Custom Aluminum Parts

- Global delivery as fast as 30 days

- Machined prototypes in as fast as 9 days.

- Perfect Service And High Quality

- Tolerances down to +-0.005mm

- ISO 9001:2015, ITAF 16949

>>>All uploaded drawings are strictly confidential, check the confidentiality agreement

Fabrication Aluminum Parts Supplier – Custom Aluminum Components Manufacturer

Be-cu’s Parent Company Established in 1995, and recognized as a viable and profitable outsourcing option for aluminum parts project needs, We know the use of lightweight metals is frequent nowadays. This makes aluminum parts fabrication elements very appealing for many industries. Fortunately for you, custom aluminum parts has been our top knowledge for years.Be-cu has been making aluminum parts of various sizes, from miniature to oversized, and various shapes, from simplest to the most complicated.

• Empowered by 100+ advanced facilities

• 10000+ case studies produced

• Serving 3000+ clients worldwide

• Supported by hundreds senior machinists with over 20 years of experience

Be-cu Shop has custom machined aluminum parts for over 30 years. You can design and order your parts with our free rapid quote tooling or upload your own CAD file to our email:[email protected] for a fast quote.

What Is Aluminum Parts – Aluminum Define

Aluminum parts are actually pure aluminum or aluminum alloy parts obtained by various processing methods.

Aluminum (Aluminium) is a metal element, the element symbol is Al, and the atomic number is 13. The content of aluminum in the earth’s crust is second only to oxygen and silicon, ranking third, and it is the most abundant metal element in the earth’s crust. The development of the three important industries of aviation, construction and automobiles requires the material properties to have the unique properties of aluminum and its alloys, which greatly facilitates the production and application of this new metal aluminum. The application is very wide.

Aluminum is a silver-white light metal. Extensible. Commodities are often made into columns, rods, flakes, foils, powders, ribbons and filaments. In moist air, it can form an oxide film that prevents metal corrosion. The aluminum powder treated with acid can burn violently when heated in the air, and emit a dazzling white flame. Easily soluble in dilute sulfuric acid, dilute nitric acid, hydrochloric acid, sodium hydroxide and potassium hydroxide solution, insoluble in water, but can slowly react with hot water to form aluminum hydroxide, relative density 2.70, elastic modulus 70Gpa, Poisson’s ratio 0.33 . Melting point 660 ℃. Boiling point 2327 ℃. It is widely used for its light weight, good electrical and thermal conductivity, high reflectivity and oxidation resistance. The aluminum used for daily utensils is usually called “steel” or “steel grade”. The thermal expansion coefficient of Al at (room temperature) 25°C is 0.0000236mm/°C or 23.6ppm·k-1

Custom Aluminum Parts Applications – What is Custom Aluminum Parts Used for

Because the fabrication allows a very high precision without altering the structure of the material with a good rate of manufacture, fabrication is becoming increasingly common as its machine range, control systems and cutting tools are just growing. Our fabrication service is used to produce a variety of custom-designed fabrication parts and products in all areas of the industry:

Experienced To Offer More Manufacturing Options

Upholding this standard requires an exceptional commitment to manufacturing resources. The wide variety of machining technology options in the Be-Cu prototype machine library is supported by an in-house tooling capability that adapts tools to the unique characteristics of each material.Our aluminum science engineers will help you choose suitable metal alloys and machining processes(include aluminum cnc machining and more) to address your part-making needs.

The Case Studies Of Custom Aluminum Parts

You have a complex aluminum parts design, Our fabrication service can help you turn it into a reality. With the right equipment, strong technical knowledge, and a focus on quality.. From tool design to finishing and then on to shipment, Be-cu prototpe ensure that every project is completed to a high standard and that your orders are delivered on time, every time.

