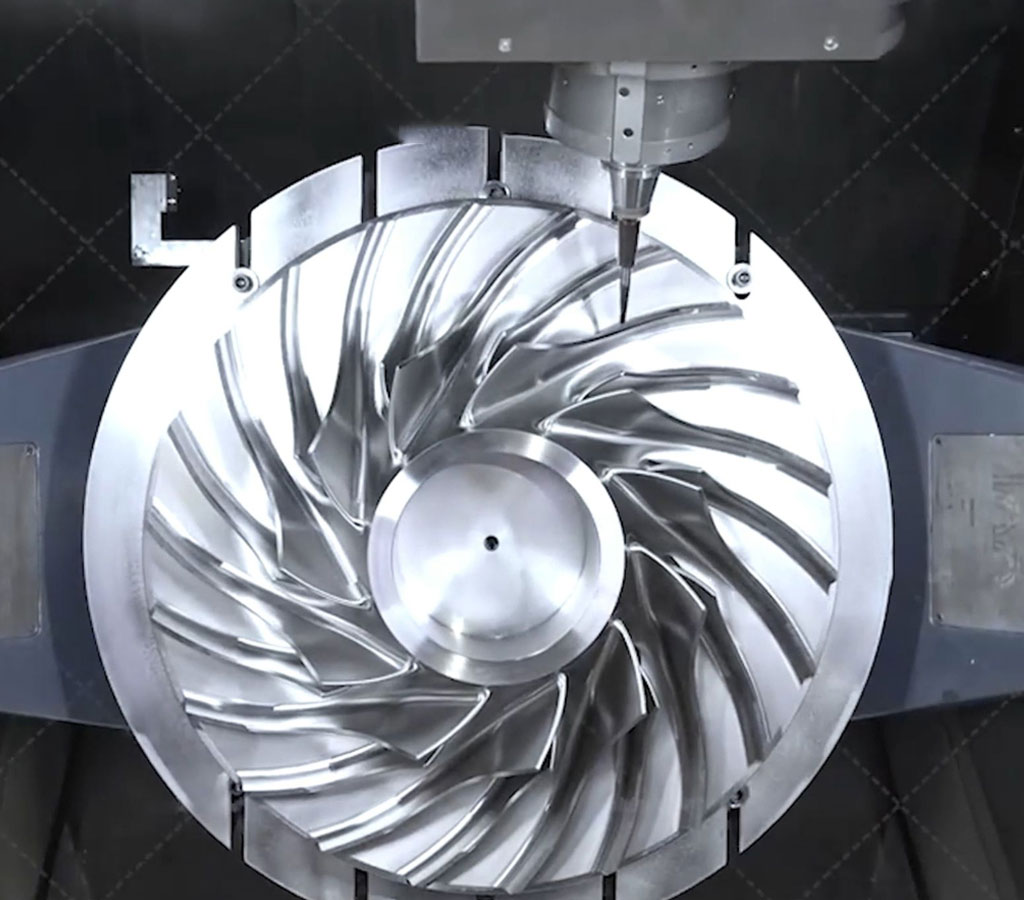

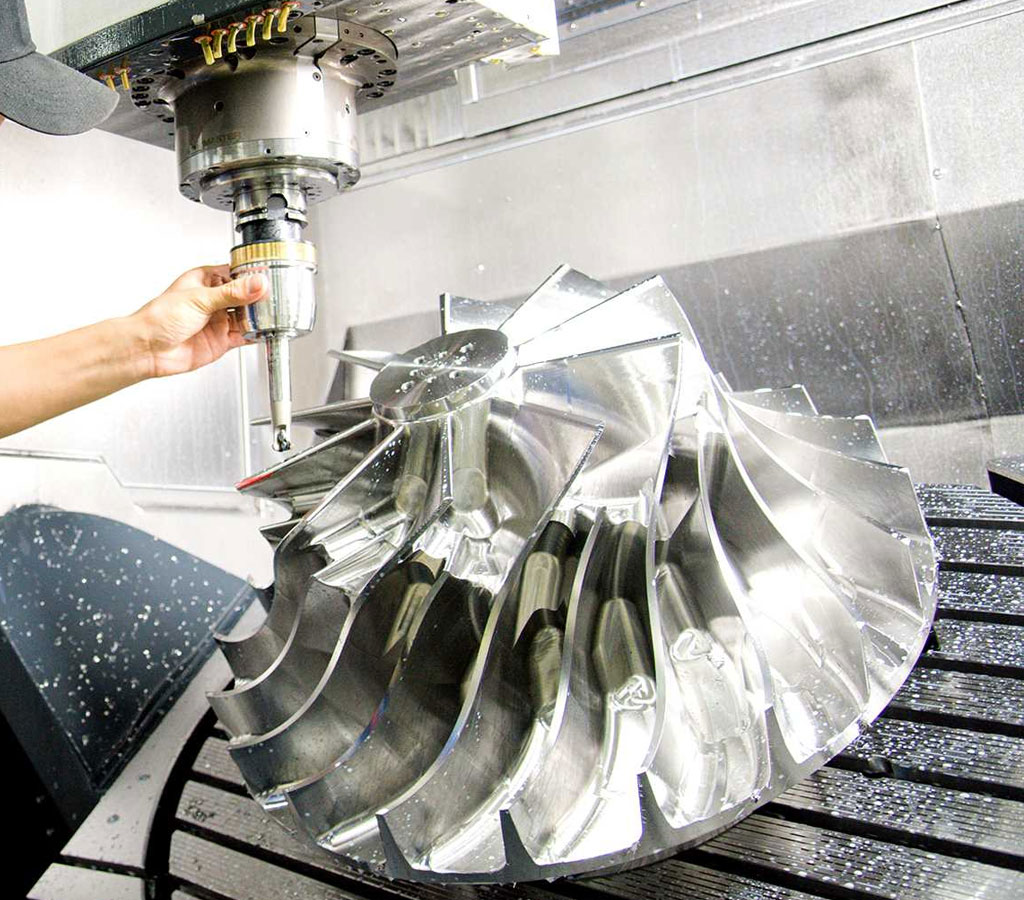

Complex Impeller Machined to The Highest Standards

Be-Cu has extensive experience with CNC machining for the impeller industry. Impeller machining refers to the process of manufacturing impellers, which are rotating components commonly found in aerospace,pumps, turbines, compressors, and other fluid handling devices.Precision and accuracy are of the utmost importance when machining components for civil Impeller and military Impeller needs.

Our skilled machinists work closely with clients to develop the specific impeller and spare parts your project requires.Be-Cu’ engineers have decades of experience producing high-quality, precision components, giving them an unmatched level of industry expertise. In many cases, our engineers refine component designs, improving the application as a whole.

An Impeller Machining Process – How To CNC Machining An Impeller

The machining process for impellers involves several steps to create a precise and efficient component. Here’s a general overview of the impeller machining process:

Design and Modeling

Material Selection

Material Preparation

CNC Machining

Balancing

Finishing

Quality Control

Assembly

Impeller Machining Services – Custom CNC Impeller Machining

With a commitment to excellence and a passion for cutting-edge technology, we are your trusted partner for all your impellers CNC machining needs. From concept to reality, we specialize in crafting intricate and high-precision impellers that drive efficiency and performance across industries.

At Be-Cu, we understand that every impellers project demands utmost accuracy and attention to detail. Our state-of-the-art facility is equipped with the latest CNC machinery, operated by a team of skilled engineers who bring years of expertise to the table. Whether you require customized impellers for aerospace applications, industrial machinery, or any other specialized field, we take pride in transforming your visions into tangible masterpieces.

With a strong emphasis on quality, we adhere to rigorous manufacturing standards to ensure that each impeller leaving our facility not only meets but exceeds your expectations. We collaborate closely with our clients, working hand in hand to comprehend your unique requirements and deliver solutions that elevate your projects to new heights.

5 Axis Impeller Machining

