The Rapid Development Of The Automotive Machining Industry

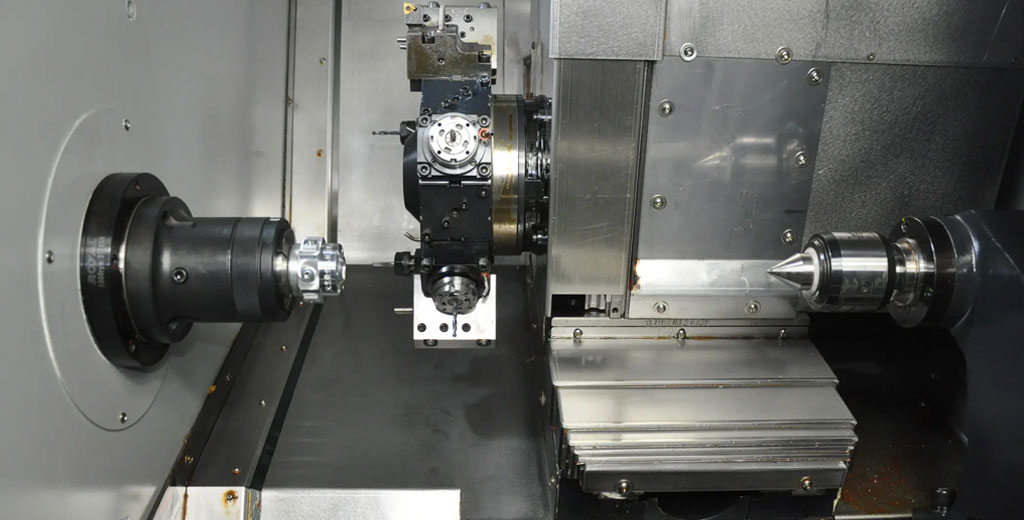

With the rapid development of the automotive industry, in which CNC machine play a very key role, the automotive industry not only relies on the technological progress of precision automotive CNC machining, but also drives its development. Almost every aspect of the production of precision automotive parts uses CNC machine.

CNC machining offers advantages such as high precision and automation, which determine the kind of applications it can be used for. However, almost all industries will require CNC machines to machine parts, with multi-axis CNC machines being ideally suited to machining some of the most complex parts. As CNC machines can handle almost any type of material, they are used for a wide range of applications.

CNC machining is a cost effective manufacturing process. The process is compatible with a large range of materials. As a result, CNC machining contributes to a wide range of applications in a variety of industries. Manufacturers and machinists use this process in a variety of ways. This includes direct manufacturing processes, indirect manufacturing processes or in combination with other processes.

CNC Automotive Machining Applications

Be-cu.com is one of China’s leading CNC Machining Automotive Components Manufacturers that are pass to 16949 Certification. Whether we are designing and manufacturing automotive engine parts or transmission car parts, we ensure the highest tolerances and precision CNC automotive machining process. Be-Cu Prototype Inc is committed to improving vehicle design and performance throughout the industry.Our CNC machines are available in a variety of configurations, such as 3 and 5 axis CNC machining, can achieve varying of complex automotive parts.

