Fabrication Services

- Rapid Prototyping & Volume Production & Mass Volume Production

- 1 to 100000+ Metal and Plastic Parts

- Global delivery as fast as 10 days

- Equipped and experienced to offer more machining & material options

>>>All uploaded drawings are strictly confidential, check the confidentiality agreement

Rapid Manufacturing On Demand

Want to shorten production cycle and reduce cost of your projects? Integrated multiple advanced technologies, Be-cu fabrication services can simplify the manufacturing process and speed up large batch production of oem parts, as well as achieve a higher level of accuracy and precision. At Be-cu.com, we are dedicated to making the world’s best prototypes and precision parts for a wide range of industries, including: automotive, electronic,IPC,medical device, aerospace, consumer & commercial products,jewelry made and more,Be-cu has been specialized in CNC machining and diecasting parts production and other fabricate services China for over 30 years and always maintaining the highest standard in delivery speed and reliable quality of precision manufacturing components. Our experience in rapid prototyping & rapid manufacturing, such as CNC machining and injection molding services enables us to make the most of both metal and plastic prototype for many different project types.

With the help of high-level technology and efficient equipment, as well as rigorous attitude, we passed the ITAF:16969 And ISO9001:2015 quality certification, which supports the long-term development of Be-cu CNC milling, CNC turning, CNC milling-turning, CNC drilling, 3/4/5 axis machining, metal casting,3d printing, laser cutting,metal etching, mold manufacturing,stamping,precision spinning and sheet metal,powder metallurgy, metal forging etc.And, we transform your ideas into a market-ready product with a super short turnaround, which helps launch your ideas fast. Find out what we can do for you!

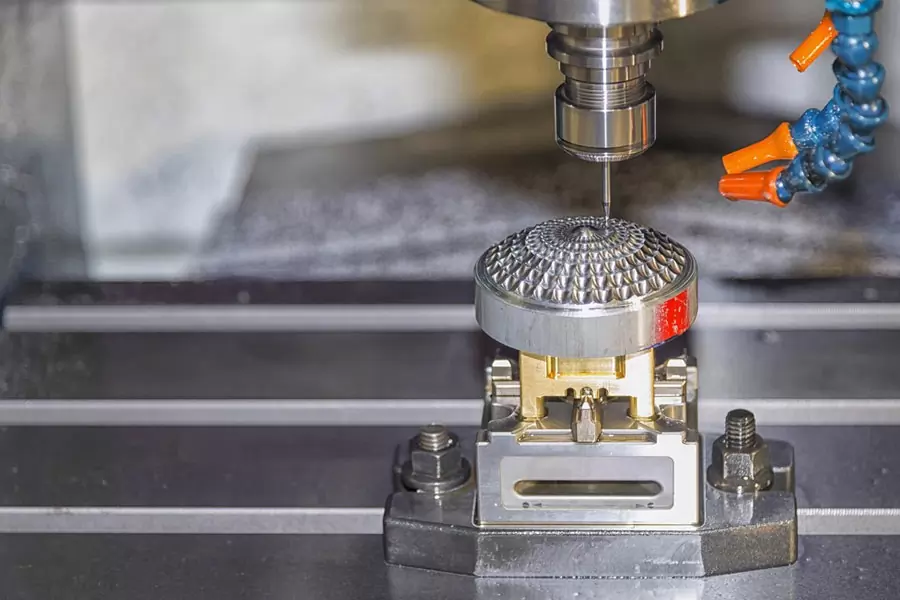

CNC milling (computer numerical control milling) is a CNC machining process that involves removing material from the workpiece by rotating and moving a cutting tool, such as a milling cutter, and positioning the workpiece properly, to produce or finish a custom CNC machining object.Be-cu is a professional China CNC company provides superior precision CNC milling services with advanced machines including CMC milling center and milling machining centers from the general 3-axis to 5-axis and accomplished machinists.

