CNC Machining For Jewelry

With the continuous improvement of people’s living standards, people’s requirements for the aesthetics of jewelry are also constantly improving. Jewelry often needs to add flowers and engrave certain patterns on its surface to increase its aesthetics. For example, bracelets. People will process meaningful and complex patterns on the outer surface of the bracelet. While new product ideas bring new markets, It also brings great challenges to the surface approval and engraving of jewelry.

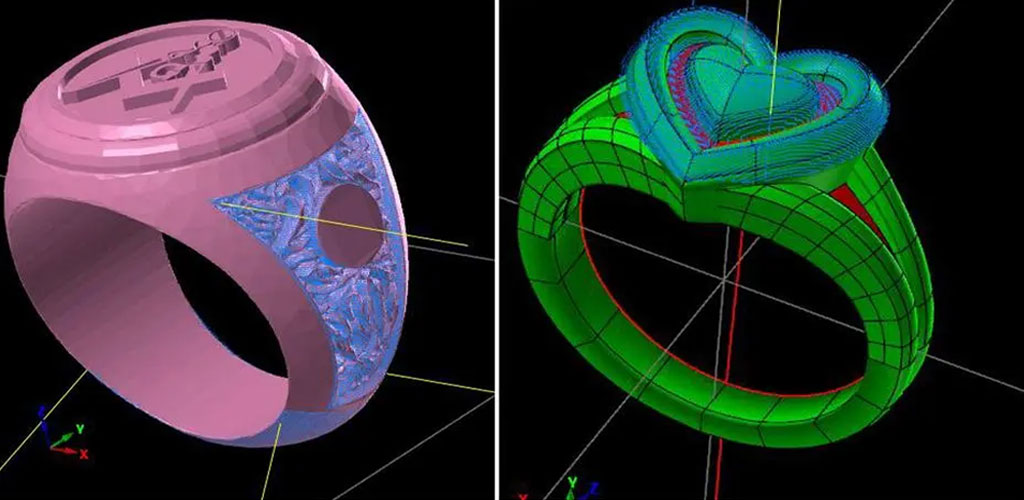

Flower batching and engraving are an important process in jewelry processing. With the continuous development of numerical control technology, although people gradually use cnc equipment to replace manual flower batching, the existing CNC equipment needs to be processed before flower batching and carving. First establish the 3D model of the jewelry through computer-aided design, and then wrap the computer-aided designed batch pattern on the outer surface of the 3D model through projection.

CNC machining is another rapid prototyping process transforming the jewelry industry as it occupies an important place in jewelry design.CNC machining involves the use of computer-aided design (CAD) software to create a digital model of the jewelry design. The CAD file is then converted into a format that the CNC machine can understand.

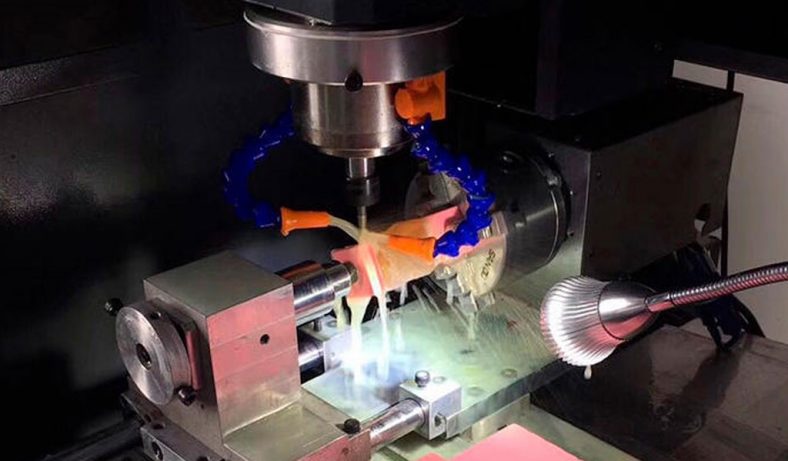

Once the design is prepared, the CNC machine precisely carves or mills the jewelry piece from a solid block of material, such as metal or wax. The machine’s cutting tools follow the instructions provided by the CAD file to create intricate shapes, patterns, and details with high accuracy.

