Why Choose Small Batch CNC Machining For Your Projects?

With the development of industrial design, product updates and iterations, and the increasing demand for personalized customization, many industries will consider giving up high mold costs and long mold opening and mold modification time, and choose CNC small batch rapid prototyping.Small batch Production, especially for hardware product manufacturing, the product accuracy and surface treatment effect of CNC Machining will be higher than that of mass production(via metal molding and mold manufacturing), and the aging time is much faster than opening mold. Small batch trial production, saving mold and time cost for customers.

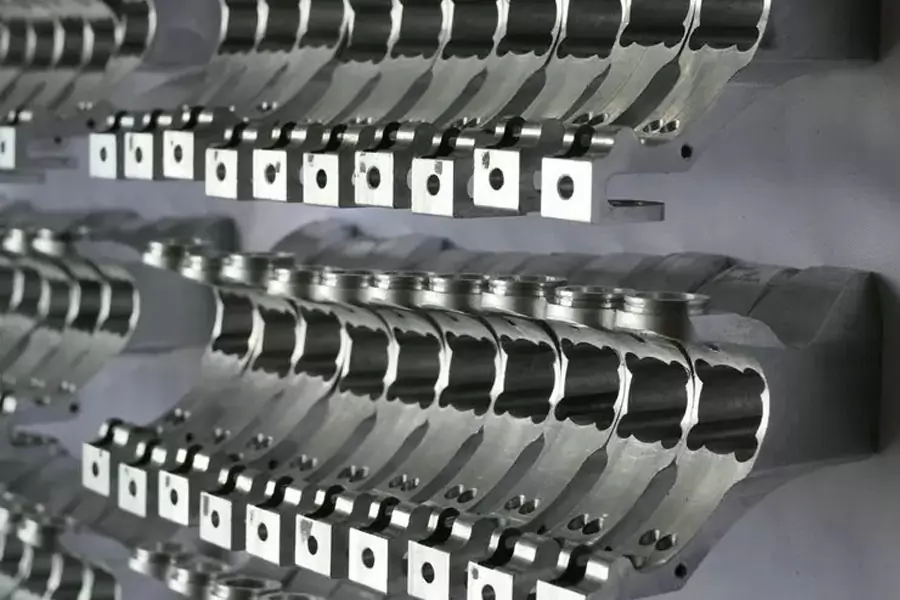

1-500 PCS Small Batch CNC Machining Services In China

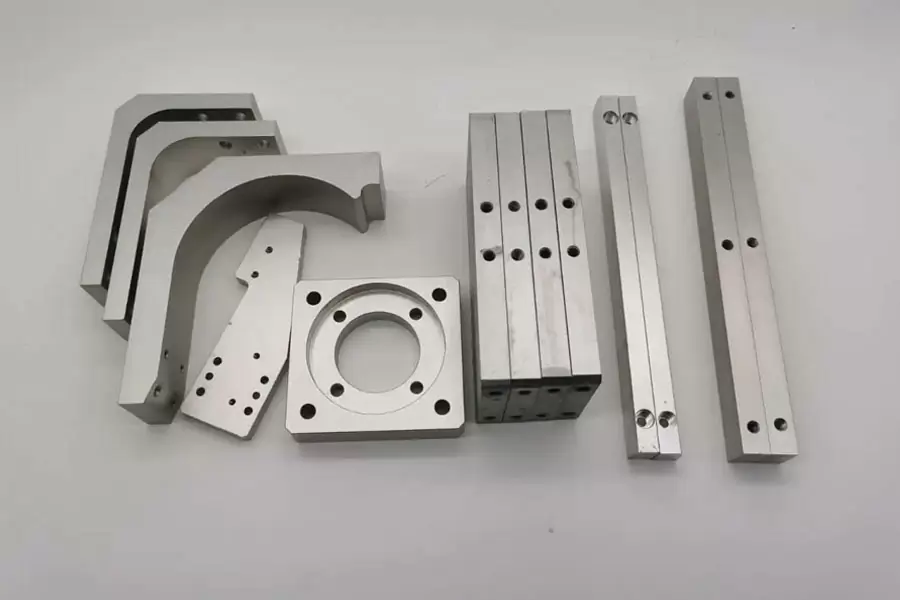

Looking for reliable, quick-turn 1-500 PCS Small Batch CNC Machining services suppliers and precision batch machining product manufacturers? Small batch normally asked for the quantity from 1 to 500pcs. At Be-cu.com, no matter the lot size you want to order, we can get it done for you. Even better, our production engineers will help you create a custom, cost-effective manufacturing solution.

