Metal Etching Service – Precision Etched Metal Parts Company

Etching is the technique of removing part of material using chemical reaction or physical impact. Etching techniques can be classified into wet etching and dry etching.

What Is Metal Etching

Etching is an emerging chemical etching method. After exposure, plate making and development, the protective film of the area to be etched is removed, and the chemical solution is contacted during etching to achieve the effect of dissolution and corrosion, forming the effect of concave-convex or hollow-out molding, and the etching process is minimal. The opening is related to the thickness of the material. At present, the smallest opening that can be made by etching is 0.02mm. The hole spacing is 0.1mm stainless steel as an example, and the hole spacing of 0.1mm can be made. The depth accuracy is up to +/-0.0075mm.

It can be used to make copper plates, zinc plates and other printing concave-convex plates at the earliest, and it is also widely used in the processing of weight-reducing instrument panels, nameplates and thin workpieces that are difficult to process by traditional processing methods; after continuous improvement and development of process equipment, it can also be used It is used in the manufacturing of precision etching products of thin electronic parts in aviation, machinery, and chemical industries. Especially in semiconductor manufacturing processes, etching is an indispensable technology.The benefit of photolithography on thin metal parts is precision edges with low tolerances. The chemical metal etching process makes the surface smooth and uniform without burrs, pits and stress deformation. Other attractive features of the etching process are speed and low cost for parts with complex features and complex designs.

If you want to find a cost-effective and rapid Metal Etching solution for your manufacturing needs, Be-cu.com can be a good choice for you. At Be-cu.com, our Metal Etching services provide multiple types of precision metal etching to manufacture custom etching parts with high accuracy, as a top-notch etching engineering and etching service supplier, we can also provide design services, high-precision prototypes, as well as etched parts for medium to high-volume runes.Get your Metal Etching project started today. Upload your CAD file to our online quote page to receive a quote, work with our engineers to optimize your design, and move to production when you’re ready. You can specify the post-production and finishing options you need for your etched parts, along with any inspection requirements. When your order is ready, we’ll package and ship the finished parts to you.

Our Custom Metal Etching Service

Backed by outstanding manufacturing capabilities and 10+ years of industry experience, Be-cu Prototype offers superior quality custom metal etching services with excellent result potential. We combine highly skilled machinists with cutting-edge metal etching facilities to etch anything from delicate aluminum foils to thick steel sheets. Enjoy precision etching service with an extensive range of advanced processes and technology.While photochemical machining is our core capability, we can use our extensive production resources to give you a ready-to-use component, no matter what your requirement.

Etching From Prototype to Production – Why Choose Us?

Most design engineers trust “traditional” sheet metal fabrication. However, for many industries such as automotive, aerospace, electronics and healthcare, the manufacturing of complex precision components can present challenges.

Laser Cutting And Stamping are two of the most common methods of shaping and cutting detailed design features, but, while reliable, they can also create in-process issues.

There is a solution: photochemical etching, a metalworking process that uses chemical etchants to create complex and high-precision components. Although easy to define, it is important to understand the main reasons for choosing photolithography in the production process.

Photochemical Etching eliminates potential stress as there is no thermal or physical impact on the etching process. Again, no punchy or harsh cuts, and no burr-like edges. By using photochemical etching, you can eliminate uncertainty and guarantee quality and repeatability of all components.

Photochemical Etching can simplify this process because it eliminates stress and burrs, enabling product delivery to an exceptional standard in days rather than weeks or months. It also reduces tooling costs as problems caused by traditional methods no longer need to be corrected, providing certainty throughout the supply chain.

BE-CU.COM has a strong independent R&D team and chemical laboratory, and has been cooperating with the Ph.D. of Harbin Institute of Technology to discuss and solve the problems existing in the etching process industry, and has achieved great success.