From the perspective of style, CNC jewelry is mainly based on regular geometric structures and abstractly deformed animals and plants, with few natural shapes such as flipped and hollowed out to avoid excessive cutting and reduce the yield of precious metals. In terms of ornamentation, according to its formal characteristics, it can be divided into three types:

- Geometric patterns formed by the combination of points, lines and surfaces;

- Copying and portraying the current popular “IP”;

- Combining with traditional culture, such as Confucian etiquette, Buddhist culture, Christian culture, etc., carry out remodeling and innovation.

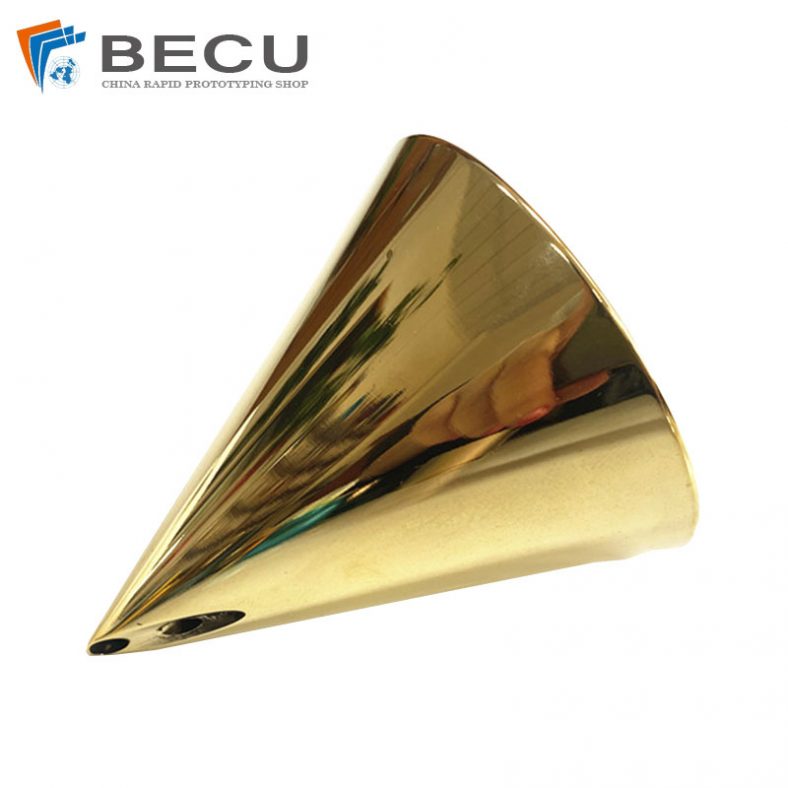

In terms of material selection, since the CNC precision machining process requires metal hardness to meet the range of precious metal hardness, except for some special texture performances that require alloys to increase the hardness of precious metals to achieve the desired effect, gold, platinum, and 18k gold and various silver products have been involved.

After CNC machining metal forming, the richness of product color can be increased by post-processing baking paint, electroplating, firing enamel, etc., so as to achieve the expected sensory effect.

It is worth mentioning that the application of CNC technology provides a great development space for the design of jewelry functional structure, which puts forward higher requirements for jewelry design in terms of combination splicing and functional treatment. Nowadays, the very common “car flower piece” diamond setting process has the visual effect of multiplying the diamond while improving the aesthetics. The “car flower piece” here refers to the “diamond car flower inlay” process. The so-called “car flower process” is simply to use CNC technology to cut metal planes with different angles. Each plane is cut at the angle of the diamond’s cutting refraction surface, and polished to a diamond-like mirror surface, showing a diamond-like refraction effect. Ultimately, it serves the purpose of magnifying the diamond. The precision of this kind of craftsmanship is unimaginable in the era of manual manufacturing. The designer uses the advantages of CNC technology to realize innovation in product structure starting from product functionality.

The Advantage Of Jewelry Cnc Machining

Jewelry CNC Machining offers several advantages over traditional handcrafted methods. It allows for precise and consistent production, faster turnaround times, and the ability to replicate designs with ease. CNC machines can produce complex shapes and intricate patterns that may be challenging to achieve manually.

