What Is Precision Spinning Lighting Parts

Precision spinning lighting parts are lighting accessories manufactured by precision spinning technology, with excellent mechanical properties and beautiful appearance. They are usually made of high-quality metal materials, such as stainless steel, aluminum alloy, etc., and undergo precise spinning, shearing, grinding and other processes to achieve the required optical and mechanical properties.There are many types of precision spinning lighting parts, including lampshades, lamp holders, lamp holders, lamp arms, lamp holders, etc. The design and manufacturing process of these parts requires a high degree of precision and technical support to ensure their stability and reliability during installation and use.

The working principle of precision spinning lighting parts is mainly to adjust the light and create an atmosphere through light reflection and refraction. For example, the curved shape of the spinning lampshade can change the direction of the light, making the light softer and more uniform; while the adjustment mechanism of the spinning lamp holder can adjust the angle and height of the light to meet different lighting needs.

Precision spinning lighting parts are widely used in lighting, decoration, display and other fields. For example, in commercial lighting, lighting with precision spinning technology can create unique light and shadow effects and enhance brand image; in home decoration, spinning lighting parts can become an important part of interior decoration, creating a comfortable lighting environment .

With the continuous development of science and technology, precision spinning lighting parts are also improving. In the future, with the development of technologies such as intelligence and high efficiency, precision spinning lighting parts will be more intelligent and energy-saving, bringing a richer visual experience to people’s lives.

Precision Spinning Lighting Parts – LED Light Parts Spun Specialist

In the dynamic realm of modern lighting, where aesthetics and functionality intertwine to shape ambiances and experiences, emerges a beacon of excellence and innovation – Be-Cu.com. As a leading manufacturer of precision spinning lighting parts, we have etched our name in the annals of the industry through an unwavering commitment to craftsmanship, technology, and creative illumination solutions.

Our journey began with a vision to redefine illumination, transcending the conventional paradigms to engineer spinning lighting parts that not only radiate light but also captivate hearts and minds. Since our inception, we have striven for nothing less than perfection, forging an identity rooted in precision, quality, and ingenuity.

Craftsmanship that Transcends Boundaries

At Be-Cu.com, every piece is more than a mere component; it’s an embodiment of meticulous craftsmanship and dedication. Our team of skilled artisans and engineers weave together their expertise to give life to designs that seamlessly merge form and function. With an unwavering commitment to precision, we manufacture spinning lighting parts that push the boundaries of creativity and innovation.

Pioneering Technology and Innovation

Innovation is at the core of our DNA. As technology evolves, so does our commitment to harnessing its potential. Our state-of-the-art manufacturing facilities are equipped with cutting-edge machinery and advanced automation, enabling us to maintain exceptional levels of precision and consistency. We leverage the power of innovation to create spinning lighting parts that not only meet industry standards but also set new benchmarks for performance and elegance.

Customization: Illuminating Unique Visions

Understanding that every project carries a unique vision, we embrace customization as a cornerstone of our approach. Our team collaborates closely with clients to understand their needs, aspirations, and design sensibilities. This collaborative process empowers us to craft spinning lighting parts that align seamlessly with the project’s aesthetic and functional requirements, breathing life into spaces with a distinctive allure.

Quality Assurance and Sustainability

Uncompromising quality is non-negotiable in our pursuit of excellence. Each spinning lighting part undergoes rigorous quality checks to ensure it meets our stringent standards. Our commitment to quality is mirrored by our dedication to sustainability. We prioritize eco-friendly practices, utilizing materials and processes that minimize our environmental footprint, without compromising on the excellence that defines our brand.

Global Reach, Local Approach

While our reach spans the globe, our approach remains rooted in local values. We understand the importance of a personal touch, and our global network is complemented by a personalized service that ensures our clients’ needs are met with attention and care. Our ability to seamlessly bridge the gap between global expertise and local service has earned us the trust and loyalty of clients worldwide.

In conclusion, Be-Cu.com is not just a manufacturer of precision spinning lighting parts; we are architects of illumination experiences. Our commitment to craftsmanship, innovation, customization, quality, and sustainability define who we are and what we create. Join us in this luminous journey as we continue to shape spaces and perceptions through brilliance that knows no bounds.

The Advantage Of Lighting Parts Spinning

Metal spinning offers a range of advantages to those looking for a very versatile, streamlined process, including:

- Lower Costs – Compared to the tools employed in alternative forming methods, Lighting Parts spinning tools are typically 10% of the cost.

- Shorter Lead Times – The Lighting Parts spinning process amounts to significantly shorter turnaround times – tools and spun components can be available within weeks rather than months.

- Maximum Design Flexibility – Lighting Parts spinning tools can be quickly and easily changed to accommodate evolving product designs, enabling flexibility when it’s needed most.

