Custom Precision Sheet Metal Fabrication Services In China

Sheet Metal Fabrication is called sheet metal. Specifically, for example, the use of plates to make chimneys, iron barrels, fuel tanks, oil tanks, ventilation pipes, elbows and small heads, sky-round areas, funnels, etc. The main process include cutting(laser cutting), bending, bending, forming, welding, riveting, etc. Certain geometric knowledge. Sheet metal parts are thin metal parts, that is, parts that can be processed by stamping, bending, stretching and other means. With the development of laser drilling technology, the laser cutter has realized automated operation. The application in the sheet metal industry has changed the fabrication method of traditional sheet metal technology, realized unmanned operation, greatly improved production efficiency, and realized the whole process. The automatic operation has promoted the development of the sheet metal economy, and has improved the punching effect to higher level, and the effect is remarkable.

BE-CU Prototype is a specialist that can sheet metal fabricate industrial parts and custom sheet metal service using a wide variety of manufacturing techniques. With Sheet Metal Services at BE-CU, you can get your sheet metal parts in a much more accurate and fast way, compared to conventional plate processing. Our newest sheet metal machines can meet your needs of high volume while maintaining high repeatability, top quality and tight tolerance. Over the past years, we have earned a good reputation for producing custom parts with reasonable pricing and on-time delivery, and also capable of working with sheet metal equipment and laser cutter to provide sheet metal parts and services for our customers. Serviced electronics, communications, aerospace, lighting, energy, medical, transportation, military and defense industries , welcome to submit an inquiry online.

Certifications & Quality

- ISO 9001:2015 certified

- Production volumes range from prototype to 10,000 pieces annually.

- Average 7 days turnaround time and 99.85% on time delivery

- Multiple options of sheet metal materials to meet specific properties.

- Finishing and secondary services

- Capable of fabricating parts up to 12 ft. length and +/-0.001 in. tolerance.

- Capable of fabricating sheet metal parts from 0.006 to 0.25 in. thickness

- ITAF 16949 certified

Why Choose Our Sheet Metal Fabrication Services

10 years of continuous research and practice in press feed line manufacturing has endowed Be-cu as one of China’s competitive supplier in the metalworking market. Be-cu provides the world widest range of SHEET METAL PARTS, establishes a world throughout customer network, matching needs of small press shops up to major automotive market players. Be-cu is aiming to achieve the cutting-edge technologies required by the evolution of materials available today

Sheet Metal Fabrication Materials:Carbon Steel,Aluminum, Copper, Magnesium, Stainless Steel, Steel And Galvanized Steel,Titanium

How Does We Sheet Metal Fabrication Work

Sheet metal fabrication is a manufacturing process that involves transforming flat sheets of metal into finished products or components. It typically involves several steps, including design, cutting, bending, assembling, and finishing. Here’s BE-CU sheet metal work process:

1.Receiving Metal Sheet

2.Sheet Metal Blanking

3.CNC Metal Bending

4.Benchwork

5.Industries Welding

6.Pneumatic Flat Grinding

7.Surface Treatment

8.Semi-Finished Inspection

9.Screen Printing

10.Connection And Assembly

11.Quality Inspection

12.Storage

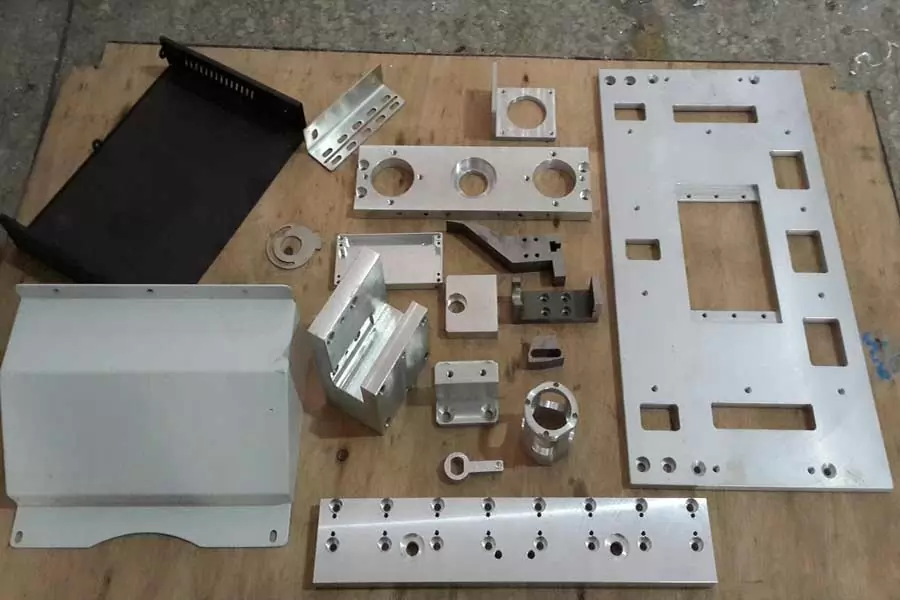

Precision Sheet Metal Manufacturing Services At BE-CU

1.Pressure Riveting

2.Expanding Riveting

3.Pull Nut

4.Pull Riveting

5.Riveting

6.Corner Cutting

7.Bending

8.Forming

9.Cutting Material

10.Blanking

11.Return

12.Punching

13.Punching Convex Hull

14.Punching And Tearing

15.Hole Extraction

16.Tapping

17.Leveling

18.Threading

19.Drilling

20.Chamfering

21.Print

22.Counterbore

23.Flattening

24.Punching Mesh And Reaming

Material You Can Choose for Your Sheet Metal Parts

Be-Cu prototype uses a wide range of material selections for our sheet metal fabrication process. Among our materials are aluminum, stainless steel, brass, magnesium, copper, carbon steel, bronze, galvanized steel, and more. Each material is available in different grades and varieties. Rest assured that all the materials used for your sheet metal parts are durable, corrosion-resistant, long-lasting, rust-proof, wear-resistant, and high-performance. If you want a specific material to be used in the sheet metal fabrication process, don’t hesitate to contact us!