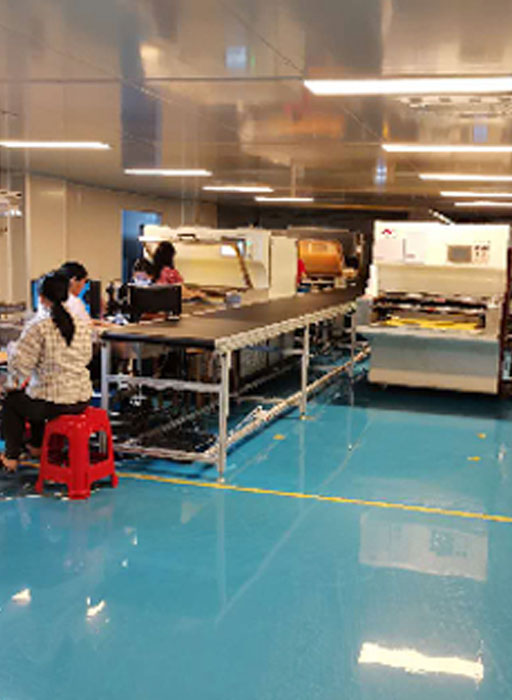

- Be-cu Prototype with 16 total automatic etching lines (10 horizontal and 6 vertical etching lines) which can deal with massive demand that request 700K piece per day as well as your individual customized small size requesting proceed by half automatic etching line.

- We have ful set of automatic production lines for cleaning, coating, development, etching and stripping etc with strong.

- Smallest line width 0.015mm, aperture 0.03mm with smallest tolerance as t 0.01mm can be fulfilled to meet your requirements

- Be-cu uses state-of-the-art digital imaging machines to precisely map designs onto the metal sheets and eliminate variations so production remains consistent – as do we.

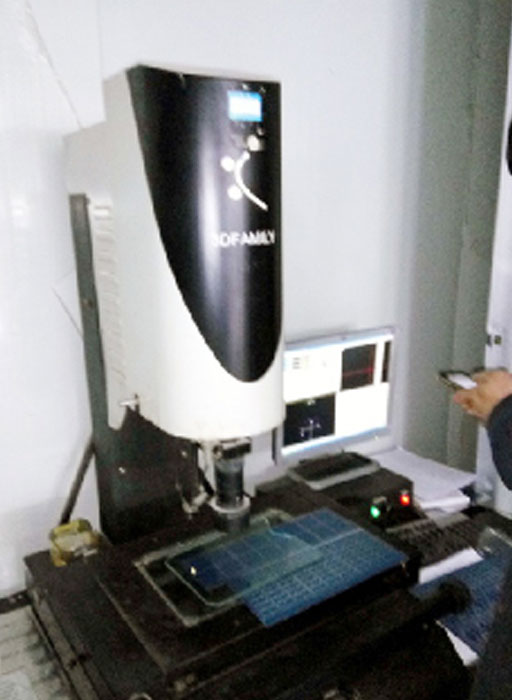

With an ISO 9001:2015 certificated manufacturing factory, we provide material and full dimensional inspection reports as your request. You can always rest assured the parts you get from Be-cu.com will exceed your expectations.To use our online metal etching service, submit your design file for metal etching services and get instant metal etching quotes.

It has a factory building covering an area of 10,000 square meters, equipped with a 100,000-level dust-free workshop, 16 etching production lines, and more than 120 employees, which can greatly meet the production needs of customers.

Metal Etching Process In BE-CU Prototype

Metal Etching Materials – Materials for Precision Etching

There is a multitude of materials available for precision etching. Here are some notable cases of metal etched. During the design phase, engineers decide which type of metal is the best choice for a part’s function in many industrial applications.

For example, most electronic components require non-corrosive, highly conductive metals such as copper and phosphor bronze. In the automotive and aerospace industries, the weight and strength of metals are very important.Aluminum is one of the popular materials used for etching manufacturing and its four most common grades are especially suited as etching, that is, 1000 series, 3000 series,4000 series, 5000 series and 6000 series.

However, the results are the same for all metal etched parts.Stainless steel is an ideal option to fabricate etched parts because of its great weldability, formability, and corrosion tolerance.Granted, not all metal types are etched in the same process, for example photoetching copper involves a different etchant than steel, while photoetching aluminum requires lower temperatures in the etcher. For Copper, it has high formability, strength, corrosion resistance, and conductivity, so it’s also a perfect material used in the precision etching process.

