Custom Jewelry

As one of China largest jewelry and accessories oem maker since 1995, Be-cu.com online provides custom precision manufacturing services for jewelry made industry worldwide.

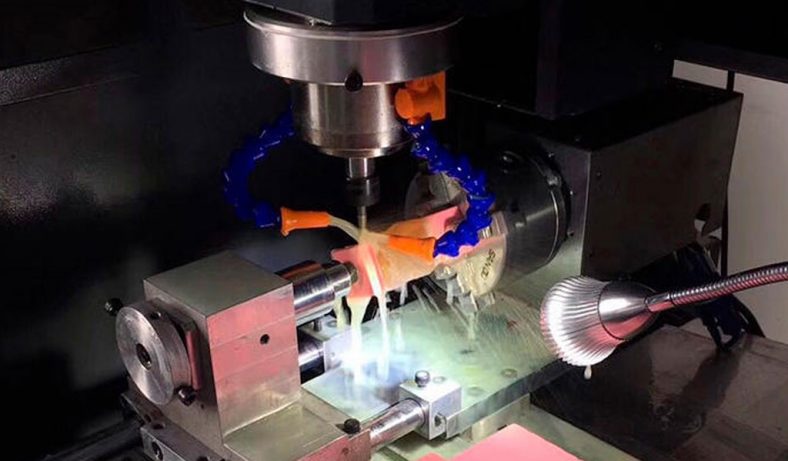

- Over 100 high-technology Auto-production machines for ensuring luxury quality base on low labor cost

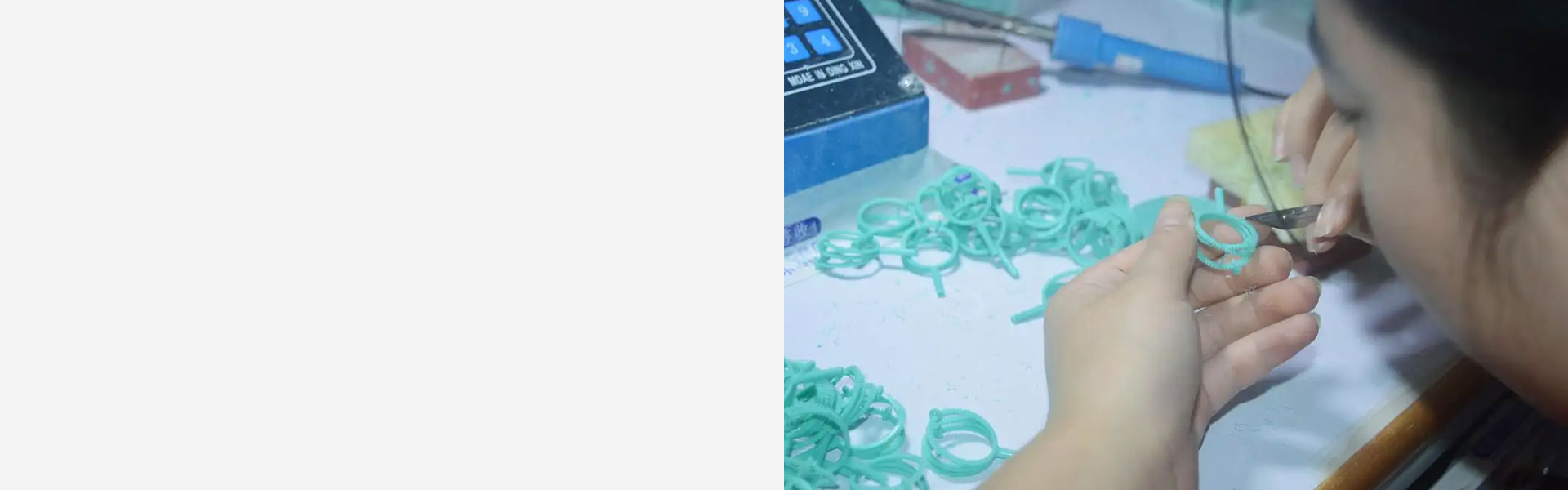

- Over 200 long-working experienced labors for ensuring well-processed performance and packages.

- Professional QC Teams to work piece by piece for ensuring every piece being good before shipment

BE-CU advanced Jewelry manufacturing shop routinely works with a wide variety of materials, ranging from stainless steel,copper, brass, carbon steel, aluminum, titanium,gold, silver, platinum and more. We can always choose a suitable precision manufacturing process to reach your requirements. Send your inquiry or drawing fast to get an online custom jewelry quote.

>>>All uploaded drawings are strictly confidential, check the confidentiality agreement

Custom Jewelry And Accessories – Online Custom Made Jewelry Manufacturer

As a manufacturer of jewelry with 30 years of experience, we built a modern machine park, so in addition to the production itself, our rapid prototyping and volume production solutions for jewelry includes a wide variety of processing methods, each having unique machining characteristics and challenges. , such as CNC machining services, foundry services, 3d printing,laser cutting,etching,galvanization, soldering, production of personalized jewelry and production of advertising jewelry (see the tabs below). Choose from over 30 plastic and metal machining materials are available for outward appearance prototypes and advanced sense in jewelry and accessories industry as fast as possible.