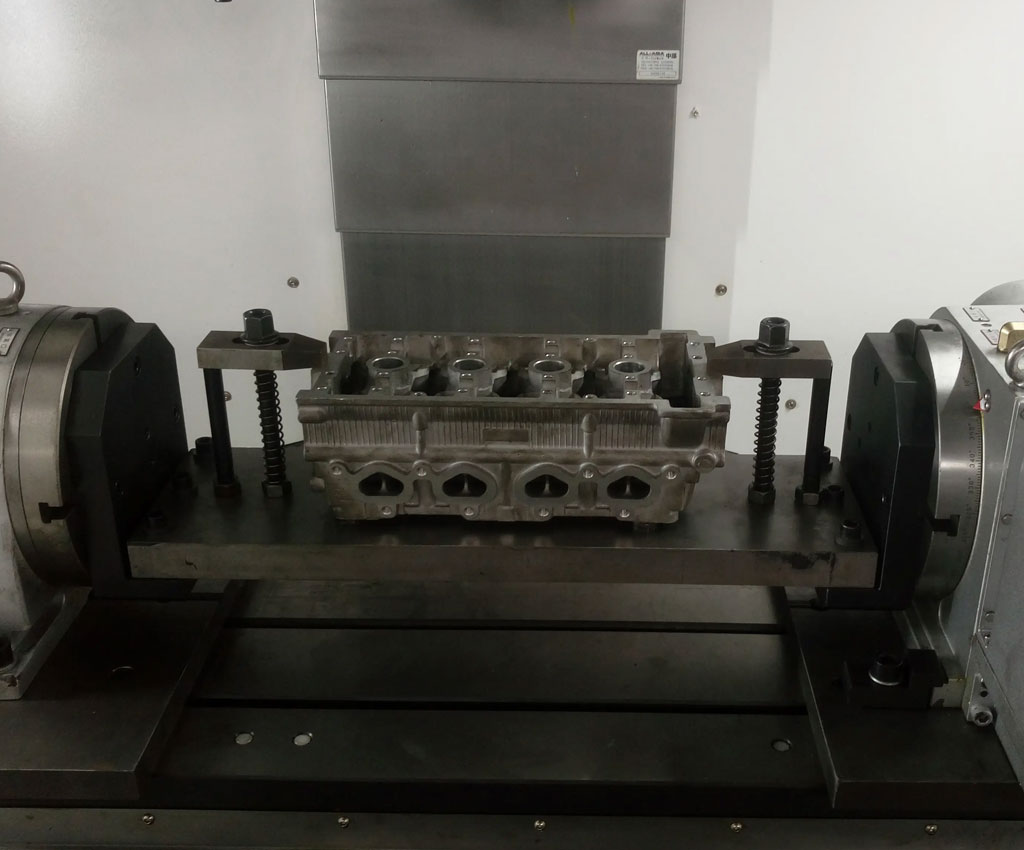

1.Automotive Engine Components

Precision CNC Machining (including CNC milling, CNC turning, EDM wire cutting and other processes) can be used to manufacture several important components of an automotive internal combustion engine.

For example, a large aluminium alloy block can be machined into an engine block (or cylinder block), a metal structure that includes the engine cylinder in which the moving piston moves up and down.

2.Precision Parts In Car Gearbox

The gearbox is a very critical transmission mechanism in a vehicle and it has a large number of gear and shaft parts. Nowadays, in high-quality automotive manufacturing, all gear and shaft workpieces in gearboxes can be manufactured directly by CNC machines. This is a significant advantage when machining high-precision machined parts such as gears. Today, they are often manufactured using gear shaping, gear shaving and gear hobbing processes. As a result, they offer high machining accuracy and high productivity. After shafts have been machined into stepped shafts, there are machining processes such as milling keyways and brushed splines, which greatly increase the precision of the fit. After the gearbox housing casting, the end faces and shaft holes must be milled on CNC machining centre machines, and the machining centre ensures spacing between the shafts.

CNC machines can manufacturing several other automotive parts including, but not limited to, suspension components, exhaust components, carburettor housings, fluid system components, bushings and valve seats. Manufacturing technology is also particularly useful for the customisation of vehicles and their specific automotive components, as CAD allows for rapid changes to part design and the manufacture of bespoke parts.

Cnc Machining Automotive Parts – Automotive Machining Specialist

Be-cu.com manufactures custom automotive parts for Vehicle Engine Structure, Engine Valve And Connecting Rod Crank, cars, motorcycles, Engine Fuel Supply System and more. Using processes such as 3 axis, 4 axis, 5 axis, cnc turning machine, we make parts for car applications. Capable of handling parts from 0.08 to 80 inches (2-500mm) length by 0.08 to 30 inches (2-500mm) wide and 0.08 to 20 inches (2-2000mm) inches diameter. Parts turning from 0.1 to 36 inches in length and 0.1 to 24 inches diameter. Tolerance ranges up to +/-0.0005 inches.

Also provides offshore contract manufacturing, automation, OEM/ODM, engineering, product development, prototyping, pilot production, quality assurance and supply chain management services. As an industry veteran, we’re trusted to make parts for innovators ranging from fortune 500 companies to hobbyists. All parts are expertly inspected and fall under our quality guarantee. See our full machining capabilites for more info.

Why Choose Our Automotive Machining Service?

- Save time and money for your automotive project but quality guaranteed.

- High productivity, outstanding efficiency and high accuracy

- A wide range of material grades and alloy materials can be machined

- Custom complex Automotive machined parts and components at specific tolerances

- High speed machining for prototyping and low to high volume production runs

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

Top China Automotive Cnc Machining Parts & Case Studies

With the continuous maturity and development of CNC Machining technology, more and more car manufacturers have introduced this technology for prototype testing, design proofing, parts customization and other applications. By exploring our success stories, you can learn about: the development of CNC Machining in the automotive industry, the application of CNC Machining in automotive molds, how CNC Machining changes the automotive manufacturing supply chain, and more.