A 5-axis CNC machine has the capability to move the cutting tool along five different axes: X, Y, Z, and two additional rotational axes, typically referred to as A and B. This enables the machine to approach the workpiece from multiple angles and orientations, which is especially advantageous when dealing with intricate and contoured shapes like impellers. This technique allows for greater flexibility and precision in creating complex impeller geometries compared to traditional 3-axis machining.

Revolutionary DMU 5 axis CNC machines and Wire EDM services allow for faster, more accurate construction of impeller. Our fast turnaround time coupled with consistent accuracy makes the production of even the most precision-dependent components a breeze. What is considered impossible at lesser impeller machine shops is commonplace for Be-Cu.

Experience the synergy of advanced technology, precision craftsmanship, and dedicated customer service. Choose Impeller CNC Machining Service for the precision you demand and the innovation you deserve. Your success is our driving force, and we look forward to embarking on this journey of excellence together.

Why Choose Our Impeller Machining Service?

- Save time and money for your impeller project but quality guaranteed.

- High productivity, outstanding efficiency and high accuracy

- A wide range of material grades and alloy materials can be machined

- Custom complex impeller machined parts and components at specific tolerances

- High speed machining for prototyping and low to high volume production runs

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

Top China Cnc Machining Impeller Gallery

With the continuous maturity and development of CNC Machining technology, more and more impeller manufacturers have introduced this technology for prototype testing, design proofing, parts customization and other applications. By exploring our success stories, you can learn about: the development of CNC Machining in the impeller industry, the application of CNC Machining in impeller molds, how CNC Machining changes the impeller manufacturing supply chain, and more.

-

5 Axis Machining Aluminum-Magnesium Alloy Water Aerator Impeller

-

Precision CNC Machining Inconel 718 Cast Impeller

-

5 Axis CNC Machining Pump Impeller

-

3-Way Centrifugal Compressor Closed Impeller By 5 Axis Machining

-

CNC Machined UHMW-PE Plastic Impellers And Gears

-

5 Axis CNC Precision Machining PEEK Valve Body And Impeller

-

ISO 9001:2015 Certified Machining PEEK Balance Impeller

-

5-Axis Linkage Cnc Machining Aluminum Turbocharger Impeller