Service & Capabilities Of OEM Jewelry And Accessories

BE-CU has extensive experience with OEM Jewelry And Accessories Production.

- Pick your own design, including the pattern, texture, material, and color

- Choose gold plating (14k, 18k, 24k), silver plating, platinum plating, and rose gold plating, in different thicknesses

- High polish or high shine finishing by using the polishing wheel to coat the jewelry piece to a glossy shine

- Sturdy and recycled packaging prevents scratches and enhances the protection of the jewelry.

- Supply the unique works that clients appeal by metals, plating, & stones to meet specific price points to meet margin demands

- Pick the location to engrave your brand logo in the jewelry, indented or raised.

The Advantage Of Our Manufacturing Jewelry

Manufacturing Jewelry offers several advantages, both for businesses and consumers. Here are some key advantages of jewelry manufacturing:

Customized Jewelry

Quality Assurance

Cost Efficiency

Flexibility & Scalability

Innovation And Technology Integration

Job Creation And Economic Impact

The Process Of Our Manufacturing For Jewelry

Jewelry manufacturing involves the process of creating jewelry items, such as rings, necklaces, bracelets, earrings, and brooches. It encompasses various stages, from design conception to the final product. Here are the typical steps involved in jewelry manufacturing:

- Design: The jewelry manufacturing process begins with the creation of a design. This can be done by a jewelry designer or a team of designers. They may use computer-aided design (CAD) software or create hand-drawn sketches to visualize the piece.

- Material selection: Once the design is finalized, the next step is selecting the materials for the jewelry piece. Common materials include precious metals like gold, silver, platinum, and alloys. Gemstones, diamonds, pearls, and other decorative elements may also be chosen at this stage.

- Wax or computer modeling: Depending on the manufacturing method, a wax model or a computer model is created based on the design. For wax modeling, a skilled craftsman carves the design into a block of wax, creating a prototype. In computer modeling, the design is translated into a 3D model using specialized software.

- Casting: Casting is the process of transforming the wax or computer model into metal. The wax model is encased in a mold material, such as plaster or ceramic, and heated to remove the wax, leaving a cavity. Molten metal is then poured into the mold, filling the cavity and taking the shape of the desired jewelry piece.

- Finishing and assembly: Once the metal has cooled and solidified, the jewelry piece is removed from the mold. It undergoes various finishing processes, including polishing, filing, and buffing, to refine its surface and remove imperfections. Gemstones, if included, are set into the piece, and any additional elements, such as clasps or earring hooks, are attached.

- Quality control: The finished jewelry piece goes through a quality control process to ensure it meets the desired standards. This involves inspecting for any defects, checking gemstone settings, verifying metal purity, and assessing overall craftsmanship.

- Plating or surface treatment (optional): Some jewelry items undergo additional surface treatments, such as plating, to enhance their appearance. Common plating options include gold plating, silver plating, or rhodium plating, which provide a thin layer of metal over the base material.

- Packaging and distribution: Once the jewelry piece passes quality control, it is ready for packaging. It may be placed in a jewelry box, pouch, or other suitable packaging, along with branding and information about the piece. The finished jewelry is then distributed to retailers, wholesalers, or directly to customers.

It’s important to note that jewelry manufacturing can involve both traditional craftsmanship and modern technologies. The specific processes and techniques may vary depending on the manufacturer, the complexity of the design, and the desired level of quality.

The Case Studies Of Metal Jewelry And Accessories

You have a complex part design, Our Custom Jewelry And Accessories service can help you turn it into a reality. With the right equipment, strong technical knowledge, and a focus on quality.. From tool design to finishing and then on to shipment, Be-cu prototpe ensure that every project is completed to a high standard and that your orders are delivered on time, every time.

-

CNC Machining Metal Chess Pieces,Board And Sets

-

Acrylic Laser Cut Earrings

-

Microporous 3-Dimensional Cut Stainless Steel Circular Tube

-

Laser Cutting Iron Art Wall Decorations

-

Custom Brass Hanging Signs For Wall Decorations

-

Hollow Laser Cut And Carved Copper Bookmark

-

3D Laser Cutting Of Square Tube Jewelry

-

Right Angle Laser Cut Density Board

-

Laser Engraving Snowflake Plywood Craft

-

Laser Cut Round Plywood World Clock In Wall Hanging

-

Casting Silver Rings

-

Investment Cast 925 Silver Moon Earrings

-

Custom Stainless Steel 316 Goblet By Turning

-

3D Scan And SLA Printing Money Tree Ornaments

-

CNC Machining Double Threaded Pen Nib

Latest Jewelry Manufacturing Blog,Encyclopedia And Guide

View the custom Jewelry Manufacturing prototypes and end-use parts we’ve produced for our customers.