-

Large CNC Turning Inconel 625 Automobile Engine Camshafts

-

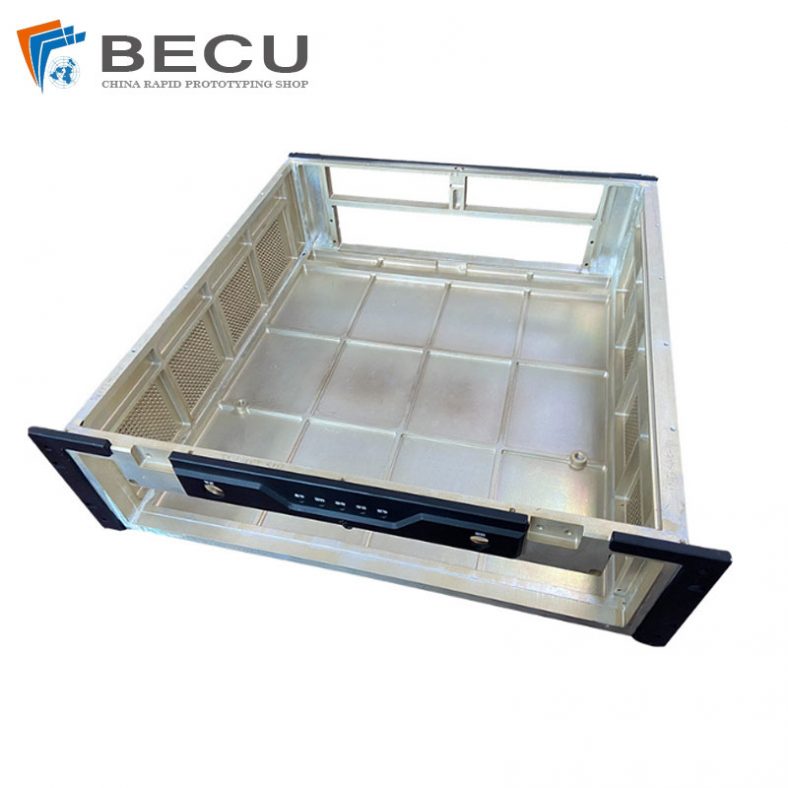

Precision Machining 6063 Aluminum Military Computer Server Chassis

-

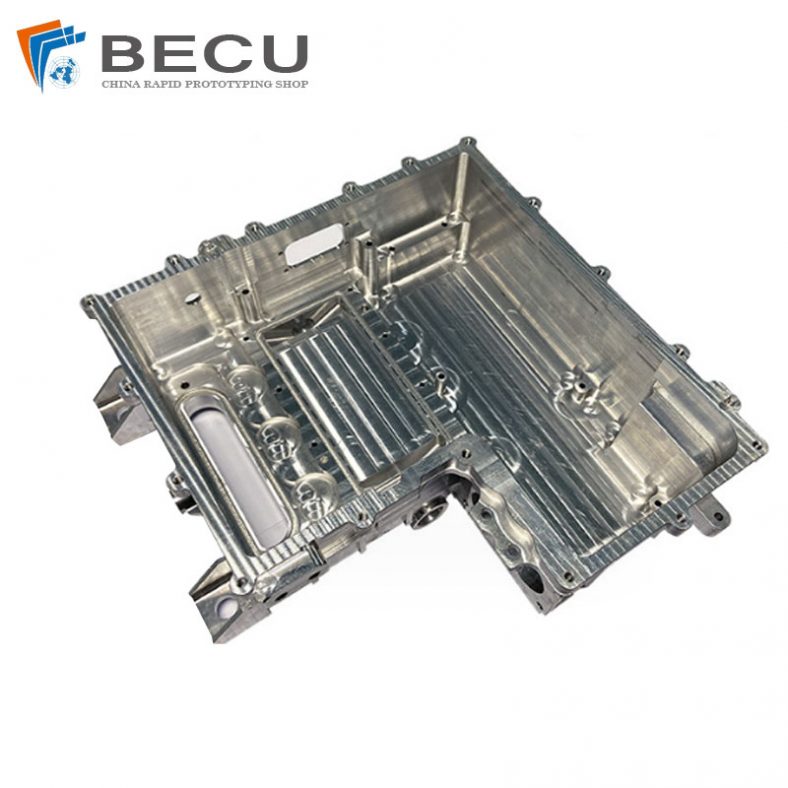

CNC 6063 Aluminum Automotive Motor End Cover

-

Sintering YG6 Tungsten Alloy Non-Slip Thread Screw

-

Precision Machining 6061-T1 Automobile Motor Prototype

-

New Energy Vehicle Air Conditioning Dynamic And Static Disk Components

-

3/4/5 Axis Precision Milling Custom Vehicle Parts

-

DMU Five-Axis Cnc Machining Aluminum Alloy Complex Structures Parts

-

5 Axis Milling Machining Car Tail Light Housing

-

5 Axis CNC Milling Aluminum Automotive Motor Enclosure

-

Lathe And Milling Machine CNC Machining Cup-shaped Aluminum Alloy Parts

-

CNC Machining Precision Aluminum Alloy Auto Parts