- Stainless Steel – Corrosion resistance, good high and low temperature performance, good toughness, easy forming, good weldability

- Copper – Excellent thermal and electrical conductivity, solderability, strength and ductility make it suitable for forming

- Beryllium Copper – Stronger than copper, maintains strength at low temperatures, conducts electricity and heat, resists corrosion, can be hardened or softened by heat treatment, suitable for forming

- Brass – Like other red metals, it is a good thermal and electrical conductor, ductile, corrosion and wear resistant

- Cold Rolled Steel – high strength, smoother and brighter surface than carbon steel, making it more resistant to corrosion, spring properties, retains shape when formed

- Aluminum – good conductor of heat and electricity, good toughness, high strength at extreme temperatures, corrosion resistant

Be-cu.com’s precision etching service is ideal for use on many materials. Below are some etching materials you could use for your next project.

Be-cu is so much more than a etching shop. We are an industry leader in metal etching services. Don’t leave your machining needs to anyone but the experts at Be-cu.

Think about BE-CU if other metal etching shops have no capability to complete your high-standard components. For the specific tolerance details of different parts, please contact us.

Surface Finishing Options for Metal Etching

Parts made using Metal Etching usually feature excellent finishes. At Be-cu.com, we offer various custom finishing options that boost the produced part’s functionality, appearance, and durability.

- BLACKENING SERVICES

- ELECTROPOLISHING

- PAINTING

- PASSIVATING

- REAMING

- TUMBLING

- CUSTOM PACKAGING

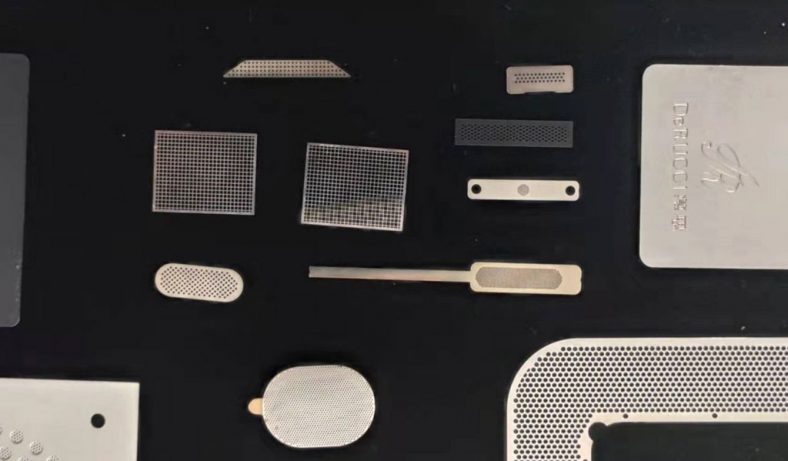

Precision Metal Etching Parts & Case Studies In China

Because Be-cu is so specialized in metal manufacturing, we are the China metal etching of choice. Be-cu.com has over 95,000 square feet of manufacturing space in three locations. Our unparalleled level of automation and our deep dedication to quality support our proud tradition of outstanding customer service. All Be-cu Metal Etching facilities offer a wide variety of unique services and capabilities that allow us to produce the highest caliber of custom metal etching in both large and small quantities – quickly and competitively.Be-cu.com will make the difference in your project. Contact Be-cu at [email protected] or request a quote with our easy-to-use online form.

