China Online Custom Wire EDM Machining Services

Wire Cutting technology is a kind of electrical machining technology, which is short for Wire EDM. More commonly used in hardware molds. The cutting knife body is a thin line. Since the knife body is a line, it can be turned at any time in 360 degrees at any time. As a result, it is possible to cut workpieces of any shape. At present, wire cutting mostly relies on a phenomenon similar to arc discharge to dissolve metal to achieve the cutting effect. Therefore, wire cutting can only be applied to metals or electrical conductors.

China is the first country to apply wire cutting technology to industrial production. Wire cutting generally has the following process: first, formulate the process route, then select the processing benchmark of the workpiece, and then determine the threading hole and the starting point and the cutting route.

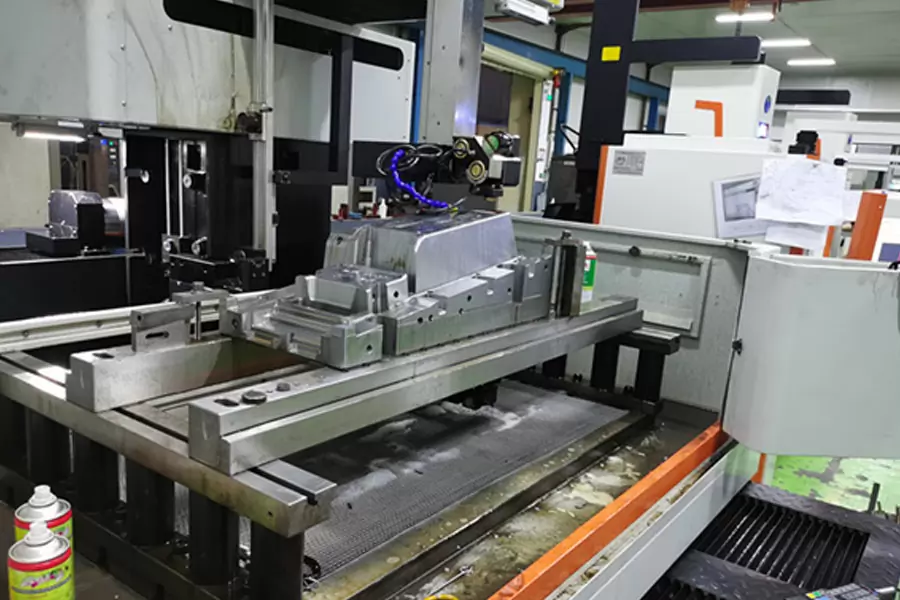

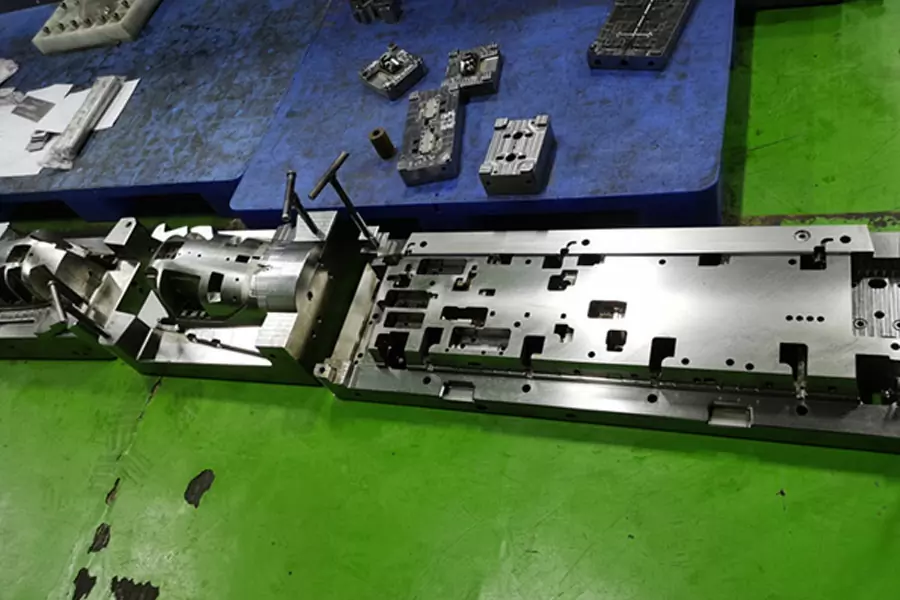

BE-CU is a leading wire edm machining company in China, providing efficient and quick wire cutting services for precision machined components manufacturing and mold accessories. BE-CU is a wire cutting company that has the ability to follow specific blueprints made by CAD and CAM software, and create a wide variety of products, parts, components, and objects with repeatability and well-controlled tolerances.

Our wire cutting services allow a diversity of materials such as steel, bronze, brass, aluminum, etc., depending on the sizes, shapes, and characteristics of the mold and precision parts. Various advanced wire cutting tools and techniques are used. The combination of different equipment is popular in order to get the job done efficiently. Precision wire cutting at be-cu.com will help you ensure that these parts can not only be manufactured precisely, but also be produced repeatedly with this accuracy.