Precision and Accuracy

Complex Designs

Replicability

Efficiency and Time Savings

Material Versatility

Customization

Waste Reduction

Scalability

With the transformation of the market consumption structure, the consumer groups of light luxury jewelry are huge, and CNC precision machining jewelry is fine and efficient, which is the best choice for manufacturing light luxury jewelry. Nowadays, products processed by CNC technology are very common in the market. Among them, the classic styles launched by major international brands such as Cartier, Van Cleef & Arpels, and Bulgari are the most influential. Domestic jewelry factories mainly focus on high imitation products, and are also trying to design and develop CNC jewelry. As a traditional industry, jewelry manufacturing has always been inseparable from the development of industrial processes. Under the background of the global promotion of industrial intelligent transformation, all jewelry factories have begun to upgrade their production methods. Artificial intelligence technology, automation technology, and 3D printing technology are applied to the establishment of the production line. The connection between CNC precision machining technology and digital design model has become the core component of automatic machining. It is foreseeable that, driven by the wave of “Industry 4.0”, automated production represented by CNC will become one of the most important production methods to meet the huge future luxury jewelry market.

Jewelry CNC Machining Service In China

For CNC Machining Jewelry, Be-Cu Prototype offers the highest degree of service with a basis of 30+ years experience serving the jewelry industry. Be-Cu Prototype offering advanced Jewelry CNC Machining Services ( milling,engraving,turning, drilling) for jewelry industry, Be-cu offers a complete range of CNC Machined jewelry and accessories!Our jewelry cnc machining workshop and experts deliver confidence. We have perfected the art of producing large jewelry volumes with complete JIT reliability, backed by the quality and long-term reliability our customers expect.

Push the boundaries of the technology, explore new materials and design applications with us – we love to get involved.

We can advise on materials, designs and even hole placement. We are lucky to work with some excellent jewellery designers and labels, providing them with fantastic quality jewellery and the packaging to.

CNC Machining Prototype For Jewelry

BE-CU offers superior-quality in-house prototyping and custom manufacturing services for your jewelry project. We specialize in fast-turn jewelry prototype to ensure the smooth running of your product design cycle. Our rapid prototyping services help you solidify your creative concept and refine design principles before large-scale manufacturing.

Whether CNC Machining is the ideal manufacturing process for your jewelry project or traditional jewelry investment casting is better-suited for your needs, working with an experienced manufacturing partner like BE-CU can help you make the right decisions to get better quality parts faster. Start making the precision machining jewelry you need today — contact us to get started or simply upload your jewelry files to get an instant DFM analysis of your designs, explore material options, and to get a quote online.

Metal Jewelry CNC Machining Service

Rapid prototyping processes such as Jewelry CNC machining are essential processes in many manufacturing industries. CNC machining is nothing short of a miracle for manufacturers, providing high-speed manufacturing with complete automation and ultra-high precision.

CNC Machining jewelry combines the advantages of computer-controlled precision with the artistry of jewelry design. It offers efficient and consistent production, the ability to create intricate designs, and the flexibility to work with various materials.Below are our Basic Jewelry CNC Services

Jewelry CNC Milling

Jewelry CNC milling is used to apply a machined surface finish on metal or for creating complex 3D shapes. Looking something like a drill press, a milling machine uses a cutting tool that moves in all three dimensions, removing material to achieve the desired jewelry shape , A block of material is placed on a moving table below the cutter. While the cutting tool turns, a computer controls the vertical (Z axis) motion of the cutter and the horizontal (X and Y axis) motion of the block of material.

When it comes to jewelry manufacturing, CNC milling is the more prevalent technique. CNC milling allows for greater flexibility in creating intricate designs, detailed patterns, and custom shapes that are commonly found in jewelry pieces. CNC milling machines use multiple-axis movements to precisely cut and shape jewelry components from solid blocks of material.