-

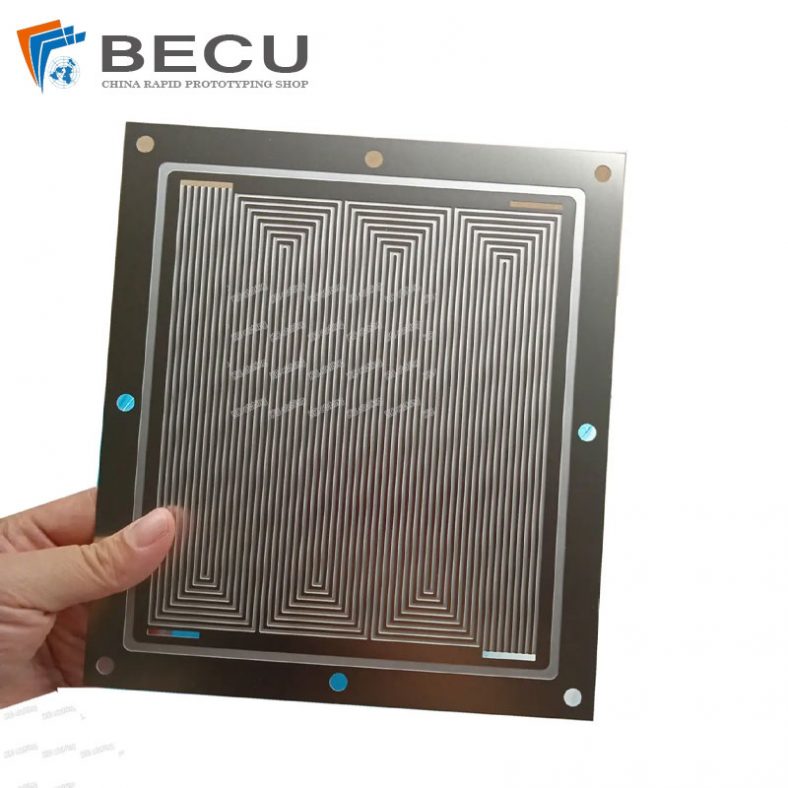

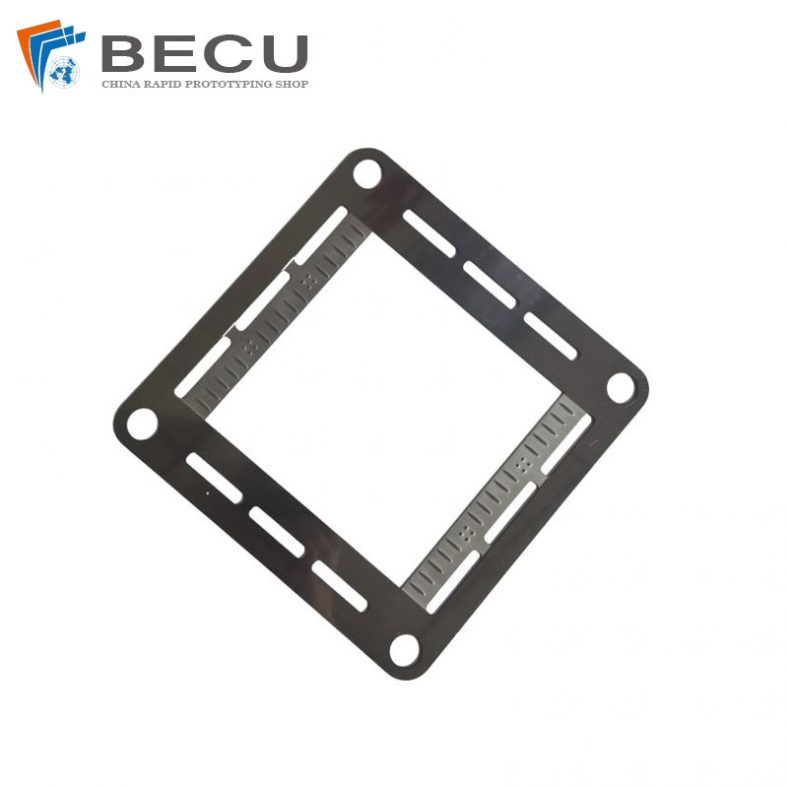

Metal Etched Hydrogen Fuel Cell Metal Bipolar Plates

-

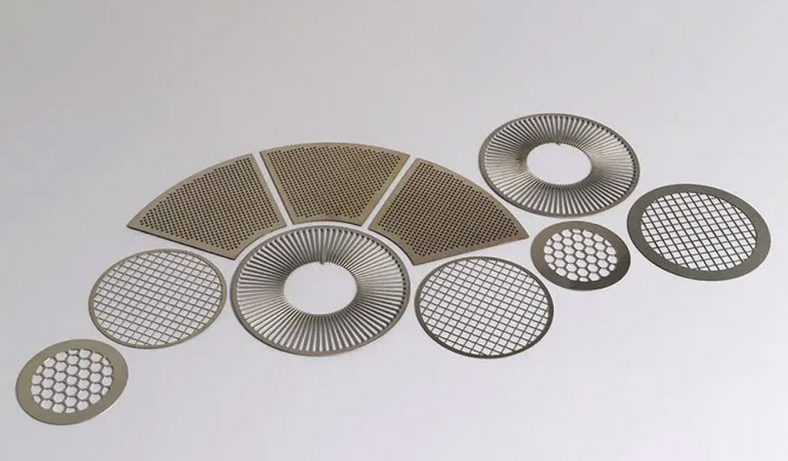

Precise Etching Stainless Steel 316 High-Speed Hair Dryer Networks

-

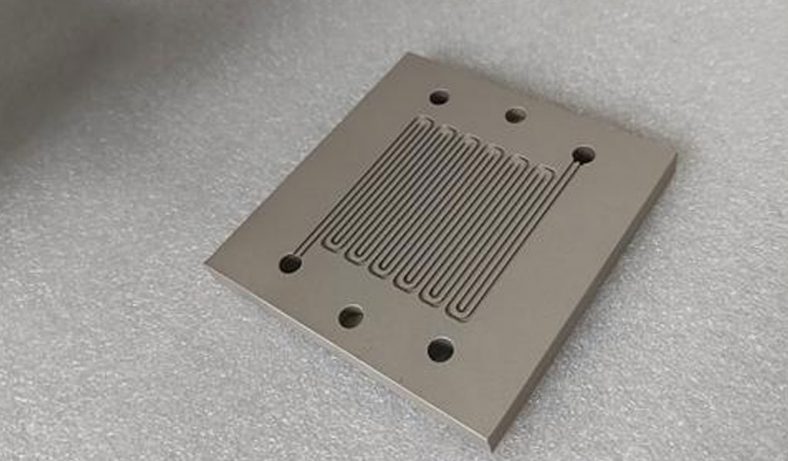

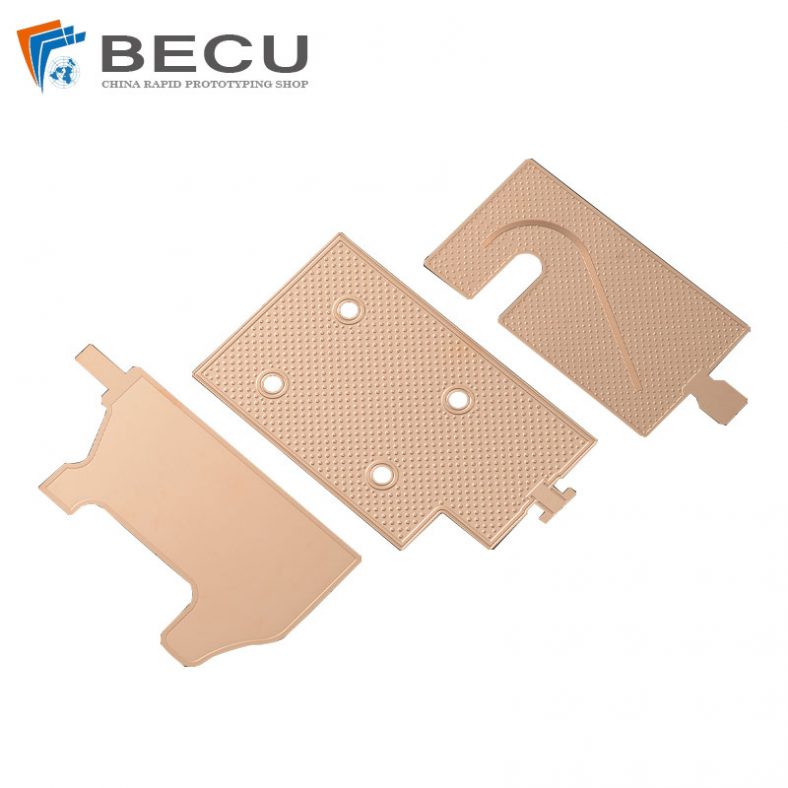

Etched VC Uniform Temperature Cooling Plate

-

Etching LED EMC Packaging Bracket

-

Planar Etched Molybdenum Alloy Micro-Air Mesh

-

Chemical Etching Stainless Steel 316 Bipolar Flow Plates

-

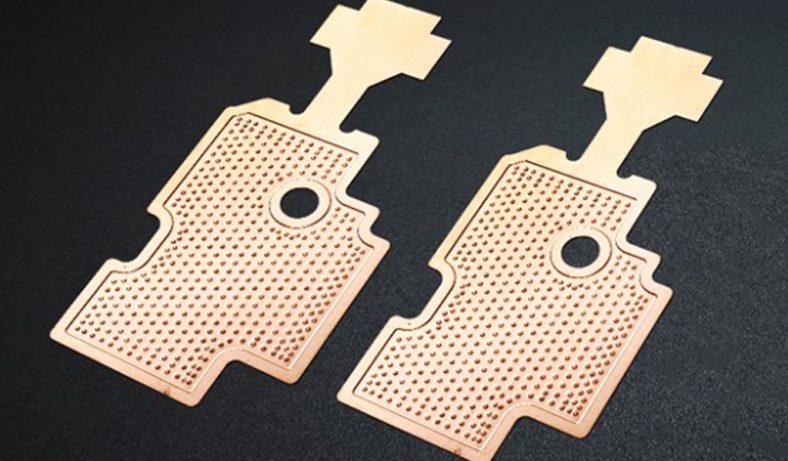

Etching Low Resistivity Copper 110 Contact Rings

-

Hollow Laser Cutting Brass 360 Jewelry

-

Laser Cut And Etching 303 Jewelry Pendant