-

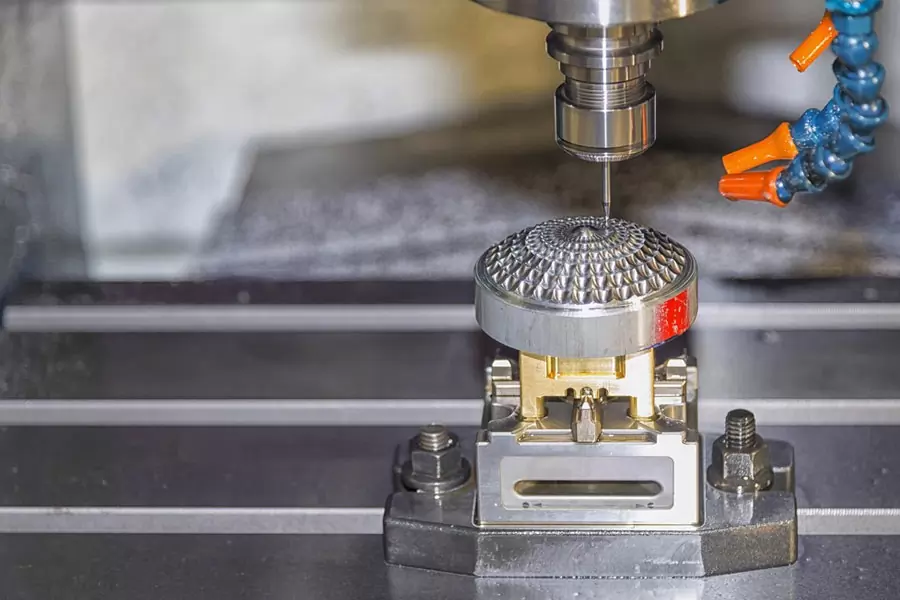

5 Axis Machining Aluminum-Magnesium Alloy Water Aerator Impeller

-

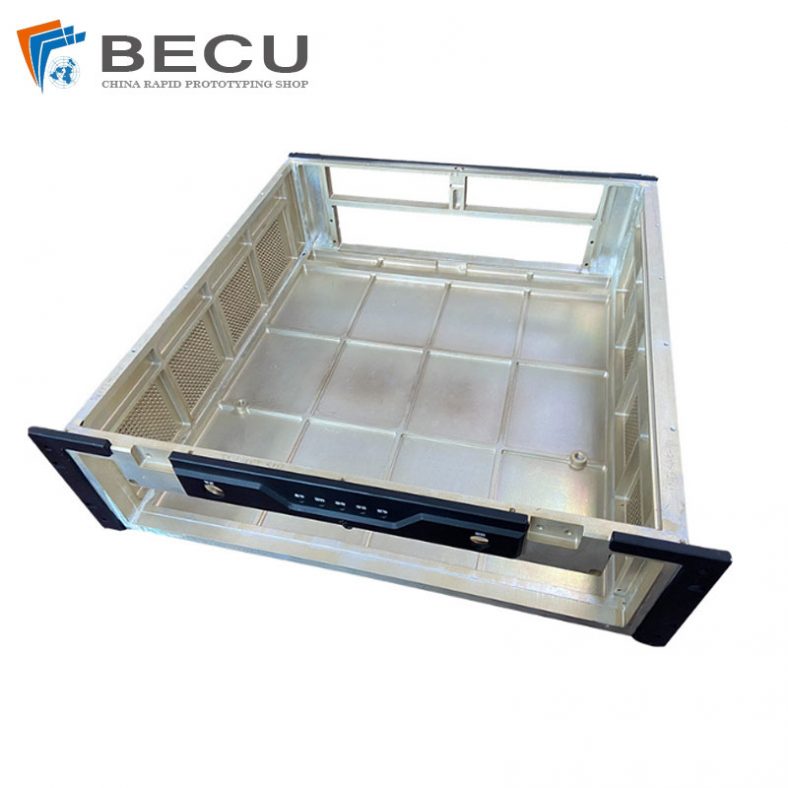

Precision Machining 6063 Aluminum Military Computer Server Chassis

-

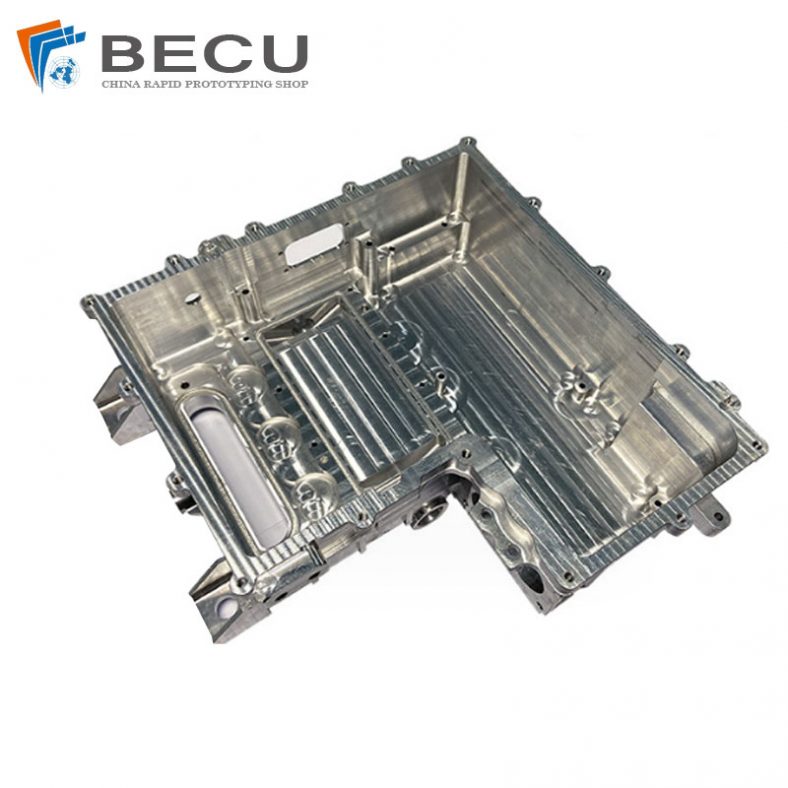

CNC 6063 Aluminum Automotive Motor End Cover

-

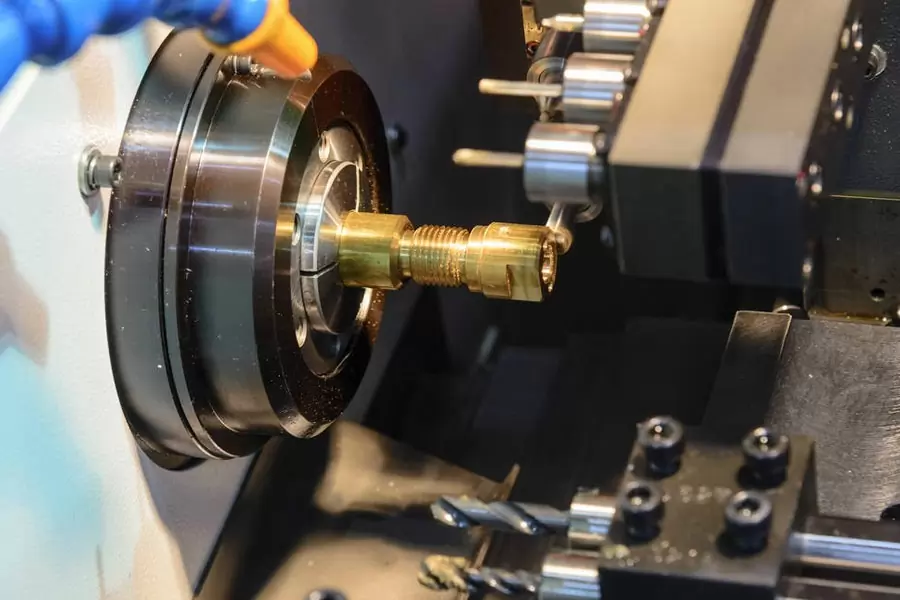

CNC Machining Gas Stove Bottom Joint

-

CNC Turning 6063 Bicycle Tightening Disc

-

Precision CNC Machining Unmanned Aerial Vehicle Motor Base

-

Metal CNC Machining Motor Front And Rear Covers

-

5 Axis CNC Machining Pump Impeller

-

3-Way Centrifugal Compressor Closed Impeller By 5 Axis Machining

-

CNC Machining For Camera L Bracket