Precision Stamping For Electronic Industry

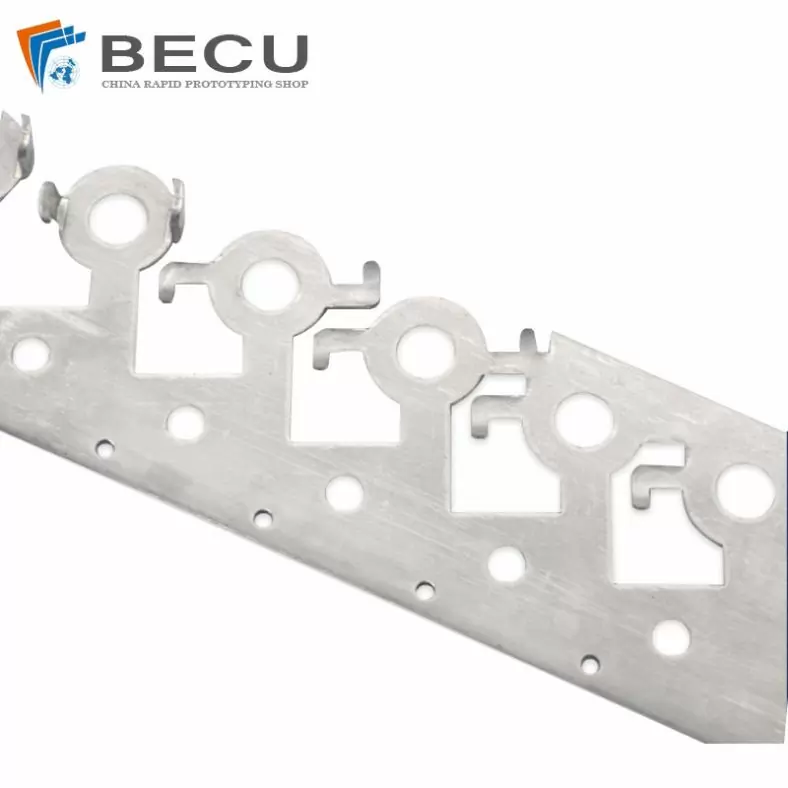

In the ever-evolving landscape of the electronic industry, the demand for smaller, more intricate components continues to rise. These components are the building blocks of modern devices, from smartphones to medical devices, and they rely heavily on precision manufacturing techniques. One such technique that plays a crucial role in producing these intricate parts is precision stamping. Precision stamping is a specialized manufacturing process that involves creating complex parts with high accuracy and consistency, making it an indispensable method within the electronic industry.

