Custom Cnc Machining – China Cnc Machining Services Online

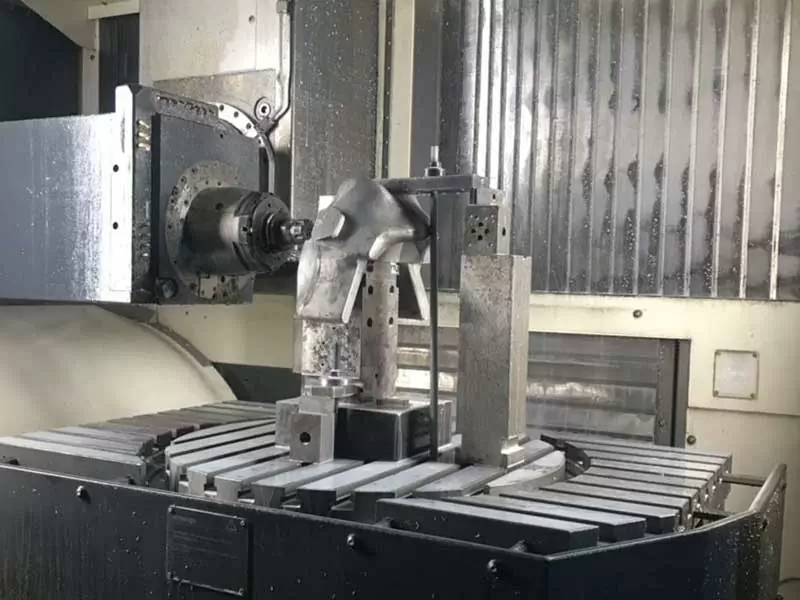

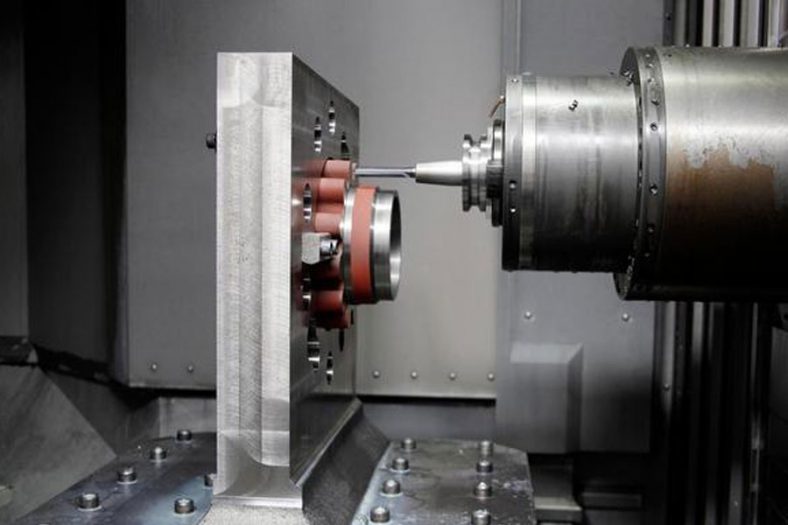

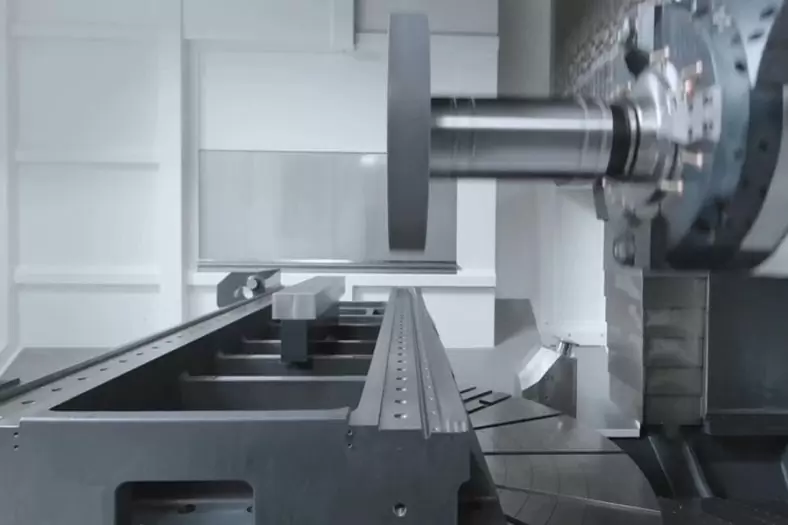

BE-CU Prototype 5 Axis CNC machining operation allows us to facilitate short lead times and competitive pricing on precision prototypes CNC machining and masters, and also for short-run needs, high request, and presentation models. We operate the latest software and machines manufactured by MAZAK And DMU, including part beds up to 84″ x 30, which includes processing continuous, smooth, and complex curved parts. Complex feature and contoured surface programming is handled with the latest version of Mastercam, a package that programs quickly and runs NC check to verify each setup and cutter path is accurate.

We manufacture high-quality CNC milled parts/CNC turned parts/Swiss Machining parts in China as well as other spare parts in China according to your drawings in prototype size or small series. Send your CAD files or inquiry to us, a fast, free online CNC quote of required CNC components will be back. Get your CNC Machining Parts into processing in the shortest time.

Many of our custom cnc machined parts are annealed for maximum strength and durability. This ensures you receive the quality part your company deserves.Nothing leaves our facility with sharp or non-machined edges. This is a standard process for us that allows our clients to receive a nice, clean, ready-to-use custom machined parts.We also offer engineering, drafting, welding, annealing, polishing, molded part alterations and more, always for all of your custom metal or plastic prototype manufacturing needs.Let be-cu.com(Top China Cnc Machining Manufacturer) be the non-standard parts solution to your selection, design, prototype, or production needs!