Certifications & Advantage

- ISO 9001:2015 certified

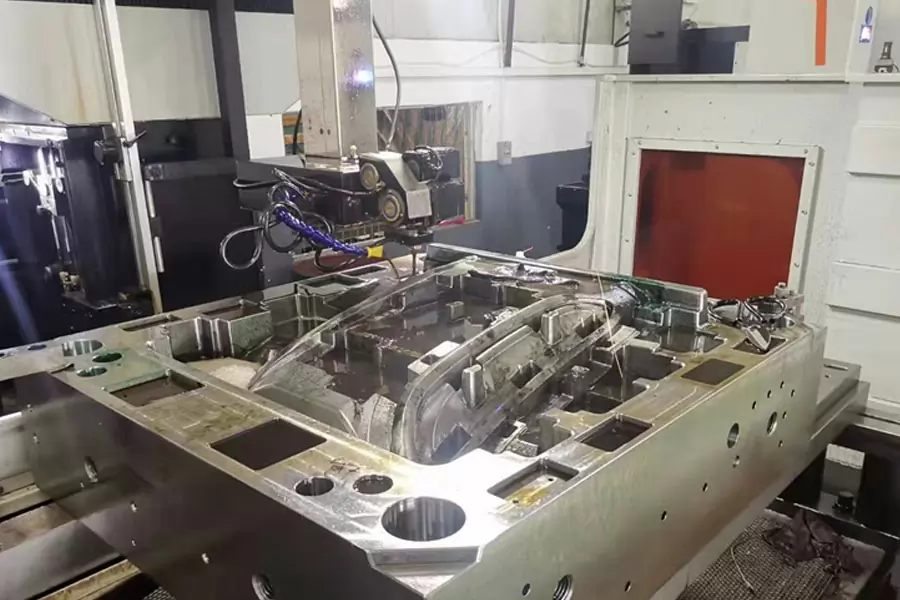

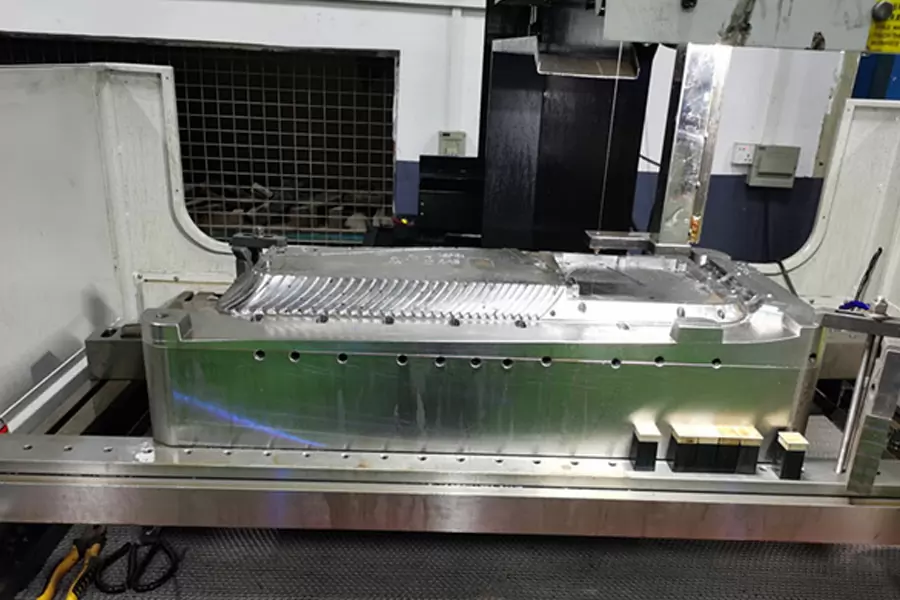

- 2m Large Wire Cutting

- Large-Scale Automobile Die Cutting

- Large-Scale Furniture Die Cutting

- 40 Sets 500*600mm Middle Speed Wire Cutter

- 8 sets of super large 2m 1.5m*1.2m Middle Speed Wire Cutter

- 2 sets western Wedm-ls Cutter

- 2 Taiwan imported precision fine hole EDM machines

- Single Side Cutting 40°, Cutting Height 1 Meter

- Load-Bearing More Than 5 Tons, Swing Large Taper Wire Cutting

- Quantity flexibility. From prototypes to low/high volume production, we can meet your requirements with exact specifications.

- Quality Assurance. Our team of highly skilled workers and strict quality control and inspection will ensure the quality of the final parts.

- Strong Professionalism. Electric Discharge Machining services at BE-CU will maintain integrity, consistency, productivity, and economy.

- High Standard. Our purpose is to achieve perfection in wire cut EDM machining through continuous improvement and upgrading.