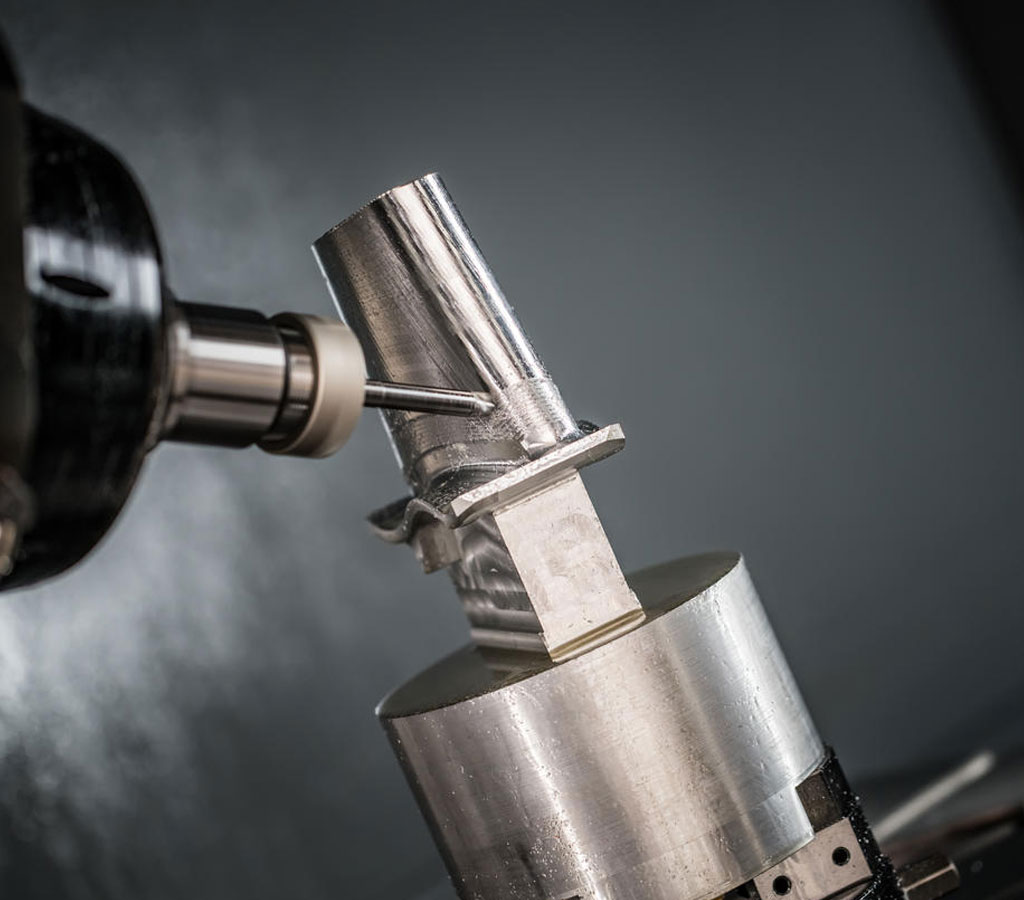

Jewelry CNC Turning

Jewelry CNC turning is a machining process that involves the rotation of a workpiece while a cutting tool moves in a linear motion to remove material and create the desired shape. Our Jewelry CNC turning services enable high speed and high quality turning of metals. If you need online CNC turning we are one of the most capable and affordable sources and we can get the job done right.

From one-off prototypes to low-volume production runs, our turning capacity is at your service for producing high-quality jewelry. Our precision CNC turning is well-known in the industry for its unsurpassed quality and accuracy, ensuring the apperance of every jewelry we manufacture.

The Case Studies Of Jewelry CNC Machining

You have a complex jewelry design, Our jewelry CNC Machining service can help you turn it into a reality. With the right equipment, strong technical knowledge, and a focus on quality.. From tool design to finishing and then on to shipment, Be-cu prototpe ensure that every project is completed to a high standard and that your orders are delivered on time, every time.

-

CNC Machining Metal Chess Pieces,Board And Sets

-

Custom Stainless Steel 316 Goblet By Turning

-

CNC Machining Double Threaded Pen Nib

-

CNC Machining Brass Solid Gourd Keychain

-

Precision Turning Solid Wenchang Pagoda Copper Ornament

-

Custom Hexahedron Tungsten Dnd Dice

-

Turn-Mill Machining 6061-T1 Bicycle Trim Gasket

-

CNC Turning Stainless Steel 316 Men Spinner Rings

-

Precision Turning Brass 353 Cone Housing

-

CNC Machining Rearview Mirror Hub Pendant

-

Custom Chinese Antique Feng Shui Compass Via Cnc Machining

Online Cooperate With Jewelry CNC Machining Company

Be-cu works with customers all over the world to bring customers ideas to life with the highest quality precision engineered metal components on the planet. We have both precision laser cutting and molds making capabilities that include both conventional and modernized production line. If you are looking for a partnership to help you apply new tools and technologies, or help you fully realize your design vision, let us help you move your business forward, contact our team ([email protected])or quote online today to get the conversation started.