SLS 3D Printing

- MAX PART SIZE:300 x 330 x 450 mm

- LEAD TIMES:From 5 Working Days

- TOLERANCE:± 0.3% (min: ± 0.15 mm)

- MIN PART SIZE:1 x 1 x 8 mm

- LAYER HEIGHT:100 microns

- MIN WALL THICKNESS:1.0 mm

>>>All uploaded drawings are strictly confidential, check the confidentiality agreement

SLS 3D Printing Services – China Leading Selective Laser Sintering Parts Supplier

BE-CU is a rapid prototype and manufacturing expert with over 30 years experience,has been specialized in offering best OEM Selective Laser Sintering services for superior quality low cost 3d printing parts with the operation of an impressive range of state-of-the-art 3d printer, such as end-use, low-volume production or prototyping etc. .We provides professional high-end industrial quality SLS 3D printing service.

From prototyping to small-batch production, our global network of certified SLS 3D printing facilities will allow you to produce highly accurate parts with quality and strength comparable to injection molding.Upload your CAD files, receive an instant Selective Laser Sintering 3D printing quote and get your parts into production in less than 5 minutes.

Our expertise in additive manufacturing, high-end functional testing prototypes, 24 hours services, competitive price, on time delivery drop- shipping to over 150 countries to help you transform your ideas into projects, bring your innovative products to market faster, reduce your production costs, save your research and development time.Metal finishing service is a essential choice to achieve your design perfectly. Be-cu is an accomplished finished parts manufacturer, our workers and craftsman are capable to provide SLS 3D Printing services and a wide range of surface treatment services including aluminum anodizing, painting, passivation, electroplating, powder coating, polishing, black oxide, conversion coating, abrasive blasting, etc. Here are the introductions to different types of metal finishes, more details please feel free to contact us.

- Anodizing (Anodized)

- Passivation

- Plating (Electroplating)

- Painting

- Black Oxide (Hot Blackening)

- Polishing

- Powder Coating

- Heat Treatment

- Satin Finish

- Abrasive blasting (Sandblasting)

- Conversion coating

Why Choose Be-cu SLS 3D Printing Service

- No minimum order quantity

- Metal or plastic 3D printed prototype and production parts in 7-10 days

- Precision custom 3D printing parts at affordable prices

- Online free quote in the shortest time

- Single prototypes or complex shapes are both allowed

- A wide selection of metal or plastic materials

- Commercial and industrial-grade 3D printers

- Cooperative supplier assistance project

- Provide a quick solution for small batches of complex prototypes

- We provide with our partner

- 3D printing services for metals and plastics

- Meet the rapid needs of complex prototype designers

The Material Of SLS 3D Printing Services

During the molding process, the unsintered powder acts as a support for the cavity and cantilever of the model, so SLS-molded workpieces do not require support structures like SLA-molded workpieces. Compared with SLA, the materials used in the SLS process are relatively rich, mainly including paraffin, polycarbonate, nylon, slender nylon, synthetic nylon, ceramics and even metal.

When the workpiece is completely formed and completely cooled, the worktable will rise to its original height. At this time, the workpiece needs to be taken out and the powder on the surface of the model needs to be removed with a brush or compressed air.

The SLS process supports a variety of materials, forming workpieces without support structures, and high material utilization. Although the price and material price of SLS equipment are still very expensive, the material needs to be preheated before sintering, and the material will volatilize odor during the sintering process, and the working environment of the equipment is relatively demanding.

Materials that can be successfully processed by SLS are paraffin, polymer nylon, carbon fiber, glass fiber, polymer, metal, ceramic powder and their composite powder materials

If you are having any problem to get your sls 3D printing parts done, contact us and try to get a solution from BE-CU.

SLS 3D Printing Applications – What is SLS 3D Printing Used for

China Top SLS 3D Printing Supplier & Manufacturer – Be-cu offers worldwide clients affordable, rapid, high precision custom SLS 3D Printing Services, variety of materials available to meet the needs of different industries!

What Is SLS 3D Printing? – SLS 3D Printing Define

SLS 3D printing technology, SLS is called powder sintering in the industry, grasping two key words, powder and sintering, are the characteristics of SLS, SLS printing technology uses powder to spread a layer of powder material on the upper surface of the formed part, And heated to a certain temperature just below the sintering point of the powder, the control system controls the laser beam to scan on the powder layer according to the cross-sectional profile of the layer, so that the temperature of the powder rises to the melting point, sintered and formed with the lower part. achieve bonding. After the completion of one layer, the worktable is lowered by one layer of thickness, and the spreader rolls spread a layer of uniform and dense powder on it to sinter a new layer of cross-section until the entire model is completed.

How Does SLS 3D Printing Work? – Steps of SLS 3D Printing Process

- First, heat the powder bin and the build area to a temperature close to the melting temperature of the material, and lay a layer of powder material.

- Second, use the laser to scan the cross section of the layer, raise the powder temperature to the melting point, and selectively sinter the area to be printed to form a bond.