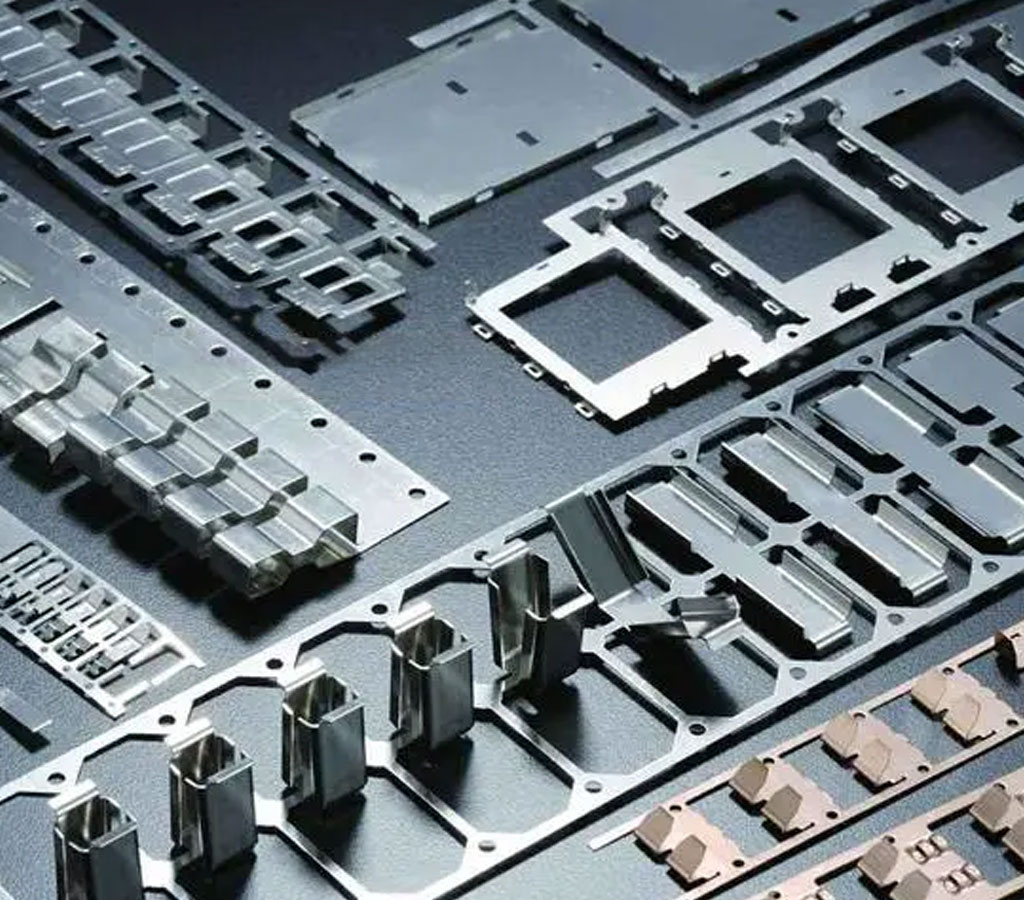

Precision stamping, often referred to as precision metal stamping or micro-stamping, is a manufacturing process that involves forming, cutting, and shaping metal sheets or coils to create intricate parts with tight tolerances. This process is used to produce components with complex geometries, such as connectors, terminals, springs, and other vital parts used in electronic devices. The goal of precision stamping is to create parts that are not only accurate and consistent but also cost-effective in large-scale production.

The Role of Precision Stamping in the Electronic Industry

The electronic industry thrives on innovation and miniaturization. As devices become smaller and more powerful, the components within them must follow suit. This is where precision stamping steps in. The ability to manufacture tiny components with high precision is essential to the performance, reliability, and overall functionality of electronic devices.Precision-stamped parts are used in a wide range of electronic applications:

Miniaturization and Complex Geometries

Example: Microconnectors

Microconnectors, such as those used in smartphones and wearable devices, require precise stamping to create the fine pins and sockets that establish electrical connections. These connectors are not only compact but also engineered to maintain reliable connectivity even with frequent use.

Consistency and Quality

Example: Battery Contacts

Battery contacts in electronic devices need to be manufactured with precision to guarantee a secure connection between the battery and the device. Inaccurate stamping could lead to intermittent connections, affecting the device’s performance and reliability.

Cost-Effectiveness in Mass Production

Example: Printed Circuit Board (PCB) Terminals

Precision-stamped PCB terminals, used to connect components on a circuit board, are produced en masse. Their consistent dimensions and straightforward design make them ideal candidates for cost-effective precision stamping.

Material Versatility

Example: Flexible Printed Electronics

Flexible electronics, used in applications like bendable displays and wearable sensors, rely on precision stamping to shape flexible substrates while maintaining the integrity of conductive paths. This highlights the versatility of precision stamping in handling diverse materials.

Customization and Specialization

Example: Medical Devices

Medical devices often require specialized connectors, terminals, and components that must adhere to stringent quality and performance standards. Precision stamping ensures that these components are manufactured with the required precision and consistency.

Advancements in Material Science

Example: Conductive Inks

Conductive inks, which enable printing of electronic circuits, are finding applications in smart packaging, sensors, and even electronic tattoos. Precision stamping techniques are being explored to pattern these inks onto substrates with the required precision.

Integration with Automation and Industry 4.0

Example: Smart Manufacturing

Smart manufacturing principles are being applied to precision stamping lines, where sensors collect data on parameters like stamping force, tool wear, and temperature. This data is analyzed to optimize production processes and minimize downtime.

Environmental Considerations

Example: Reduced Material Waste

Precision stamping’s high material utilization rate and minimal scrap generation contribute to a reduction in material waste compared to traditional machining methods.

In essence, precision stamping serves as the backbone of the electronic industry, providing the essential components that power our interconnected world. Its ability to create intricate, high-quality parts with consistency and efficiency ensures that electronic devices continue to evolve and improve, meeting the demands of a technology-driven society.

