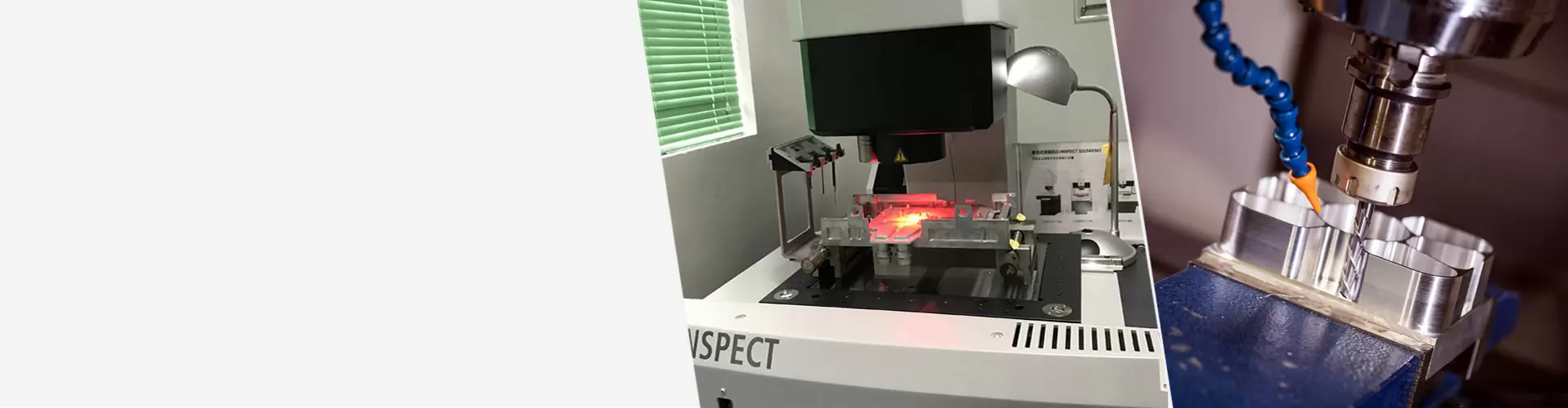

Quality Inspection

- 100% Fully Inspected And Shipped

- Multi-level incoming order review

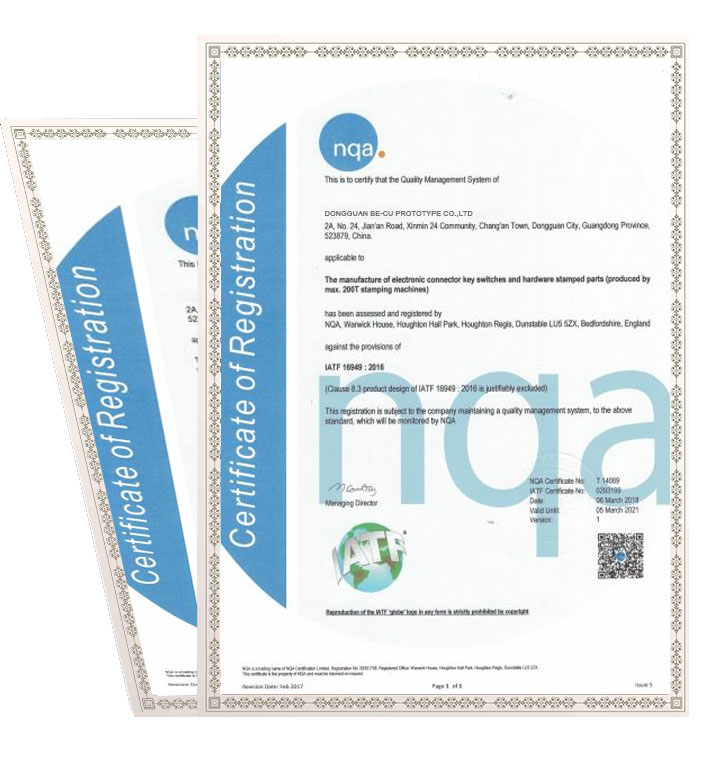

- ISO9001 Quality System Certification

- Detailed records of incoming raw materials

- We Solemnly Promise: If Quality Problems Occur Due To Fabrication,

BE-CU Is Responsible For Free Repair or Reproduction, And Bear The Return Freight

>>>All uploaded drawings are strictly confidential, check the confidentiality agreement

Quality Assurance In Whole Process

We believe that only a complete process is an effective means to ensure quality

Strict Management Of The Supply Chain

- Both self-operated(Cnc Machining Shop,Die Casting Factory,3D Printing Shop etc) and cooperative suppliers must comply with the quality management system

- Strictly selected suppliers: only 1 out of 6 applicants can be selected

- Covering upstream and downstream: strictly control material and surface treatment suppliers.

Professional Engineer Review Process

Be-cu has 20+ professional design engineers, mold engineers, and material auditors.

The professional engineers are responsible for reviewing the drawings before fabrication, and if they find errors in the drawings, and the optimization of the process, they will communicate with customers in time to eliminate problems before fabrication.

Control The Fabrication Process

- The parts will be fabricatied in strict accordance with the established technological process

- FAI first inspection report can be provided, and mass fabrication can be done after passing

- There are patrol inspections in the production process to ensure that each process is correct.

100% Fully Inspected And Shipped

- BE-CU.COM has a professional quality inspection team to ensure the quality of parts

- The processed parts are 100% inspected before shipment to ensure that they meet your requirements.