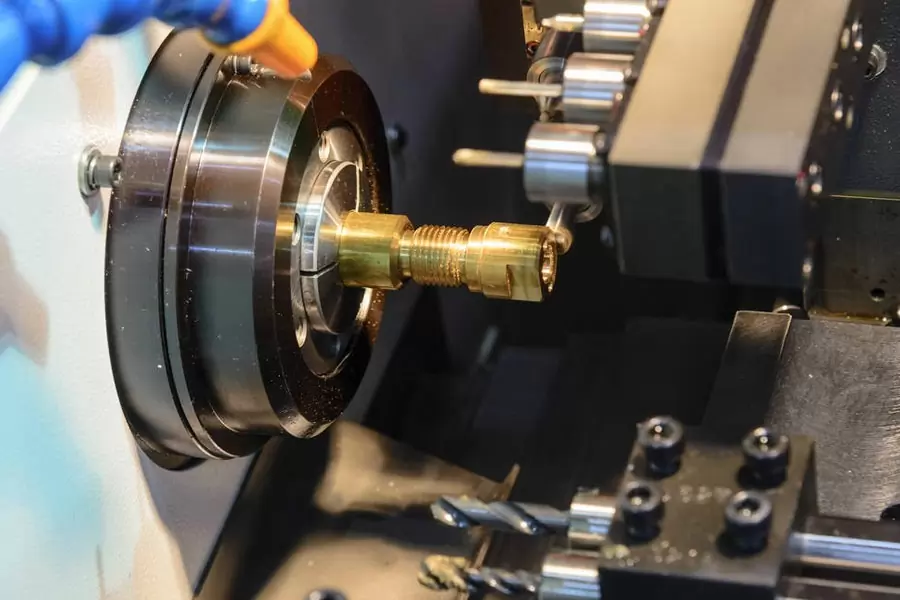

Turning allow us to get high-speed turning of both plastics and metals from bar or block material. The turning process allows the production of complex external and internal geometries, including generating all kinds of threads. For any round shaped components, for example, shafts, worms, spheres, CNC turning is a more efficient method compared with CNC milling. BE-CU’s turning capability can make prototypes all the way through mass production parts, has been specialized in offering best OEM CNC lathe services.

Originally developed for producing watch parts, CNC Swiss screw machining is designed for miniature parts and excels in producing long slender parts. Because of the unique design of the Swiss machine, CNC Swiss turning services allow multiple operations are executed simultaneously in several zones in a short time. Be-cu promise to deliver high-quality ultra-precision machining and miniature swiss parts, plus a company-wide commitment to maintaining a completely predictable parts supply at any production volume or level of precision.

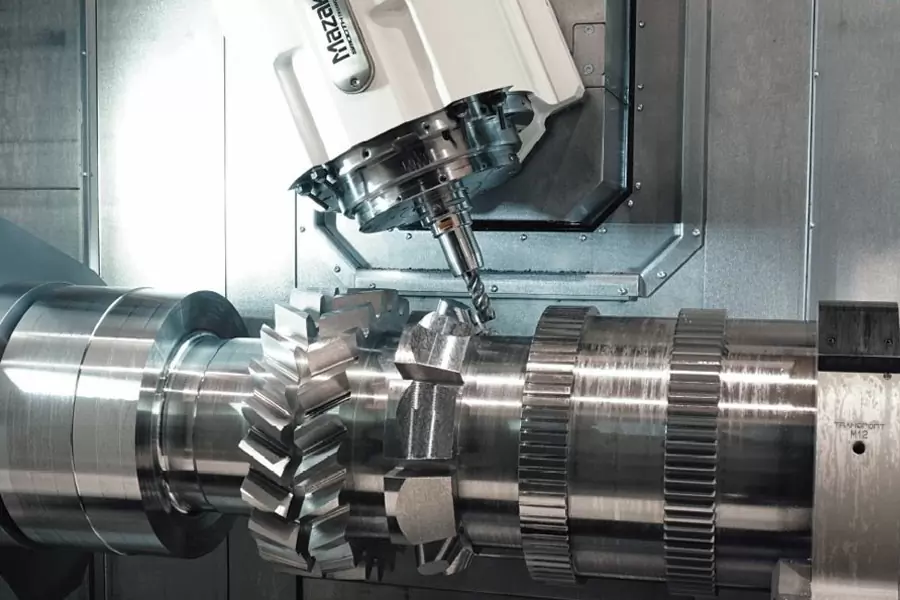

5-Axis machining uses the complex parts of a CNC machine to move cutting equipment across 5 different axes simultaneously.Therefore, 5 axis CNC machining services allow infinite possibilities of the machined parts. Hook surface machining, unusual shape machining, hollow machining, punching, oblique cutting, and more special processes can be done with 5 axis CNC service.BE-CU’s 5 axis CNC machining and 5 axis milling capability can make prototypes all the way through mass production parts.