-

Stainless Steel Sheet Metal Fabrication

-

Aluminum Sheet Metal Fabrication

-

Copper Sheet Metal Fabrication

-

Brass Sheet Metal Fabrication

-

Steel Sheet Metal Fabrication

-

Titanium Sheet Metal Fabrication

-

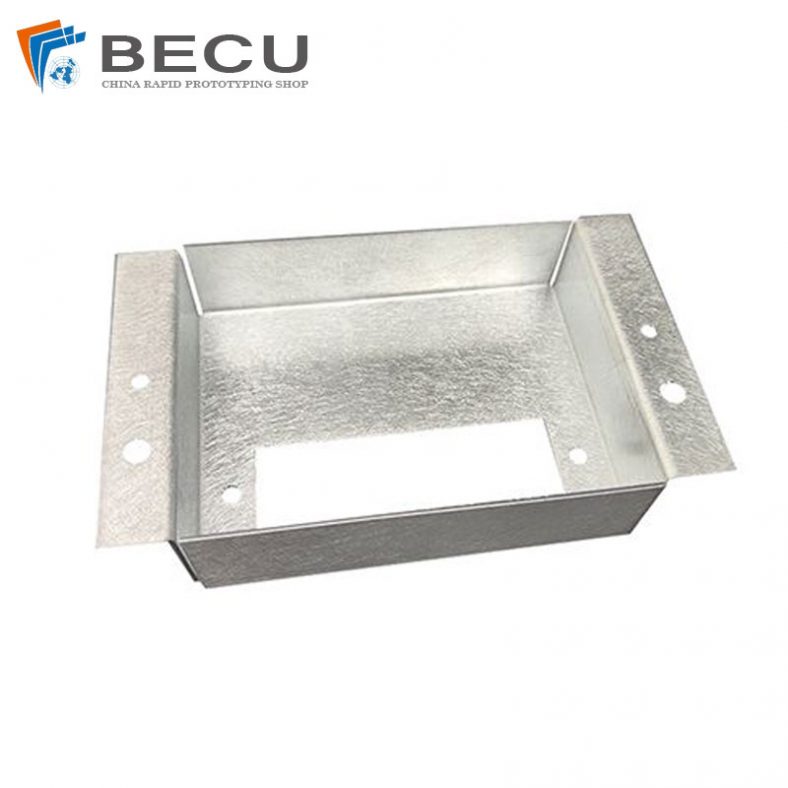

Galvanized Steel Sheet Metal Fabrication

-

Mild Steel Sheet Metal Fabrication

-

Bronze Sheet Metal Fabrication

Our Sheet Metal Fabrication Applications

Be-Cu prototype offers custom sheet metal fabrication for creating structures, machines, and parts that includes:

Top Sheet Metal Fabrication Services Capabilities

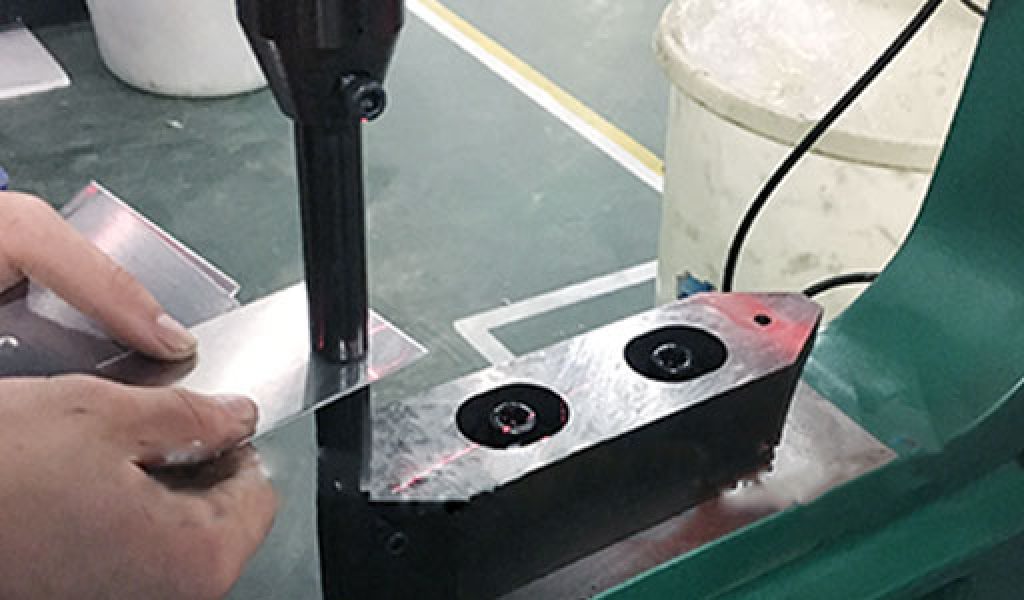

Laser Cutting

CNC Bending

Roll Round

Welding

Forming

Polishing And Other

Our Outstanding Sheet Metal Fabrication Equipment

- FY1015 Feiyue Laser Cutter

- FY2030 Feiyue Laser Cutter

- FY5030 Feiyue Laser Cutter

- FY4050 Feiyue Laser Cutter

- 4000W BS Laser Cutter

- 150w CO2 Laser Cutting Engraving Machine

- 3000w 10kw SF Series 3D 5-Axis Laser Cutting Machine

- Check Out BE-CU Equipment List

-

Sheet Metal Fabrication Injection Molding Machine Hopper

-

Sheet Metal Fabrication Funnel For Agricultural Machinery

-

Sheet Metal Fabrication Galvanized Spiral Air Duct

-

PCS Fan Ductwork Sheet Metal Housing

-

Custom Sheet Metal Surgical Instrument Sterilization Box For Beauty Salon

-

Precision Fabrication Green Energy EV Charging Station Cabinet

-

TA1TA2 Alloy Sheet Metal Manufacturing Machinery Support Parts

-

Sheet Metal Fabrication Aluminum 5052 Medical Box For Fire Fighting

-

Outdoor Rainproof Weak Current Communication Network Sheet Metal Cabinet

-

Sheet Metal Fabrication POS Machine Box Shell

-

Sheet Metal Fabrication Industrial Computer Bottom Cover

-

Sheet Metal Fabrication Strongbox Enclosure

-

Sheet Metal Fabrication Large BBQ Grill Enclosure

-

Sheet Metal Fabrication For Large Japan Mill Machine Enclosure

-

Sheet Metal Fabrication Distribution Electric Cabinet

-

Sheet Metal 32 Inch LCD Industrial Bracket

-

Metal Fabrication Cold Rolled Sheet Medical Device Enclosure

-

Sheet Metal Manufacturing 10.1 Inch Hardware Monitor Enclosure

-

32-Inch Medical Sheet Metal All-In-One Machine Cabinet

-

Precision Fabrication Wall Mount Gaming Computer Case Chassis

-

0.8MM All Aluminum Sheet Metal Mini Host Computer Chassis

-

3MM Fabrication Aluminum 5052 Brushed Battery Box

-

12.1 Inch Vertical Inquiry Kiosks

-

65-Inch Vertical Touch All-in-one Advertising Machine Sheet Metal Shell

The Influence Of Materials On Sheet Metal Fabrication Technology

Sheet metal fabrication is a key technology that sheet metal technicians need to master, and it is also an important process for forming sheet metal products. Sheet metal fabrication includes traditional cutting, blanking, bending and forming and other methods and process parameters, as well as various cold stamping die structures and process parameters, various equipment working principles and operating methods, and new stamping technology. and new technology. The fabrication of sheet metal parts is called sheet metal fabrication. Sheet metal parts are thin-plate hardware parts, that is, parts that can be processed by means of stamping, bending, stretching, etc. A general definition is a part with a constant thickness during fabrication.There are three main types of sheet metal fabrication: punching, bending and stretching. Different fabrication techniques have different requirements for the sheet metal. The selection of sheet metal materials should also consider the selection of sheet metal according to the approximate shape and fabrication technology of the product.

The Material Influence Of Blanking

Blanking requires that the sheet should have sufficient plasticity to ensure that the sheet does not crack during blanking. Soft materials (such as pure aluminum, rust-proof aluminum, brass, red copper, low carbon steel, etc.) have good punching properties, and parts with smooth cross-section and small inclination can be obtained after punching; hard materials (such as high carbon Steel, stainless steel, duralumin, super duralumin, etc.) have poor quality after blanking, and the unevenness of the section is large, especially for thick sheets. For brittle materials, tearing is easy to occur after punching, especially when the width is small.

The Material Influence Of CNC Bending Process

Sheets that need to be bent should have sufficient plasticity and a lower yield limit. The sheet with high plasticity is not easy to crack when bending, and the sheet with lower yield limit and lower elastic modulus has small rebound deformation after bending, and it is easy to obtain the bending shape with accurate size. Materials with good plasticity such as low carbon steel, brass and aluminum with carbon content less than 0.2% are easy to bend and form; materials with greater brittleness, such as phosphor bronze (QSn6.5~2.5), spring steel (65Mn), hard aluminum , super hard aluminum, etc., must have a relatively large relative bending radius (r/t) when bending, otherwise cracking is easy to occur during the bending process.

Special attention should be paid to the selection of the hard and soft state of the material, which has a great influence on the bending performance. For many brittle materials, bending will cause cracking of the outer fillet or even bending fracture. There are also some steel plates with high carbon content. If you choose In a hard state, bending will also cause the outer fillet to crack or even break, which should be avoided as much as possible.

The Material Influence Of Drawing Process

Sheet metal drawing, especially deep drawing, is one of the more difficult sheet metal fabrication processes. It not only requires the drawing depth to be as small as possible, the shape as simple as possible, and a smooth transition, but also requires the material to have good plasticity. , it is very easy to cause the overall distortion of the parts, local wrinkling, and even cracks in the stretched parts.

