What Is CNC Machining Lighting Parts

CNC machining refers to Computer Numerical Control machining, which is a manufacturing process that involves the use of computer-controlled machines to create precise and intricate parts from a variety of materials. CNC machining is widely used in various industries, including aerospace, automotive, electronics, and more, to produce complex components with high accuracy and consistency.

CNC machining lighting parts specifically refer to components used in lighting fixtures that are manufactured using CNC machining processes. These parts can include a wide range of components such as:

- Housings: The outer shells or casings of lighting fixtures that house the electrical components and protect them from environmental factors.

- Heat Sinks: These are designed to dissipate heat generated by lighting elements, such as LED bulbs, to ensure proper functioning and longevity of the lighting fixture.

- Mounting Brackets: Components that facilitate the installation and attachment of lighting fixtures to walls, ceilings, or other surfaces.

- Reflectors: Components that help control the direction and distribution of light emitted from the fixture.

- Lens Covers: Transparent or translucent covers that protect the lighting elements while also controlling the diffusion of light.

- Adjustment Mechanisms: Parts that allow for adjusting the direction or angle of the lighting, commonly used in adjustable spotlights or track lighting.

- Connectors and Wiring Components: Parts responsible for connecting electrical components within the lighting fixture, ensuring proper electrical connectivity.

- Decorative Elements: Intricate designs or embellishments used for aesthetic purposes in lighting fixtures.

CNC machining is ideal for producing lighting parts because it offers high precision, repeatability, and the ability to create complex shapes and features. The process involves creating a 3D computer model of the part using Computer-Aided Design (CAD) software and then converting that model into a set of instructions that a CNC machine follows to shape the raw material into the desired part.

This manufacturing approach allows for efficient production, custom lighting fixtures parts, and consistent quality across lighting parts. It’s worth noting that while CNC machining is commonly used, other manufacturing methods such as injection molding, die casting, and 3D printing might also be employed for producing lighting components, depending on factors like material, complexity, and production volume.

CNC Milling LED Light Parts

CNC milling is a specific type of CNC machining that involves the use of rotary cutting tools to remove material from a workpiece to create the desired shape. CNC milling is commonly used to produce various lighting parts with precision and accuracy.CNC milling is highly versatile and can produce lighting parts with complex shapes, intricate details, and tight tolerances. It is commonly used in the production of various lighting fixtures, including ceiling lights, wall sconces, desk lamps, chandeliers, and more. The process’s ability to create accurate and repeatable parts makes it a preferred choice for manufacturing high-quality lighting components.