CNC Metal Machining Services

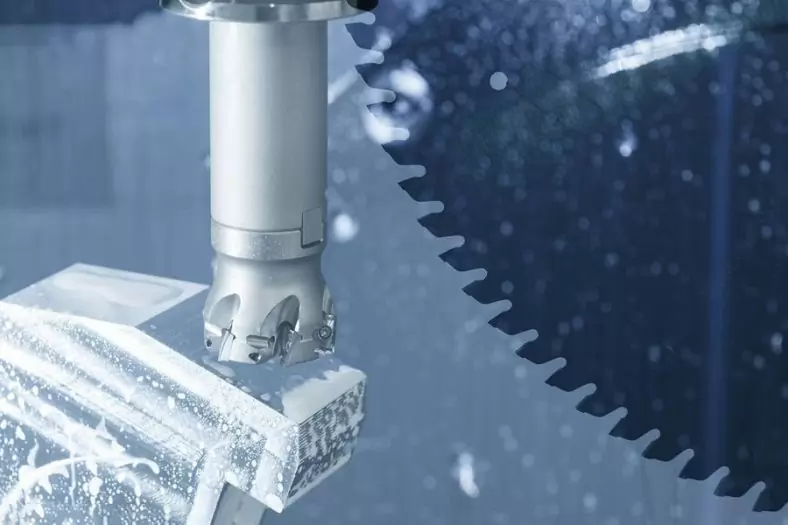

Be-cu has strong metal CNC Machining capabilities and rich experience, and provides customized solutions, you can freely choose hundreds of different metals and alloys to fit your needs, whether your machining needs are simple or complex, whether the quantity is low volume or mass.With our various of advantaged CNC machine and lathes, we can handle all of your specific metal CNC machining needs, and ensure you will get the highest quality part at a short lead time.

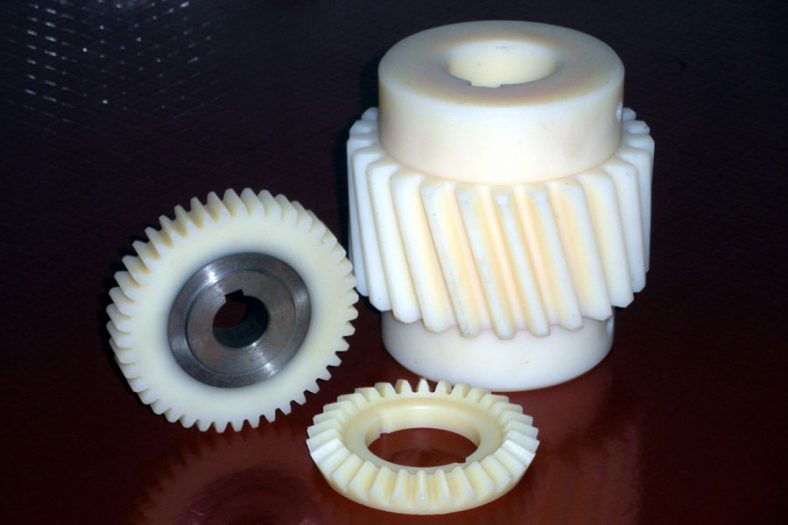

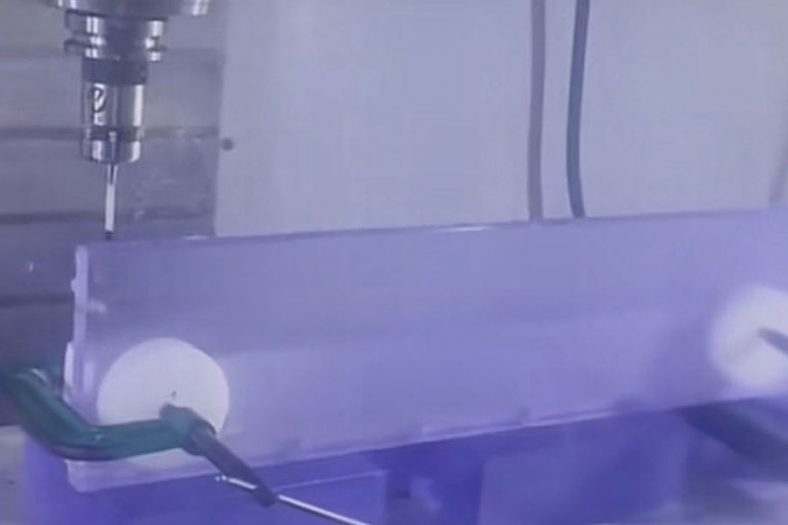

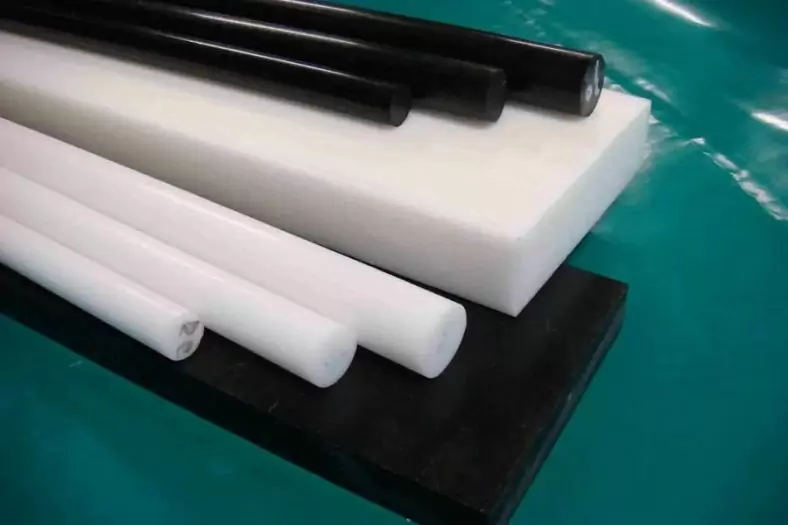

CNC Plastic Machining Services

Be-cu.com offers a state-of-the-art CNC plastic machining service, guaranteeing consistent quality and fast turnaround times. With over 75 plastic milling and plastic turning machines at our disposal via our in-housing networks, we can provide consistent capacity and competitive pricing.With us you can produce complex orders for prototypes as well as low volume CNC production runs in a wide variety of plastics and surface finish options.