- Customer satisfaction. Fast turnaround, on-time delivery, high quality, competitive prices, and best service help us win high customer satisfaction.

- ITAF 16949 certified

Wire EDM Machining Materials

| Aluminum Alloy | In view of the low melting point and low boiling point of aluminum alloy, the thermal conductivity is good, so a very high cutting speed is required. | However, the surface of aluminum alloy will produce oxide film at high temperature, which will reduce the conductivity. | There are two solutions to this. First, the pulse discharge current can be increased and the discharge time can be shortened. After wire cutting, the surface is smooth and rough. |

| Carbon Steel | Carbon steel has a higher melting point, so there is less electro-erosion during machining, and the speed is correspondingly lower. | In order to improve work efficiency, while increasing the discharge current and increasing the time, the pulse interval should also be appropriately increased. | In actual processing, it should be Heat treatment in advance so as not to affect the subsequent process. Unquenched 45 steel has a very slow cutting speed. On the contrary, 45 steel after quenching is not very sticky and has a smoother surface, so the processing is more stable. |

| Stainless Steel | The melting point of common supplementary rigidity is generally between 1400 and 1500 ℃, and the thermal conductivity is also between 20 and 29. | Because there are emulsions during work, many black adhesives will be attached, which will cause problems. | Therefore, it is necessary to increase the pulse interval, flushing pressure and flow rate. |

| Copper | Pure copper has high density, high viscosity, high thermal conductivity and high melting point, resulting in a small amount of electrical corrosion. | In order to improve efficiency, the pulse interval should be reduced appropriately to eliminate the influence of thermal conductivity. | However, the brass material is soft, and the chips float on the working surface |

| More Material |

Our Outstanding Wire Cutting Equipment

- CNC Swiss Turn by Tsugami

- MAZAK 5 Axis Turn-Mill Machine

- CNC Swiss Turn by Tsugami

- High Speed Drilling-Tapping Machine

- DMU 5 Axis Cnc Machine

- CNC Mill Turn Centers—12 machines

- Multi Spindle Cam Automatics

- CNC Brother Production Milling

- Check Out BE-CU Equipment List

-

Precision Grinding Tungsten Steel Mold Parts

-

5 Axis CNC Machining Medical Olecranon Plate

-

Special-Shaped Non-Standard Medical Device Needles

-

High-Speed Steel (HSS) Die Punching Needles

-

Precision Tungsten Copper Alloy Eccentric Insert

-

5 Axis CNC Machining Spiral Bevel Gear Mold

-

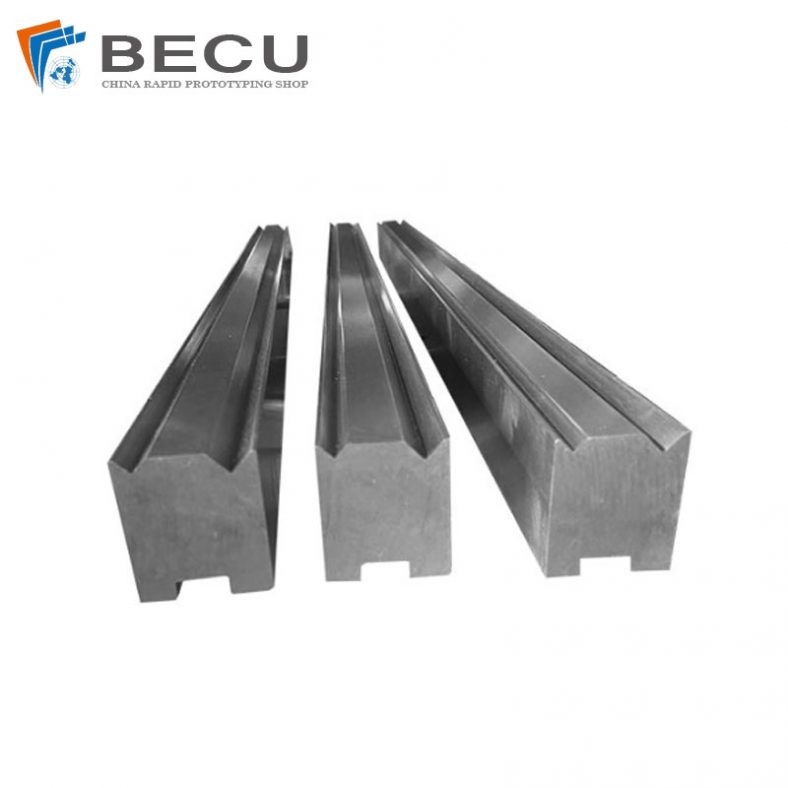

42CrMo Steel CNC Machining Bender Dies

-

Carbide Tungsten Valve Seat For Oil And Gas Industry

-

Non-Standard Position Component For Mold

-

5 Axis CNC Machining Pump Impeller

-

Custom Hexahedron Tungsten Dnd Dice

-

Tungsten Carbide 3D Printer Nozzle