototype Company offers non-metal plating, matte plating, and mirror plating effects. The non-metallic parts have high surface gloss and high-quality anti-metal texture after electroplating treatment.

Strong Collaborative Manufacturing Network

Be-cu has 8 self-operated factories, serving 10,000+ customers in more than 30 countries and regions around the world.

In the future, Be-cu will continue to empower traditional manufacturing and create a full industrial chain for manufacturing OEM parts

Fast proofing and mass production of parts, 24-hour quotation system, minimum order of 1 piece, delivery in the fastest 2 days, 100% full inspection.

Under the control of ISO9001 and TS 16949,All processes are carried out through hundreds of advanced die casting machines, 5-axis machining, and other facilities, ranging from blasters to Ultra Sonic washing machines

Strict follow-up and control of the entire process from quotation to delivery.Other Serviced Include Sheet metal rapid proofing, stamping die manufacturing and high-speed stamping, forging die manufacturing, etc.,

-

Professional Small Baler Aluminum Alloy Die-casting Mold Production

-

China Die Casting Factory Manufactures Surface Sprayed Aluminum Valve Body

-

Extrusion Die-casting Polyurethane-Coated Aluminum Alloy Profiles

-

CNC Machined Rotary Head Aluminum Parts

-

Custom Precision Aluminum Die Cast Brackets and Finishes

-

Turning And Milling Of Valve Body Parts

-

CNC Machining Non-standard Aluminum Tube Customization

-

Open Mold Custom Aluminum Die-Casting Automotive Distributor

-

Open Die Casting Of Automotive Brake Aluminum Alloy Parts

-

Retainer Cast Aluminum Custom Machining and Finishing