CNC Machining Tolerances

Our standard tolerance for metal is DIN-2768-1-f and plastic is DIN-2768-1-m in CNC machining. We can also achieve special tolerances as long as you indicate your requirements on your drawing. For the specific tolerance details of different parts, please contact us.

| Type | Tolerance |

|---|---|

| Linear dimension | +/- 0.025 mm +/- 0.001 inch |

| Hole diameters (not reamed) | +/- 0.025 mm +/- 0.001 inch |

| Shaft diameters | +/- 0.025 mm +/- 0.001 inch |

| Part size limit | 4000×1500×600 mm 157 * 60 * 24 inch |

CNC Machining Industries | What Industries Use CNC Machining Service?

During the past 30 years, we have provided various of metal or plastic components to the customers all over the world.At Be-Cu.com, we have the experience and equipment to accurately machine high-tolerance parts and components for manufacturers in any industry, including Aerospace, Automotive, Elevator, Optic,Electronic, Medical, and needed Jewelry CNC Machining companies. As an ISO 9001 certified and ITAR registered company, Be-Cu is experienced in meeting high standards and special requirements while providing fast production, quality and cost reductions.

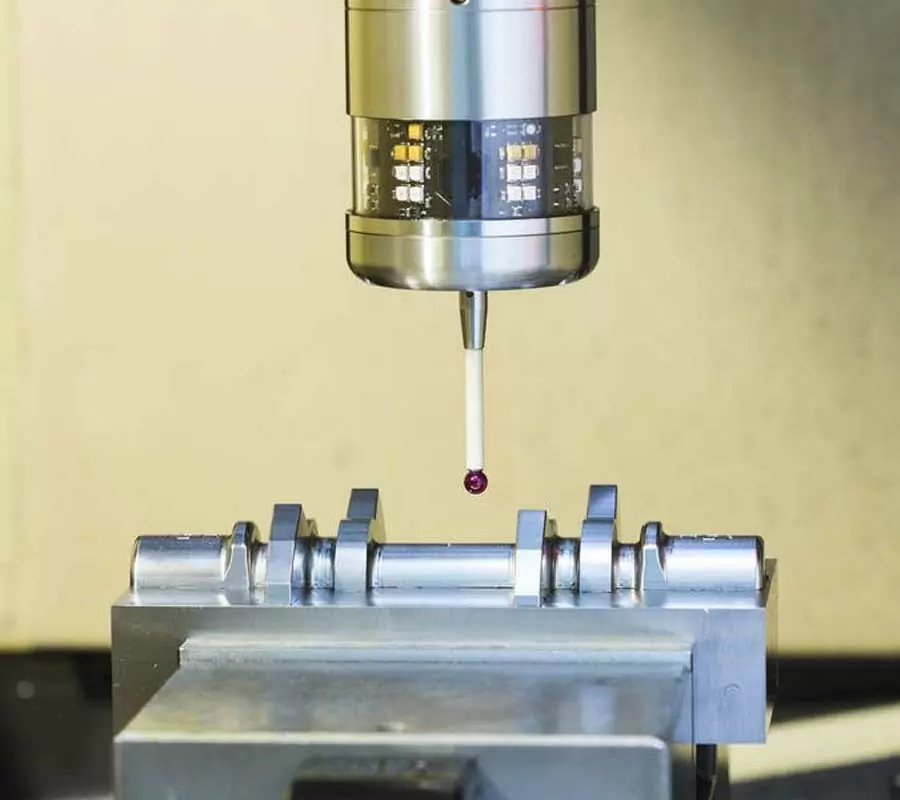

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Average 7 days turnaround time and 99.85% on time delivery

- Multiple options of machining materials to meet specific properties.

- Skilled in KanBan and other customer driven quality and inventory management systems

- ITAF 16949 certified

Prototype CNC Machining Materials

| Aluminum | 2024, 5083, 6061, 6063, 7050, 7075, etc. |

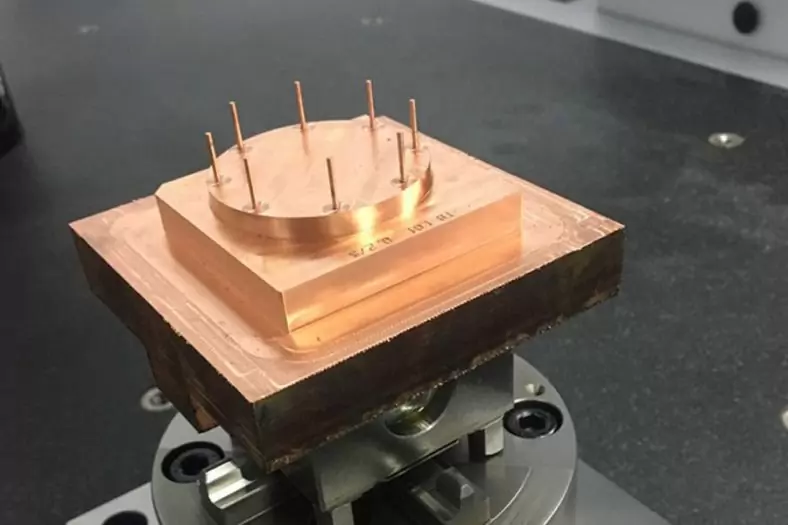

| Copper Alloy | brass 360, 101 copper, 110 copper, 932 bronze, zinc, etc. |

| Titanium Alloy | grade 2, grade 5, etc. |

| Stainless Steel | 303, 304, 410, 17-4, 2205 Duplex, 440C, 420, 316, 904L, etc. |

| Superalloy | Kovar,Hastelloy,Inconel,monel,etc |

| Zinc Alloy | 3#,6#,9# etc., |

| Engineering Plastic | POM (Delrin), ABS (Acrylonitrile Butadiene Styrene), HDPE, Nylon, PLA, PC (Polycarbonate), PEEK (Polyether Ether Ketone), PMMA (Polymethyl Methacrylate or Acrylic), PP (Polypropylene), PTFE (Polytetrafluoroethylene), etc. |

| Other | Other CNC machining materials: Graphite, VeroClear |

We accept both small and large run jobs, Minimum quantity for order is 1.