-

Precision Etching FeCrAl Resistor Sheet For Electronics Products

-

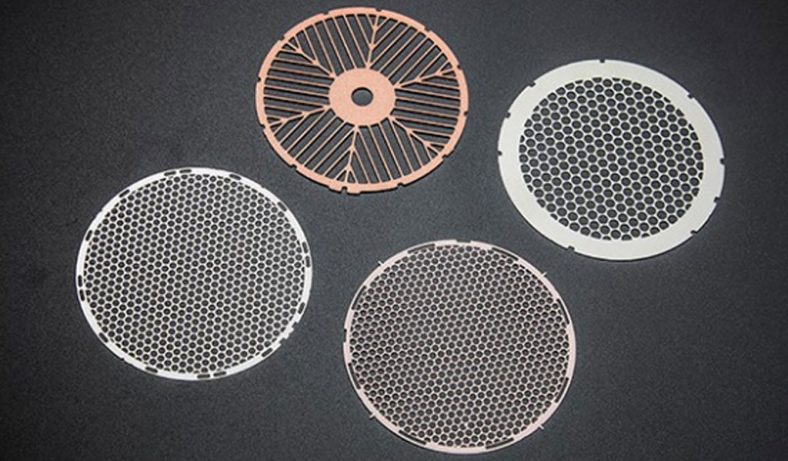

Photo Chemical Etching Microporous Dust Filter For Automotive Speaker

-

Precision Etching Automotive Audio Grille

Metal Etching for Industrial Applications

Metal etching affords both machinists and industries extensive benefits—little wonder why it has become the go-to process for metal fabrication.Metal etching facilitates the high-precision production of prototypes and thin parts regardless of volume. Here are the industrial applications of metal etch parts according to industries.

Be-cu’s etching services meet these needs by providing faster product turnaround without compromising quality so your products can reach consumers and their homes faster than your competition. Whether your needs include mass-produced samples or not, we’re up to the challenge. With Be-cu we can usually produce a prototype within 24 hours.

- 3C Products

- Medical Device Parts

- Pilotless Aircraft Parts

- Vehicle Parts

- Intelligent Component

- DIY Toys

- RF/Microwave

- Electronics (In the electronics industry, etching is used to produce a wide variety of products such as printed circuit boards, step templates, EMI/RF shielding, foil strain gauges)

- Signs, labels and nameplates (such as industrial nameplates and labels, souvenirs, hotel signs, elevator doors, trophies and trophies, wayfinding signs)