Be-cu.com has 30 sets of professional small batch CNC equipment, 16 of which are equipped with automatic tool changer, 3 sets of 5-axis CNC, and equipped with turning, milling, grinding, EDM and other equipment and processes, whether it is hardware or plastic For small batch production of CNC materials, Be-cu.com can provide customers with products that combine multiple processes such as processing, surface treatment, and trial assembly.

Due to the wide variety of hardware materials, Be-cu.com commonly used hardware materials in small batch processing:

Aluminum alloy, magnesium alloy, zinc alloy, titanium alloy, stainless steel (martensite, austenite, duplex stainless steel), Copper alloys, low carbon steels, nickel alloys, and even tungsten steels with the same hardness as CNC tools, as well as different names of material grades in different countries, are equipped with a direct-reading spectrum analyzer to ensure the authenticity of the raw materials used.

The analyzer stimulates a variety of alloy materials, collects full spectrum information, and analyzes the content of each element in the alloy material, thereby determining the grade of the alloy material, ensuring the authenticity and physical property requirements of the raw materials, and strictly controlling the quality from the source!

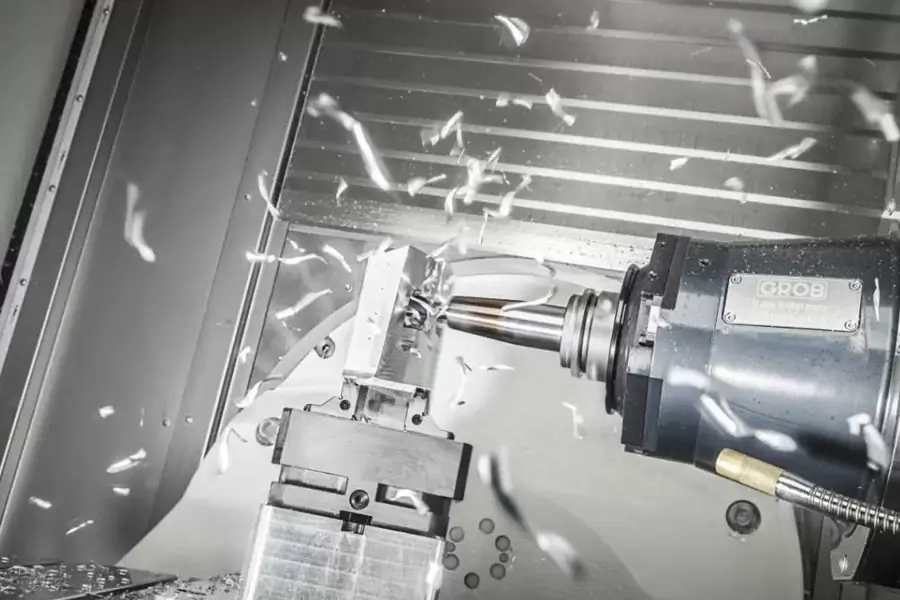

In addition to CNC precision machining, we will combine other machining processes to achieve the machining accuracy of the product according to the product structure and accuracy requirements.

For example: fine grinding, fine turning, fine milling, boring, reaming, etc., the machining accuracy is 10-0.1um, and the surface roughness Ra value is 0.3-0.8um. In addition, for the positions that cannot be machined by CNC machining, the use of electric Spark (discharge) machining, so that the product can meet the customer’s drawing requirements.

- Medical research equipment, medical equipment;

- Scientific research units, research institutions;

- Automobiles, motorcycles, bicycles;

- Industrial robots;

- Electronic appliances, lighting;

- More

In addition to CNC technology, Be-cu also has rich experience in surface treatment. The existing surface treatment processes include: painting, baking paint, powder spraying, sand blasting, shot blasting, anodizing, thick film oxidation, micro-arc oxidation, electroplating , electrophoresis, laser engraving, silk screen printing, wire drawing, mirror polishing, dyeing, blackening, CD pattern, etching, highlighting, etching pattern, glue, etc., to add the icing on the cake for your products.

From pre-quote process analysis-pre-processing process plan formulation–communication during cnc machining–after-sales problem feedback, Be-cu.com will allocate a corresponding team for each order, plan the process in advance, and send orders regularly every day Progress, handle customer’s process technical consultation and after-sales service within 1 hour, and let customers rest assured!Over the years, Be-cu.com has become a small batch CNC machining vendor for several big and small industry brands. Up to now, we have handled more than 10000 CNC machined projects with small-batch quantities.As a prototyping and low volume manufacturing expert, Be-cu.com can offer a top-notch precision small batch CNC machining service for just this purpose. If you have such requirements, we will be your best choice. Contact us by today!

Why Choose Our Small Batch CNC Machining Service?

- Save time and money for your cnc project but quality guaranteed.