Short lead times are often available 2-7 days.

Standard lead time is 2 weeks.

Based on our many years of material know-how and numerous innovative manufacturing methods, we can realize your rapid prototyping project in China in a timely and cost-effective manner.

Our skillful engineers will find the optimal solution for your individual needs and will gladly advise you in the selection of the suitable manufacturing method.

-

Cnc Machining Aluminum

-

Cnc Machining Brass

-

Cnc Machining Cast Iron

-

Cnc Machining Copper

-

Cnc Machining Hastelloy

-

Cnc Machining Inconel

-

Cnc Machining Invar

-

Cnc Machining Kovar

-

Cnc Machining Magnesium

-

Cnc Machining Monel

-

Cnc Machining Stainless Steel

-

Cnc Machining Steel

-

Cnc Machining Tantalum

-

Cnc Machining Titanium

-

Cnc Machining Tungsten

-

Cnc Machining Zinc

Top CNC Machining Services Capabilities

-

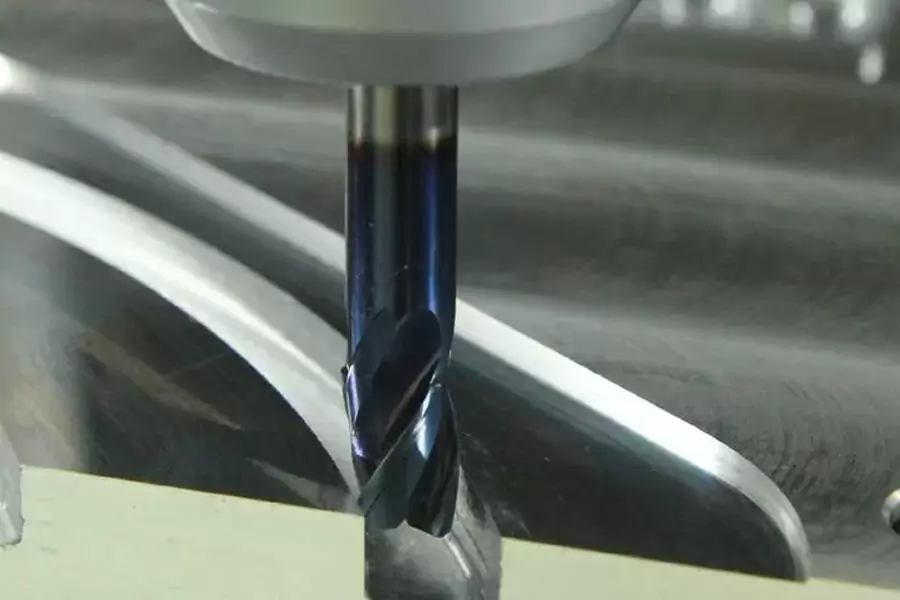

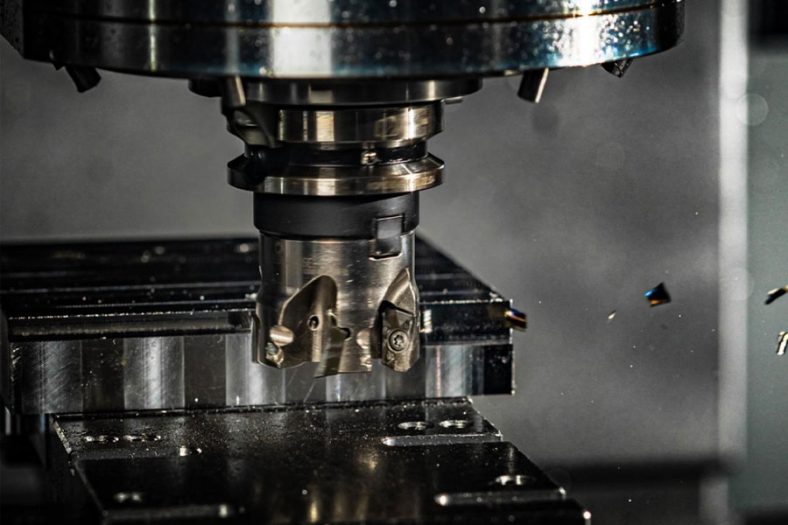

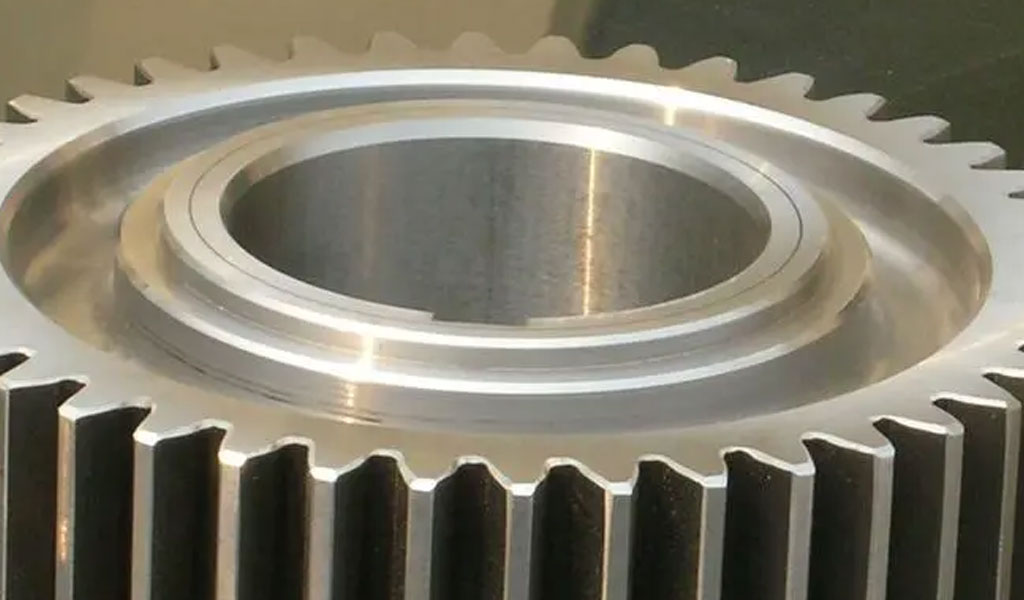