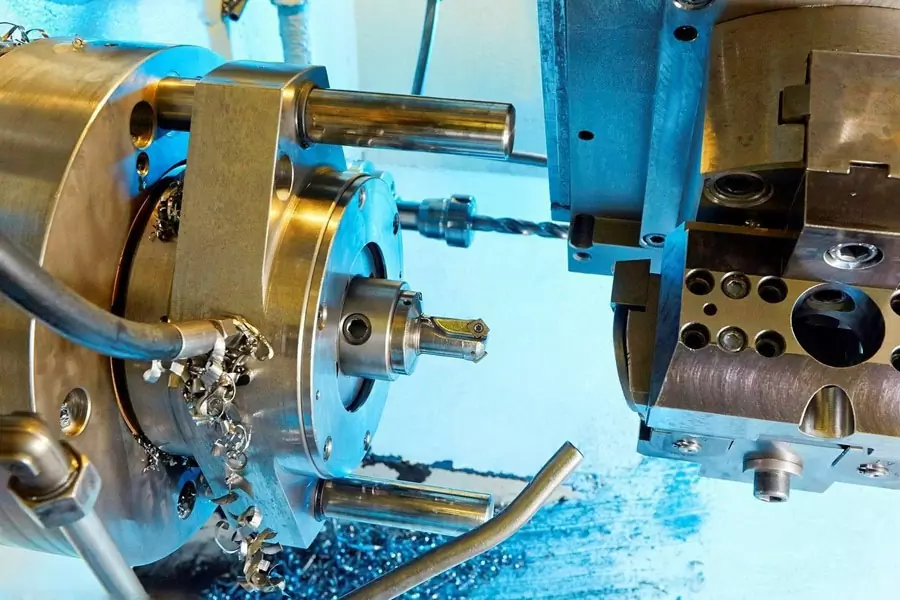

Turn-mill is a compound machining technology, to execute designed multiple kinds of tasks with the computer numerical control when the cutting tool and workpiece are both rotating. Be-cu provides machining services utilizing the most advanced technology in multitasking manufacturing. CNC mill/turn centers require less processing time and less handling, while lowering costs and enhancing the quality and productivity that Be-cu has provided for over 30 years.

Micromachining of size and shape with very high precision with a small cutting amount. Using extremely precise tools, tight tolerances, and machines that specialize in this area, allows the manufacturing of intricate micro components used most notably in the medical and electronics industry. Most features of miniature machined parts are not visible to the naked eye without magnification, thus requiring the use of very high-resolution inspection equipment.

Cnc Drilling is the cutting process in which the workpiece does not move, making the cutter move, aligning the cutter center with the hole center, and making the cutter rotate. CNC Drilling Services is primarily done on CNC machines including CNC milling machines and lathes. CNC drilling service produces round holes, typically for machine screws and bolts.China BE-CU Company’s drilling capability can make prototypes all the way through mass production parts.

Stamping is a forming method of applying external force to plates, strips, pipes and profiles by presses and molds to produce plastic deformation or separation, so as to obtain workpieces (punchings) of required shape and size. Although there are many other processes out there, such as spinning, stretching, deep drawing, etc., it is the most commonly used method to make parts and products.The stamped blanks are mainly hot-rolled and cold-rolled steel plates and strips.

Be-cu is a trusted online metal casting services supplier.With decades of experience and expert capabilities, our metal casting services can use an extensive range of materials using die casting, investment casting, sand casting and other technologies.According to your requirements and applications, we’ll offer suggestions for the product design, suitable materials, and the most cost-effective methods for metal casting and manufacturing.

3D printing is an additive manufacturing process of creating three dimensional solid parts from a CAD design or digital file by laying down successive layers of material.Be-cu provides a range of high-quality 3D printing (additive manufacturing) services, including FDM, SLA, SLS,MJF,SLM and more. This allows for the 3D printing of plastics and metals, and provides options for both prototyping and production. Our 3D printing service ensures accuracy and speed.