Electronic stamping is at the heart of China manufacturing. Be-cu.com fabricates parts for several Electronic companies across the China We take a lot of pride in working closely with Electronic product developers and buyers to get parts made fast and right the first time. Our team of dedicated Electronic stamping mechanics, mold operators and programmers get it, we understand that speed and price won’t make a difference if the mold and parts aren’t right. We are entrusted with the custom Electronic sheet metal parts of top global companies. Experience why they keep coming back to Be-Cu stamping company for their Electronic parts, request a quote today.

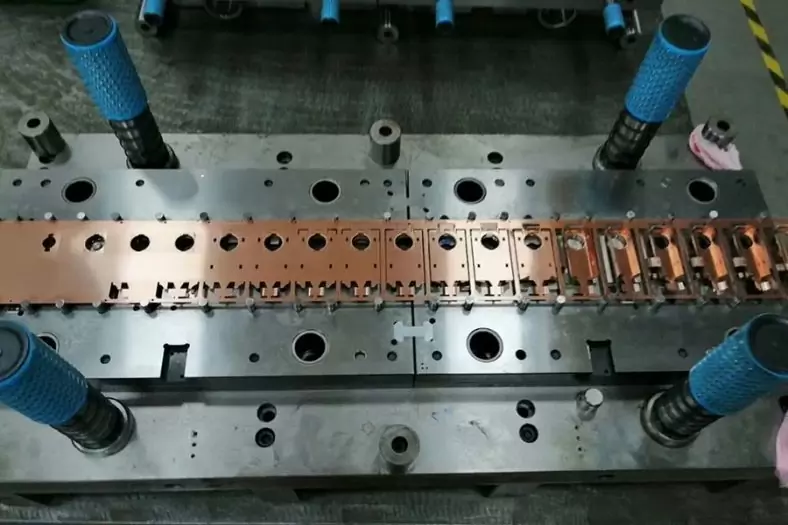

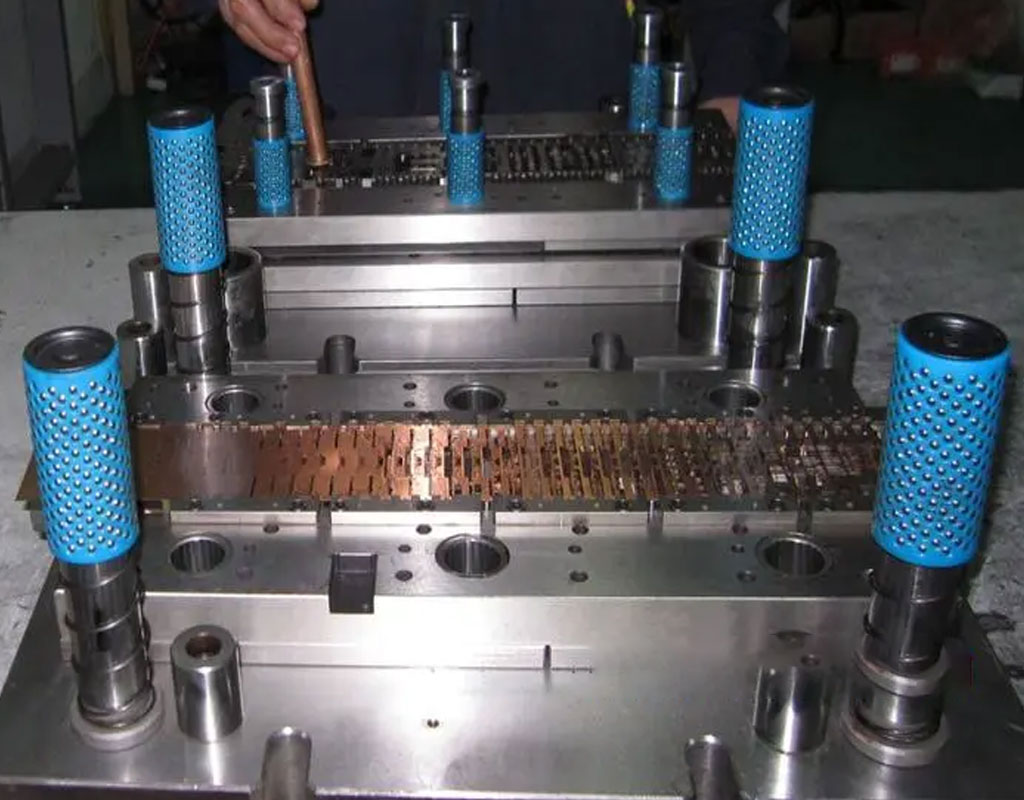

Tooling And Mold Making For Electronic

Tooling and mold making are symbiotic with the electronics industry, contributing significantly to its growth and innovation. These processes enable the production of intricate components integral to modern electronic devices. From the sleek casings of smartphones to the intricate circuitry of printed circuit boards (PCBs), tooling and mold making provide the foundation for cutting-edge technological advancements.