Cnc Milling

3-4-5 Axis up to Ø 300

-

Cnc Turning

3 mm-450 mm in diameter

-

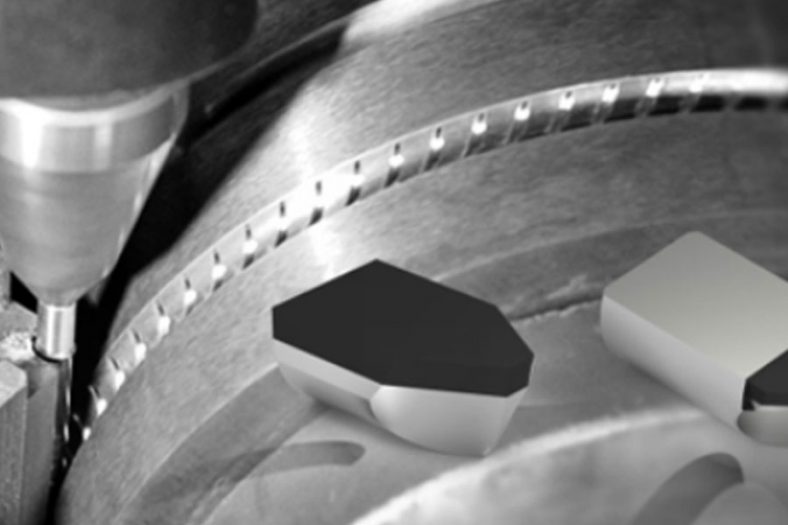

5 Axis Machining

Mazak/DMG 5 Axis

-

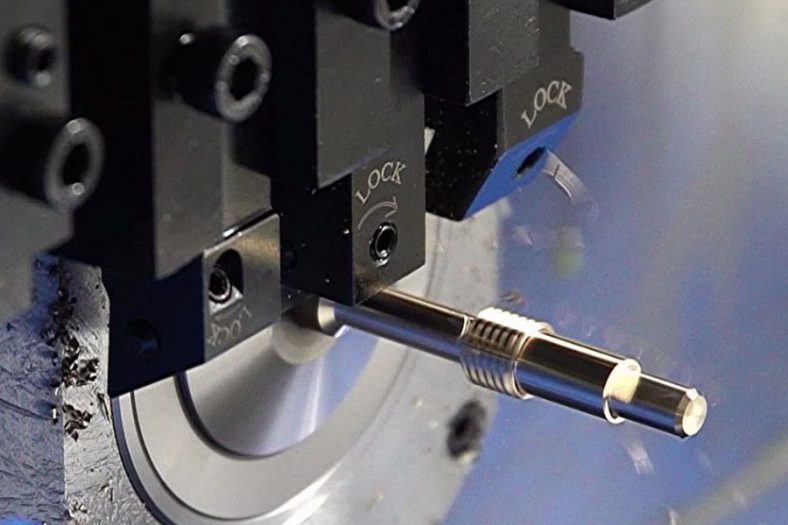

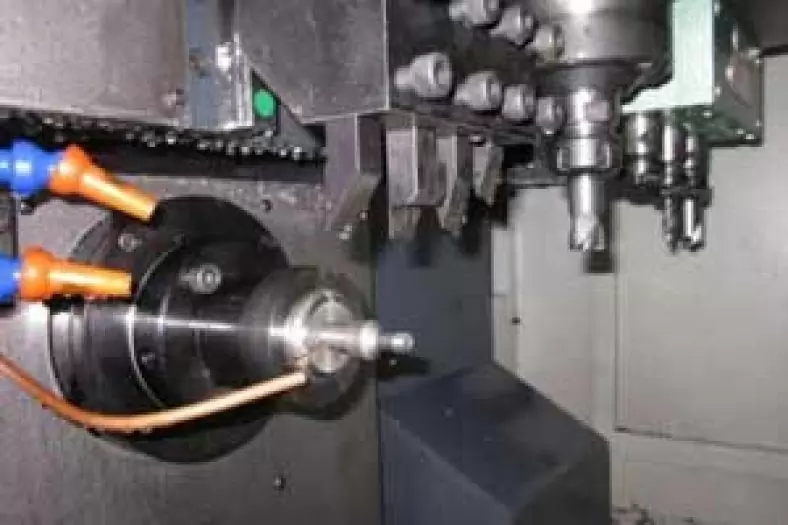

Swiss Machining

12-Axis Swiss CNC

-

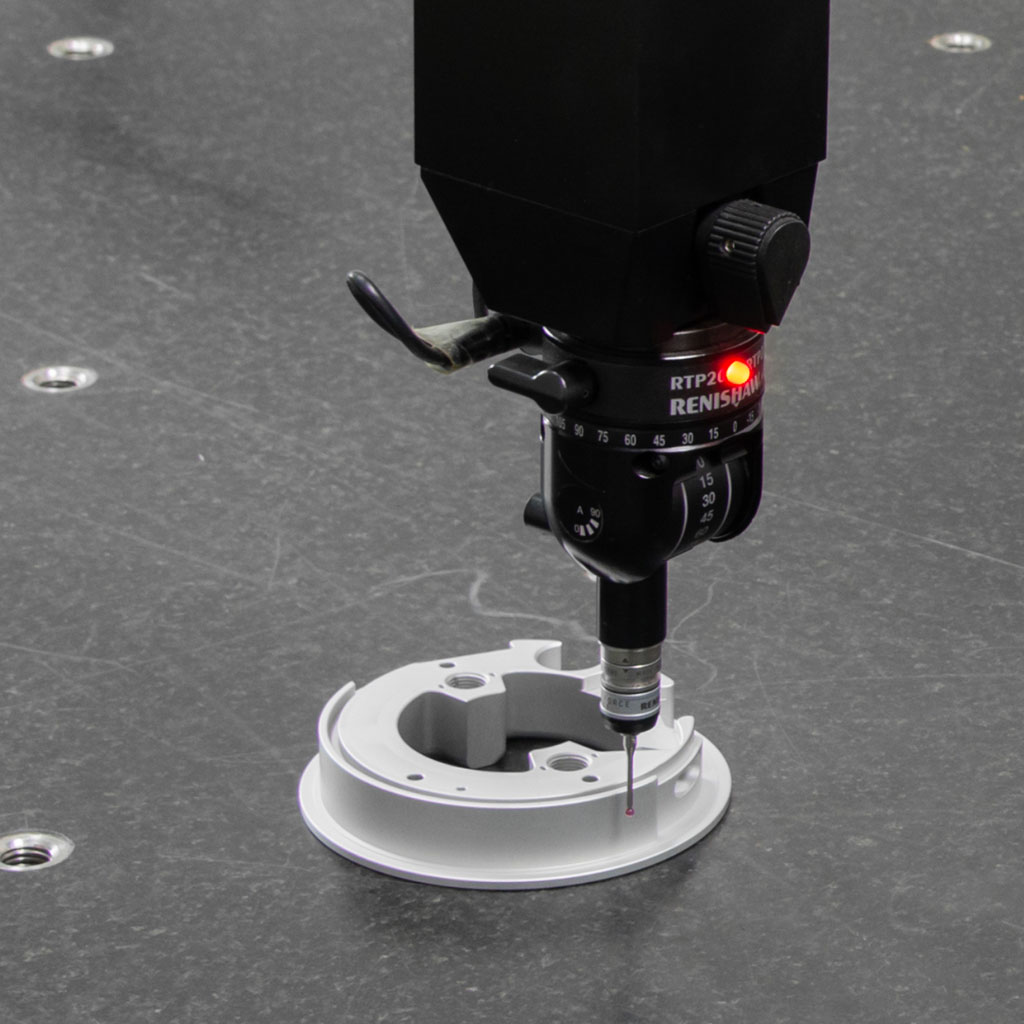

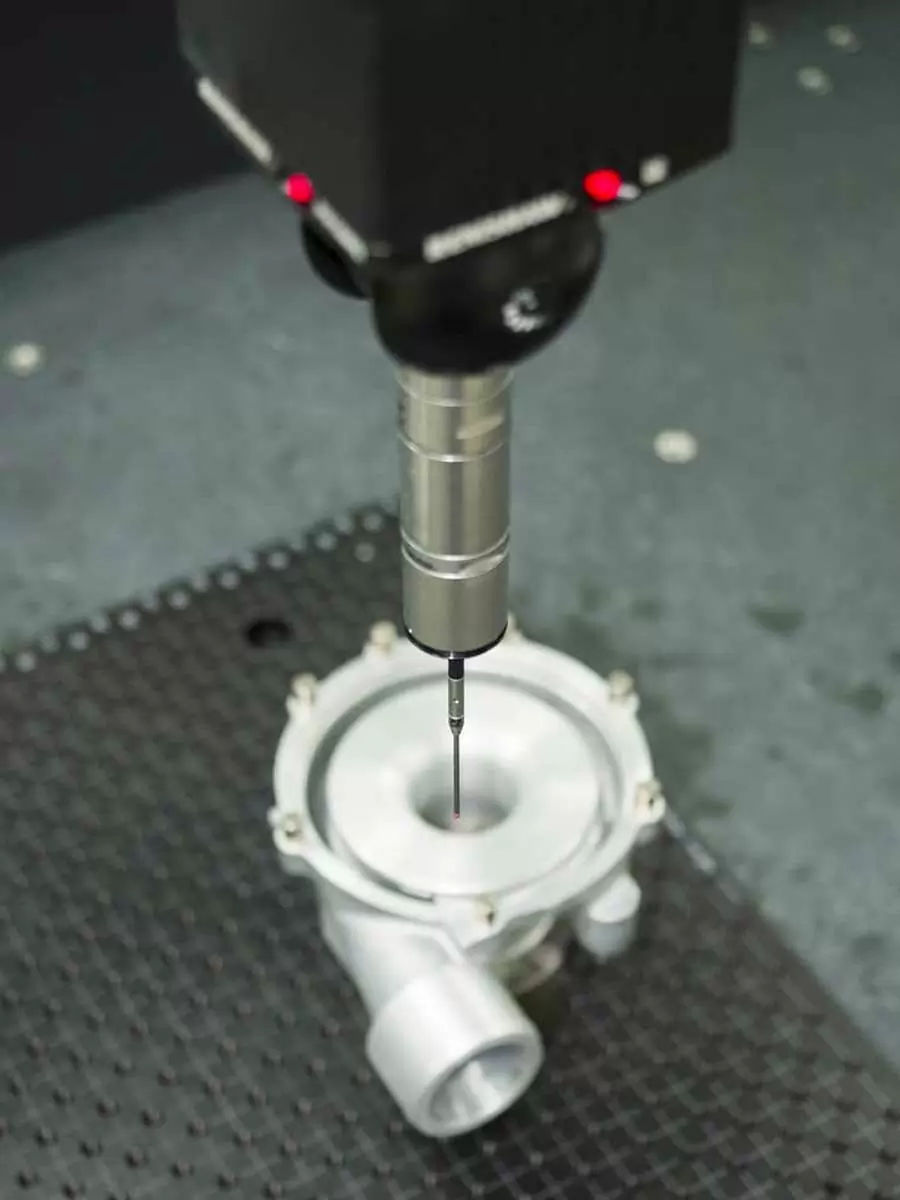

Micromachining

Medical Precision CNC Machining

-

Cnc Mill-Turn

One and done with CNC Mill/Turn

-

CNC Drilling

CNC Deep Hole Precision Drilling

-

CNC Cutting

Excellent Cleaner Edges

Our Outstanding Cnc Machine Equipment

- CNC Swiss Turn by Tsugami

- MAZAK 5 Axis Turn-Mill Machine

- CNC Swiss Turn by Tsugami

- High Speed Drilling-Tapping Machine

- DMU 5 Axis Cnc Machine

- CNC Mill Turn Centers—12 machines

- Multi Spindle Cam Automatics

- CNC Brother Production Milling

- Check Out BE-CU Equipment List

Our Case Studies Gallery Of CNC Machined Parts