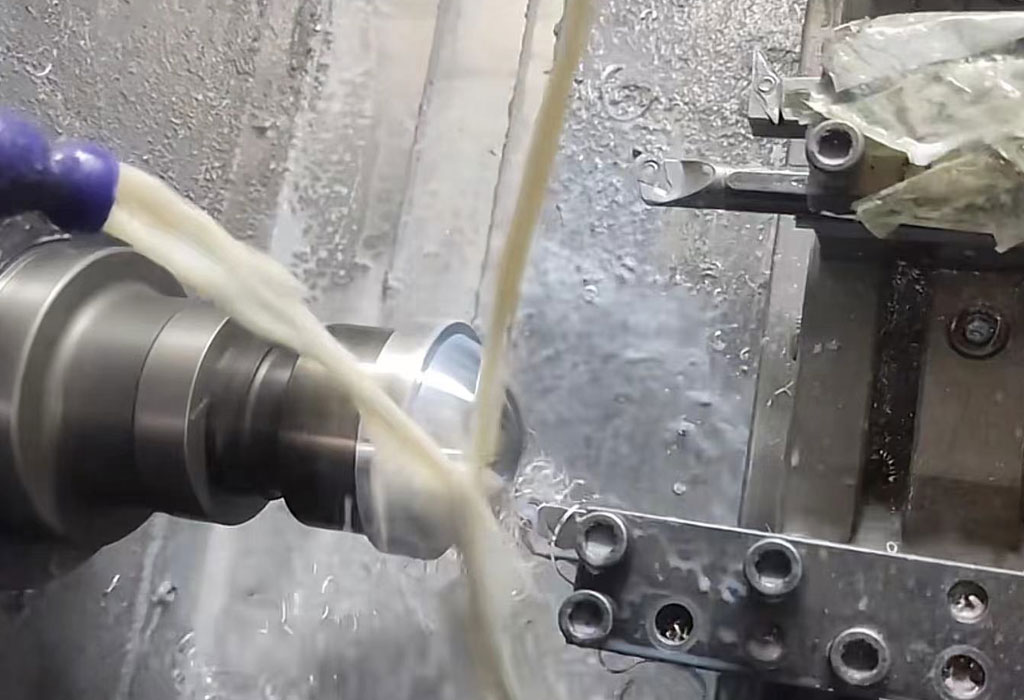

CNC Turning LED Light Parts

CNC turning is another common machining process used to create precision parts, including LED light components. While CNC milling involves rotating cutting tools to remove material from a stationary workpiece, CNC turning involves rotating the workpiece while a stationary cutting tool removes material. CNC turning is particularly well-suited for parts with rotational symmetry, such as shafts, cylinders, and other round or cylindrical components often found in LED lights.

CNC turning is efficient for creating LED light parts with round or cylindrical geometries, where rotational symmetry is a key design consideration. It allows for precise control over dimensions, tolerances, and surface finish. This process is commonly used in producing components like LED light housings, heat sinks, connectors, and mounting brackets. CNC turning helps ensure consistency and accuracy in the manufacturing of LED lighting products.

Cnc Machining Lighting Parts – LED Light Parts Machining Specialist

LED Lighting industry components require the highest precision,appropriate price and accuracy to ensure easy placement in complex equipment, such as heatsink, housing, and base.

Our advanced 5-axis CNC machines precisely mill components that meet the rigorous demands of the LED Lighting industry, ensuring the highest tolerances possible. Be-Cu prototype understands how each component fits into the project as a whole and its application of use, allowing our machinists to effectively machine parts so they fit perfectly into their assembly.

More than one million times a month Be-Cu prototype delivers a new cnc machined custom component, including hundreds of thousands made in led light parts. Each individual component is produced with a focus on top productivity, and on maintaining a supply of components that never runs dry.

Why Choose Our Light Parts Machining Service?

- Save time and money for your led light project but quality guaranteed.

- High productivity, outstanding efficiency and high accuracy

- A wide range of material grades and alloy materials can be machined

- Custom complex lighting parts machined parts and components at specific tolerances

- High speed machining for prototyping and low to high volume production runs

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for LED customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

Top China Lighting Cnc Machining Parts & Case Studies

With the continuous maturity and development of CNC Machining technology, more and more lighting manufacturers have introduced this technology for prototype testing, design proofing, parts customization and other applications. By exploring our success stories, you can learn about: the development of CNC Machining in the lighting industry, the application of CNC Machining in die casting lighting parts, how CNC Machining changes the led light manufacturing supply chain, and more.

-

Precision Turning 20° Acrylic Downlight Reflector

-

4 Axis Machining Highly Transparent Acrylic LED Tunnel Light Lens

-

CNC Turning Wear-Resistant HDPE Fasteners

-

Precision Machining Black HDPE IP65 Waterproof Plug

-

CNC Machining Welding Fixture Base For LED Industries

-

Precision CNC Machining Aluminum 7075 Spotlight Base

-

Cnc Turning Machining Brass Alloy LED Chandelier Accessories

-

Cnc Turning Custom 3W LED Showcase Light Brass Alloy Housing

-

Cnc Turning 3W Brass Showcase Lighting Enclosure

-

Custom LED Grow Light Ring Brass Accessories By Cnc Turning

-

Precision Turning Machining Brass LED Light Accessories

-

5 Axis CNC Milling Aluminum 6061 Led High Bay Lighting Parts