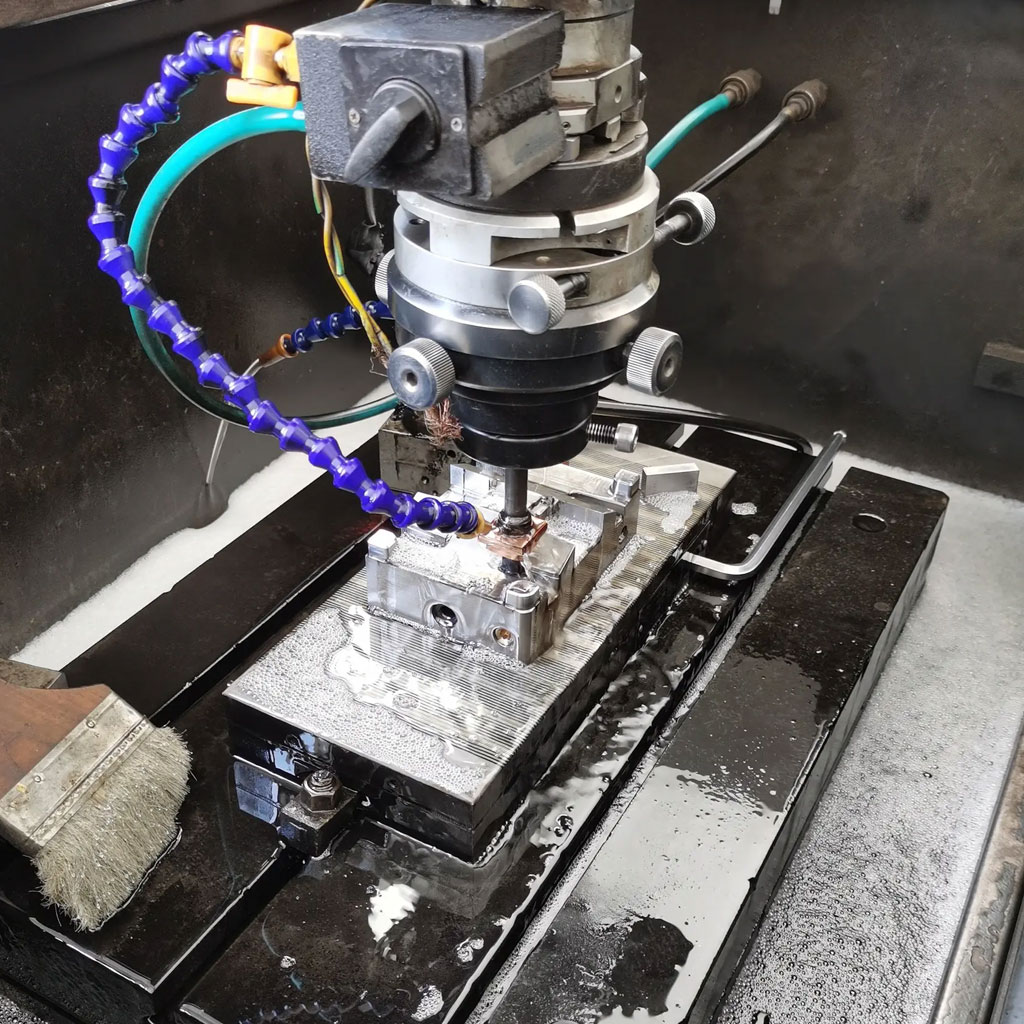

Tooling and mold making are critical steps in the journey from a design on paper to a finished electronic product in hand. These processes bridge the gap between creativity and manufacturability, enabling designers to translate their concepts into tangible, functional devices. Tooling refers to the creation of specialized tools, while mold making involves crafting molds that replicate the desired product’s shape and features. Together, they ensure consistent, precise, and efficient production, making them indispensable in the electronics manufacturing industry.