The lower the yield limit and the larger the plate thickness directional coefficient, the smaller the yield ratio σs/σb of the sheet, the better the stamping performance, and the greater the limit degree of primary deformation. When the plate thickness directivity coefficient>1, deformation in the width direction is easier than deformation in the thickness direction. The larger the R value of the stretch fillet, the less likely it will be thinned and broken during the stretching process, and the better the tensile properties will be. Common materials with better tensile properties are: pure aluminum sheet, 08Al, ST16, SPCD.

The Material Influence Of Stiffness

In the design of sheet metal structures, it is often encountered that the rigidity of sheet metal structural parts cannot meet the requirements. Structural designers often use high carbon steel or stainless steel instead of low carbon steel, or use hard aluminum alloys with higher strength and hardness instead of ordinary aluminum alloys , expecting to increase the stiffness of the part, in fact, there is no obvious effect. For the material of the same base material, the strength and hardness of the material can be greatly improved through heat treatment and alloying, but the change in stiffness is small, and the rigidity of the part can be improved. Only by changing the material and changing the shape of the part can a certain effect be achieved. , elastic modulus and shear modulus of different materials

The Main Way Of Sheet Metal Connection

In sheet metal fabrication, sheet metal parts must be connected and fastened in a certain way. The main methods of sheet metal connection can be welding, screw connection, riveting and bonding.

- Welding – is a process method of local or overall heating of the weldment or plastic deformation of the weldment, or simultaneous heating and plastic deformation to achieve permanent connection, which can be divided into: manual arc welding, gas shielded arc welding, Laser welding, segment welding and contact welding, our main workers use gas shielded contact welding. 1.1 Gas shielded arc welding – During gas shielded arc welding, the electrode arc area and the welding pool are under the protection of shielding gas, and argon gas is used to shield the surface of the weld metal oxides and inclusions. Welding can be applied in any spatial position, and the forming process of welding can be observed and adjusted with the naked eye, and the production efficiency is high.

- Contact welding – a welding method in which the joints are heated instantaneously during contact welding, and the welded parts are pressurized to form a welded joint in a molten or non-melted state. It can be divided into butt welding, spot welding and seam welding.

- Threaded connection – Threaded connection has the advantages of easy local installation, convenient disassembly, and simple operation. It is often used in detachable steel structure connections. It can be divided into screw connection and bolt connection.

- Riveting – riveting is a method of connecting parts or assemblies of metal structures with rivets. There are many types of rivets. Our commonly used rivets include closed round head blind rivets, closed countersunk head blind rivets and openings. Type round head blind rivets, open type countersunk head blind rivets.

- Bonding – a connection method in which the desired connection is bonded together with an adhesive.

- Plug-in – plug-in has the advantages of easy installation, convenient disassembly, and simple operation. Compared with other connection methods, the connection between the sheet metal parts can be completed by using the properties of the sheet metal parts without damaging the sheet metal parts themselves. material properties.

Online Cooperate With China Sheet Metal Fabrication Company

Be-cu works with customers all over the world to bring customers ideas to life with the highest quality precision engineered metal components on the planet. We have both precision sheet metal fabrication capabilities that include both conventional and modernized production line. If you are looking for a partnership to help you apply new tools and technologies, or help you fully realize your design vision, let us help you move your business forward, contact our team ([email protected])or quote online today to get the conversation started.

Latest Sheet Metal Fabrication Blog,Encyclopedia And Guide

Check out our latest sheet metal fabrication blogs, we share industry trends, design tips, and experience earned from manufacturing.

-

The Main Electrical Panels Types: Differences and Uses

-

NEMA 13 Enclosure

-

All About Welding Methods: Process, Define And More

-

Sheet Metal Bending Structural Process Design

-

The 10 Basic Bending Tooling Components Explained

-

TOP 10 Best Way To Cut Sheet Metal

-

What Is Sheet Metal Gutter Fabrication?

-

How to Welding Aluminum – Is Aluminum Hard to Weld & What Aluminum is Unweldable?