Online Custom Plastic Injection Service In China

What Is Plastic Injection Molding?The mass production plastic parts method in which the plastic is plasticized in the heating barrel of the injection molding machine, and then injected into the cavity of a closed mold by a plunger or a reciprocating screw to form a plastic product. This method can process products with complex shapes, precise dimensions or with inserts, and the production efficiency is high. Most thermoplastics and some thermosetting plastics (such as phenolic plastics) can be processed in this way. The material used for injection molding must have good fluidity in order to fill the mold cavity to obtain the product.

Plastic Injection Molding also has the highest variety of materials, colors, and configurations when compared to CNC machining or even 3D printing. Beyond materials, injection molded parts can have custom cosmetics, polishes, or surface textures.

Need mold making supplies for large quantities of production parts? Looking for a more cost effective and time efficient way of manufacturing parts? Don’t miss our injection molding services! At BE-CU.COM, we provide high quality and affordable injection molding for prototypes and production parts with quick turnaround times.

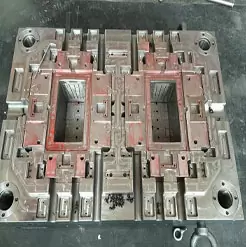

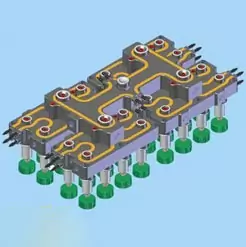

Be-cu build the molds for plastic injection molding, at the beginning of Plastic injection moldingthe mold design, we take the injection molding into consideration, it allow us to be able to achieve the shortest molding cycle time, minimum maintenance cost. Every second of cycle time and every piece of plastic raw materials we selected would eventually benefit our customers. Low volume production order are welcome as well, it always happened when customer feel the cost is unbearable especially the mold making cost. Be-cu is able to provide a full range of solutions to lower down your budget for low volume project with good quality. Our experts work with you together to find the best solution for your companies.

The Advantage Of BE-CU Plastic Injection Service

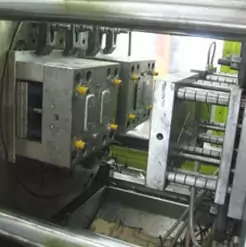

BE-CU has a number of large-scale cooperative injection molding suppliers, engaged in molds, injection molding, spraying, pad printing, thermal transfer, and has a wealth of production follow-up experience for various plastic products.The core cooperative injection molding supplier has twelve 50T-200T injection molding machines, all of which are equipped with manipulators, mold temperature controllers, automatic assembly lines, and dust-free purification workshops. There are 4 automatic production lines in the oil spraying department: one 10,000-level automatic spraying production line (two sprays and two baking), 1 production line (one spray and one baking); 1 manual spraying production line, with a daily output of 150,000 pieces above. With brand-new professional technology, with an environmentally friendly anti-static, fully air-conditioned, dust-free workshop, the working environment is superior, the production equipment is complete, and the product testing equipment is perfect. We can manufacture complete items or just components, regularly or one-time purchases, and offer a customized assemblage, stamping, and packing service when it is necessary.Our team members are skilled in their areas of design, mold building, and plastic molding; thus, no matter if you’re seeking a task to have complete plastic molding production or you require a prototype trial, we can cater to your entire demands.

Plastic Mold Markets We Serve:plastic mold/Computer/Business Equipment;/Injection mold machining/Medical Industrial/Packaging – Food/Beverage/Construction/Lawn & Garden / Machinery/Consumer Appliance/Electronics/Electrical/Agricultural/Household Utility Ware/PLA injection molding

The Advantage Of Plastic Injection Process

- Good dimensional accuracy.

- High productivity, easy to realize automatic operation.

- Excellent surface finish.

- Large volume production available.

- little need to finish parts after molding.

- Automation to save manufacturing costs.

- Excellent repeatability and flexibility.

- Injection molding produces low scrap rates relative to traditional manufacturing processes like CNC machining.

- Minimize the material waste.

The Materials Of Plastic Injection

- Polycarbonate

- Polyoxymetheylene (POM)

- Polystyrene (PS)

- Acrylonitrile Butadiene Styrene (ABS)

- Polypropylene (PP)

- Polyethylene (PE)

- Thermoplastic Polyurethane (TPU)

- Thermoplastic Rubber (TPR)

- Check Out BE-CU Material List

The Advantage Of China Plastic Injection Service

- plastic injection molding companies in China produce high-quality molds and injection molding parts like companies in the United States and Europe, but at substantially lower pricing, typically 30-60% lower than US mold makers.

- China injection molding is arguably among the very best in the plastic injection molding industry. Plastic injection molding companies in China have extensive experience in plastic injection molding and can provide you with extensive knowledge and experience in this area.

- plastic injection molding companies in China are capable of providing a wide range of injection molding. Besides making injection molds, China mold makers also provide a manufacturing service. Those China plastic injection molding companies could provide small-scale experimentation molds and high-volume mass production molds.

- China injection molding lead times are shorter. Normally, it takes 3-8 weeks, depending on the tool size and complexity. Mold manufacturers in China can ensure that their molds are processed 24 hours per day, seven days per week, through adequate worker arrangements.

- The main China injection molding market region is characterized by a complex supply chain system comprising raw material procurement, manufacturing, logistics, and distribution.

Our Outstanding Plastic Injection Molding Equipment

- 50T-200T injection molding machines

- 4#Automatic electrostatic dust removal room

- Powerful air purification system

- Mold temperature controllers

- Anti-static, dust-free, air-conditioned workshop

- Automatic assembly lines

- Oil spraying department

- Check Out BE-CU Equipment List

-

5 Axis CNC Machining Spiral Bevel Gear Mold

-

Small Precision Injection Molding Inserts

-

Plastic Storage Box Plastic Injection Mold

-

Injection Molding PE-UHMW Retaining Buckle And Ring

-

Cnc Machined UHMW-PE Bottle Turner

-

Shower Inclosure Sleeve By Plastic Injection

-

Injection Secret Security Machine Control Shell

-

Sewing Machine Industrial Control Shell By Plastic Injection

-

Upper And Lower Cover Of Seed Metering Machine