As technology evolves, so do the challenges in tooling and mold making for electronics. Miniaturization, complex geometries, and material innovations are pushing the boundaries of traditional manufacturing techniques. Innovations such as additive manufacturing (3D printing) are gradually finding their way into tooling and mold making, offering novel solutions to complex manufacturing challenges.

Tooling and mold making form the unsung heroes of the electronics manufacturing industry, allowing designers to realize their visions and consumers to interact with innovative devices. The precision, craftsmanship, and engineering that go into these processes ensure that the electronics we use daily meet the highest standards of quality and functionality. As technology marches forward, the collaboration between electronics and tooling will continue to shape our world, driving progress and innovation in ways we can only imagine.

Electronic Stamping Supplier – Precision Stamping For Electronic Parts

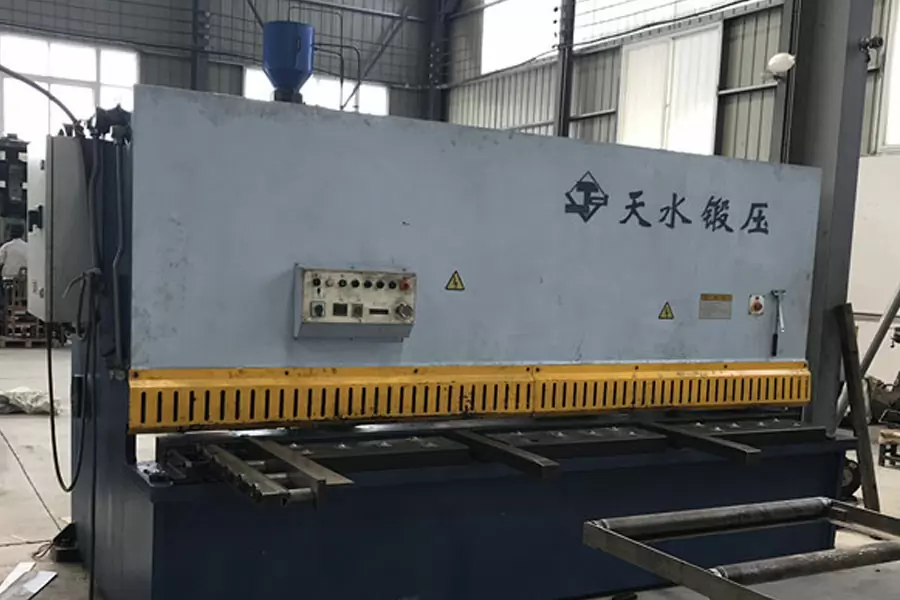

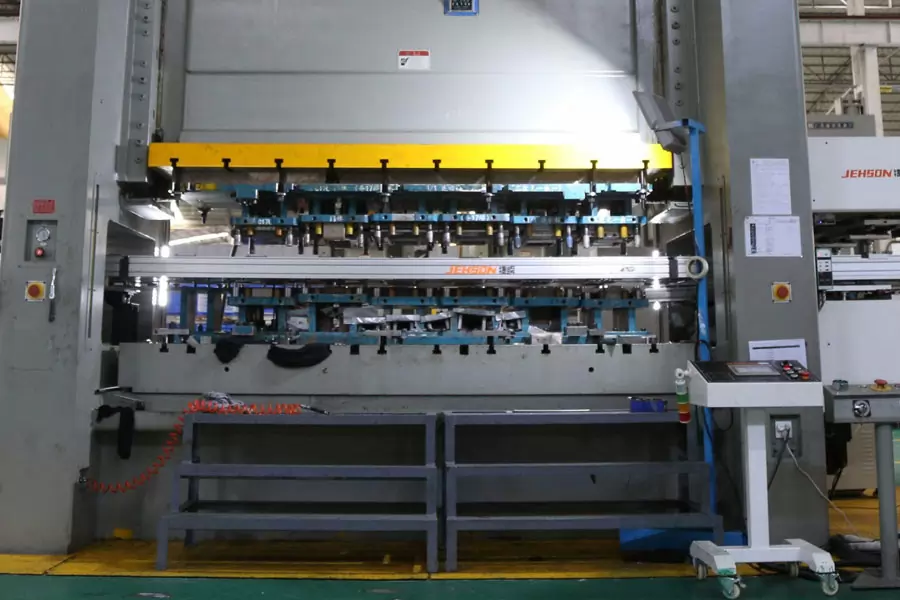

With over 20 years of experience, Be-Cu is a premier metal stamping company that specializes in deep drawn stamping, bending, punching, and forming. As an ISO 9001:2015 certified company, we offer expert full-service solutions, including design, prototyping, and tooling for low- to high-volume productions.