- High productivity, outstanding efficiency and high accuracy

- A wide range of material grades and alloy materials can be machined

- Custom complex cnc machined parts and components at specific tolerances

- High speed cnc machining for prototyping and low to high volume production runs

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

Small Batch Parts Quality inspection

- The Swiss Dantsin multi-function altimeter can measure the height, thickness, diameter, center distance, position and other data of the product;

- For heat-treated products, our quality department will use a hardness tester to test to ensure the heat-treated hardness and performance of the products;

- Needle gauge from 0.5-20mm, thread plug gauge from M1-M20, micrometer from 0-200, is the standard configuration of the new precision production department and quality department;

- Two-dimensional image measuring instrument can measure multiple geometric dimensions on the plane, including diameter, radius, length, angle, width, height, depth, point-to-point distance, point-to-line distance, center-to-center distance, etc.

- The automatic three-coordinate detector adopts Leitz LSP detection technology, which has the performance of measurement accuracy, scanning efficiency and good repeatability. Equipped with one of the most complete software available today: QUINDOS, programmed by the engineer, can measure workpieces with multi-surface geometries.

- Be-cu strictly implements the ISO9001:2015 quality system standard. Every process and every process is based on quality, which will help you worry and let you rest assured!

Top Small Batch CNC Machining Case Studies

At Be-cu.com, we provide Small Batch CNC Machining services for a vast range of industries. These industries may include niche sectors that require high accuracy, specialist, quality parts without sacrificing quality. Based on our experience and decades of professionalism, we can carry out Small Batch Machining projects in-house. This is done by taking them through the initial consultation to the machining as well as inspection of the final products.

If you are looking for a supplier of Small Batch CNC Machining parts, no match it is prototyping or high precision order, we can make for you. Talk to us by today.

-

5 Axis Cnc Machining Titanium Motorcycle Frame

-

Custom Stainless Steel Marine Deck Screws

-

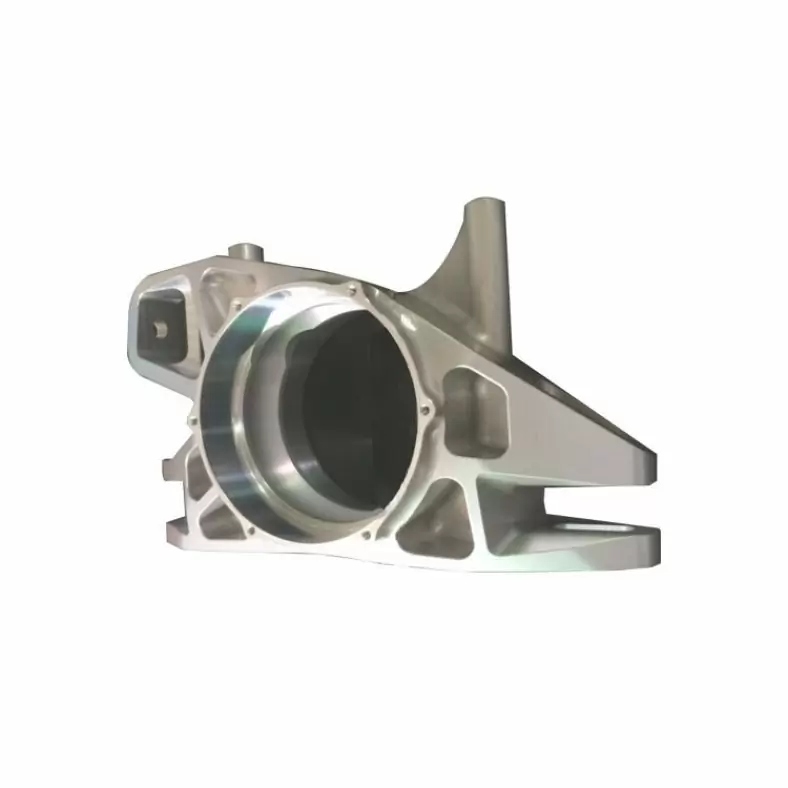

Aluminum Alloy Automotive Signal Shield Shielding Cavity

-

CNC Machining Military-grade Electronic Housing

-

Custom Smart Audio Shell Parts And Base

-

Metal Control Panel Electronic Enclosure

-

Metal Control Panel Electronic Base

-

6061-T Fingerprint Solid State Hard Drive Housing

-

6061-T Industrial Control Notebook Housing

-

Aluminum 6061-3T Ultralight Bicycle Handlebar

-

Aluminum 6061-T Optoelectronic Communication Product Housing

-

Aluminum 6061-T Power Consumption Instrument Bottom Cover And Housing