- Seamless, High-Quality Construction – Lighting Parts spinning produces smooth, durable objects without seams or welds, for parts require feature superior strength and great aesthetics.

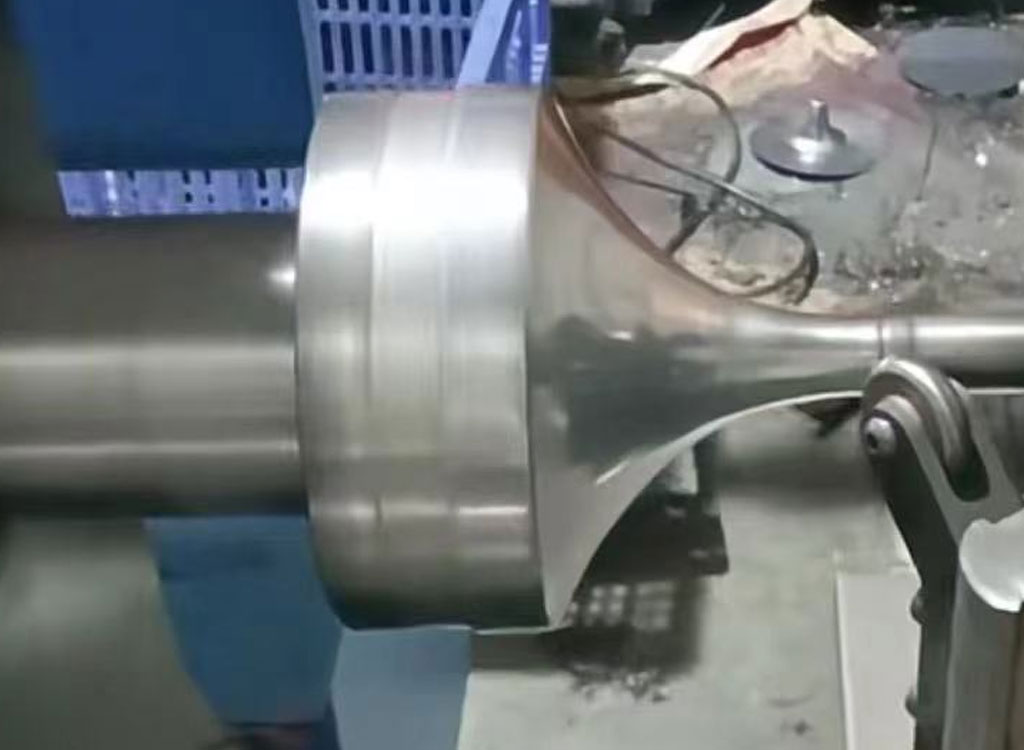

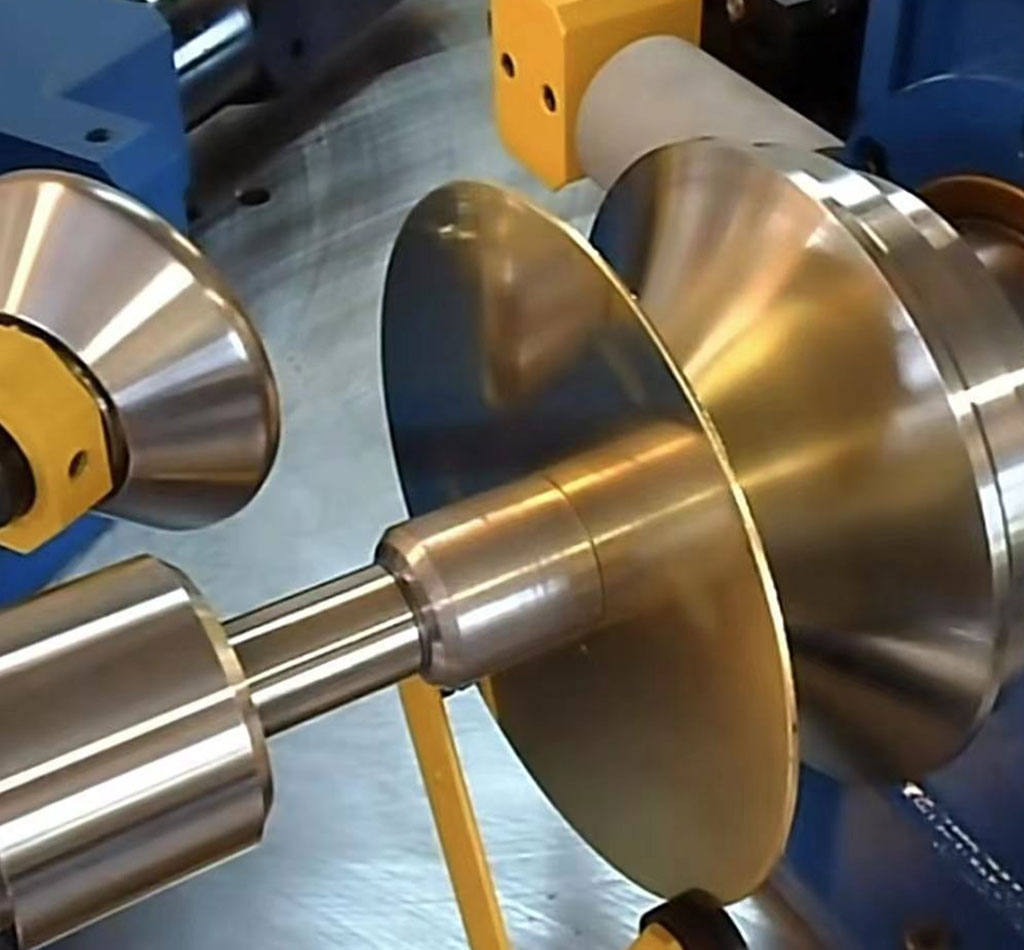

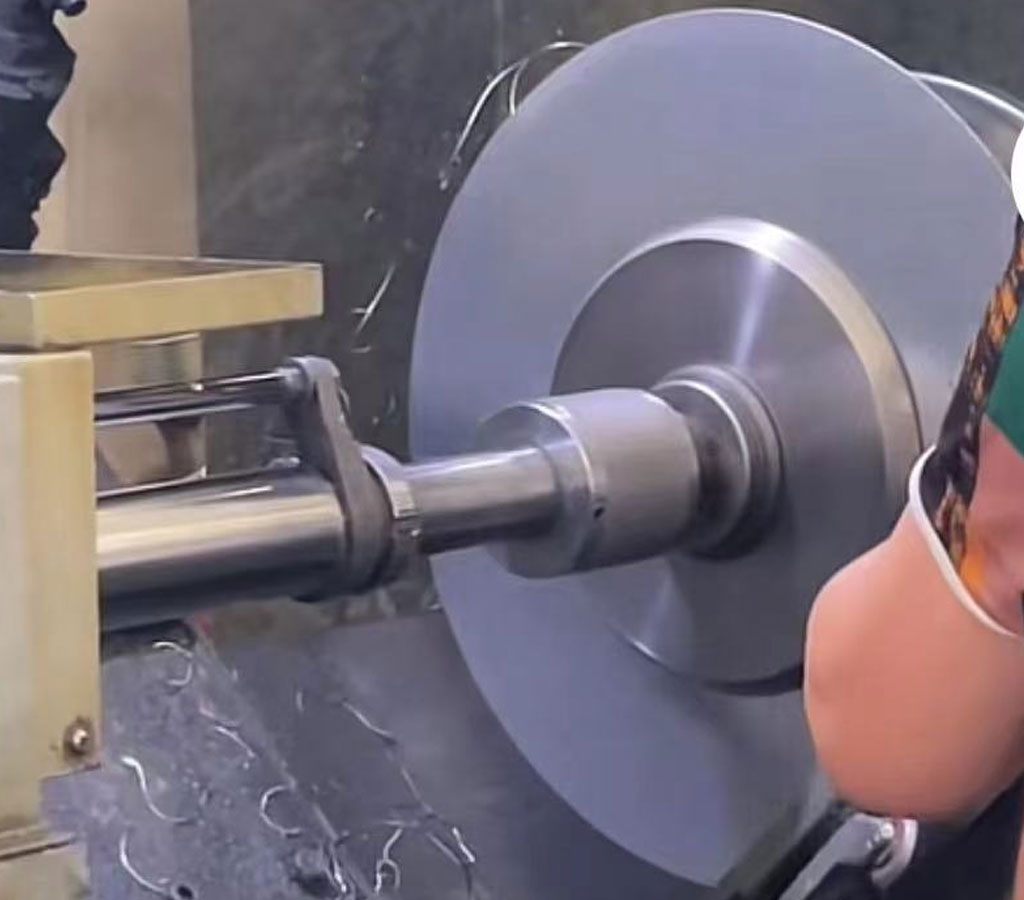

Our Case Studies Gallery Of Spun Lighting Parts CNC Spinning

Put Be-cu.com’ experience to work for all of your custom lighting parts spinning and spin forming needs—from traditional manual Lighting Parts spinning to cutting edge CNC Lighting Parts spinning. The spun Lighting Parts spinning process is perfect for a wide variety of industries that require consistent tolerances, fast turn-around, and uncompromising quality.