Sheet metal is a widely used form of raw material, usually 0.006 and 0.25 inches thick sheet used in sheet metal fabrication. Sheet metal is a widely used form of raw material, usually 0.006 and 0.25 inches thick sheet used in sheet metal fabrication. Be-cu’s custom sheet metal prototyping services offer a fast and cost-effective solution for your projects. Services including bending, punching, cutting standard gauge metal for both prototypes and low volume production runs.

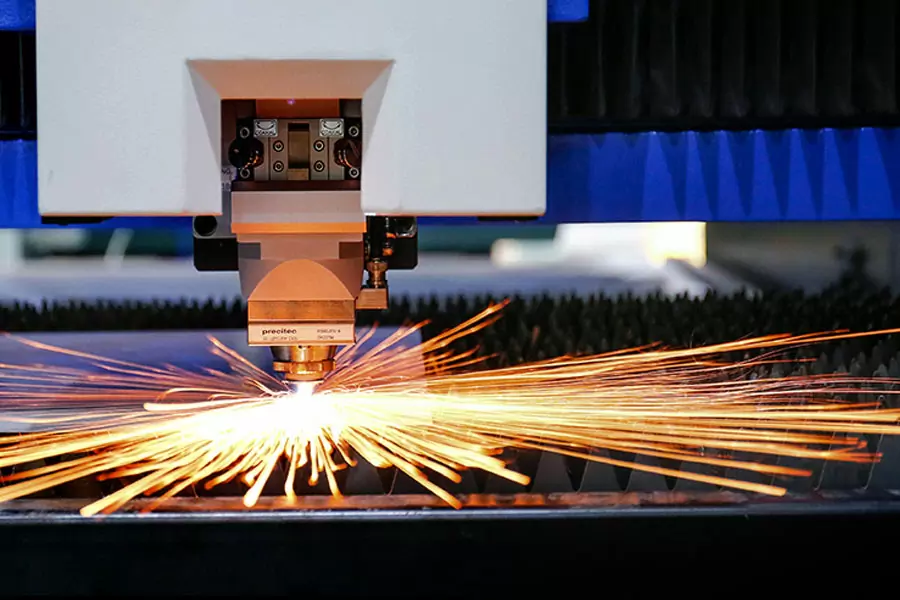

BE-CU precision laser cutter, sophisticated manufacturing facilities and advanced inspection equipment, as well as professional engineers and skilled machinists are assisting our laser cutting manufacturing to meet the customers requirements, capabilities including large laser cutting, cnc bending, Rounding Machining, and Etching. We provide a complete selection of cut shape including Tube Laser Cutting, Plate Laser Cutting, Welding Processing, etc.

