Plastic Parts

- Global delivery as fast as 30 days

- Machined prototypes in as fast as 9 days.

- Perfect Service And High Quality

- Tolerances down to +-0.005mm

- ISO 9001:2015, ITAF 16949

>>>All uploaded drawings are strictly confidential, check the confidentiality agreement

Custom Plastic Parts – Fabrication Plastic Parts Company

With the rapid development of the plastic industry and the continuous improvement of plastic performance, plastic parts have been more widely used. Plastic parts are replacing traditional metal parts in different fields. A properly designed plastic part can often replace multiple traditional metal parts. , so as to simplify the product structure and save the manufacturing cost.

Be-cu’s custom plastic parts prototyping and plastic cnc machining services offer a fast and cost-effective solution for your projects. a variety of we capabilities:

Services including cnc machining,plastic injection, 3d printing, cutting standard gauge plastic for both prototypes and low volume production runs. Our fabrication service produces durable, end-use plastic parts with a wide selection of materials and finishes that meet your specifications, for a variety of industries like: Automotive, Medical device, Aerospace, electronics, energy and robotics.Be-cu has machined, printed, and molded plastic parts for over 10 years. You can rapid instant a free quote or upload your own CAD file for a fast quote.

What Is Plastic Parts – Plastic Parts Define

Plastic is mainly composed of carbon, oxygen, hydrogen and nitrogen and other organic or inorganic elements. The finished product is solid, and it is a molten liquid during the manufacturing process. Therefore, it can be melted by machine heating, flowed by pressure, and cooled by cooling. Solidified to form various shapes, this large and varied material group is called plastic.Plastic Parts, refers to the name of the article after the structural change is finally fabrication by changing the plastic material with a suitable manufacturing process.

The Processing Properties Of Plastic

- Most of the plastic raw materials can be recycled, but since the plastic used for re-use (nozzle material) is more brittle than the general raw materials, it can only be mixed with new materials (raw materials) and used together. The maximum proportion should not exceed 25%, which should be based on customer requirements. The standard is the principle. Various types of plastic materials have different melting points and different injection pressures, so they must not be confused in production.

- Since plastic products need to be matched with color, plastic raw materials can be divided into: granulated material, toner material, color seed material, such as adding liquid to color the plastic raw material today. The granulated raw material has already mixed the pigment into the raw material , Each plastic material has been colored, so the color of the product is stable and uniform. Toner material and color seed material are mixed raw materials of color or toner, the cost is low, and there is no need to store a large amount of colored raw materials. However, the color is not stable, It is more difficult to control uniformity in production.

Custom Plastic Parts Applications – What is Custom Plastic Parts Used for

Because the fabrication allows a very high precision without altering the structure of the material with a good rate of manufacture, fabrication is becoming increasingly common as its machine range, control systems and cutting tools are just growing. Our fabrication service is used to produce a variety of custom-designed fabrication parts and products in all areas of the industry:

The Case Studies Of Custom Plastic Parts

You have a complex plastic parts design, Our fabrication service can help you turn it into a reality. With the right equipment, strong technical knowledge, and a focus on quality.. From tool design to finishing and then on to shipment, Be-cu prototpe ensure that every project is completed to a high standard and that your orders are delivered on time, every time.

