High Precision Optical Parts And Components

“Optical parts” generally refers to components or elements that are used in optical systems or devices, which involve the manipulation and control of light. These parts are designed and manufactured to interact with light in specific ways to achieve desired optical properties. Optical parts are essential components in various optical instruments, devices, and systems used in fields such as microscopy, photography, astronomy, telecommunications, and more.Here are a few examples of common optical parts:

- Lenses: Lenses are transparent optical elements that refract (bend) light in order to converge or diverge it. They are crucial components in cameras, telescopes, microscopes, and eyeglasses. Lenses can have different shapes and properties to correct aberrations and focus light accurately.

- Mirrors: Mirrors are reflective optical elements that redirect light by reflecting it off their surfaces. They are used in various optical systems, including telescopes, laser systems, and optical resonators.

- Prisms: Prisms are transparent optical elements with flat polished surfaces that can refract and reflect light. They are often used for beam splitting, dispersion, and image rotation.

- Filters: Optical filters are components that selectively transmit, absorb, or reflect certain wavelengths of light. They are used to control the spectral content of light in applications such as photography, spectroscopy, and lighting.

- Beam Splitters: Beam splitters are devices that split a light beam into two or more parts. They are commonly used in interferometers, microscopy setups, and laser systems.

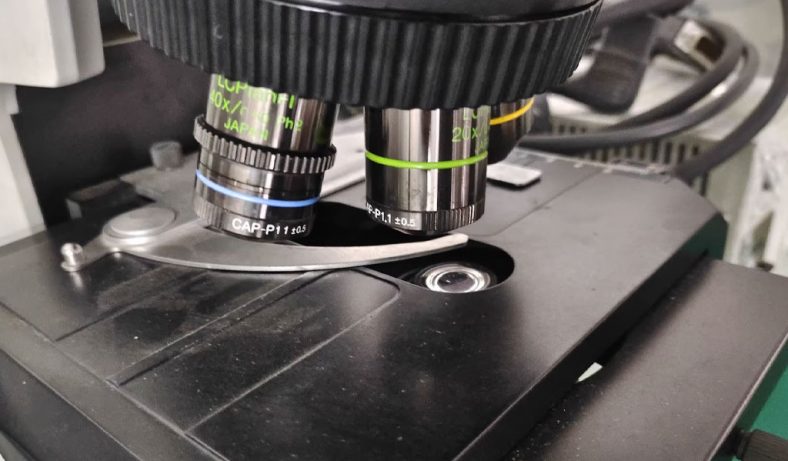

- Microscope and microscope components:An electron microscope typically features a lens holder, which helps to handle and protect the delicate lens. As you may have guessed, the optical performance of electron microscopes depends on the dimensional accuracy of the lens and lens holder.

- Polarizers: Polarizers are components that allow only light with a specific polarization orientation to pass through. They are used in applications such as LCD displays, photography, and optical microscopy.

- Diffraction Gratings: Diffraction gratings are optical elements with a periodic pattern of grooves that disperses light into its component wavelengths. They are used in spectroscopy and wavelength separation.

- Waveplates (Retarders): Waveplates are birefringent optical elements that alter the phase or polarization of light passing through them. They are used in polarization control and manipulation.

- Beam Expanders and Collimators: These components are used to control the size and divergence of a light beam. They are important in laser systems and optical communication.

- Optical Windows: Optical windows are flat, transparent optical elements that allow light to pass through while protecting the internal components of an optical system from environmental factors.

- Laser components:Lasers are essential devices in a wide range of industries, especially the medical sector, where they are used for surgical procedures. A laser is made of several components, all of which must be fabricated to high accuracy and tight tolerances to achieve desirable performance.

These are just a few examples of the many types of optical parts used in various optical applications. The design, manufacturing, and selection of optical parts depend on the specific requirements of the optical system and the properties of light that need to be controlled and manipulated.