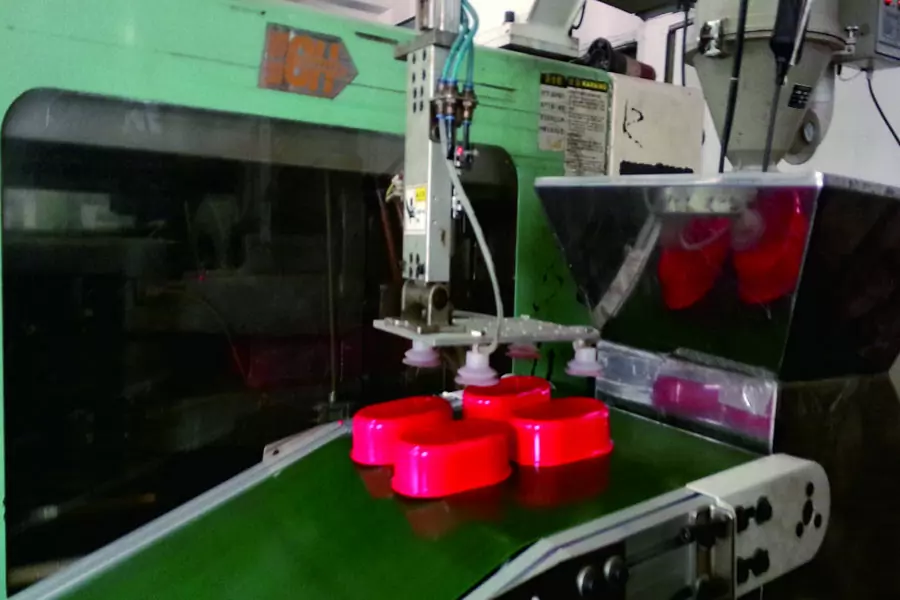

At Be-cu.com, we produce high-quality prototype moldings from aluminum molds with quick turnaround times. Our customers can test out their designs for manufacturability and functionality, fast. We also offer plastic injection molding for your high-volume production needs.Whether you need rapid tooling, mass production mold making or end-use plastic molding with tight tolerances, our team of experienced specialists can offer a cost-effective solution at each stage.

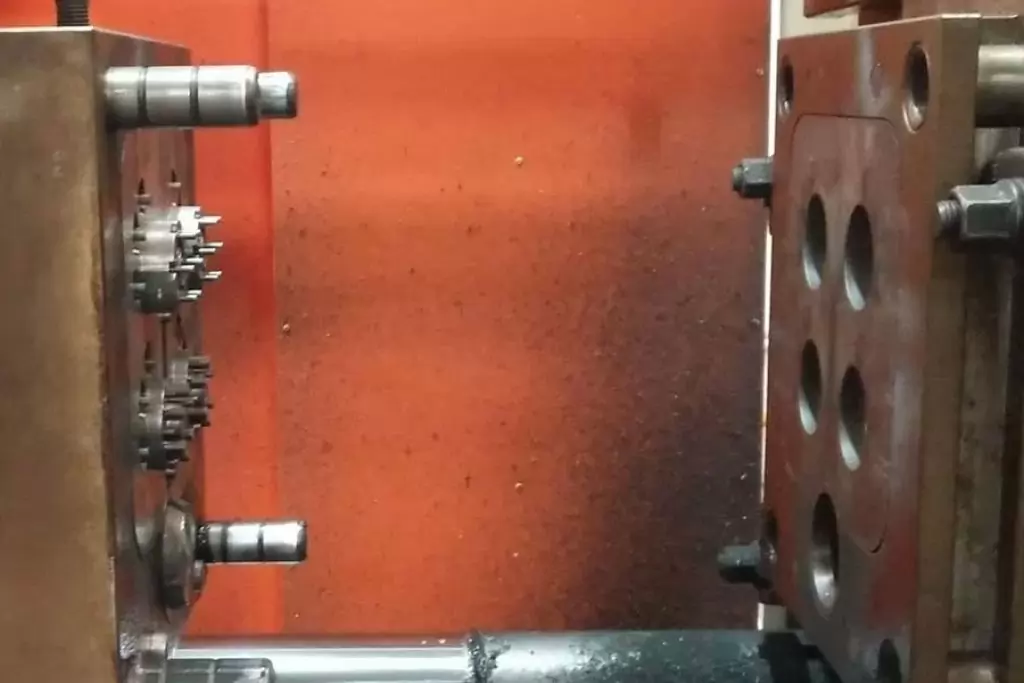

Need mold manufacturing supplies for mass production parts? Be-cu is known as the best mold maker in China. With mold making facilities in house and resources from our partners, we are able to provide plastic injection molds for both rigid plastics and rubbers, metal injection molds for all type of precision stainless steel parts, and pressure die casting molds for aluminum, magnesium and zinc. We offer low-cost local production molds and high-quality exported molds for all your project needs.

Powder metallurgy (PM) is a unique, highly developed method of manufacturing ferrous and nonferrous parts. It is a versatile, cost-effective, and constantly expanding technology that is rapidly gaining worldwide popularity.PM provides for controlled permeability and allows for the use of inventive composites with unique properties. Be-cu PM process provides close dimensional tolerance, minimal machining, good surface finish, and excellent part-to-part reproducibility from moderate to high volume part production.

Forging is a typical manufacturing process of shaping metal using localized compressive forces, it is usually performed with forging tools like hammers or presses. Forged parts can range in weight from less than a kilogram to hundreds of metric tons. To lower the price of your CNC machining parts, our forging service can offer a large number of prototypes in batch, then we use CNC techniques and machines to modify the appearance and achieve other specifications, which greatly shortens the lead time.