- After the sintering is completed, the building platform moves down, the scraper is covered with a layer of powder material, and the content of step 2 is repeated until the entire model is completed.

- After the printing is completed, the forming chamber is cooled (generally the temperature is below 40 degrees), and the parts can be taken out for subsequent processing.

The Advantage Of SLS 3D Printing

The main advantage of SLS is that it does not require a supporting structure. Unsintered powder provides all necessary support for the part. Therefore, SLS can be used to create free-form geometries, as long as it is within the parameters of the printing process, designers can display their talents as they want without worrying about manufacturing.When printing with SLS, especially for small batch production, it is very important to make full use of the entire build volume and increase the print-to-bin ratio (the volume ratio of the printed product in the entire print bin).

After the maximum print height is determined according to the layout requirements of the printed products, it will take approximately the same amount of time to print regardless of the number of printed products in the print control. This is because the speed of laying powder on each layer determines the total printing time (laser scanning happens very quickly), and the machine will have to cycle through the same number of layers.Therefore, for a factory that does SLS process 3D printing services, it can use a large number of orders, and optimize the combination of order products as much as possible in the same printing warehouse for production, which will greatly reduce the printing cost and improve the printing speed. (Reduce the time of waiting for orders and making up orders, and start production quickly).

- There are many materials that SLS can use. The materials that can be used include polymer, metal, ceramic, gypsum, nylon and other powders. However, due to the refinement of the market, metal materials will now be called SLM. Now the material used in SLS should account for 90% of nylon material, so we usually default to SLS as printing nylon material.

- Accuracy, now the normal accuracy is to achieve a tolerance of plus or minus 0.2mm.

- No need for support, it does not need a support structure, the suspended layer in the lamination process can be directly supported by the unsintered powder, which should be one of the biggest advantages of SLS.

- The utilization rate of materials is high, and the utilization rate of materials is high. Since there is no need for support and no need to add a base, it has the highest material utilization among several common 3D printing technologies, and the price is relatively cheap, but it is more expensive than SLA.

The Case Studies Of SLS 3D Printing Parts

You have a complex part design, Our SLS 3D printing service can help you turn it into a reality. With the right equipment, strong technical knowledge, and a focus on quality.. From tool design to finishing and then on to shipment, Be-cu prototpe ensure that every project is completed to a high standard and that your orders are delivered on time, every time.

-

3D Printing High Performance Nylon Parts

-

SLS 3D Printing Casual Shoe Model

-

SLA 3D Printing Handsome Black Hat Model

-

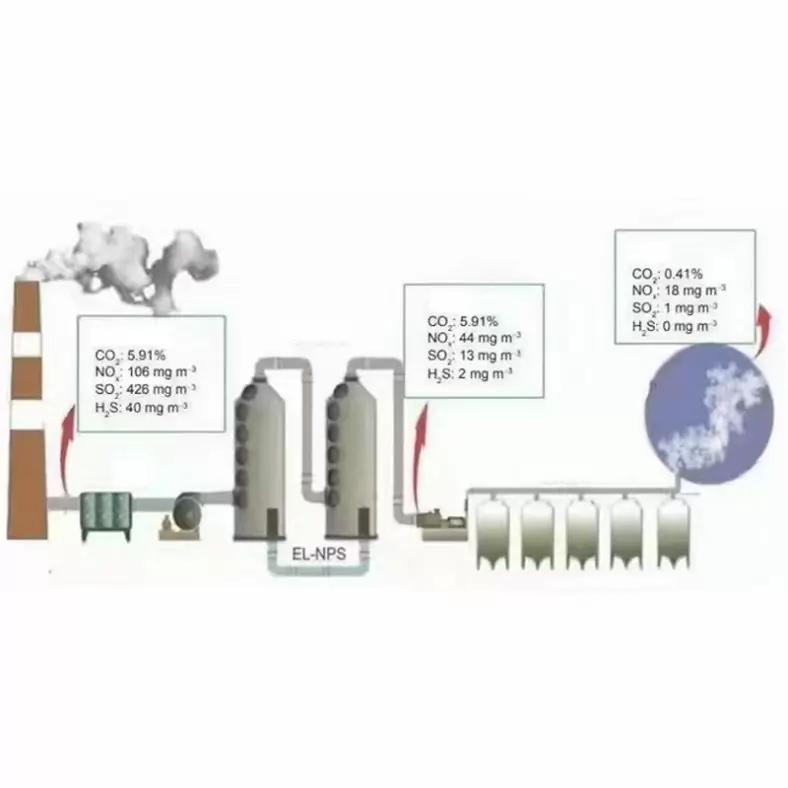

SLA 3D Printing CO2 Fixation Equipment Model Using Microalgae

-

3DP Rapid Prototyping Ancient Temple

-

SLA 3D Printed Cruise Ship Model

-

SLA 3D Printed Transparent Resin Toy Truck Model

-

SLA 3D Printing ABS Smart Speaker Backplane

-

3D Printing Full Transparent Acrylic Lampshade Model

-

SLA 3D Printing Nylon Resin Prototype