Our team can handle precision jobs large and small from our 44,000-square-foot facility, which is outfitted with 30 in-house, specialized presses. Using in-house engineering and tooling capabilities, we can design and create custom tooling for your project or work with your existing tooling.

At Be-Cu, we pride ourselves on being a trailblazing electronic stamping supplier that delivers precision, innovation, and reliability to businesses,We can produce custom component parts from a variety of metals, including: Aluminum, Brass, Stainless Steel, Beryllium Copper, Inconel, etc. With a steadfast commitment to excellence, we have emerged as a trusted partner for all your electronic stamping needs.

We are a forward-looking company specializing in the design, production, and distribution of cutting-edge electronic stamping solutions. Our team of seasoned experts combines decades of experience with a passion for technology, allowing us to stay at the forefront of this rapidly evolving industry. From concept to completion, we work closely with our clients to understand their unique requirements and provide tailor-made solutions that exceed expectations.Contact us today to learn more about our electronic components manufacturing solutions, or request a quote to explore our competitive pricing.

Why Choose BE-CU Stamping Mold Making Services

- High production capability and competitive prices for stamping service are offered.

- We have rich metal stamping manufacturing experiences for over 20 years and earned a good reputation.

- Multiple of stamping mold designs & types – 3D printed stamping mold & deep drawing mold (work in with CNC machining service) are available to meet custom needs.

- Do precision metal stamping parts manufacturing according to your drawings or samples.

- 700T Mechanical Press | Press bolster size: 35001500mm | Shut Height: 900mm | Coil feeder size: W600mmT4mm.

- Finish the parts with service of mold making in time to provide the strongest support for your R&D projects.

- Our automated quoting, design analysis, and manufacturing process allows us to ship stamping orders in as fast as 1 day.

- CMM machine | Brand: CAISI | Table Size: 1000800600mm | Software:PC-DMIS | Hardnessss machine | Spec.: 20-70HRC

- Accurate CAE analysis helps to improve parts quality and optimize tooling process. Concurrent engineering, product design review, and early involvement can help shorten the project lead-time.

- We have the most experienced engineers and tooling partners that will really make a difference in your lead times, costs and final quality.

- Be-cu has 8 designers with engineering capability for simulation, strip layout and die design. Our engineers and tools experts help prior to the development with technical advice in order to minimize problems during the subsequent production process.Can make up for your one-stop needs for plastic proofing and mass production

Electronic Stamping Operations

- Blanking

- Bending

- Punching

- Coining

- Drawing

- Embossing

- Piercing

- Curling

Our team of assemblers specialize in mechanical and electrical assembly of components. We are experienced with a large variety of assembly from simple one or two part additions to complete complex cabinets and assemblies.

Electronic Stamping Material

- Steel

- Stainless Steel

- Aluminum

- Copper

- Brass

- Nickel

- Galvanized

Our Outstanding Electronic Stamping Equipment

- Connecting Rod Metal Stamping Machine

- Electronic Cold Stamping Machine

- 3D Automatic Stamping Equipment

- 40-700T Metal Stamping Machine

- EDM Wire Cuuter

- Explorer CMM, Stroke 1200*1000*800

- Caisi CMM, Stroke 1000*800*600

- Cnc Machining Center

- Check Out BE-CU Equipment List

Top Electronic Stamping Parts And Case Studies

You have a complex electronic part design, Be-cu.com can help you turn it into a reality. With the right equipment, strong technical knowledge, and a focus on quality.. From tool design to finishing and then on to shipment, Be-cu ensure that every project is completed to a high standard and that your orders are delivered on time, every time.

-

Precision Metal Stamping Bank Unattended Terminal Circulation Module Housing

-

Aluminum Blanks Via Precision Stamping

-

Precision Stamping Services For Stainless Assembling Blanks

-

Multi-Station Stainless Steel Stamping Galvanized Sheet

-

Precision Stamping Self-Service Cash Withdrawal All-In-One Device Core Module

-

Metal Stamping 5G Communication Base Station Cabinet Control Module

-

Aluminum Deep Drawing Medical LED Display Enclosure