-

3D Printing Pool Pressure Cleaner Parts and Accessories

-

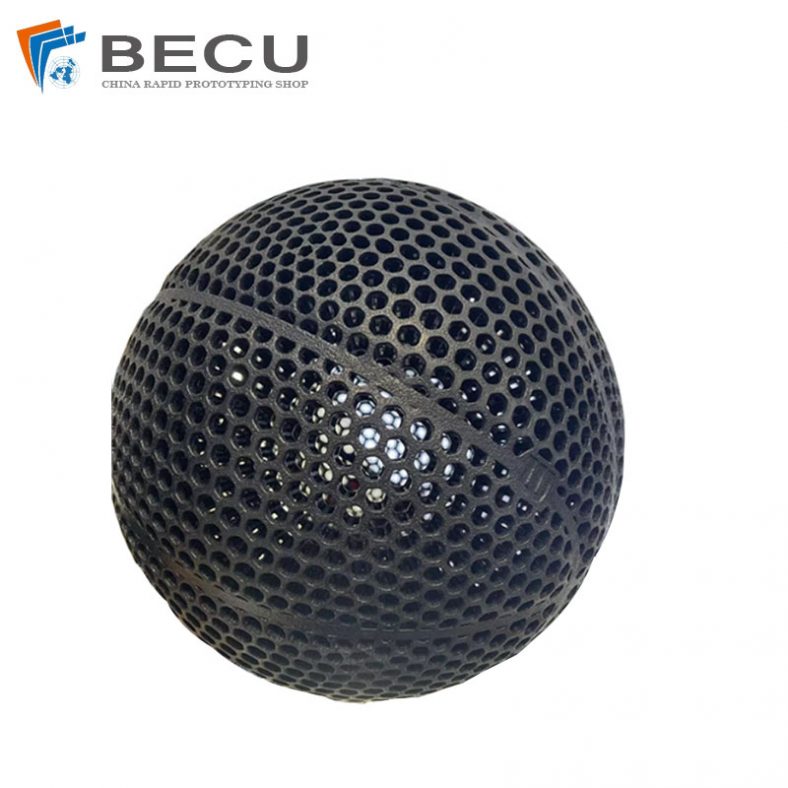

Nylon 3D Printed Size 5 Basketball

-

Black Nylon Medical Threaded Screw By MJF 3D Printing

-

MJF 3D Printing Black Nylon Red Dot Sighting For Medical

-

CNC Machining Anti-static Translucent PC Optical Parts

-

Precision Turning 20° Acrylic Downlight Reflector

-

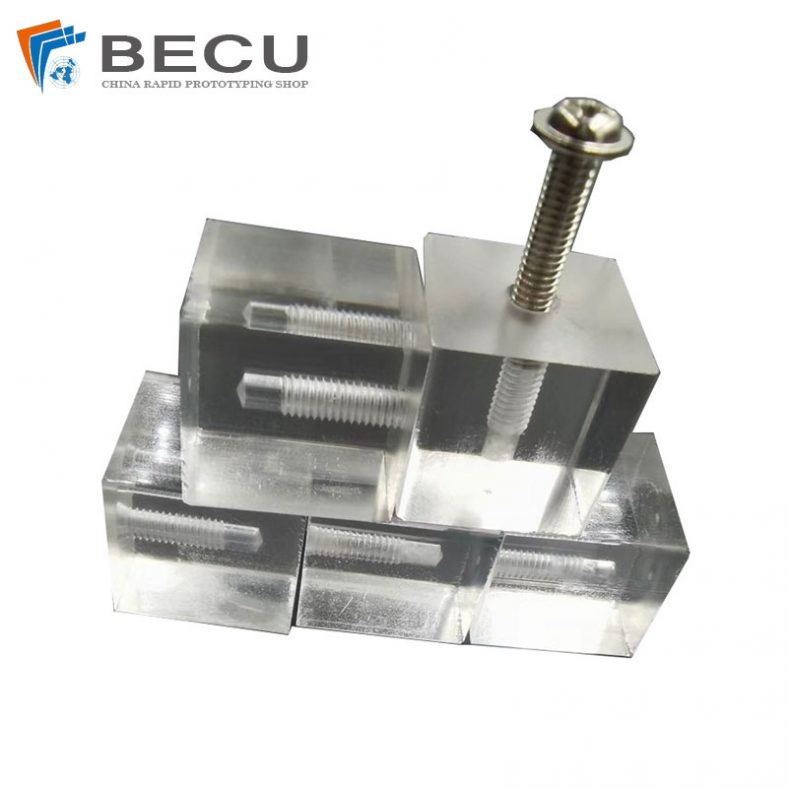

Transparent Acrylic Faceted Cube Threaded Clamp

-

CNC Turning Transparent PMMA Wear-Resistant Mechanical Parts

-

4 Axis Machining Highly Transparent Acrylic LED Tunnel Light Lens

-

Development Resin Samples For Sports Shoes