- BE-CU can provide packaging customization, assembly, surface treatment and other procedures

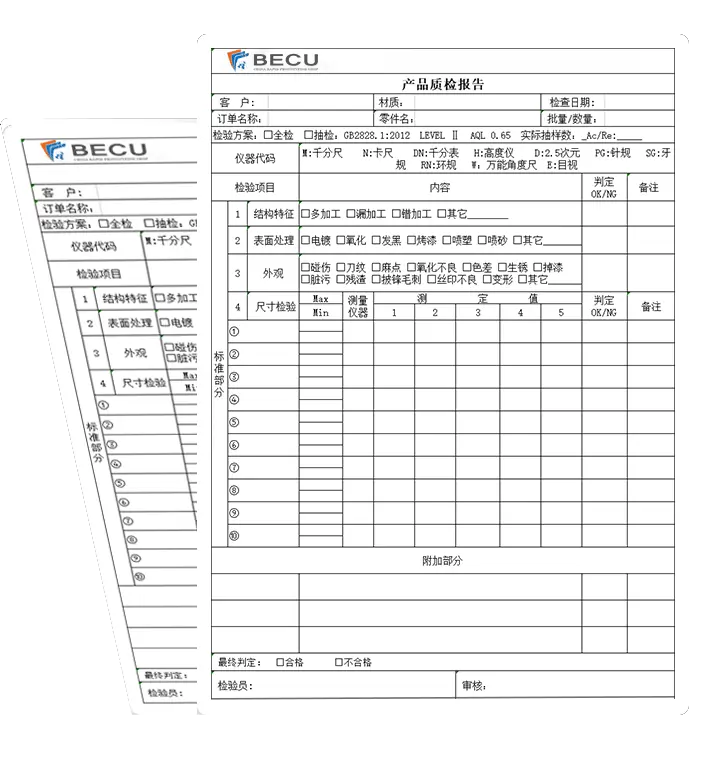

Inspection Report

- Standard Quality Inspection Card

- Material Report

- Size Inspection Report

- FAI First Inspection Report

- Hardness Inspection Report

- Salt Spray Inspection Report

- Dimensional CMM Inspection Report

- Custom: Can Be Provided According To Your Requirements

Inspection Equipment

Quality System That Meets Your Needs

We have ITAF 16949 And ISO9001:2015 quality management certification, While quality is more than just a certification. Our factory has the necessary internal parts quality control system, In recent years, We use ERP system for production management, so we are able to handle every step of the production process – from initial quotation to final delivery.

Many Technologies, One Standard: On-Time Quality

Our custom parts services are bolstered by our extensive be-cu machine library and general breadth of fabricate technology. Few can match be-cu in adherence to exacting specifications, or in the re-creation of complex geometries for high volume fabrication of all types of specialized material parts.See examples of our case studies on our Products Page

At BE-CU, we have implemented a Strict Quality Inspection Standard for our fabrication services to inspect parts and ensure the consistency of cosmetic appearance. We are proud to be fully certified. This demonstrates our commitment to continuous quality improvement, respect for our workers and for the environment.

-

CNC Machining Bakelite Circuit Board Test Fixture

-

Precision Grinding Tungsten Steel Mold Parts

-

5 Axis CNC Machining Medical Olecranon Plate

-

Special-Shaped Non-Standard Medical Device Needles

-

High-Speed Steel (HSS) Die Punching Needles

-

Precision Tungsten Copper Alloy Eccentric Insert

-

5 Axis CNC Machining Spiral Bevel Gear Mold

-

Small Precision Injection Molding Inserts

-

5 Axis Machining Aluminum-Magnesium Alloy Water Aerator Impeller

-

Large CNC Turning Inconel 625 Automobile Engine Camshafts

-

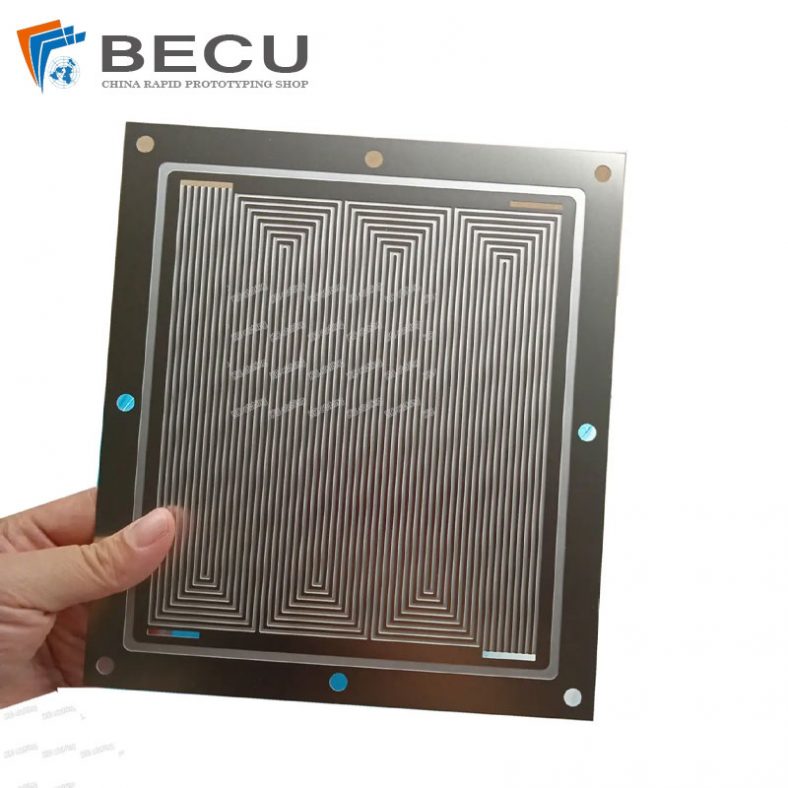

Metal Etched Hydrogen Fuel Cell Metal Bipolar Plates

-

Prototype CNC Spinning Stainless Steel 316L Outdoor Camping Pot