Our ISO certified equipment is designed to handle custom tolerances and high-volume orders while maintaining quality control and quick project turn-around times. Specializing in large components and parts, our machines are equipped to carry out a variety of services.Whether you need customized parts, fusing of complex components, or finishing and polishing services, Be-cu.com specializes in work with challenging job.We machine rapid prototypes and low & large volume production orders for customers in multiple industries: medical devices, aerospace, automotive, defense, electronics, hardware startups, industrial automation, machinery, marine and robotics, and many more.Couldn’t find the case studies you want? Contact us now, we have a strong in-housing supply chain, can CNC machining any prototype project and parts for you.

-

Precision Grinding Tungsten Steel Mold Parts

-

5 Axis CNC Machining Medical Olecranon Plate

-

Special-Shaped Non-Standard Medical Device Needles

-

High-Speed Steel (HSS) Die Punching Needles

-

Precision Tungsten Copper Alloy Eccentric Insert

-

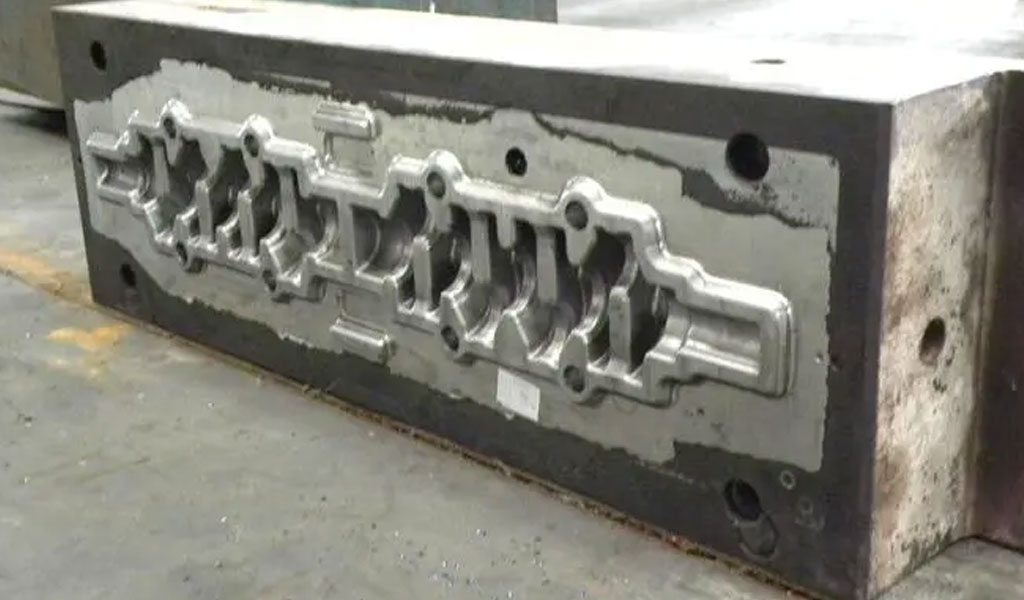

5 Axis CNC Machining Spiral Bevel Gear Mold

-

Small Precision Injection Molding Inserts

-

5 Axis Machining Aluminum-Magnesium Alloy Water Aerator Impeller

-

Swiss Machining And Bending 304 Hand Sewing Needle For Textile Machinery

-

Automatic Swiss Turning Stainless Steel 316L U-bolt

-

CNC Machining Anti-static Translucent PC Optical Parts

-

Precision Turning 20° Acrylic Downlight Reflector

-

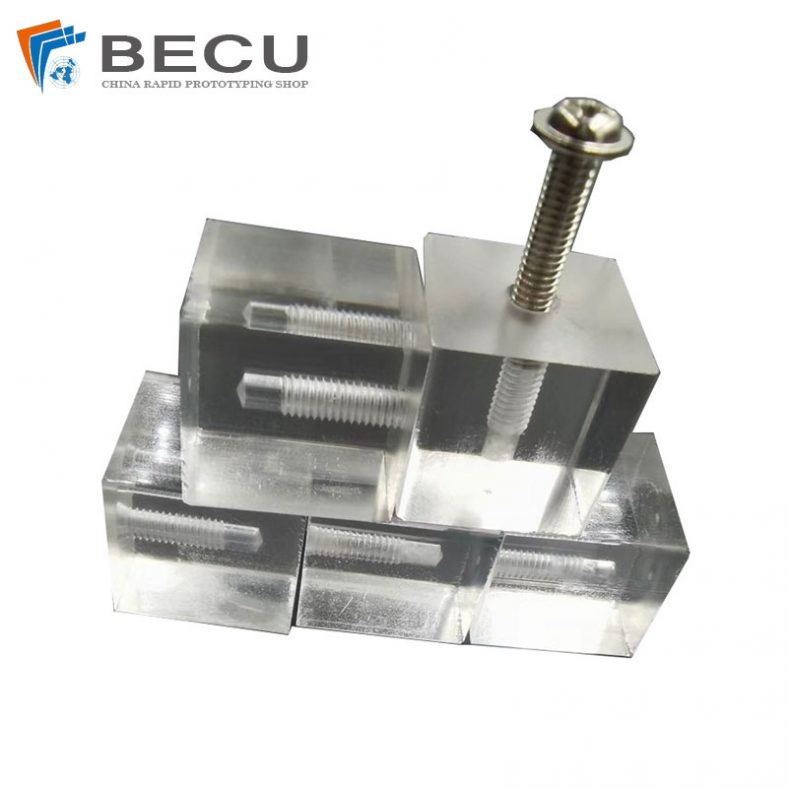

Transparent Acrylic Faceted Cube Threaded Clamp

-

CNC Turning Transparent PMMA Wear-Resistant Mechanical Parts

-

4 Axis Machining Highly Transparent Acrylic LED Tunnel Light Lens

-

CNC Machining Metal Chess Pieces,Board And Sets

Be-Cu Prototype – View CNC Machining Video

Be-Cu is committed to inspiring complete customer confidence in our ability to supply precision cnc machined components to a wide variety of industries, straight from our plant in China.