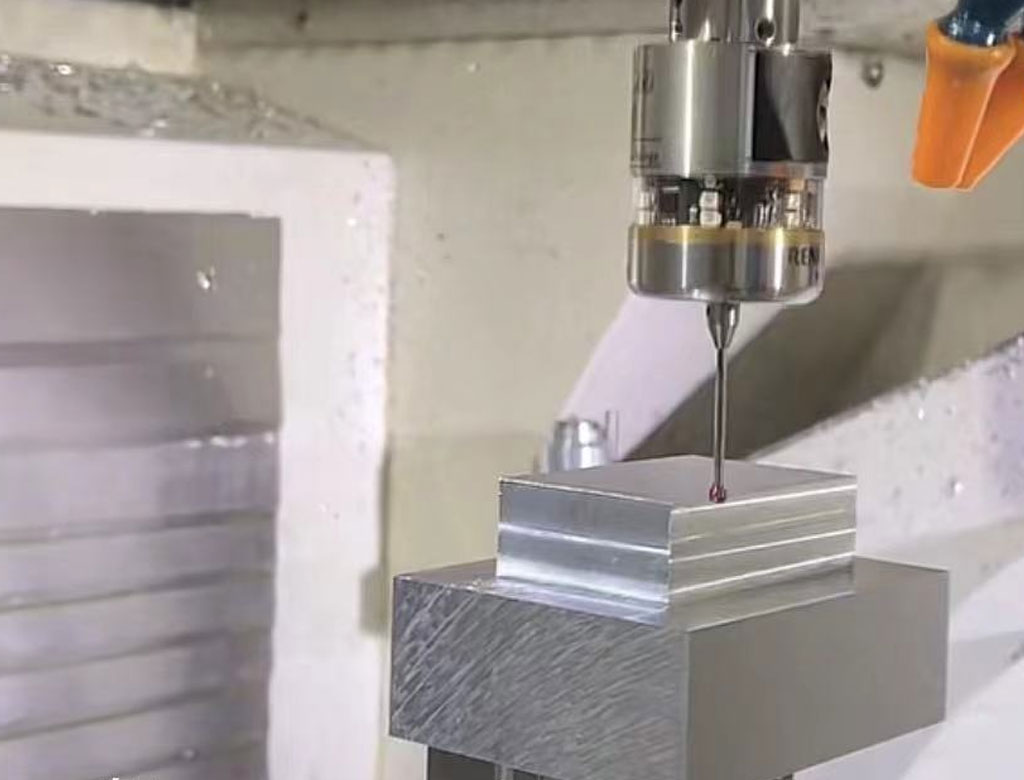

CNC Machining Service for Optical Parts

Be-Cu Prototype provides precision machining for a wide range of optical industry applications, from Optical Isolator Components manufacturing to CNC turning of stainless steel, copper, aluminum, and brass optical components to tube lens hardware and much more. Our Optical parts and components cnc machining service consistently meet the tight tolerances required by this ever-growing industry.

Our extensive experience and superior equipment enable us to turn even the most complex designs into tangible products. From prototypes and one-offs to full production runs with quantities in the tens of thousands, Be-Cu Prototype delivers top quality, high precision parts for customers in all sectors of the optical industry. We can produce parts that match your design specifications exactly—quickly, efficiently, and with perfect repeatability.

Optical Machining Company – CNC Optical Parts Machining

Precision is of the utmost importance in the Optical industry. A single imperfection or faulty component can cause thousands of dollars in damage when it comes to Optical lens and camera components, in addition to being a huge safety risk.

Be-Cu prototype is a pioneering industry leader specializing in precision optical fabrication and machining to the highest accuracy for their specific application.Our precision optics manufacturing services are capable of consistently producing parts with tolerances as low as ±0.0001in, accommodating nearly every precision requirement from our customers in the optical industry.Be-Cu is ISO 9001:2015 certified, which gives our customers in the optical industry confidence that their lathed parts will be thoroughly inspected and documented by our impeccable quality control department.With a relentless commitment to innovation, quality, and customer satisfaction, we have established ourselves as a trusted partner for clients seeking unparalleled precision and accuracy in optical components.

As an approved supplier of Optical parts for BENQ,Ordro,SEAGULL, and many others, you can trust Be-Cu to successfully machine your precision parts.We has the resources to supply turnkey optical components that require additional services such as heat treating, plating, grinding, polishing, and electroplating.For top quality, tight tolerance optical fabrication with unrivaled customer service, look no further than Be-Cu prototype. Request a quote or contact us for turnkey CNC machining for your precision optical components.

We Can Machining Material of High Precision Optical Components

One thing all of optical components have in common is high-quality materials. For all optical machined components,Be-Cu only trusts the best materials which is why we utilize the following materials for producing industry-leading optical parts.

More Complex Optical Manufacturing Capabilities

When it comes to Complex Optical Manufacturing, we can work with EDM machine,precision turn-mill machine ,5 axis machine —such as DMU and 3+2 axis cnc machine—and other specialty equipment that find extensive use in optical parts and components. No matter what difficulty your project requires,Be-Cu prototype will deliver perfect precision parts that meet or exceed your expectations.We offer an optical parts machine shop capable of production volumes ranging from a single-part rapid prototype up to 100,000-part mass production runs. Additionally, our advanced CNC lathe equipment enables us to deliver customers shorter part delivery lead time, typically often between 2-8 weeks.

Why Choose Our Optical Machining Service?

- Save time and money for your optical project but quality guaranteed.

- High productivity, outstanding efficiency and high accuracy

- A wide range of material grades and alloy materials can be machined

- Custom complex optical machined parts & components at specific tolerances

- High speed machining for prototyping and low to high volume production runs

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

Top China Optical Cnc Machining Parts & Case Studies

With the continuous maturity and development of CNC Machining technology, more and more optical manufacturers have introduced this technology for prototype testing, design proofing, parts customization and other applications. By exploring our success stories, you can learn about: the development of CNC Machining in the optical industry, the application of CNC Machining in optical molds, how CNC Machining changes the optical manufacturing supply chain, and more.Some examples of o ptical products we can manufacture are:

-

CNC Machining Anti-static Translucent PC Optical Parts

-

Precision Turning 20° Acrylic Downlight Reflector

-

4 Axis Machining Highly Transparent Acrylic LED Tunnel Light Lens

-

CNC Machining For Camera L Bracket

-

Custom Electron Optical Instrument Sight Bracket

-

Customized Optical Instrument Projector Components By 4 Axis Mill

-

Precision Milling Astronomical Telescope Wide-angle Lens Eyepiece Element

-

Custom Cnc Milling Machining Aluminum Alloy 2024 Parts

-

5 Axis Machining Optical Communication Parts And Telecom Parts

-

CNC Machining Custom Non-standard Flashlight Shell Aluminum Parts

-

CNC Machining Of Non-standard Aluminum Fixture Plate

-

CNC Machining Precision Optical Instrument Accessories

-

Non-standard Custom CNC Machining Torch Aluminum Parts

-

Precision Lathe Processing Optical Instrument Mirror Body

-

CNC Machined Optical Instrument Parts