Be-Cu prides itself with a long standing history of quality components delivered to its valued customers manufactured by exceptional employees.Our CNC machining services deliver parts made from a wide range of plastics and metals. Over 50 high precision CNC mills, lathes, sink and wire EDMs and surface grinding machines – enable us to deliver custom CNC machining for a wide variety of industries & clientele.

Today, we are offering an parts cnc machining video at our facility and operations. Now, you have the opportunity to explore the process of your custom part being made, from ordering high-grade raw material to your on-time shipment.

Why Choose China CNC Machining Service?

With the promise of low costs and fast turnaround times, Chinese CNC machining services are a popular choice for companies looking to outsource their machining needs. In fact, cooperating with China suppliers for CNC machining is a tendency for global product developers by virtue of their superior capabilities and efficiency that few other countries can match.Many Trading companies and physical factories want to import from China, but always lack the confidence to try due to issues such as language barriers, complicated international trade processes, fraud or poor product quality. The following BECU will introduce to you the service advantages of CNC machining in China and the advantages and disadvantages compared with CNC machining services in the United States, so that you can better choose the right supplier and obtain high-quality parts.

The Benefit Of China CNC Machining Service

There are several benefit and reasons why one might choose China for CNC machining services:

Cost-Effectiveness

Manufacturing Capabilities

Wide Range Of Capabilities

High Production Capacity

Quality Control

Flexibility And Customization

China CNC Machining Service VS USA CNC Machining Service

When comparing China CNC machining services to those in the USA, there are several factors to consider:

- Cost: China generally offers lower labor costs, resulting in more competitive pricing for CNC machining services. However, it’s important to note that the cost advantage may vary depending on the complexity of the parts, material requirements, and other factors.

- Quality: Both China and the USA have a wide range of CNC machining service providers, and the quality can vary in both countries. While there are reputable and reliable manufacturers in China, quality control can be more challenging to ensure due to the vast number of suppliers. In the USA, quality control standards and certifications are often perceived to be higher.

- Communication and language: Engaging with Chinese manufacturers may involve communication challenges due to language differences and potential cultural barriers. Working with local CNC machining services in the USA can offer the advantage of easier communication, faster response times, and better alignment on project requirements.

- Intellectual property protection: Intellectual property (IP) concerns can be a consideration when choosing between China and the USA. China has faced scrutiny in the past for IP infringement issues, but efforts have been made to improve protection. The USA generally has stronger IP protection laws and enforcement mechanisms.

- Lead times and logistics: China’s vast manufacturing infrastructure and efficient supply chain allow for faster production and shorter lead times. However, shipping and logistics times can be longer when compared to domestic CNC machining services in the USA. Local manufacturing can offer advantages in terms of quicker turnaround times, easier collaboration, and reduced shipping costs.

- Customization and flexibility: Both China and the USA offer customization and flexibility in CNC machining services. Chinese manufacturers are often open to accommodating custom requirements and prototypes. In the USA, proximity and cultural alignment can facilitate smoother collaboration and easier iteration during the production process.

Ultimately, the choice between China CNC machining services and those in the USA depends on various factors such as cost considerations, desired quality standards, communication preferences, IP concerns, lead times, and the specific requirements of your project. Careful evaluation and due diligence are essential in selecting a reliable and suitable CNC machining service provider, regardless of the country.

Online Cooperate With CNC Machining Company

- Surface Hardness: HRC50-63

- Smoothness: Ra0.3μm

- Precision: ∞

- CPK=∞

- Surface Hardness: HRC50-60

- Smoothness: ∞

- Precision: 1T6

- CPK=1.66

- Surface Hardness: HRC58-63

- Smoothness: Ra0.4μm

- Precision: 1T5

- CPK=∞

- Surface Hardness: ∞

- Smoothness: ≤Ra0.4μm

- Precision: IT6

- CPK=1.66

- Surface Hardness: HRC58-63

- Smoothness: Ra0.6μm

- Precision: ∞

- CPK=1.72

- Surface Hardness: ∞

- Smoothness: ∞

- Precision: High Precision

- CPK=1.7

Be-Cu Prototype is one of the leading cnc machining companies in China. If you are in the market for an cnc machining project, Our factory in China is an excellent company to work with. With years of experience in the industry, Be-Cu Prototype is a reliable partner that can help you produce high-quality cnc machining parts cost-effectively.

Just simply upload your CAD files and submit RFQs with clear information online.

We’ll send you design for manufacturability analysis and transparent pricing.

Our experts will produce your parts with the required technologies and materials.Besides, our engineer sales offers you a real-time update on the production stage.

Once parts pass quality inspections they are well packed,delivered to your door directly with stringent deadlines.. Rest assured with our 30-day quality guarantee.

Be-cu works with customers all over the world to bring customers ideas to life with the highest quality precision engineered metal components on the planet. We have both precision cnc machining and molds making capabilities that include both conventional and modernized production line. If you are looking for a partnership to help you apply new tools and technologies, or help you fully realize your design vision, let us help you move your business forward, contact our team ([email protected])or quote online today to get the conversation started.

Latest CNC Machining Blog,Encyclopedia And Guide

Check out our latest cnc machining blogs, we share industry trends, design tips, and experience earned from manufacturing.

-

How to Calculate CNC Machining Cost & Prices

-

Top 30 CNC Machining Companies and Manufacturers in USA

-

CNC Machining for Bronze – Tips & Things to Consider

-

Top 10 Advance CNC Machine Company & Global Brands

-

Military CNC Machining : Exploring Precision in Warfare

-

Calculating CNC Machining Time For Milling,Turning,5 Axis,Turn-Milling

-

Glocal CNC Machining Comparison: China vs Japan vs USA vs German

-

What Is Cnc Machining